Introduction

Nitinol is a fascinating nickel titanium alloy that has captured the attention of scientists and engineers alike. Known for its remarkable properties, nitinol is not just a material; it’s a game-changer in various fields, particularly in medicine and engineering. Understanding what is nitinol allows us to appreciate its significance in advancing technology and improving lives.

Understanding Nitinol and Its Significance

At its core, nitinol is a unique nickel material that exhibits extraordinary characteristics, such as shape memory effect and superelasticity. These properties make nitinol an ideal candidate for numerous applications, from medical devices to robotics. The significance of nitinol lies not only in its innovative uses but also in how it pushes the boundaries of what materials can achieve.

The Science Behind Nitinol

The science behind nitinol revolves around its composition—primarily nickel and titanium—and how these elements interact at different temperatures. This interaction gives rise to the unique nitinol properties that allow it to return to a predetermined shape when heated or deformed under stress. By delving into the mechanics of nitinol nickel titanium, we uncover the intricate balance between temperature changes and material behavior.

Overview of Nitinol Applications

Nitinol's versatility opens up a world of possibilities across various industries, particularly in medical applications where precision is paramount. From stents that maintain arterial patency to guidewires that navigate complex vascular systems, the applications are vast and impactful. As we explore further into nitinol's heat treatment processes and mechanical properties, we will see how this innovative material continues to revolutionize technology today.

What is Nitinol

Nitinol, a remarkable alloy, has garnered attention for its unique properties and diverse applications. This nickel-titanium material stands out in various fields, particularly in medicine and engineering. Understanding what nitinol is requires a closer look at its composition and the fascinating characteristics that make it so valuable.

Definition and Composition

Nitinol is an alloy primarily composed of nickel and titanium, typically containing around 50-60% nickel by weight. This specific ratio is crucial as it influences the alloy's unique properties, such as shape memory effect and superelasticity. The name Nitinol itself derives from its components—Nickel Titanium Naval Ordnance Laboratory—highlighting its origins in military research.

The composition of nitinol not only defines its identity but also underpins its versatility across various applications. With its distinct atomic structure, nitinol exhibits behaviors that are not typical of conventional metals or alloys. This combination of nickel material with titanium results in a product that can undergo significant transformations under different temperature conditions.

Nitinol Nickel Titanium Explained

At the heart of nitinol's functionality lies the interplay between nickel and titanium within the alloy matrix. The unique bonding characteristics between these two elements contribute to what we refer to as nitinol properties, which include the ability to return to a predetermined shape when heated above a certain temperature. This phenomenon is known as the shape memory effect.

Moreover, when subjected to stress or strain at lower temperatures, nitinol can exhibit superelasticity—a property that allows it to deform significantly without permanent damage. Such behavior makes nitinol an ideal candidate for applications requiring flexibility and resilience, especially in medical devices where precision is paramount. Understanding how this nickel titanium combination works opens doors to innovations across multiple sectors.

The Unique Nitinol Properties

What truly sets nitinol apart are its extraordinary material properties that defy traditional metal behavior. For instance, the shape memory effect enables devices made from nitinol to adapt dynamically during surgical procedures or other applications where flexibility is crucial—think stents expanding within arteries!

Furthermore, nitinol's superelasticity allows it to absorb energy efficiently while returning to its original form after deformation—a highly sought-after trait in various engineering solutions. These unique properties are complemented by exceptional fatigue resistance compared to other materials; this ensures longevity even under repeated stress cycles.

In summary, understanding what is nitinol involves appreciating how this innovative alloy combines nickel with titanium to create something truly special—an adaptable material with extensive potential across numerous fields including medicine and beyond.

Nitinol Material Properties

When it comes to understanding what is nitinol, one must delve into its fascinating material properties that set it apart from other nickel materials. Nitinol, a nickel-titanium alloy, boasts unique characteristics that make it indispensable in various applications, particularly in the medical field. The combination of its shape memory effect and superelasticity creates a synergy that enhances its performance across multiple domains.

