Introduction

Nitinol, a remarkable alloy of nickel and titanium, has captured the imagination of scientists and engineers alike. Its unique properties and diverse applications have made it a game changer in various fields, from medicine to aerospace. In this introduction, we will explore the magic of Nitinol, its fascinating history, and the innovative ways it is reshaping technology.

Discover the Magic of Nitinol

What makes Nitinol so enchanting? At its core lies a special structure that allows it to exhibit shape memory and superelasticity—two phenomena that enable it to return to its original form after deformation. This extraordinary characteristic opens up a world of possibilities in the applications of Nitinol, making it an essential material for everything from medical devices to robotics.

Why Nitinol is a Game Changer

The game-changing nature of Nitinol stems from its unique composition and properties. Unlike traditional materials, Nitinol can adapt dynamically under changing conditions, which is particularly valuable in medical applications where precision is critical. With advancements in understanding the history of Nitinol and its types, researchers continue to unlock new potential uses that could revolutionize industries.

Unveiling the Properties of Nitinol

To fully appreciate what sets Nitinol apart, one must delve into its remarkable properties. The alloy’s shape memory effect allows for transformative capabilities in devices like stents and actuators—an innovation that enhances patient care significantly. Moreover, the diverse types of Nitinol available enable tailored solutions for specific challenges across various sectors, showcasing just how versatile this material truly is.

The History of Nitinol

Nitinol, a remarkable alloy of nickel and titanium, has a rich history that spans several decades. Its unique properties have led to a wide range of applications, particularly in the medical field and beyond. Understanding the journey of nitinol from its discovery to modern applications helps appreciate its significance in technology today.

From Discovery to Modern Applications

The history of nitinol began in the 1960s when it was discovered by researchers at the Naval Ordnance Laboratory in Maryland. They were investigating new materials for military applications when they stumbled upon this unique alloy with incredible shape memory properties. Over the years, nitinol's fascinating characteristics have paved the way for innovative applications in various fields, including medicine, robotics, and aerospace engineering.

Initially used for specialized military components, the applications of nitinol quickly expanded into medical devices such as stents and guidewires. The ability of nitinol to return to its original shape after deformation makes it an ideal candidate for minimally invasive surgeries. Today, nitinol is also being explored for use in advanced robotics through the integration of Nitinol actuators that enhance movement efficiency and precision.

Key Figures in Nitinol Research

The journey of nitinol would not be complete without acknowledging the key figures who contributed significantly to its research and development. Among them is Dr. William J. Buehler, who played a pivotal role in discovering and characterizing this alloy's unique properties during his tenure at the Naval Ordnance Laboratory. His work laid the groundwork for understanding Nitinol structure and composition, which opened doors for countless innovations.

Another influential figure is Dr. John E. McCaffrey, who made significant advancements in applying nitinol within medical technologies during his career at several biomedical companies. His contributions helped solidify nitinol's position as a game-changer in various medical applications by demonstrating its effectiveness and reliability under different conditions.

These pioneers have inspired subsequent generations of researchers to explore new types of Nitinol alloys and their potential uses across diverse industries—from health care to aerospace—ensuring that this extraordinary material continues to evolve.

Milestones in Nitinol Development

Numerous milestones punctuate the history of nitinol development that highlight its growth from a laboratory curiosity to a critical component across multiple sectors. One significant milestone occurred when FDA approval was granted for Nitinol stents in 1996; this marked a turning point as it showcased practical applications within medicine that could save lives through minimally invasive procedures.

Another notable milestone was achieved with advancements in manufacturing techniques during the early 2000s that enabled high-quality production of what is now known as what is nitinol wire—a versatile form used extensively across industries due to its excellent mechanical properties and adaptability.

As research continues into more sophisticated types of Nitinol alloys tailored for specific tasks—such as enhanced fatigue resistance or improved thermal stability—the future looks bright for this remarkable material with ever-expanding potential across various fields.

Nitinol Structure and Composition

Nitinol, a remarkable alloy of nickel and titanium, showcases a unique structure that contributes to its extraordinary properties. Understanding the composition of Nitinol is crucial for grasping its diverse applications in various fields. This section delves into the intricacies of Nitinol alloys, the science behind its shape memory effect, and the unique properties that make it so valuable.

