Introduction

In the world of automation, the demand for precise and efficient motion control has led to innovative solutions, one of which is the shape memory alloy linear actuator. These remarkable devices utilize the unique properties of shape memory alloys (SMAs) to provide reliable actuation in a variety of applications. From robotics to aerospace, SMA linear actuators are transforming how we approach automation equipment and linear products.

Understanding the Basics of SMA Actuators

Shape memory alloys are materials that can remember their original shape after being deformed, thanks to a unique phase transformation process. When heated or cooled, these materials undergo a change that allows them to return to their predetermined form. This characteristic makes SMA linear actuators not only fascinating but also incredibly useful in various engineering applications where precision is paramount.

Applications of Shape Memory Alloy Actuators

The versatility of shape memory alloy linear actuators opens doors to numerous applications across different industries. In medical devices, for instance, they can control stents and other implantable devices with remarkable accuracy. Similarly, in robotics and automation equipment, SMA actuators enable smooth movements and adaptations that traditional linear products simply cannot match.

Benefits of Customization in Actuators

One of the standout features of SMA linear actuators is their potential for customization based on specific needs and requirements. Tailoring actuator wire properties allows engineers to optimize performance for unique applications across various sectors—from automotive systems to aerospace components. This level of customization not only enhances functionality but also ensures that each actuator operates efficiently within its designated environment.

What Are Shape Memory Alloys?

Shape memory alloys (SMAs) are fascinating materials that exhibit unique properties, allowing them to return to a predetermined shape when heated above a certain temperature. This remarkable behavior is the cornerstone of many applications, especially in automation equipment where precision and efficiency are paramount. Among the various types of SMAs, Nitinol stands out due to its exceptional characteristics and versatility, making it a popular choice for creating shape memory alloy linear actuators.

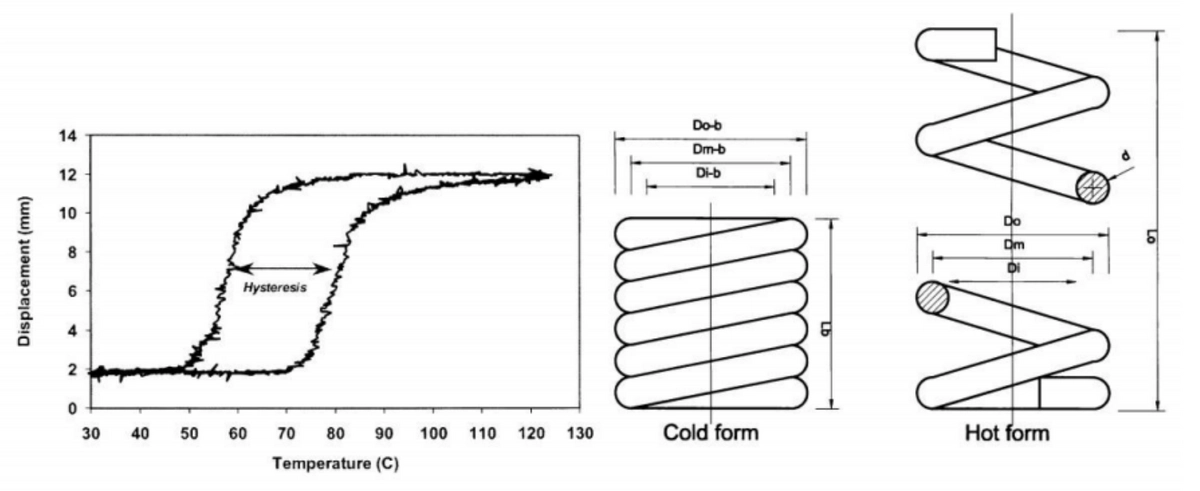

The Science Behind SMA

The science behind shape memory alloys revolves around their ability to undergo phase transformations between two distinct crystal structures: martensite and austenite. When cooled below a specific temperature, SMAs transform into a softer martensitic phase that can be deformed easily; upon heating, they revert to the more rigid austenitic phase, recovering their original shape. This transformation is what enables SMA linear actuators to function effectively in various automation applications by converting thermal energy into mechanical motion.