Shape Memory Effect

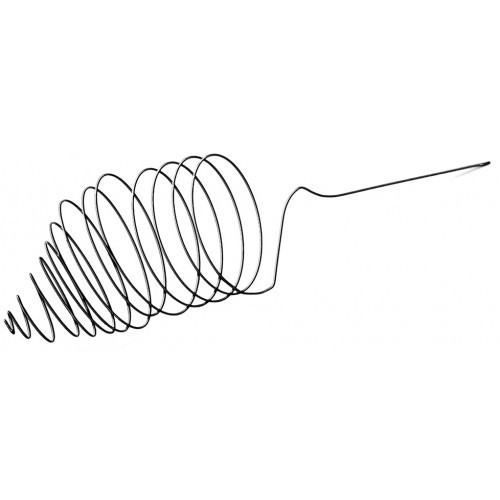

The shape memory effect is one of the most intriguing nitinol properties that captures the imagination of scientists and engineers alike. Essentially, this phenomenon allows nitinol to return to a predetermined shape when heated above a certain temperature after being deformed at lower temperatures. This remarkable ability makes nitinol nickel titanium an ideal candidate for applications such as self-expanding stents and guidewires in medical devices.

Imagine a paperclip bent out of shape; when heated, it could magically revert to its original form—that's the essence of the shape memory effect in nitinol! This property not only enhances functionality but also increases reliability in critical situations where precision matters most. By leveraging this unique feature, designers can create innovative solutions that improve patient outcomes and streamline surgical procedures.

Superelasticity in Nitinol

Another standout characteristic among nitinol material properties is superelasticity, which occurs when the alloy is subjected to stress beyond its yield strength at body temperature. Unlike traditional materials that would permanently deform under similar conditions, nitinol exhibits an extraordinary ability to undergo significant strain while returning to its original state once the stress is removed. This flexibility allows for greater design freedom and resilience in applications ranging from orthodontics to robotics.

Superelasticity arises from a reversible phase transformation within the material's crystalline structure—a process that sets nitinol apart from conventional nickel materials. In practical terms, this means devices made from nitinol can withstand dynamic forces without compromising their integrity or performance over time. The implications for industries such as aerospace and automotive are vast; components can be engineered with enhanced durability while maintaining lightweight characteristics.

Temperature and Performance Relationship

The relationship between temperature and performance is crucial when considering nitinol heat treatment processes aimed at optimizing mechanical properties for specific applications. Nitinol’s behavior changes dramatically with temperature fluctuations; understanding these nuances allows engineers to tailor their designs effectively based on operational conditions. For instance, adjusting heat treatment parameters can enhance either superelasticity or shape memory effects depending on the intended use.

In medical applications where precision is paramount—like stents or surgical tools—temperature control becomes vital during manufacturing processes to ensure optimal performance characteristics are achieved consistently across batches. Moreover, awareness of how different temperatures affect these unique properties enables manufacturers to anticipate potential challenges during deployment or use scenarios involving varying thermal environments. Ultimately, mastering this temperature-performance relationship unlocks new possibilities for innovation within both existing technologies and emerging fields utilizing what is nitinol.

Nitinol Heat Treatment

Nitinol heat treatment is a crucial process that significantly influences the material's properties, making it essential for various applications. Understanding what is nitinol and how heat treatment affects its characteristics can help optimize this unique nickel titanium alloy for specific uses. By carefully controlling the heat treatment processes, manufacturers can enhance the nitinol properties that are vital in fields like medicine and engineering.

Heat Treatment Processes

The heat treatment of nitinol involves several processes, including solution treatment, aging, and quenching. During these stages, nitinol undergoes transformations that affect its phase structure and mechanical properties. For instance, heating the nitinol nickel titanium alloy to a specific temperature allows it to achieve its desired shape memory effect and superelasticity.

In practical terms, solution treatment involves heating the material above its transformation temperature to dissolve precipitates before rapid cooling or quenching occurs. Aging follows this step where the material is reheated at lower temperatures to achieve optimal strength and flexibility. These processes are vital in ensuring that the final product exhibits desirable nitinol material properties such as high fatigue resistance and shape recovery.