Understanding Nitinol Alloys

Nitinol alloys are primarily composed of nickel and titanium in varying ratios, typically around 50% of each element. The precise Nitinol composition can significantly affect its mechanical properties and performance in different applications. By adjusting the ratio of these two metals, researchers can create various types of Nitinol tailored for specific uses, from medical devices to aerospace components.

The history of Nitinol reveals how these alloys were developed for their unique characteristics—particularly their ability to return to a predetermined shape when heated. This adaptability has led to numerous innovative applications of Nitinol across industries. For instance, medical professionals rely on specialized Nitinol stents that expand upon reaching body temperature, showcasing the versatility offered by different types of Nitinol alloys.

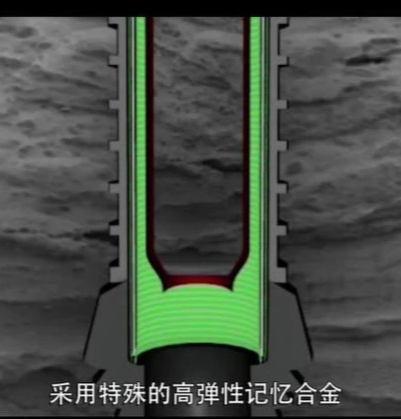

The Science Behind Nitinol’s Shape Memory

At the heart of what makes Nitinol so fascinating is its shape memory effect—a phenomenon where the material remembers its original form after being deformed under stress. When subjected to heat above a specific temperature known as the transformation temperature, the structure reverts back to its pre-deformed shape due to changes in crystal structure at an atomic level. This property is not just intriguing; it has practical implications across numerous applications.

For example, in surgical settings, understanding this science allows for creating devices like stents that are easily inserted into blood vessels but expand once they reach their target site inside the body. Similarly, engineers utilize this feature in designing nitinol actuators that respond dynamically to changes in temperature or stress conditions—allowing for more efficient robotic movements or systems that adjust automatically under varying loads.

Unique Properties of Nitinol

The unique properties of Nitinol extend beyond just shape memory; they also include superelasticity—a characteristic allowing it to undergo significant deformation without permanent damage when subjected to stress within certain limits. These combined attributes make it an ideal material for high-stress environments such as aerospace engineering and advanced medical devices where durability is essential.

Moreover, because nitinol wire exhibits excellent fatigue resistance and biocompatibility, it's often used in critical applications like orthopedic implants or minimally invasive surgical instruments—demonstrating both reliability and safety within human bodies. As we continue exploring new types of nitinol and their potential uses across industries—from robotics with nitinol actuators to life-saving medical technologies—the future looks bright for this extraordinary alloy.

Innovative Medical Applications of Nitinol

Nitinol, with its unique properties and remarkable composition, has revolutionized the medical field through various innovative applications. The combination of its shape memory and superelasticity makes Nitinol an ideal material for medical devices that require flexibility and resilience under stress. As we delve into the applications of Nitinol in medicine, we will explore how this extraordinary alloy is saving lives and enhancing surgical techniques.

Nitinol Stents: A Lifesaving Technology

Nitinol stents are a prime example of the transformative applications of nitinol in healthcare. These tiny mesh tubes are designed to keep arteries open after they've been cleared of blockages, significantly improving blood flow to vital organs. Thanks to the unique properties of Nitinol, these stents can expand at body temperature, adapting perfectly to the contours of blood vessels while providing strength and support.

The history of nitinol plays a crucial role in understanding how these stents came to be; researchers harnessed its shape memory effect to create devices that could be delivered via minimally invasive procedures. The composition of nitinol allows for a high degree of flexibility during insertion, which is essential for navigating the complex pathways within the human body. As a result, patients experience reduced recovery times and lower risks associated with traditional surgical methods.

Moreover, ongoing advancements in nitinol technology continue to enhance stent design and functionality. Newer generations are being developed with drug-eluting capabilities that release medication over time to prevent re-blockage, showcasing just one way that the applications of nitinol are evolving in response to patient needs.

