Introduction

In the realm of modern materials, few have made waves quite like the nitinol alloy. This remarkable combination of nickel and titanium, known as a shape memory alloy, possesses unique properties that set it apart from traditional nickel materials. With its ability to return to a predetermined shape when heated, nitinol alloys are revolutionizing various industries, particularly in medicine.

What is Nitinol Alloy?

Nitinol alloy is an innovative metal primarily composed of nickel and titanium, celebrated for its extraordinary characteristics. Unlike standard nickel metal, this unique alloy exhibits both shape memory and superelasticity—making it an ideal candidate for applications requiring flexibility and resilience. When subjected to specific temperatures, nitinol can remember its original form, which opens up exciting possibilities in medical devices and surgical tools.

The Rise of Nitinol in Medicine

The rise of nitinol in medicine has been nothing short of phenomenal over the past few decades. Surgeons now rely on nitinol alloys for a variety of applications ranging from stents to orthopedic implants due to their biocompatibility and mechanical performance. As healthcare continues to evolve toward minimally invasive procedures, the demand for innovative materials like superelastic nitinol is expected to soar.

Why Should You Care About Nitinol?

You might be wondering why you should care about this fascinating material called nitinol alloy. Well, if you've ever had a medical procedure involving stents or implants, chances are you've encountered it firsthand! Understanding the properties and benefits of nitinol alloys not only enhances your appreciation for modern medicine but also highlights how advancements in material science can lead to better patient outcomes and improved quality of life.

Nitinol Alloy: A Game Changer in Surgery

The emergence of nitinol alloy has transformed the landscape of surgical procedures, particularly through its unique properties that make it a valuable asset in modern healthcare. Surgeons now have access to tools and implants that not only enhance efficiency but also improve patient outcomes significantly. This section explores how nitinol is reshaping surgery, focusing on minimally invasive techniques, recovery times, and its vital role in stents.

Minimally Invasive Procedures

One of the most exciting applications of nitinol alloy is its role in minimally invasive procedures. Traditionally, surgeries often required large incisions, leading to longer recovery times and increased risk of complications; however, the flexibility and adaptability of nitinol nickel titanium allow for smaller instruments that can navigate complex anatomical structures with ease. The shape memory alloy properties enable devices to return to a predetermined shape after being deformed, making them ideal for intricate surgical maneuvers without causing significant trauma to surrounding tissues.

Nitinol’s superelastic characteristics further enhance its usability in these procedures by allowing instruments to bend and flex during surgery while maintaining their effectiveness. This means surgeons can perform delicate operations with greater precision and less discomfort for patients. As a result, the use of nitinol alloys is rapidly becoming a standard practice in various surgical fields.

Enhanced Recovery Times

Enhanced recovery times are another significant advantage associated with the use of nitinol alloys in surgical settings. By utilizing minimally invasive techniques made possible by these innovative materials, patients can experience quicker healing processes compared to traditional surgeries involving nickel metal components. The reduced trauma caused by smaller incisions leads not only to less postoperative pain but also shorter hospital stays.

Studies have shown that patients undergoing procedures with nitinol-based devices often report improved mobility shortly after surgery. This swift return to normal activities is crucial for overall patient satisfaction and well-being, making it clear why many healthcare providers are increasingly adopting nitinol alloys as their material of choice during surgeries.

The Role of Nitinol in Stents

Nitinol's unique properties make it an excellent candidate for stent design—devices critical for treating vascular conditions like coronary artery disease. The combination of shape memory alloy functionality and superelasticity allows stents made from nitinol nickel titanium to expand effectively once placed within blood vessels while maintaining their structural integrity over time. These characteristics enable them to adapt seamlessly within varying vessel diameters without compromising blood flow or causing injury.

Moreover, the biocompatibility associated with nitinol alloys ensures minimal risk of adverse reactions within the body compared to traditional nickel materials used previously in stent manufacturing. As a result, many patients benefit from improved long-term outcomes when treated with stents crafted from this remarkable material—demonstrating yet another example of how nitinol is revolutionizing modern medicine.

The Unique Properties of Nitinol

Nitinol alloy is not just another metal; it’s a marvel of modern materials science. This unique combination of nickel and titanium, known as nitinol, exhibits extraordinary properties that make it a game changer in various applications, particularly in the medical field. Understanding these properties—shape memory and superelasticity—can help us appreciate why nitinol alloys are revolutionizing surgery and beyond.