Impact on Mechanical Properties

Heat treatment has a profound impact on the mechanical properties of nitinol, influencing factors like tensile strength, ductility, and fatigue resistance. By adjusting parameters such as temperature and duration during heat treatments, manufacturers can tailor these mechanical properties to meet specific requirements for different applications. This level of customization makes nitinol an attractive choice over traditional materials for various industrial uses.

For example, properly treated nitinol demonstrates enhanced superelastic behavior under stress while maintaining impressive return-to-original-shape capabilities when heated or deformed within certain limits. Additionally, understanding how these treatments affect nitinol's performance helps engineers design components that withstand rigorous conditions without compromising safety or functionality. This adaptability makes it indispensable in critical areas such as medical devices where reliability is paramount.

Optimizing Nitinol for Applications

To optimize nitinol for specific applications, careful consideration must be given to both the heat treatment processes used and their subsequent effects on mechanical properties. This means selecting appropriate temperatures based on intended use—whether it's medical implants requiring biocompatibility or industrial tools needing high durability against wear and tear. The versatility of nitinol allows engineers to push boundaries by creating innovative solutions tailored precisely to project demands.

Moreover, ongoing research into advanced heat treatment techniques continues to reveal new possibilities for enhancing performance across various sectors beyond just medicine—think aerospace engineering or robotics! As we explore what is nitinol further through experimentation with different alloys and treatments, we unlock even more potential applications waiting to be discovered in our ever-evolving technological landscape.

Nitinol Mechanical Properties

Nitinol, a remarkable nickel titanium alloy, boasts a unique set of mechanical properties that contribute to its versatility in various applications. Understanding these nitinol mechanical properties is essential for harnessing its potential in fields ranging from medicine to aerospace. The interplay between tensile strength, flexibility, and fatigue resistance sets nitinol apart from traditional materials.

Tensile Strength and Flexibility

When we talk about what is nitinol, one cannot overlook its impressive tensile strength combined with remarkable flexibility. This nickel material can endure significant stress while maintaining its shape, making it ideal for applications where durability is crucial. The unique nitinol properties allow it to return to its original form after deformation, which is particularly beneficial in medical devices like stents and guidewires.

The combination of high tensile strength and flexibility means that nitinol can be bent or twisted without breaking—an attribute not commonly found in other metals. This flexibility allows for innovative designs that can adapt to various conditions while remaining reliable under pressure. Furthermore, the ability of nitinol nickel titanium to withstand repeated cycles of deformation without losing integrity enhances its appeal across multiple industries.

Fatigue Resistance of Nitinol

Fatigue resistance is another standout feature when discussing nitinol material properties. Unlike many conventional metals that may fail after repeated stress cycles, nitinol exhibits exceptional resilience due to its unique microstructure and phase transformation characteristics. This makes it an ideal candidate for applications where cyclic loading occurs frequently.

The superelasticity inherent in nitinol contributes significantly to its fatigue resistance, allowing it to absorb energy during deformation without permanent damage. This quality ensures longevity and reliability in critical applications such as orthopedic implants or dental devices where failure could have severe consequences. Therefore, understanding how heat treatment influences these mechanical properties further enhances the performance of this extraordinary nickel titanium alloy.

Comparison with Other Materials

When comparing nitinol with other materials, the differences become strikingly clear regarding mechanical properties like tensile strength and fatigue resistance. Traditional metals such as stainless steel may offer good strength but often lack the same level of flexibility that nitinol provides through its unique composition as a nickel titanium alloy. Moreover, while many materials succumb to fatigue over time under constant stress conditions, nitinol's superior performance makes it a game-changer in demanding environments.

In medical applications specifically, the advantages are even more pronounced; devices made from this innovative alloy often outperform their stainless steel counterparts due to reduced risk of fracture or failure during use. Additionally, the lightweight nature of this material enhances patient comfort without compromising structural integrity—an essential factor when considering what is nitinol in practical terms. As advancements continue in heat treatment processes aimed at optimizing these mechanical properties further, we can expect even more groundbreaking uses for this fascinating material.