Nitinol in Orthopedic Implants

In orthopedics, nitinol's unique structure offers significant advantages for implants used in bone repair and reconstruction. The superelastic nature of nitinol allows orthopedic implants like screws and plates to withstand high levels of stress without fracturing or deforming—an essential property when dealing with dynamic bodily movements during recovery periods.

The versatility found within different types of Nitinol means that surgeons can choose specific alloys tailored for particular applications based on their mechanical requirements. This adaptability not only enhances patient outcomes but also reduces complications associated with implant failure or rejection due to improper fitting or rigidity issues.

Furthermore, research continues into optimizing nitinol composition for even better performance in orthopedic settings; innovations include developing porous structures that promote bone ingrowth while maintaining necessary strength during healing phases. With these advancements, it's clear that the future holds exciting possibilities for further integration of nitinol technology into orthopedic practices.

Robotics and Surgical Instruments

Nitinol actuators have begun making waves in robotics and surgical instruments due to their ability to transform motion efficiently while maintaining compact designs—ideal for minimally invasive surgeries where space is limited yet precision is paramount. These actuators leverage the properties of Nitinol’s shape memory effect by converting thermal energy into mechanical movement seamlessly.

The history of nitinol reveals its potential beyond traditional uses as researchers explore more sophisticated robotic systems equipped with nimble instruments powered by this remarkable alloy. With ongoing advancements aimed at improving control mechanisms within robotic surgery tools, we can expect even greater precision when performing intricate procedures such as cardiac surgery or tumor removal.

Additionally, using what is known as smart surgical instruments—those incorporating sensors alongside nitinol components—can provide real-time feedback during operations, allowing surgeons greater insight into tissue responses throughout procedures. This fusion between robotics and medical technology exemplifies how innovative applications can redefine healthcare standards while enhancing patient safety through improved outcomes driven by cutting-edge materials like Nitinol.

Nitinol in Aerospace Engineering

Nitinol, with its unique properties and versatile applications, is making waves in the aerospace industry. The combination of its shape memory and superelasticity allows engineers to design components that can withstand extreme conditions while maintaining performance. As we delve into how Nitinol is powering space missions and contributing to advancements, it’s clear this remarkable alloy is changing the game.

Powering Space Missions with Nitinol

The applications of nitinol in space exploration are both innovative and essential. Its lightweight nature combined with impressive strength makes it an ideal choice for various spacecraft components, from actuators to structural elements. The ability of nitinol to revert to a predetermined shape when heated means that these components can adapt seamlessly under different thermal conditions encountered during missions.

Moreover, the history of nitinol showcases its development from a mere curiosity into a vital material for aerospace engineering. Engineers have leveraged the unique properties of nitinol to create deployable structures that save space during launch but expand when needed in orbit. This capability not only enhances mission efficiency but also significantly reduces launch costs.

GEE SMA’s Role in Aerospace Advancements

GEE SMA (Shape Memory Alloys) has been at the forefront of developing advanced nitinol solutions tailored specifically for aerospace applications. By focusing on the specific needs of aerospace engineering, GEE SMA has harnessed the exceptional properties of nitinol composition to create reliable systems that perform under pressure—both literally and figuratively! Their innovations include specialized actuators that respond dynamically to environmental changes, ensuring optimal operation across various scenarios.

The types of nitinol developed by GEE SMA are engineered for specific challenges faced by aerospace missions, such as extreme temperatures and radiation exposure. These tailored alloys contribute significantly to advancements in satellite technology and robotic systems used for planetary exploration. As these technologies evolve, GEE SMA continues pushing boundaries with their cutting-edge approaches.

Nitinol Deployments in Extreme Conditions

One of the standout features of nitinol is its ability to operate effectively under extreme conditions—an essential quality for any material used in aerospace applications. Whether it's soaring through space or navigating harsh planetary environments, components made from this alloy maintain their functionality thanks to their unique structure and composition.

For instance, when deployed as part of heat shields or antennae mechanisms on satellites, nitinol's shape memory effect ensures reliable performance even as temperatures fluctuate dramatically between day and night cycles in outer space. This adaptability is critical; engineers can trust that their designs will hold up against unforeseen challenges without compromising safety or performance.

