Introduction

In the ever-evolving landscape of technology, SMA linear actuators stand out as a fascinating innovation that combines the principles of smart materials with practical applications. These devices harness the unique properties of shape memory alloys (SMAs) to create motion in a compact and efficient manner. As industries push for more reliable and versatile solutions, understanding SMA linear actuators becomes increasingly essential.

Understanding SMA Linear Actuators

SMA linear actuators utilize shape memory alloys, which can return to a predetermined shape when subjected to specific stimuli, such as heat or electrical current. This remarkable ability allows them to convert thermal energy into mechanical motion, making them an attractive alternative to traditional linear actuators. By grasping how these systems function, we can appreciate their potential in various applications.

The Role of Smart Materials

Smart materials are at the heart of advancements like SMA linear actuators, enabling precise control and adaptability in engineering designs. These materials react dynamically to environmental changes or external inputs, enhancing functionality in ways that rigid components simply cannot achieve. The integration of smart materials into actuator technology is revolutionizing how we think about movement and automation.

Applications of Linear Actuators

The versatility of SMA linear actuators opens doors to numerous applications across diverse sectors including aerospace, medical devices, and consumer electronics. From adjusting satellite panels in space missions to enabling intricate movements in robotic surgery tools, these actuators are making waves everywhere you look. Their ability to deliver reliable performance while remaining lightweight and compact makes them a game-changer for modern technology.

What is an SMA Linear Actuator?

SMA linear actuators represent a fascinating intersection of engineering and smart materials. These devices harness the unique properties of shape memory alloys (SMAs) to create motion in a compact and efficient manner. As we delve into how these innovative actuators work, you'll discover why they are revolutionizing various industries.

The Science Behind Shape Memory Alloys

Shape memory alloys are metallic materials that can remember their original shape after being deformed. When heated above a certain temperature, these alloys revert to their pre-deformed shape, exhibiting remarkable elasticity and strength. Nitinol, a widely used SMA, is particularly notable for its unique transformation properties, making it ideal for applications in SMA linear actuators.

Understanding the science behind SMAs opens the door to appreciating their versatility in actuator design. The ability of SMAs to undergo phase changes allows them to convert thermal energy into mechanical work efficiently. This transformation is crucial for the functionality of SMA linear actuators and contributes significantly to their appeal over traditional options.

How SMA Linear Actuators Work

SMA linear actuators function by leveraging the thermal expansion and contraction of shape memory alloys to produce movement. When an electrical current heats the SMA wire or element within the actuator, it contracts and pulls on a connected mechanism, creating linear motion. Upon cooling, the alloy returns to its original shape, allowing for precise control over movement.

This process can be finely tuned through careful engineering design, resulting in smooth operation across various applications—from robotics to aerospace technologies. Unlike conventional electric or hydraulic systems that rely on bulky components and complex setups, SMA linear actuators offer streamlined designs that enhance efficiency while minimizing space requirements.

Benefits Over Traditional Actuators

One of the standout advantages of SMA linear actuators is their compact size coupled with high force output—an impressive feat compared to traditional actuators like electric motors or pneumatic cylinders. Their simplicity not only reduces weight but also enhances reliability since there are fewer moving parts that could fail over time.

Energy efficiency is another critical benefit; these smart devices consume power only when moving rather than maintaining constant energy input like many traditional systems do—resulting in lower overall energy costs during operation. With customization options available from manufacturers like GEE SMA, users can tailor these innovative solutions further to meet specific needs without sacrificing performance.

The Power of Nitinol

Nitinol, a unique shape memory alloy (SMA), is revolutionizing the world of linear actuators with its remarkable properties. Its ability to return to a predetermined shape when heated makes it an ideal candidate for applications that require precise movement and control. The versatility of Nitinol SMA linear actuators allows them to be utilized in various industries, showcasing their impressive capabilities.