Key Characteristics of Nitinol

Nitinol, an alloy primarily composed of nickel and titanium, possesses several key characteristics that make it particularly suitable for use in linear products like SMA linear actuators. One significant trait is its superelasticity, which allows Nitinol to endure substantial deformations without permanent damage—ideal for dynamic environments found in automation equipment. Additionally, Nitinol exhibits excellent fatigue resistance and corrosion resistance, ensuring longevity and reliability in demanding applications.

Advantages Over Traditional Materials

When comparing shape memory alloy linear actuators made from Nitinol with traditional materials used in actuator wire or other linear products, several advantages become apparent. For starters, SMA actuators are often lighter than their conventional counterparts while providing similar or superior performance levels—an essential factor in industries where weight savings contribute to overall efficiency. Furthermore, the unique operational principles of SMAs allow for more compact designs without sacrificing functionality; this results in innovative solutions tailored specifically for modern automation needs.

The Role of Shape Memory Alloy Linear Actuators

Shape memory alloy linear actuators are revolutionizing the way we think about automation equipment. These innovative devices leverage the unique properties of shape memory alloys (SMAs) to provide precise movement and control in various applications. By converting thermal energy into mechanical work, SMA linear actuators offer a compact and efficient alternative to traditional linear products.

How SMA Linear Actuators Work

At the heart of a shape memory alloy linear actuator is the actuator wire, typically made from Nitinol, a nickel-titanium alloy known for its remarkable ability to remember its original shape. When heat is applied, the wire contracts, creating motion that can be harnessed for various tasks in automation equipment. This transformation occurs at specific temperatures, allowing for precise control over movement and force.

The mechanism is simple yet effective: as the SMA wire heats up, it changes from a martensitic phase (the low-temperature phase) to an austenitic phase (the high-temperature phase), leading to contraction. Once cooled down, the wire returns to its original length and shape, ready for another cycle of actuation. This process not only enhances efficiency but also minimizes energy consumption compared to other linear products.

Real-World Applications in Automation Equipment

Shape memory alloy linear actuators have found their niche in numerous real-world applications within automation equipment across various industries. For instance, they are widely used in robotics for precise positioning tasks where space is limited and weight matters—think robotic arms or surgical instruments that require delicate movements. Their compact design allows manufacturers to integrate them seamlessly into existing systems without compromising performance.

In addition to robotics, these actuators are also employed in aerospace applications where reliability and lightweight materials are paramount. From deploying satellite components to controlling flaps on aircraft wings, SMA linear actuators play a crucial role in enhancing operational efficiency while maintaining safety standards. The adaptability of these actuators makes them ideal for environments that demand high precision under varying conditions.

Comparing SMA Linear Actuators to Other Linear Products

When comparing shape memory alloy linear actuators with other linear products on the market, several key differences emerge that highlight their advantages. Traditional electric or pneumatic actuators may provide similar functionality but often come with bulkier designs requiring more space and power sources—two things that modern automation equipment strives to minimize.

SMA linear actuators excel due to their simplicity and reduced need for external components like motors or pumps; they operate solely based on thermal changes within the actuator wire itself! This not only reduces complexity but also cuts down on maintenance costs associated with more intricate systems—a win-win scenario for manufacturers looking for effective solutions.

GEE SMA: Innovation in Nitinol

When it comes to innovation in the world of shape memory alloys, GEE SMA stands out as a beacon of excellence. Their commitment to pushing the boundaries of what a shape memory alloy linear actuator can achieve is evident in every product they produce. By integrating cutting-edge technology with Nitinol's unique properties, GEE SMA has positioned itself as a leader in the actuator market.

Overview of GEE SMA Productions

GEE SMA specializes in manufacturing high-performance linear actuators that leverage the remarkable capabilities of Nitinol, a shape memory alloy known for its unique ability to return to predefined shapes when heated. The company’s production process is meticulously designed to ensure that each shape memory alloy linear actuator meets stringent quality standards while delivering exceptional performance for various applications. With an emphasis on innovation, GEE SMA continually refines its actuator wire and design processes to create products that outperform traditional linear products.

