Introduction

Nitinol muscle wire, a remarkable alloy of nickel and titanium, has transformed various industries with its unique properties and versatile applications. This shape memory alloy wire exhibits the ability to return to a predetermined shape when heated, making it invaluable in fields ranging from medical devices to robotics. Understanding the science behind nitinol nickel titanium is crucial for harnessing its full potential and unlocking innovative solutions across multiple sectors.

Understanding Nitinol and Its Applications

Nitinol wire stands out due to its extraordinary characteristics, including superelasticity and shape memory effects. These properties allow nitinol muscle wire to perform effectively under different conditions, leading to groundbreaking applications in medical devices such as stents and guidewires. Additionally, its adaptability makes it an ideal choice for robotics, where precise movements are essential for functionality.

The Science Behind Shape Memory Alloys

At the core of nitinol's capabilities lies the science of shape memory alloys (SMA). When subjected to specific temperatures, these materials can undergo phase transformations that enable them to remember their original shapes after deformation. This phenomenon is what sets nitinol nickel titanium apart from traditional materials like nickel wire, allowing for innovative designs that enhance performance in challenging environments.

Custom Wire Forming Explained

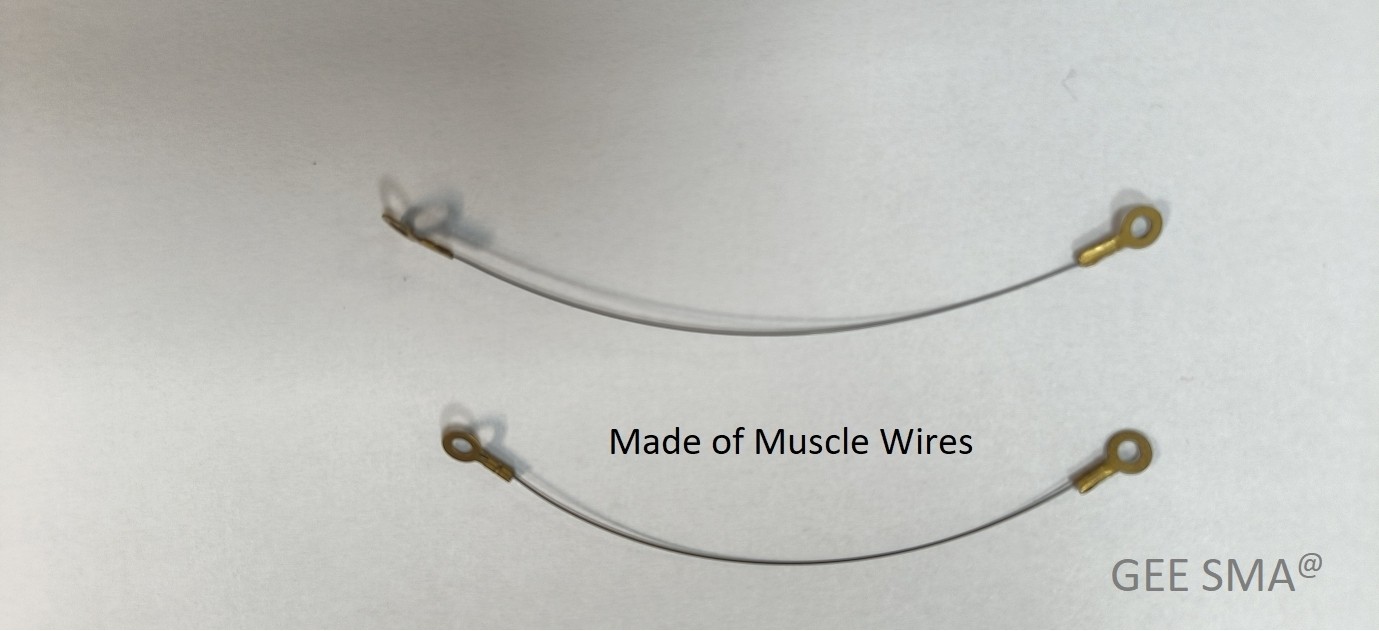

Custom wire forming is an essential process in creating specialized nitinol products tailored to meet specific needs across various industries. By manipulating the properties of shape memory alloy nitinol during production, manufacturers can achieve desired configurations and functionalities that standard wires cannot provide. This customization not only enhances product performance but also opens up new avenues for innovation in applications ranging from aerospace engineering to consumer electronics.

