Introduction

In the realm of modern materials, few innovations capture the imagination quite like nitinol muscle wire. This remarkable alloy, composed of nickel and titanium, boasts unique properties that allow it to return to a predetermined shape when heated. Whether you're an engineer, a hobbyist, or just someone curious about cutting-edge technology, understanding nitinol muscle wire opens up a world of possibilities.

Discover the Magic of Nitinol Muscle Wire

Nitinol muscle wire is not just any ordinary wire; it’s a game-changing material that can transform how we approach design and functionality in various fields. With its ability to contract and expand based on temperature changes, this shape memory nitinol wire serves as an actuator wire that can create movement without traditional motors or gears. Imagine a world where tiny devices can mimic muscle movements—this is the magic of nitinol muscle!

Why Nitinol is a Game Changer

The versatility of nitinol nickel titanium makes it an essential component across numerous industries—from robotics to healthcare and beyond. Its lightweight nature combined with strength means that engineers can innovate without being bogged down by conventional limitations. As we explore the capabilities of this material further, it's clear why so many are eager to buy nitinol wire for their projects.

Exploring Unique Applications of Nitinol

The applications for nitinol muscle wire are as diverse as they are exciting! From enhancing robotic movements to revolutionizing medical devices like stents and surgical tools, the potential seems limitless. As researchers continue to uncover new uses for shape memory nitinol wire, we stand on the brink of a technological renaissance that could redefine our everyday lives.

What is Nitinol Muscle Wire?

Nitinol muscle wire is a remarkable material that combines the unique properties of nickel and titanium, resulting in a shape memory alloy that has captivated engineers and inventors alike. This innovative wire can remember its original shape, allowing it to return to that form when heated. It’s a game-changer in various applications, from robotics to medical devices, making it essential for anyone looking to harness the power of nitinol.

Composition of Nitinol Nickel Titanium

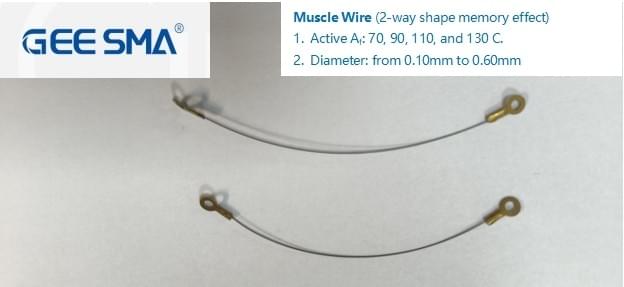

Nitinol is an intriguing alloy primarily composed of nickel and titanium, typically containing around 55% nickel and 45% titanium by weight. This specific ratio gives nitinol its extraordinary properties, such as superelasticity and the ability to undergo phase transformations at different temperatures. When you buy nitinol wire, you're investing in a material that is not only lightweight but also incredibly strong, making it ideal for a multitude of applications.

The Science Behind Shape Memory Alloys

At the heart of nitinol's magic lies its classification as a shape memory alloy (SMA). This means that when the wire is deformed at lower temperatures, it can revert back to its pre-deformed shape upon heating above a certain threshold temperature. The science behind this phenomenon involves intricate changes in crystal structure; it's this transformation that allows nitinol muscle wire to perform tasks like actuating mechanisms or adjusting shapes in response to temperature changes.

How Nitinol Wire Works

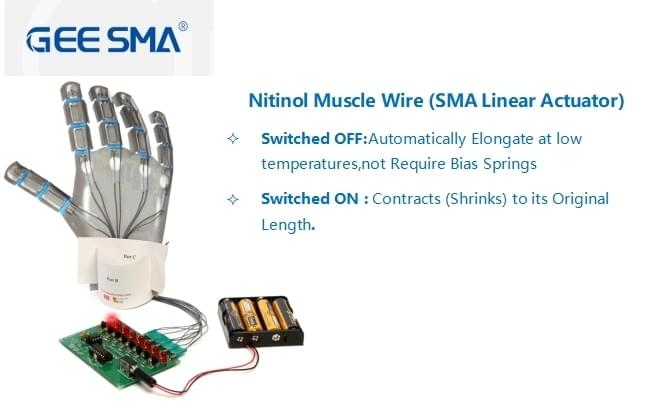

Nitinol wire operates on the principles of thermal expansion and contraction due to its unique molecular structure. When heat is applied, the nitinol muscle wire transitions from one crystalline phase to another—specifically from martensite (the low-temperature phase) to austenite (the high-temperature phase). This transition generates enough force for practical applications such as moving parts in robotic systems or enabling stents within medical devices; thus demonstrating why actuator wire made from nitinol is so highly sought after across various industries.