The versatility of GEE SMA's offerings allows them to cater to diverse industries, from robotics and medical devices to aerospace and automation equipment. Each actuator is engineered with precision, ensuring reliable operation under demanding conditions while maintaining efficiency and longevity. This dedication not only enhances the performance of their actuators but also sets new benchmarks in the industry.

Nitinol in Space Missions

One of the most exciting applications for Nitinol-based technologies lies within space missions, where reliability and performance are paramount. GEE SMA has been instrumental in developing shape memory alloy linear actuators specifically designed for use in extreme environments encountered during space exploration. These actuators are lightweight yet robust, making them ideal for deployment on spacecraft where every gram counts.

The unique properties of Nitinol allow these actuators to function effectively despite fluctuating temperatures and harsh conditions found beyond Earth’s atmosphere. They can perform critical tasks such as deploying solar panels or adjusting satellite antennas with precision that traditional linear products may struggle to achieve under similar circumstances. By incorporating advanced materials like Nitinol into their designs, GEE SMA continues to contribute significantly to the success of various space missions.

Customer-Specific Solutions by GEE SMA

Understanding that one size does not fit all, GEE SMA prides itself on offering customer-specific solutions tailored precisely to meet individual client needs within different sectors. Whether it’s customizing actuator wire specifications or adapting designs for specific automation equipment requirements, their team collaborates closely with clients throughout the development process. This bespoke approach ensures that each shape memory alloy linear actuator performs optimally within its intended application.

Case studies reveal how companies have benefited from these tailored solutions—ranging from enhanced efficiency to improved functionality—by integrating customized SMAs into their existing systems or new projects alike. The flexibility inherent in their manufacturing process means that clients can expect innovative solutions without compromising on quality or performance standards expected from top-tier linear products. In this way, GEE SMA not only meets market demands but actively shapes them through innovative engineering practices.

Customizing SMA Linear Actuators

In the world of automation equipment, customization is key to maximizing performance and efficiency. Shape memory alloy linear actuators (SMA linear actuators) offer unique advantages, but tailoring them to specific applications can unlock their full potential. This section delves into how actuator wire can be customized, the unique requirements across various industries, and real-world case studies showcasing the benefits of tailored solutions.

Tailoring Actuator Wire for Performance

The performance of a shape memory alloy linear actuator heavily relies on the properties of its actuator wire. By adjusting parameters such as diameter, alloy composition, and heat treatment processes, manufacturers can create SMA wires that respond optimally to specific operational demands. This level of customization not only enhances the efficiency of SMA linear actuators but also enables them to perform reliably in diverse environments.

For instance, a thicker actuator wire may provide greater force output but at the expense of speed. Conversely, a finer wire could facilitate faster actuation but with reduced load capacity. Striking the right balance through careful tailoring ensures that these linear products meet precise specifications for each application without compromising on performance.

Unique Requirements for Different Industries

Different industries have distinct needs when it comes to automation equipment and linear products like shape memory alloy linear actuators. In medical devices, for example, precision and reliability are paramount; therefore, SMA actuators must be designed to operate seamlessly within strict tolerances while maintaining biocompatibility. Meanwhile, aerospace applications demand lightweight solutions that withstand extreme conditions—attributes that can be achieved through specialized actuator wire formulations.

The automotive industry also presents unique challenges; here, durability under varying temperatures and mechanical stresses is essential for long-term functionality. Customizing SMA linear actuators allows engineers to address these requirements directly by selecting appropriate materials and designs tailored specifically for each sector's operational context.

Case Studies of Customized Actuators

To illustrate the impact of customized shape memory alloy linear actuators in real-world scenarios, consider a recent project involving an advanced robotic arm used in precision manufacturing tasks. The client required an actuator capable of rapid movements with high accuracy while maintaining compact dimensions—an ideal job for customized SMA technology! By optimizing both the actuator wire properties and design configurations based on rigorous testing feedback from initial prototypes, engineers delivered a solution that exceeded expectations.

Another notable case involved developing an SMA linear actuator for a cutting-edge prosthetic limb manufacturer seeking enhanced user experience through improved responsiveness and adaptability during movement. By customizing the actuator's thermal response characteristics to align with human body temperature variations during activity cycles, users experienced unprecedented fluidity in motion—a significant breakthrough in prosthetic technology!