Shape Memory and What It Means

One of the most fascinating aspects of nitinol alloys is their ability to remember a predetermined shape. When heated above a certain temperature, nitinol transforms into its original form after being deformed, showcasing what we call shape memory. This property allows for innovative designs in medical devices, such as stents that expand automatically at body temperature, offering significant advantages over traditional nickel materials that lack this capability.

This shape memory effect is not just a neat party trick; it has real-world applications that enhance patient care. For instance, when deployed within the human body, a nitinol stent can expand to fit the artery's dimensions precisely without requiring invasive procedures to adjust its shape manually. The implications for minimally invasive surgeries are profound—less trauma means quicker recovery times for patients.

Superelastic Nitinol and Its Applications

In addition to its shape memory capabilities, superelastic nitinol presents another layer of utility that sets it apart from conventional nickel metal components. Superelasticity allows nitinol to undergo significant deformation under stress without permanent changes to its structure—a feature not commonly found in traditional nickel materials. This means devices made from superelastic nitinol can absorb shocks and flex under pressure while returning to their original configurations.

The applications of superelastic nitinol are vast and varied; they range from orthodontic wires that flex comfortably around teeth to guidewires used in complex surgeries that navigate through challenging anatomical pathways. This flexibility reduces the risk of complications during procedures while improving overall outcomes for patients who benefit from these advanced devices. As such, superelastic nitinol is becoming an essential material in many high-performance medical tools.

Comparing Nitinol with Traditional Nickel Materials

When comparing nitinol alloys with traditional nickel materials, the differences become strikingly clear. While nickel metal has been a reliable choice for various applications due to its strength and corrosion resistance, it simply cannot match the unique properties offered by nitinol alloys like shape memory and superelasticity. These differences translate directly into better performance metrics in medical implants and devices.

For instance, traditional nickel materials often require more extensive surgical interventions due to their rigidity compared to the adaptable nature of nitinol alloys—a factor that can significantly impact patient recovery times and comfort levels post-surgery. Moreover, when considering biocompatibility—the ability of a material to interact safely with biological systems—nitinol stands out as being far superior due to its less reactive nature compared with standard nickel compounds known for causing allergic reactions or other complications.

In summary, the unique properties inherent in nitinol alloys make them indispensable in modern medicine today—not merely as alternatives but as superior options compared to traditional nickel materials.

GEE SMA: Leaders in Nitinol Innovation

When it comes to the cutting-edge world of nitinol alloys, GEE SMA stands out as a beacon of innovation. This company has dedicated itself to producing high-quality nitinol shapes and components that are revolutionizing medical devices. By harnessing the unique properties of nitinol, such as its shape memory and superelasticity, GEE SMA is pushing the boundaries of what's possible in healthcare.

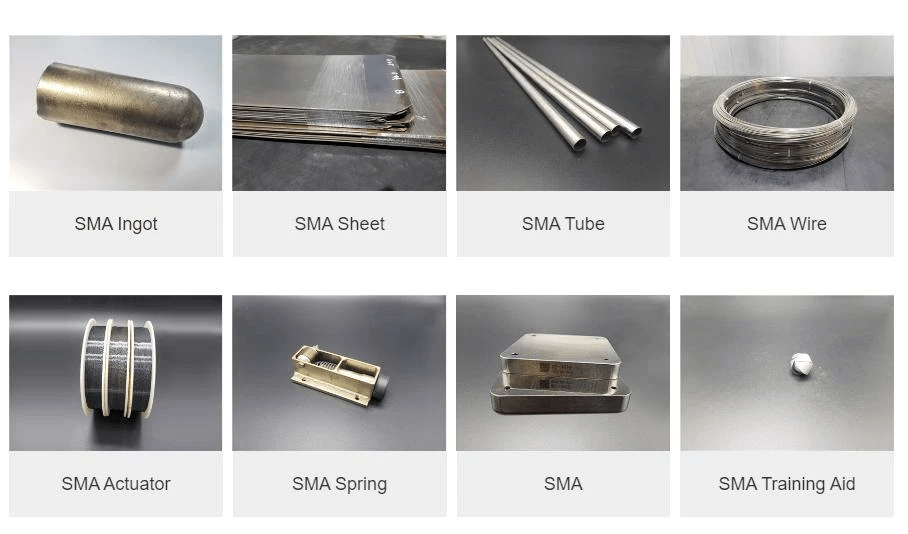

High-Quality Nitinol Shapes and Components

GEE SMA specializes in crafting high-quality nitinol shapes and components that cater to a variety of medical applications. Their expertise in nitinol nickel titanium allows them to create products that exhibit exceptional strength and flexibility, making them ideal for surgical instruments and implants. Unlike traditional nickel materials, which often lack the same level of performance under stress, these nitinol alloys provide surgeons with reliable tools designed for precision.