Actuators and Robotics

Nitinol muscle wire is redefining the landscape of robotics, bringing with it a unique blend of flexibility and strength that traditional materials simply can't match. By harnessing the properties of nitinol nickel titanium, engineers are developing actuators that can mimic natural muscle movements. This transformation opens up a world of possibilities in robotic design and functionality.

Transforming Robotics with Actuator Wire

Actuator wire made from nitinol muscle wire is revolutionizing how we approach robotics. Unlike conventional motors, which can be bulky and rigid, nitinol wire provides lightweight solutions that contract and expand based on temperature changes. This shape memory nitinol wire allows for smoother movements, making robots more agile and capable of performing intricate tasks.

By integrating nitinol muscle into robotic systems, developers are creating machines that can adapt to their environments in real-time. For instance, soft robotics—where flexibility is key—benefit immensely from this technology as it enables delicate handling in applications like surgery or material manipulation. As industries look to enhance automation processes, the versatility of actuator wire continues to be a game changer.

Case Studies in Robotic Applications

Several innovative projects have successfully incorporated nitinol muscle wire into their designs, demonstrating its potential in real-world applications. One notable example is the development of robotic fingers that utilize nitinol wires for precise gripping motions; these fingers can adjust their grip strength based on the object being handled. This capability showcases how implementing nitinol nickel titanium can lead to advancements in dexterity for robotic systems.

Another fascinating case study involves drones equipped with wings made from shape memory nitinol wire; these wings can change shape during flight to optimize aerodynamics based on conditions encountered mid-air. Such enhancements not only improve efficiency but also extend operational capabilities beyond what was previously achievable with standard materials. These examples illustrate the diverse range of possibilities when integrating nitinol muscle into robotic designs.

The Future of Nitinol in Automation

Looking ahead, the role of nitinol muscle wire in automation seems poised for significant growth as industries increasingly recognize its advantages over traditional actuation methods. With ongoing research focused on enhancing performance metrics such as response time and energy efficiency, we may soon see even more sophisticated applications emerge across various sectors—from manufacturing to healthcare robotics.

Moreover, as costs decrease and accessibility improves for those looking to buy nitinol wire for their projects, hobbyists and entrepreneurs alike will be able to explore creative uses for this remarkable material within DIY robotics kits or custom inventions. The future holds exciting prospects where shape memory nitinol wire becomes a staple component not just in professional settings but also among enthusiasts eager to push boundaries.

In conclusion, the integration of actuator wires made from nitinol will undoubtedly continue transforming robotics as we know them today—bringing about innovations that enhance functionality while maintaining lightweight designs essential for advanced automation solutions.

Medical Devices and Healthcare

Nitinol muscle wire has carved a niche for itself in the medical field, transforming how we think about devices and treatments. This unique alloy, composed of nitinol nickel titanium, exhibits remarkable properties that make it ideal for various applications in healthcare. From stents to surgical tools, nitinol wire is revolutionizing patient care by providing innovative solutions that enhance functionality and safety.

The Role of Nitinol Muscle in Medicine

The role of nitinol muscle wire in medicine cannot be overstated; it serves as a critical component in many advanced medical devices. Its shape memory capabilities enable it to return to a predetermined shape when heated, making it perfect for applications like stents that need to expand within the body. Surgeons appreciate the precision and reliability offered by nitinol muscle, which can adapt seamlessly to the unique anatomy of each patient.

Moreover, this remarkable material allows for minimally invasive procedures thanks to its flexibility and strength. When you buy nitinol wire for medical applications, you're investing in technology designed to improve patient outcomes significantly. As the industry continues to embrace this innovative alloy, we can expect even more groundbreaking uses for nitinol muscle wire in healthcare.