Properties of Nitinol Shape Memory Alloys

Nitinol stands out due to its distinct properties, which include shape memory effect and superelasticity. The shape memory effect enables the material to remember a specific form, allowing SMA linear actuators to revert back to this configuration upon heating. Superelasticity provides the added benefit of significant deformation under stress without permanent change, making Nitinol an exceptional choice for applications requiring resilience and adaptability.

The combination of these properties results in SMA linear actuators that are not only efficient but also highly reliable under varying conditions. This reliability is crucial in fields such as aerospace and medical devices where performance can be a matter of life or death. Furthermore, Nitinol's biocompatibility enhances its appeal in medical applications, ensuring safety and effectiveness.

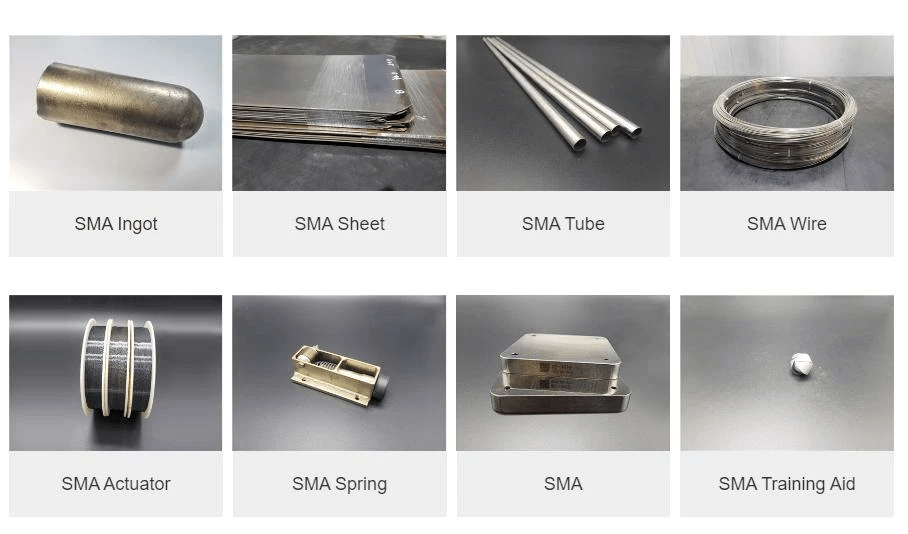

GEE SMA and Nitinol Innovations

GEE SMA has been at the forefront of innovation in the realm of Nitinol technology, pushing the boundaries on what is possible with SMA linear actuators. Their research has led to advancements that enhance both performance and durability, ensuring that their products meet the demands of modern engineering challenges. By integrating cutting-edge manufacturing techniques with advanced material science, GEE SMA continues to set new standards for linear actuator technology.

One notable innovation from GEE SMA involves optimizing the thermal response time of their Nitinol-based actuators, allowing for quicker actuation compared to traditional materials. This improvement opens up new possibilities for real-time applications where speed is critical—think robotics or precision surgical tools! As GEE SMA refines these technologies further, they remain committed to providing customizable solutions tailored specifically for client needs.

Real-world Applications of Nitinol

The real-world applications of Nitinol are vast and varied, spanning multiple industries thanks to its unique properties as an SMA linear actuator. In aerospace engineering, it plays a pivotal role in deploying mechanisms such as wing flaps or landing gear due to its lightweight nature combined with robust performance under extreme conditions. Moreover, this capability extends into space missions where every gram counts; using Nitinol can lead to significant weight savings while maintaining functionality.

In medical devices like stents or robotic surgical instruments, the biocompatibility and precision offered by Nitinol make it an indispensable material choice—helping save lives while performing complex procedures with utmost accuracy. Additionally, consumer electronics have begun adopting this technology too; think about smart gadgets that require compact designs without compromising on power or efficiency! As industries continue embracing innovations from GEE SMA’s developments in Nitinol technology, we can expect even more groundbreaking uses emerging on the horizon.

