Introduction

In the realm of advanced materials, few substances capture the imagination quite like nitinol shape memory alloys. These remarkable materials not only exhibit the ability to return to their original form after deformation but also possess a unique set of properties that make them invaluable in various applications. As we delve into the world of nitinol, we will uncover its extraordinary characteristics, particularly superelastic nitinol, and explore how these properties are revolutionizing modern technology.

Understanding Shape Memory Alloys

Shape memory alloys (SMAs) are metallic materials that can remember their original shape when heated above a certain temperature. This fascinating phenomenon is primarily due to phase transformations within the alloy's structure, allowing it to revert back to its predetermined form after being deformed. Nitinol, an alloy of nickel and titanium, is one of the most well-known SMAs and showcases some of the most impressive nitinol properties that have captured researchers' attention.

The Marvel of Nitinol Properties

What sets nitinol apart from traditional metals is its dual capability: it can exhibit both shape memory and superelasticity under different conditions. Superelastic nitinol allows for significant deformation without permanent change when subjected to stress at certain temperatures, making it incredibly versatile in practical applications. These unique nitinol properties not only enhance performance but also open doors for innovative uses across various industries.

Applications of Nitinol in Modern Technology

The applications for nitinol material are as diverse as they are groundbreaking, especially in fields such as medicine and robotics. In particular, nitinol wire medical devices have transformed surgical procedures with their flexibility and biocompatibility, leading to safer and more effective interventions. Beyond healthcare, industries like aerospace are beginning to harness the potential of this remarkable alloy for next-generation technologies that promise greater efficiency and resilience.

What Are Shape Memory Alloys?

Shape Memory Alloys (SMAs) are a fascinating class of materials that can return to a predetermined shape when subjected to specific thermal conditions. Among these alloys, Nitinol stands out due to its unique ability to remember its original form, providing remarkable versatility in various applications. With characteristics that defy traditional metal properties, Nitinol shape memory continues to capture the imagination of engineers and scientists alike.

Definition and Characteristics

At its core, a shape memory alloy is a metallic material that exhibits two distinct phases: martensite and austenite. The defining characteristic of Nitinol shape memory is its ability to undergo phase transformation in response to temperature changes, allowing it to revert back to its original shape after being deformed. This unique behavior is complemented by other notable nitinol properties, such as superelasticity—a phenomenon where the material can undergo significant deformation without permanent damage.

In practical terms, this means that Nitinol can be stretched or bent into new shapes while remaining capable of returning to its initial configuration when heated or cooled appropriately. The dual nature of nitinol materials not only makes them incredibly useful but also adds an element of intrigue for researchers exploring their potential across various fields.

How Nitinol Shape Memory Works

The magic behind how Nitinol shape memory works lies in its phase transformation capabilities. When heated above a certain temperature known as the transformation temperature, the alloy transitions from the martensitic phase (which is more flexible) to the austenitic phase (which has fixed dimensions). This transition allows for an impressive range of motion and adaptability in applications ranging from medical devices like stents made with nitinol wire medical technology to intricate robotic components.

When cooled below this critical temperature, Nitinol reverts back into its martensitic state—allowing it to be reshaped under stress without any lasting deformation. This cycle between phases enables superelastic nitinol functionality; it can absorb significant energy during deformation and release it upon returning to its original form, making it ideal for dynamic applications where flexibility is key.

Importance of Phase Transformation

Phase transformation is not just an interesting scientific concept; it's at the heart of what makes Nitinol so valuable across multiple industries. Understanding how this process works allows engineers and designers to harness nitinol properties effectively in their innovations—from creating self-expanding stents that adapt precisely within blood vessels, ensuring optimal performance and patient safety, to developing advanced robotics capable of complex movements.

Moreover, the ability for nitinol materials to undergo reversible transformations means they have potential environmental applications as well—think energy-efficient systems that adjust based on external temperatures or forces! As we continue exploring these possibilities, it's clear that mastering phase transformation will unlock even more incredible uses for this remarkable alloy.

The Unique Properties of Nitinol

Nitinol, a remarkable alloy of nickel and titanium, is celebrated for its unique properties that set it apart from conventional materials. Among these properties are superelasticity and shape memory capabilities, which allow nitinol to return to predetermined shapes when exposed to specific temperatures. Understanding these characteristics is crucial for harnessing the full potential of nitinol in various applications, especially in the medical field.

Superelastic Nitinol Explained

Superelastic nitinol is a fascinating phenomenon that occurs when the material undergoes phase transformation under stress at certain temperatures. Unlike traditional metals that deform permanently when stretched, superelastic nitinol can endure substantial deformation and then revert to its original shape once the stress is removed. This property makes nitinol wire medical applications particularly advantageous, as devices made from superelastic nitinol can withstand mechanical forces while maintaining their integrity.