The Versatility of Nitinol Muscle Wire

Nitinol muscle wire is a remarkable material that embodies the cutting-edge capabilities of shape memory alloys. This unique wire, composed primarily of nitinol nickel titanium, exhibits extraordinary properties such as superelasticity and the ability to return to a predetermined shape when heated. These characteristics make nitinol wire an ideal candidate for various applications across multiple industries, showcasing its versatility and innovative potential.

Unique Properties of Nitinol Wire

The unique properties of nitinol wire stem from its distinct phase transformation capabilities. When subjected to temperature changes, this shape memory alloy wire can revert to its original form, enabling it to perform mechanical work without external power sources. Additionally, the superelasticity of nitinol muscle wire allows it to withstand significant deformation while returning to its original shape upon unloading, making it incredibly resilient and reliable in demanding applications.

Moreover, nitinol nickel titanium offers exceptional corrosion resistance and biocompatibility, which are crucial for many medical applications. These attributes ensure that nitinol wire remains functional over long periods without degrading or causing adverse reactions in biological systems. As a result, the unique properties of nitinol wire not only enhance performance but also expand its usability across diverse fields.

Applications in Medical Devices

Nitinol muscle wire has become a staple in the medical device industry due to its impressive functionality and adaptability. From stents and guidewires to surgical instruments, the applications of this shape memory alloy are vast and varied. For instance, when used in stents, nitinol nickel titanium can expand within blood vessels at body temperature, providing critical support while minimizing invasiveness during procedures.

Furthermore, the flexibility and strength of SMA wire enable precise control in minimally invasive surgeries where traditional tools might struggle. The use of nitinol wire is also prevalent in orthodontics; it allows for gentle adjustments over time without excessive force on teeth or gums. This versatility illustrates how vital nitinol muscle wire has become in advancing modern medicine.

Innovations in Robotics Using SMA Wire

The robotics sector is rapidly embracing innovations powered by SMA wires like nitinol muscle wire due to their lightweight nature and energy-efficient operation. Engineers are increasingly utilizing this shape memory alloy for actuators that mimic natural muscle movement—providing robots with enhanced dexterity and responsiveness compared to traditional motors or servos made from nickel wire or other materials.

One notable application includes soft robotics that utilize nimble movements inspired by biological systems; these robots can navigate complex environments more effectively thanks to the inherent flexibility of nitinol nickel titanium components. Moreover, researchers are exploring how combining multiple strands of SMA wires can create intricate movements that were previously unattainable with conventional robotic designs.

As advancements continue in robotics fueled by innovations involving SMA wires like those made from nitinol muscle wire, we can expect transformative changes not only within industrial automation but also across healthcare solutions where precision is paramount.

GEE SMA: A Leader in Nitinol Manufacturing

When it comes to the world of nitinol muscle wire, GEE SMA stands out as a frontrunner in the manufacturing domain. Their dedication to producing high-quality nitinol wire, specifically nitinol nickel titanium alloys, is matched by their commitment to customization. This ensures that clients receive tailored solutions that meet their unique requirements, making GEE SMA a go-to choice for industries ranging from medical devices to robotics.

Commitment to Quality and Customization

GEE SMA’s commitment to quality is evident in every strand of nitinol wire they produce. They employ rigorous testing protocols and adhere to international standards, ensuring that their shape memory alloy wire not only meets but exceeds expectations. Moreover, customization is at the heart of their operations; whether it's adjusting the diameter or modifying the alloy composition, GEE SMA provides bespoke solutions that cater specifically to client needs.

This focus on quality and customization has positioned GEE SMA as a trusted partner for businesses seeking reliable nitinol muscle wire solutions. Their ability to adapt and innovate means they can respond quickly to market demands while maintaining excellence in production standards. As industries evolve, GEE SMA remains committed to pushing the boundaries of what’s possible with nitinol nickel titanium products.

Advanced Techniques in Wire Forming

At GEE SMA, advanced techniques play a crucial role in shaping the future of nitinol wire manufacturing. The company utilizes state-of-the-art technology for forming shape memory alloy wire that enhances performance while reducing waste during production processes. These innovative methods not only improve efficiency but also ensure that every piece of muscle wire produced retains its unique properties.

Furthermore, their expertise extends beyond traditional methods; they integrate computer-aided design (CAD) systems into their workflow for precision engineering of custom shapes and forms. This allows for intricate designs that make full use of the remarkable characteristics inherent in shape memory alloy nitinol, providing clients with unparalleled options for their projects. With these advanced techniques at hand, GEE SMA continues leading the charge toward more efficient and effective applications of nitinol muscle wire.