Key Applications of SMA Linear Actuators

SMA linear actuators are revolutionizing various industries by providing unique solutions that traditional actuators simply cannot match. Their ability to convert thermal energy into mechanical motion opens up a world of possibilities, especially in sectors where precision and reliability are paramount. Let’s dive into some key applications where these innovative devices are making waves.

Aerospace and Space Missions

In the aerospace sector, SMA linear actuators play a critical role in enhancing the functionality and efficiency of aircraft systems. These compact devices can operate under extreme conditions, making them ideal for applications such as wing morphing or deploying satellite antennas in space missions. The lightweight nature of SMA linear actuators also contributes to fuel efficiency, which is a significant consideration in aerospace design.

Moreover, their reliability ensures that critical systems operate flawlessly during high-stakes missions. As aviation technology advances, the demand for lightweight yet powerful components will only increase, positioning SMA linear actuators at the forefront of future innovations. With their unparalleled performance in challenging environments, these actuators are set to redefine what’s possible in aerospace engineering.

Medical Devices and Robotics

When it comes to medical devices and robotics, SMA linear actuators offer remarkable advantages that enhance patient care and surgical precision. In robotic surgery systems, these actuators enable smooth movements that are essential for delicate procedures while maintaining a compact design that fits within tight spaces. Their ability to respond quickly to temperature changes allows for real-time adjustments during operations, improving overall outcomes.

Additionally, SMA linear actuators can be found in prosthetics and rehabilitation devices, providing users with natural movement capabilities that were previously unattainable with traditional mechanisms. This adaptability not only improves functionality but also enhances user comfort and experience significantly. As medical technology continues to advance rapidly, the integration of SMA linear actuators will likely become even more prevalent across various applications.

Consumer Electronics

The consumer electronics industry is another area where SMA linear actuators shine brightly with their innovative designs and functionalities. From adjustable smartphone stands to smart home devices like automated blinds or furniture adjustments, these small yet powerful components provide seamless operation while saving space within products. Their energy-efficient nature ensures longer battery life for portable gadgets—an essential feature for today’s tech-savvy consumers.

Furthermore, manufacturers appreciate the customization options available with SMA linear actuators from companies like GEE SMA; this flexibility allows designers to create unique products tailored specifically to consumer needs without compromising performance or aesthetics. As our homes become smarter and more connected than ever before, expect an increasing number of consumer electronics incorporating these clever little devices into their designs.

Why Choose SMA Linear Actuators?

When it comes to selecting a linear actuator, SMA linear actuators stand out due to their unique advantages. These devices leverage the remarkable properties of shape memory alloys (SMAs), making them ideal for a variety of applications. The combination of reliability, energy efficiency, and customization options makes SMA linear actuators an appealing choice for engineers and designers alike.

Reliability in Extreme Conditions

SMA linear actuators are engineered to perform reliably even in extreme conditions where traditional actuators might fail. Their ability to function under high temperatures, corrosive environments, and varying pressures makes them indispensable in industries like aerospace and medical technology. This reliability stems from the inherent properties of shape memory alloys, which can return to their original shape after deformation, ensuring consistent performance over time.

Energy Efficiency and Compact Design

One of the standout features of SMA linear actuators is their energy efficiency, which can significantly reduce operational costs. Unlike traditional actuators that often require continuous power supply to maintain position, SMA linear actuators only consume energy during actuation phases. Moreover, their compact design allows for easy integration into tight spaces without compromising functionality—perfect for modern applications that demand sleek solutions.

Customization Options from GEE SMA

GEE SMA offers extensive customization options for their linear actuators, allowing clients to tailor solutions according to specific needs. Whether it's adjusting size specifications or optimizing performance characteristics, GEE's expertise ensures that each actuator meets precise requirements. This level of customization not only enhances performance but also fosters innovation across various industries looking to harness the potential of SMA technology.