The production process at GEE SMA ensures that each component meets stringent quality standards, resulting in durable products that stand the test of time. The unique characteristics of superelastic nitinol mean these components can return to their original shape after deformation, providing both safety and reliability during procedures. With an unwavering commitment to excellence, GEE SMA has positioned itself as a leader in delivering top-notch nitinol solutions.

Advanced Technologies for Medical Devices

In today's fast-paced medical landscape, advanced technologies are crucial for developing effective devices—and GEE SMA is at the forefront of this evolution. By leveraging state-of-the-art manufacturing techniques, they produce innovative devices that utilize the remarkable properties of nitinol alloys effectively. This includes everything from stents to orthopedic implants designed with patient outcomes in mind.

The integration of advanced technologies enables GEE SMA to enhance product performance while ensuring biocompatibility—a critical factor when dealing with human tissue. Moreover, their focus on research and development allows them to stay ahead by continually improving existing designs based on feedback from healthcare professionals. With a strong emphasis on innovation, GEE SMA exemplifies how modern technology can elevate the capabilities of medical devices made from superelastic nitinol.

Custom Solutions for Unique Needs

Understanding that no two patients are alike is what sets GEE SMA apart in the realm of custom solutions for unique needs within healthcare settings. They offer tailored designs using nitinol alloy that address specific challenges faced by surgeons and patients alike—whether it’s a specialized implant or a uniquely shaped surgical tool requiring precise functionality. By collaborating closely with clients, they ensure each solution is crafted with meticulous attention to detail.

Their ability to customize products not only enhances surgical outcomes but also promotes quicker recovery times thanks to improved device performance facilitated by superior materials like nitinol nickel titanium. As healthcare continues evolving toward personalized medicine, companies like GEE SMA are essential players driving this change through innovative applications of shape memory alloy technology. Ultimately, their commitment to addressing unique needs reinforces their leadership role within the industry while showcasing the versatility inherent in nitinol properties.

Nitinol in Orthopedic Applications

Nitinol alloy has emerged as a revolutionary material in orthopedic applications, setting new standards for implants and fixtures. The unique properties of nitinol, particularly its shape memory and superelastic characteristics, provide orthopedic surgeons with innovative solutions that enhance patient care. As the demand for advanced medical devices grows, the role of nitinol alloys continues to expand within the orthopedic field.

Next-Gen Implants and Fixtures

Next-generation implants made from nitinol nickel titanium are transforming orthopedic surgery by offering unparalleled flexibility and strength. Unlike traditional nickel materials, which can be rigid and less adaptable to the body's movements, nitinol's superelastic properties allow it to absorb stress while maintaining structural integrity. This adaptability makes nitinol alloys ideal for various fixtures, such as screws and plates used in bone repair.

The innovative design of these implants not only helps in achieving better alignment during surgery but also contributes to faster healing times post-operation. Surgeons appreciate how these next-gen fixtures can accommodate natural movement without compromising stability or durability. As a result, patients benefit from improved functionality and a more seamless recovery process.

Biocompatibility of Nitinol Alloys

One of the standout features of nitinol alloys is their remarkable biocompatibility, making them suitable for long-term implantation in the human body. Unlike traditional nickel metal options that may provoke allergic reactions or inflammation, nitinol’s unique composition minimizes adverse responses from surrounding tissues. This property is particularly advantageous when considering implants that will remain in place for extended periods.

Research has shown that patients with nitinol-based devices experience fewer complications compared to those with conventional materials. This biocompatibility enables surgeons to focus on optimizing surgical outcomes without worrying about potential rejection or side effects associated with other nickel materials. Consequently, the use of nitinol alloys is becoming increasingly prevalent across various orthopedic applications.

Enhancing Patient Outcomes

The incorporation of nitinol into orthopedic procedures has led to significant enhancements in patient outcomes across the board. With its shape memory alloy characteristics, implants can adapt to physiological changes during healing processes, providing optimal support where it's needed most. Patients often report reduced pain levels and improved mobility due to the combination of flexibility and strength offered by superelastic nitinol.