Notable Projects and Collaborations

GEE SMA has been involved in numerous notable projects that showcase the versatility and reliability of nitinol muscle wire across various sectors. Collaborations with leading medical device manufacturers have resulted in groundbreaking innovations where shape memory alloy nitinol has been pivotal—think stents and surgical tools designed with precision using this remarkable material.

Additionally, partnerships within robotics have led to advancements where nimble movements are essential; here too, sma wire proves invaluable due to its unique ability to return from deformation when heated or cooled properly. These projects underscore not just technological prowess but also a commitment towards collaborative innovation—ensuring that each project contributes positively towards advancing industry standards.

Comparing Nitinol Nickel Titanium to Other Alloys

When it comes to materials used in advanced applications, nitinol nickel titanium stands out among other alloys, particularly when compared to traditional nickel wire. While both are composed primarily of nickel and titanium, nitinol muscle wire exhibits unique properties that make it a preferred choice in many scenarios. The most significant difference lies in the ability of shape memory alloy nitinol to return to its original shape after deformation, a feature that nickel wire simply does not possess.

Key Differences from Nickel Wire

One of the primary distinctions between nitinol wire and nickel wire is the phenomenon of shape memory. Nitinol muscle wire can remember its pre-deformed shape and revert back when exposed to heat or specific conditions, making it incredibly versatile for applications requiring movement or actuation. In contrast, nickel wire lacks this ability; once deformed, it stays that way unless manually reshaped, which limits its functionality in dynamic environments.

Another key difference is elasticity. Nitinol's unique composition allows it not only to recover from deformation but also provides significant flexibility and resilience under stress. Nickel wire may be strong but often doesn’t offer the same level of flexibility or adaptability as SMA (shape memory alloy) wire like nitinol.

Advantages of Shape Memory Alloy Nitinol

The advantages of using shape memory alloy nitinol extend well beyond just its unique properties; they also encompass performance enhancements across various industries. For instance, in medical devices such as stents or guidewires, the ability of nitinol muscle wire to expand and contract makes these devices easier to navigate through complex bodily structures while minimizing trauma during procedures. This capability is something traditional alloys like nickel cannot replicate.

Moreover, SMA wires like nitinol are lightweight yet incredibly strong—an essential combination for aerospace applications where every gram counts but strength cannot be compromised. The thermal responsiveness of nitinol also opens doors for innovations in robotics and automation where precise movements are crucial.

Industry Applications for Various Alloys

Different alloys serve different purposes across a plethora of industries; however, few can match the versatility found with nitinol muscle wire in specialized fields such as aerospace and medicine. While nickel wires might still hold their ground in basic electrical applications due to their conductivity and cost-effectiveness, they fall short when high performance is required under variable conditions—a domain where shape memory alloy nitinol excels.

In robotics, for example, SMA wires have been transformative by enabling more compact designs with intricate movements that mimic biological systems—something standard metal wires struggle with due to rigidity issues. Additionally, industries focused on innovative solutions find themselves leaning towards custom solutions involving nitinol due to its adaptability and performance capabilities under extreme conditions.

Custom Solutions with Nitinol Wire

When it comes to creating custom solutions, nitinol wire stands out due to its unique properties and versatility. Tailoring nitinol muscle wire for specific applications can significantly enhance performance across various industries, from medical devices to robotics. The ability to modify the composition and shape of this shape memory alloy wire allows manufacturers to meet precise customer requirements effectively.

Tailoring Nitinol Wire for Specific Needs

Customizing nitinol nickel titanium wire involves adjusting its thermal and mechanical properties based on the intended application. For instance, varying the alloy's composition can yield different transformation temperatures, enabling it to perform optimally in diverse environments. This adaptability is particularly beneficial in sectors like aerospace, where the reliability of nitinol muscle wire is paramount under extreme conditions.

Moreover, custom solutions often include specific geometries or forms that enhance the functionality of muscle wire in applications such as actuators or sensors. Engineers can design specialized shapes that maximize efficiency while minimizing weight—an essential factor in high-performance industries. By leveraging advanced manufacturing techniques, companies can create tailored nitinol wire products that align perfectly with their clients' specifications.