Innovations in Stents and Surgical Tools

Innovations surrounding stents made from nitinol muscle wire have led to significant advancements in cardiovascular treatments. These self-expanding stents offer superior performance compared to traditional options due to their elasticity and biocompatibility with human tissue. The use of shape memory nitinol wire ensures that these devices can conform perfectly within blood vessels while maintaining optimal blood flow.

Surgical tools utilizing actuator wire made from nitinol have also seen impressive developments; they provide surgeons with enhanced control during procedures. For instance, some surgical instruments now incorporate this technology for precise movements that were once challenging with conventional tools. As we witness further innovations using nitinol nickel titanium alloys, the future looks bright for surgical practices worldwide.

Biocompatibility and Patient Safety

When discussing medical devices like those incorporating nitinol muscle wire, biocompatibility is a top priority; after all, no one wants their body rejecting an implanted device! Fortunately, materials like nitinol nickel titanium demonstrate excellent compatibility with human tissue due to their inert properties. This means patients can benefit from longer-lasting implants without worrying about adverse reactions or complications.

Patient safety is paramount when developing new medical technologies; thus far, studies have shown that devices made from nitinol are reliable under various physiological conditions. As more healthcare providers adopt these advanced solutions using shape memory nitinol wire, we can expect continuous improvements in both efficacy and safety standards across the board. Investing time into understanding how best to utilize these materials will pave the way for even greater advancements in medicine.

Consumer Electronics

The integration of nitinol muscle wire into consumer electronics is revolutionizing how we interact with our gadgets. This innovative material, formed from a unique blend of nickel and titanium, brings remarkable flexibility and strength to devices, enhancing their functionality while reducing size and weight. As technology evolves, the demand for nimble yet powerful components like nitinol wire becomes increasingly crucial.

Enhancing Gadgets with Nitinol Wire

Nitinol muscle wire is a game changer for gadget designers looking to push the boundaries of what's possible. With its extraordinary shape memory properties, this actuator wire can return to a predetermined shape when heated, allowing for compact designs that can expand or contract as needed. Imagine a smartphone case that automatically adjusts to protect your device when dropped—this is just one example of how nitinol can enhance everyday gadgets.

As manufacturers explore the potential of nitinol nickel titanium in their products, we see an exciting shift toward more responsive technologies. The ability of nitinol wire to act as both a sensor and an actuator opens up new avenues in device interactivity. From adjustable earphones that conform perfectly to your ears to smart home devices that adapt based on user behavior, the possibilities are endless.

Examples of Nitinol in Everyday Devices

There are already several examples showcasing the versatility of nitinol muscle in consumer electronics today. For instance, some advanced camera systems use shape memory nitinol wire to control lens movement with precision and speed, ensuring perfect focus every time you snap a photo. Additionally, smart wearables are utilizing this innovative material for adjustable straps that mold comfortably around your wrist without compromising durability.

Another exciting application is found in robotic toys where nitinol muscle wires provide lifelike movements through simple heating mechanisms. These toys not only entertain but also educate children about robotics and engineering principles in an engaging way. As more manufacturers recognize the advantages of incorporating nitinol wire into their designs, we can expect an influx of creative applications across various electronic devices.

The Push for More Nitinol-Based Products

The momentum towards incorporating nitinol muscle wire into consumer electronics is gaining traction rapidly among innovators and engineers alike. With growing awareness about its benefits—including lightweight construction and energy efficiency—companies are eager to buy nitinol wire for experimental projects that could lead to groundbreaking products. This push represents not just a trend but potentially a paradigm shift in how we conceptualize electronic design.

Moreover, as sustainability becomes increasingly important in product development, the durability and longevity offered by materials like nitinol nickel titanium make them appealing choices for eco-conscious companies aiming for minimal waste over time. The future holds great promise as research continues into optimizing these materials further; who knows what nifty inventions await us?

As consumers become more tech-savvy and demand cutting-edge features from their devices, it’s clear that the integration of shape memory nitinol wire will play a pivotal role in shaping our digital landscape moving forward.