These case studies exemplify how tailored solutions using shape memory alloy linear actuators not only meet industry-specific demands but also pave the way for innovative applications across sectors.

The Future of SMA Actuators

The future of shape memory alloy (SMA) actuators is looking brighter than ever, with advancements in technology paving the way for innovative applications across various industries. As automation continues to evolve, the demand for efficient and reliable linear products is skyrocketing. This surge in interest highlights the importance of integrating SMA linear actuators into automation equipment to enhance functionality and performance.

Trends in Actuator Technology

Actuator technology is witnessing significant trends that are reshaping how we think about motion control and precision engineering. One notable trend is the shift towards miniaturization, allowing shape memory alloy linear actuators to deliver powerful performance in compact designs. Additionally, there’s a growing emphasis on smart actuators that can communicate with other devices, making automation equipment more interconnected and responsive.

Another exciting trend is the integration of artificial intelligence (AI) into actuator systems, enabling predictive maintenance and improved efficiency. These advancements not only enhance the capabilities of traditional linear products but also open up new avenues for customization tailored to specific applications. With ongoing research and development, we can expect even more sophisticated SMA linear actuator solutions that will redefine industry standards.

The Impact of Automation on SMA Products

Automation has become a game-changer for industries worldwide, significantly impacting how shape memory alloy products are designed and utilized. As businesses strive for greater efficiency and reduced labor costs, SMA actuators are emerging as vital components in automating processes across sectors such as manufacturing, robotics, and aerospace. Their unique properties allow them to operate seamlessly within complex automated systems while providing precise control over movement.

Moreover, the rise of Industry 4.0 has led to increased demand for smart automation equipment that can adapt quickly to changing conditions or tasks. This adaptability positions SMA linear actuators as prime candidates for integration into next-generation machinery where flexibility is paramount. As a result, manufacturers are investing heavily in developing advanced actuator wire technologies that enhance performance while reducing energy consumption.

Prospects for Further Customization

The future holds exciting prospects for further customization of shape memory alloy linear actuators tailored to meet diverse industry needs. Companies like GEE SMA are already leading the charge by offering bespoke solutions designed around specific operational requirements or environmental conditions. By focusing on unique actuator wire configurations and material compositions, these customized solutions promise enhanced performance metrics tailored precisely to each application.

Furthermore, as industries continue to diversify their operations through automation equipment upgrades and innovations, there will be an increasing need for specialized SMA products capable of addressing niche challenges effectively. This opens up opportunities not just within existing markets but also in emerging fields such as medical devices or renewable energy systems where precision actuation plays a critical role in functionality. The potential for customized SMA linear actuator solutions seems limitless!

Conclusion

As we wrap up our exploration of shape memory alloy actuators, it’s clear that these innovative devices are not just a passing trend but a transformative force across various industries. The unique properties of SMA linear actuators allow for compact designs and efficient energy use, making them ideal for automation equipment where space and precision are paramount. With their ability to adapt to different conditions, SMA actuators are revolutionizing how we think about linear products in manufacturing, robotics, and beyond.

Transforming Industries with SMA Actuators

The impact of shape memory alloy linear actuators is felt in numerous sectors, from aerospace to healthcare. These actuators provide solutions that traditional linear products simply can't match—think reduced weight and increased reliability under extreme conditions. By harnessing the power of actuator wire made from Nitinol, industries can achieve unprecedented levels of performance and efficiency.

Why Choose GEE SMA for Actuator Needs

When it comes to actuator needs, GEE SMA stands out as a leader in innovation and customization. Their expertise in producing high-quality shape memory alloy linear actuators ensures that clients receive tailored solutions that fit their specific requirements perfectly. With a commitment to excellence and customer satisfaction, GEE SMA is the go-to choice for those looking to enhance their automation equipment with cutting-edge technology.

Enhancing Automation with Custom Solutions

In today's fast-paced world, the need for customized solutions is more critical than ever, especially in automation equipment where adaptability can make or break efficiency. GEE SMA excels at providing unique actuator wire configurations that meet diverse industry demands—from robotics to medical devices—ensuring optimal performance every time. By investing in customized SMA linear actuators, businesses can future-proof their operations while enjoying the benefits of enhanced functionality and reliability.