Case Studies of Successful Custom Forming

Several successful projects illustrate the effectiveness of custom forming using nitinol wire. One notable example is a medical device company that required a specialized actuator for minimally invasive surgeries; they turned to SMA wire for its unique shape memory properties. By collaborating closely with GEE SMA, they developed a custom-formulated nitinol muscle wire solution that provided precise control and enhanced patient outcomes.

Another case involved a robotics firm seeking lightweight components for robotic limbs; they opted for customized nitinol nickel titanium due to its strength-to-weight ratio and flexibility. After extensive testing and iterations, they achieved an innovative design that allowed for fluid movement while maintaining structural integrity under load conditions. These examples showcase how tailored solutions not only solve specific challenges but also drive innovation across various fields.

Future Trends in Custom Nitinol Applications

Looking ahead, the future of custom solutions with shape memory alloy nitinol appears promising as technology continues to evolve rapidly. Emerging trends indicate an increased demand for smart materials like nitinol muscle wire in wearable technology—think fitness trackers or health monitoring devices that adapt dynamically based on user activity levels or physiological changes.

Additionally, advancements in 3D printing techniques are set to revolutionize how we approach customization within this space; manufacturers will be able to produce intricate designs featuring complex geometries previously thought impossible with traditional methods using nickel wire or other alloys alone. As industries embrace these innovations, we can expect a growing array of applications where tailored SMA wires will play pivotal roles—further solidifying their place as indispensable tools in modern engineering.

Ensuring Performance in Extreme Conditions

Nitinol muscle wire has proven to be an exceptional material for applications in extreme environments, particularly in aerospace and space missions. Its unique properties, such as shape memory and superelasticity, enable it to withstand the rigors of harsh conditions while maintaining functionality. This reliability is crucial for components that must perform flawlessly under pressure and temperature fluctuations.

Nitinol in Aerospace and Space Missions

The aerospace industry has increasingly turned to nitinol nickel titanium due to its remarkable performance characteristics. Nitinol wire can endure extreme temperatures and pressures, making it ideal for components used in aircraft and spacecraft. From actuators to couplings, this shape memory alloy wire provides the necessary resilience and adaptability needed for successful missions beyond our atmosphere.

How GEE SMA Supports Chang’e and Tianwen Missions

GEE SMA has played a pivotal role in supporting significant space missions like Chang’e and Tianwen by providing high-quality nitinol muscle wire solutions tailored for specific needs. The company's commitment to innovation ensures that their nitinol wire products meet the stringent demands of space exploration technology. By supplying reliable SMA wire components, GEE SMA helps ensure the success of these groundbreaking missions, demonstrating the versatility of shape memory alloy nitinol.

Reliability of Nitinol in Harsh Environments

One of the standout features of nitinol is its ability to maintain performance even under harsh environmental conditions. Unlike traditional nickel wire or other alloys that may fail under stress, nitinol muscle wire retains its shape memory characteristics regardless of external factors like temperature or pressure variations. This reliability makes it a go-to choice for industries ranging from medical devices to aerospace applications where failure is not an option.

Conclusion

As we look ahead, the future of nitinol muscle wire appears brighter than ever. With its unique properties and capabilities, nitinol nickel titanium is set to revolutionize various industries, from medical devices to robotics. The ongoing research and development in shape memory alloy wire technology suggest that we are only scratching the surface of what nitinol wire can achieve.

The Future of Nitinol Muscle Wire

The potential applications for nitinol muscle wire are expanding rapidly, driven by advancements in material science and engineering. As industries seek lighter, stronger materials that can adapt to changing conditions, shape memory alloy nitinol stands out as a frontrunner. Future innovations may include more efficient designs in robotics and even breakthroughs in biomedical applications that we have yet to imagine.

Customization Opportunities in Nitinol Technology

Customization is where nitinol wire truly shines, allowing for tailored solutions that meet specific needs across various sectors. Whether it’s adjusting the properties of shape memory alloy wire for a unique application or creating specialized forms for medical devices, the opportunities are endless. Companies like GEE SMA are leading the charge by offering bespoke solutions that leverage the remarkable versatility of nitinol muscle wire.

The Importance of Quality in Nitinol Production

In an industry where precision matters, ensuring high-quality production of nitinol nickel titanium is paramount. The performance and reliability of muscle wire depend heavily on stringent quality control measures throughout manufacturing processes. By prioritizing quality, manufacturers can guarantee that their nitinol products will perform optimally even under extreme conditions, reinforcing their value across critical applications.