Moreover, shorter recovery times associated with nitinol-based devices mean patients can return to their daily activities much sooner than before—an essential factor for both physical health and overall well-being post-surgery. As healthcare providers continue exploring new ways to integrate this innovative material into treatment plans, it becomes clear that the future is bright for both practitioners and patients alike when it comes to using nitinol alloys in orthopedics.

Future Trends for Nitinol in Healthcare

As we look to the horizon of healthcare innovation, nitinol alloy stands out as a key player, poised to revolutionize various medical applications. The unique properties of nitinol alloys, particularly in shape memory and superelasticity, are driving new developments that promise enhanced patient outcomes and more effective treatments. Emerging technologies harnessing these remarkable characteristics are set to redefine surgical techniques and medical devices.

Emerging Technologies in Nitinol Applications

The future is bright for nitinol applications, especially with advancements in 3D printing technology that enable the creation of intricate shapes using nitinol nickel titanium. This capability allows for tailored medical devices that can fit the unique anatomical needs of patients, promoting better integration and functionality. Additionally, researchers are exploring hybrid materials combining nitinol properties with other biocompatible substances to enhance performance even further.

Another promising area is the development of smart implants that utilize the shape memory alloy capabilities of nitinol. These implants can adapt their form in response to body temperature or other stimuli, providing dynamic support where it’s needed most. As these technologies evolve, they will likely lead to breakthroughs in minimally invasive procedures that minimize recovery times and improve overall patient experiences.

Sustainability and Nitinol Production

With growing concerns about environmental impact, sustainability has become a significant focus within the production of nitinol alloys. Manufacturers are increasingly adopting eco-friendly practices by optimizing processes to reduce waste associated with traditional nickel metal extraction methods. By utilizing recycled nickel materials alongside innovative production techniques, companies can produce high-quality superelastic nitinol while minimizing their carbon footprint.

Moreover, advancements in recycling technologies specifically for nitinol alloys are paving the way for a circular economy within healthcare manufacturing. This not only conserves resources but also addresses safety concerns related to nickel exposure by ensuring that recycled materials meet stringent health standards. As sustainability becomes a priority across industries, embracing efficient production methods will be crucial for maintaining the integrity and reputation of nitinol products.

Potential in Robotics and Beyond

The versatility of nitinol extends beyond traditional medical applications; its potential role in robotics is particularly exciting. Superelastic nitinol components could be integrated into robotic systems used for surgery or rehabilitation therapy due to their ability to withstand significant deformation without permanent change. This characteristic allows robots equipped with these materials to perform delicate movements more effectively than those relying solely on conventional metals.

Furthermore, researchers are investigating how shape memory alloys can facilitate innovations like soft robotics—machines designed to mimic biological structures while being flexible enough for intricate tasks or interactions with humans safely. The adaptability offered by nitinol properties makes it an ideal candidate for creating responsive systems capable of adjusting their behavior based on real-time feedback from their environment or users.

In conclusion, as we venture into an era where technology meets biology seamlessly through innovations like superelastic nitinol and sustainable production practices, healthcare stands ready for transformation driven by this remarkable alloy's potential.

Conclusion

In wrapping up our exploration of the nitinol alloy, it’s clear that this remarkable material has made significant strides in the medical field. From its unique properties as a shape memory alloy to its versatility in various applications, nitinol has revolutionized surgery and patient care. The shift from traditional nickel materials to advanced nitinol alloys signifies a leap towards more efficient and effective medical solutions.

Recap of Nitinol’s Medical Impact

The impact of nitinol in medicine cannot be overstated; its shape memory properties allow for innovative surgical techniques that were previously unimaginable. Unlike conventional nickel metal, nitinol provides surgeons with tools that adapt to the body’s anatomy, enhancing precision during procedures. This adaptability not only improves surgical outcomes but also contributes to shorter recovery times for patients.

Success Stories in Nitinol Applications

Numerous success stories highlight the effectiveness of nitinol alloys in real-world medical scenarios. For instance, superelastic nitinol has been instrumental in developing stents that can navigate complex vascular pathways without compromising patient safety. Additionally, orthopedic implants made from nitinol have shown promising results in improving healing rates and overall patient satisfaction—truly a testament to the power of this innovative material.

The Future of Nitinol Alloy in Medicine

Looking ahead, the future of nitinol alloy is brimming with potential as emerging technologies continue to harness its unique properties. With ongoing research into sustainability and improved production methods for these nickel titanium alloys, we can expect even broader applications across various medical fields. As robotics and other cutting-edge technologies evolve, superelastic nitinol could play an integral role in next-generation healthcare solutions.