Aerospace and Defense Applications

The aerospace and defense industries are always on the lookout for innovative materials that can enhance performance and efficiency. Enter nitinol muscle wire, a remarkable alloy of nickel and titanium that has gained traction for its unique properties. With its shape memory capabilities, this nitinol wire is revolutionizing how we think about design and functionality in advanced technologies.

Nitinol Muscle Wire in Advanced Technologies

Nitinol muscle wire is making waves in various advanced technologies, particularly in applications requiring precise movement or actuation. Its ability to return to a predetermined shape when heated makes it an ideal choice for actuator wire systems, which can significantly reduce weight without sacrificing strength. As engineers explore new avenues to integrate nitinol nickel titanium into their designs, we can expect to see smarter, lighter components that push the boundaries of what’s possible.

In aerospace applications, nitinol muscle wire serves as a game changer by enabling mechanisms that are both compact and efficient. For instance, it can be used in deployable structures such as wings or landing gear that require reliable movement without bulky motors or complex linkages. The versatility of this material means that manufacturers looking to buy nitinol wire will find it increasingly valuable for innovative designs.

How Shape Memory Nitinol Wire Affects Aerodynamics

Shape memory nitinol wire plays a crucial role in enhancing aerodynamics by allowing for dynamic adjustments during flight. When integrated into aircraft systems, this material can adapt its shape based on varying conditions—like temperature changes or aerodynamic forces—improving overall performance and fuel efficiency. By utilizing the unique properties of nitinol muscle wire, engineers are crafting designs that respond intelligently to their environments.

One fascinating application is in morphing wing technology, which allows wings to change shape mid-flight for optimal lift and drag reduction. This capability not only enhances maneuverability but also contributes to energy savings—a critical factor in modern aviation design where every ounce counts. The potential benefits of incorporating shape memory nitinol wire into these systems could lead us toward quieter, more efficient aircraft.

Military Innovations Using Nitinol

The military sector is no stranger to innovation; thus, the introduction of nitinol muscle wire has opened doors to groundbreaking advancements in defense technology. From unmanned aerial vehicles (UAVs) equipped with flexible structures to smart munitions with enhanced targeting capabilities, the applications are vast and varied. Nitinol’s lightweight nature combined with its strength makes it an attractive option for military equipment where both performance and reliability are paramount.

Moreover, researchers are exploring how nitinol nickel titanium can be utilized in robotics for search-and-rescue missions or bomb disposal units where precision is critical under pressure situations. The adaptability afforded by actuator wires made from this unique alloy allows military tools to perform tasks previously thought impossible under challenging conditions. As demand grows for cutting-edge solutions within defense sectors, investing resources into developing more nitinol-based innovations seems inevitable.

Conclusion

In wrapping up our exploration of nitinol muscle wire, it's clear that this remarkable material is not just a scientific curiosity but a transformative force across various industries. From robotics to healthcare, the versatility of nitinol nickel titanium allows for innovative solutions that enhance functionality and efficiency. As we continue to uncover new applications, the potential for nitinol wire seems boundless, promising exciting advancements in technology and design.

The Versatility of Nitinol Muscle Wire

Nitinol muscle wire stands out due to its unique properties, particularly its ability to remember shapes and return to them when heated. This characteristic makes it an ideal choice for actuators in robotics, offering lightweight and compact solutions that traditional motors can't match. Furthermore, the adaptability of nitinol muscle extends beyond robotics; it finds applications in medical devices like stents and surgical tools, showcasing its multifunctional nature.

Future Trends in Nitinol Applications

Looking ahead, the future of nitinol applications is bright and full of possibilities. With ongoing research into shape memory nitinol wire's capabilities, we can expect innovations that push boundaries even further—think self-healing materials or advanced aerospace technologies. Additionally, as industries seek more efficient solutions, the demand for actuator wire will likely surge, leading to a broader range of consumer products incorporating this versatile material.

How to Buy Nitinol Wire for Your Projects

If you're inspired by the potential of nitinol muscle wire and want to incorporate it into your projects, finding a reliable supplier is essential. Many online retailers specialize in selling high-quality nitinol nickel titanium products tailored for various applications—from hobbyist projects to industrial use. When looking to buy nitinol wire, ensure you check specifications such as diameter and transformation temperatures so you can select the best fit for your needs.