Nitinol actuators are particularly noteworthy; they provide precise movements while being lightweight enough not to burden spacecraft design constraints excessively. With continued research into new types of nitinol alloys optimized for specific tasks within aerospace engineering, we can expect even more groundbreaking applications emerging on the horizon.

Types of Nitinol and Their Uses

Nitinol, a remarkable alloy of nickel and titanium, comes in various types, each tailored for specific applications. Understanding the different types of Nitinol is crucial for harnessing its properties effectively in fields ranging from medicine to aerospace. This section will explore the distinct categories of Nitinol alloys, their unique characteristics, and their practical applications.

Distinguishing Different Nitinol Alloys

The primary types of Nitinol are categorized based on their composition and intended use. The two most common forms are shape memory alloys (SMAs) and superelastic alloys, both exhibiting fascinating properties of Nitinol that make them suitable for diverse applications. For instance, SMAs can return to a predetermined shape when heated above a certain temperature, while superelastic alloys maintain their shape even when deformed under stress.

In addition to these two main categories, there are variations within each type that cater to specific requirements such as fatigue resistance or biocompatibility. These distinctions in Nitinol structure play a significant role in determining which alloy is best suited for particular applications of nitinol—whether it’s in medical devices or aerospace components. Understanding the history of nitinol provides context for how advancements have led to the development of specialized alloys tailored for modern technologies.

Applications of Nitinol Wire

What is nitinol wire? It's an extraordinary material with unique properties that allow it to perform functions beyond traditional wires. The applications of nitinol wire range from medical devices like stents and guidewires to innovative uses in robotics and actuators, showcasing its versatility across multiple industries.

One standout feature is its ability to undergo significant deformation while still returning to its original shape under certain conditions—a property rooted deeply in its composition and structure. This makes nitinol wire particularly valuable in minimally invasive surgeries where flexibility and precision are paramount. As industries continue to explore new possibilities, the demand for high-performance nitinol wire will likely expand even further.

Nitinol Actuators in Robotics

Nitinol actuators represent one of the most exciting innovations stemming from this unique alloy's properties. These devices leverage the shape memory effect or superelasticity inherent in nitinol to create motion with remarkable efficiency and compactness—ideal traits for robotic systems where space is often at a premium. The use of nitinol actuators allows robots not only to perform complex tasks but also adapt dynamically to changing environments.

In addition, these actuators can operate without bulky motors or gears, making them lightweight alternatives that enhance overall system performance. As robotics technology evolves, incorporating various types of Nitinol will undoubtedly lead to more sophisticated machines capable of performing intricate operations with ease—making them indispensable tools across numerous sectors.

Conclusion

As we wrap up our exploration of Nitinol, it’s clear that this remarkable material is just beginning to show its potential. The future of Nitinol applications is bright, with ongoing research and innovation paving the way for new uses across various fields. From medical devices to aerospace engineering, the versatility of Nitinol continues to expand, promising exciting advancements in technology.

The Future of Nitinol Applications

Looking ahead, the applications of Nitinol are poised for significant growth as industries seek innovative solutions that leverage its unique properties. New developments in Nitinol structure and composition are leading to enhanced performance and functionality in various products. With the rise of smart materials and robotics, we can expect to see more sophisticated Nitinol actuators that will revolutionize how machines interact with their environments.

Nitinol's Impact on Technology and Health

The impact of Nitinol on technology and health cannot be overstated; it has already transformed medical treatments through devices like stents and orthopedic implants. Its shape memory effect allows for minimally invasive procedures that improve patient outcomes while reducing recovery times. As researchers delve deeper into the history of Nitinol, they uncover even more potential applications that could enhance quality of life across multiple domains.

Why You Should Care About Nitinol

So why should you care about this fascinating material? Understanding what is nitinol wire and its diverse types enables us to appreciate how it shapes our world today—whether in life-saving medical devices or cutting-edge aerospace technologies. As consumers and innovators alike, recognizing the importance of materials like Nitinol can inspire us to support advancements that improve our daily lives.