Nitinol Medical Applications

Nitinol has emerged as a revolutionary material in the medical field, primarily due to its unique properties derived from its composition of nickel and titanium. This nickel material exhibits remarkable capabilities that enhance the performance of medical devices, making them more effective and reliable. With its exceptional nitinol properties, this alloy is transforming how we approach healthcare solutions.

Role in Medical Devices

Medical devices are at the forefront of technological advancements, and nitinol plays a critical role in this evolution. The unique nitinol material properties, including shape memory effect and superelasticity, allow for innovative designs that adapt to various physiological conditions. As a result, many devices can maintain their functionality while providing enhanced patient comfort and safety.

For instance, tools used in minimally invasive surgeries benefit significantly from nitinol's flexibility and strength. This nickel titanium alloy can be engineered to create instruments that navigate complex anatomical structures with ease. By utilizing nitinol's mechanical properties effectively, manufacturers are able to develop devices that not only perform better but also reduce recovery times for patients.

Nitinol in Stents and Other Implants

One of the most notable applications of nitinol is in stents and other implants designed for vascular procedures. The combination of nitinol's shape memory effect with its ability to expand upon heating makes it an ideal candidate for stent technology. When deployed within blood vessels, these stents can conform precisely to the vessel walls while providing necessary support.

Nitinol's superelasticity allows these implants to withstand significant deformation without permanent damage, ensuring they remain functional over time. Additionally, the biocompatibility of this nickel titanium alloy minimizes adverse reactions within the body, which is crucial for long-term implantation success. As a result, patients benefit from reduced complications associated with traditional materials used in such applications.

Advantages in Surgical Procedures

The advantages offered by using nitinol extend beyond just device design; they also impact surgical procedures themselves significantly. Surgeons appreciate how instruments made from this remarkable material can reduce trauma during operations thanks to their lightweight yet durable nature. Moreover, because of their flexibility and adaptability—characteristics stemming from their unique mechanical properties—nitinol-based tools allow for greater precision during delicate maneuvers.

Furthermore, due to the heat treatment processes applied to optimize these materials for specific applications, surgeons can rely on consistent performance under varying conditions within the human body. This reliability translates into shorter operation times and improved overall outcomes for patients undergoing surgical interventions involving nitinol devices or implants. Ultimately, as research continues into what is nitinol and its potential uses within medicine expand further still—the future looks bright for both healthcare providers and patients alike.

Conclusion

In wrapping up our exploration of nitinol, it’s clear that this remarkable nickel titanium alloy holds immense potential across various fields. From medical devices to aerospace applications, the versatility of nitinol properties continues to inspire innovation. As we look to the future, understanding what is nitinol and its capabilities will be crucial for researchers and engineers alike.

The Future of Nitinol Innovations

The future of nitinol innovations is bright, with ongoing research aimed at unlocking even more of its unique properties. With advancements in nitinol heat treatment processes, we are likely to see improved performance characteristics tailored for specific applications. As industries demand more efficient and effective materials, the development of new nitinol formulations could lead to breakthroughs in technology that we can only imagine today.

Nitinol's Role in Space Exploration

Nitinol's role in space exploration is particularly exciting due to its lightweight nature and exceptional mechanical properties. The ability of this nickel material to withstand extreme temperatures and pressures makes it an ideal candidate for spacecraft components and robotic systems designed for other planets. As missions become more ambitious, incorporating nitinol nickel titanium elements could enhance the adaptability and resilience of equipment used beyond Earth’s atmosphere.

Final Thoughts on Nitinol Benefits

In conclusion, the benefits of nitinol are numerous and varied, making it a standout material in both medical and industrial sectors. Its unique combination of shape memory effect and superelasticity provides solutions that traditional materials simply cannot match. Understanding what is nitinol not only highlights its current applications but also points toward a future filled with possibilities as we continue to explore its full potential.