Future Trends in SMA Technology

The landscape of SMA technology is on the brink of exciting advancements that promise to redefine how we interact with linear actuators. As research progresses, we are witnessing a surge in innovative smart materials that enhance the functionality and efficiency of SMA linear actuators. These developments not only improve performance but also expand the range of applications for these versatile devices.

Advances in Smart Materials

Recent breakthroughs in smart materials are paving the way for more responsive and adaptive SMA linear actuators. Innovations such as enhanced shape memory alloys and advanced composites are being explored to create actuators that can respond to environmental changes more effectively. This means that future linear actuators could be lighter, stronger, and capable of operating under even more extreme conditions than their predecessors.

Moreover, researchers are focusing on integrating sensors directly into SMA systems, allowing for real-time feedback and adjustments during operation. This synergy between smart materials and actuator technology will lead to smarter systems capable of self-diagnosis and maintenance alerts. With these advancements, the potential uses for SMA linear actuators will grow exponentially across various industries.

The Growing Demand for Linear Actuators

As industries continue to evolve towards automation and precision engineering, the demand for reliable SMA linear actuators is skyrocketing. From aerospace applications requiring lightweight solutions to medical devices necessitating compact designs, every sector is recognizing the benefits offered by these innovative devices. The trend indicates a clear shift toward adopting smart technologies that can enhance productivity while minimizing energy consumption.

Furthermore, as consumers increasingly seek out energy-efficient products in their everyday lives, manufacturers are compelled to incorporate SMA technologies into consumer electronics as well. This growing awareness around sustainability is driving innovation in actuator design and functionality across various markets. Consequently, we can expect an influx of new products powered by advanced linear actuator systems tailored to meet specific user needs.

GEE SMA's Vision for the Future

At GEE SMA, our vision aligns with these emerging trends; we aim to lead the charge in developing next-generation SMA linear actuators that harness cutting-edge technologies while prioritizing user experience. Our commitment includes investing heavily in research initiatives focused on enhancing material properties and actuator performance through innovative design techniques. By collaborating with industry leaders and academic institutions, we strive to stay ahead of market demands while pushing technological boundaries.

Additionally, GEE SMA recognizes that customization will be key in catering to diverse applications across sectors like aerospace, healthcare, and robotics. We envision creating modular solutions where clients can tailor specifications according to their unique requirements without compromising on quality or efficiency. As we look forward into this promising future filled with possibilities for SMA technology, our dedication remains unwavering—delivering exceptional products that empower users worldwide.

Conclusion

The world of SMA linear actuators has transformed how we approach automation and control systems, showcasing their unique capabilities and advantages. These innovative devices harness the properties of shape memory alloys to deliver precision, efficiency, and reliability across various applications. As industries continue to evolve, the impact of SMA linear actuators will only grow, paving the way for smarter solutions.

The Impact of SMA Linear Actuators

SMA linear actuators have made significant strides in sectors such as aerospace, medical devices, and robotics by offering unparalleled performance in compact designs. Their ability to function under extreme conditions while consuming minimal energy sets them apart from traditional linear actuators. This reliability not only enhances operational efficiency but also reduces maintenance costs, making them a favorite among engineers and designers alike.

Innovations in Smart Material Technology

The field of smart materials is rapidly advancing, with ongoing research leading to breakthroughs that enhance the functionality of SMA linear actuators even further. Recent innovations have focused on improving response times and expanding the range of operating temperatures for these devices. As new developments emerge in smart material technology, we can expect even more efficient and versatile SMA linear actuators that cater to diverse industrial needs.

The Road Ahead for GEE SMA

Looking ahead, GEE SMA is poised to remain at the forefront of this exciting technological landscape by continuously innovating within the realm of shape memory alloys. With a commitment to sustainability and efficiency, GEE SMA aims to expand its product offerings while addressing growing market demands for advanced automation solutions. By investing in research and development, GEE SMA envisions a future where their SMA linear actuators redefine industry standards and elevate performance across various applications.