The ability to exhibit superelasticity means that nitinol can absorb energy without permanent deformation, making it ideal for use in dynamic environments such as the human body. For instance, stents crafted from superelastic nitinol can expand and contract seamlessly within blood vessels without compromising their structural integrity or performance over time. This innovative material ensures reliability and efficiency in critical medical devices where precision matters most.

Thermal and Mechanical Properties

Nitinol's thermal properties are just as impressive as its mechanical characteristics. The alloy exhibits a distinct transition temperature range where it changes from a martensitic phase (soft and easily deformed) to an austenitic phase (stiff and strong). This transition allows for unique functionalities; by controlling temperature variations, engineers can manipulate how nitinol shape memory operates in real-world applications.

In terms of mechanical properties, nitinol boasts high fatigue resistance compared to traditional metals like stainless steel or aluminum. Its ability to endure repeated stress cycles without failure makes it an excellent choice for components subjected to continuous movement or load-bearing situations—such as guidewires used in minimally invasive surgeries. These exceptional thermal and mechanical attributes ensure that products made from this versatile alloy perform reliably under diverse conditions.

Comparison with Traditional Metals

When comparing nitinol properties with those of traditional metals like steel or titanium alone, it's evident why this alloy has gained popularity across multiple industries. While conventional metals may excel in strength or durability individually, they often lack the unique combination of flexibility and shape memory exhibited by nitinol materials. For example, while stainless steel stents may provide strength, they do not have the same self-expanding capabilities inherent in superelastic nitinol stents.

Moreover, traditional metals typically require additional components or mechanisms for expansion or contraction during surgical procedures—adding complexity and potential points of failure—whereas devices made from nitinol wire medical technologies can achieve these functions naturally due to their inherent properties. This simplicity not only enhances performance but also reduces manufacturing costs over time—a win-win situation for both manufacturers and patients alike!

Nitinol in the Medical Field

Nitinol has carved a niche for itself in the medical field, showcasing its unique properties that make it an invaluable resource for various applications. With its remarkable ability to return to a predetermined shape when heated, nitinol shape memory is revolutionizing surgical techniques and medical devices. From stents to guidewires, the versatility of this nitinol material is proving essential in enhancing patient outcomes.

Nitinol Wire Medical Applications

The use of nitinol wire medical applications has become increasingly popular due to its exceptional characteristics, especially superelastic nitinol. This unique property allows the wire to undergo significant deformation without permanent damage, making it ideal for intricate procedures where flexibility and resilience are crucial. Surgeons appreciate how nitinol wires can navigate complex anatomical structures with ease, providing greater precision during interventions.

Nitinol wire's shape memory effect is particularly beneficial in creating devices that adapt to their environment within the body. For instance, when used in catheters or other minimally invasive tools, these wires can be manipulated at room temperature and then activated by body heat to assume their functional shapes. This adaptability not only enhances the performance of medical instruments but also reduces patient recovery time.

Furthermore, the biocompatibility of nitinol ensures that it can be safely used within the human body without adverse reactions. As a result, many hospitals have adopted nitinol wire technologies as standard practice for various procedures ranging from orthopedic repairs to cardiovascular interventions. The ongoing integration of these innovative materials signifies a bright future for medical applications involving nitinol.

Innovations in Stents and Guidewires

Innovations in stents and guidewires have taken a giant leap forward thanks to the incorporation of nitinol properties into their designs. Nitinol's superelastic nature allows stents to expand upon deployment while maintaining their structural integrity under physiological conditions. This means fewer complications and improved blood flow restoration for patients suffering from vascular diseases.

Moreover, guidewires made from nitinol are not only flexible but also possess excellent torqueability—allowing them to navigate through tight bends with ease while minimizing trauma to surrounding tissues. These innovations enable healthcare professionals to perform complex procedures more effectively than ever before, improving overall procedural success rates significantly.

As technology advances further, we can expect even more sophisticated designs utilizing nitinol material that will enhance both safety and efficacy in interventional procedures. The potential for incorporating sensors or drug-eluting capabilities into future stent designs could lead us toward even better solutions for chronic conditions like heart disease or peripheral artery disease.

Benefits of Nitinol in Medical Devices

The benefits of using nitinol in medical devices extend far beyond just its mechanical properties; they include enhanced patient safety and comfort as well as improved clinical outcomes overall. One major advantage is its ability to withstand significant stress while retaining functionality—making it ideal for long-term implants such as orthopedic screws or spinal fusion devices made from this remarkable alloy.

Additionally, because of its unique thermal responsiveness associated with the shape memory effect, devices crafted from this material can adjust dynamically according to changes within bodily conditions (like temperature fluctuations). This adaptability enhances device performance over time compared with traditional materials that may not offer similar benefits.

Finally, using superelastic nitinol leads not only toward better-designed products but also fosters innovation across various fields including cardiology and orthopedics—ultimately benefiting patients through less invasive surgeries with quicker recovery times! As research continues into new applications for this versatile alloy’s capabilities—such as targeted drug delivery systems—the future looks promising indeed!

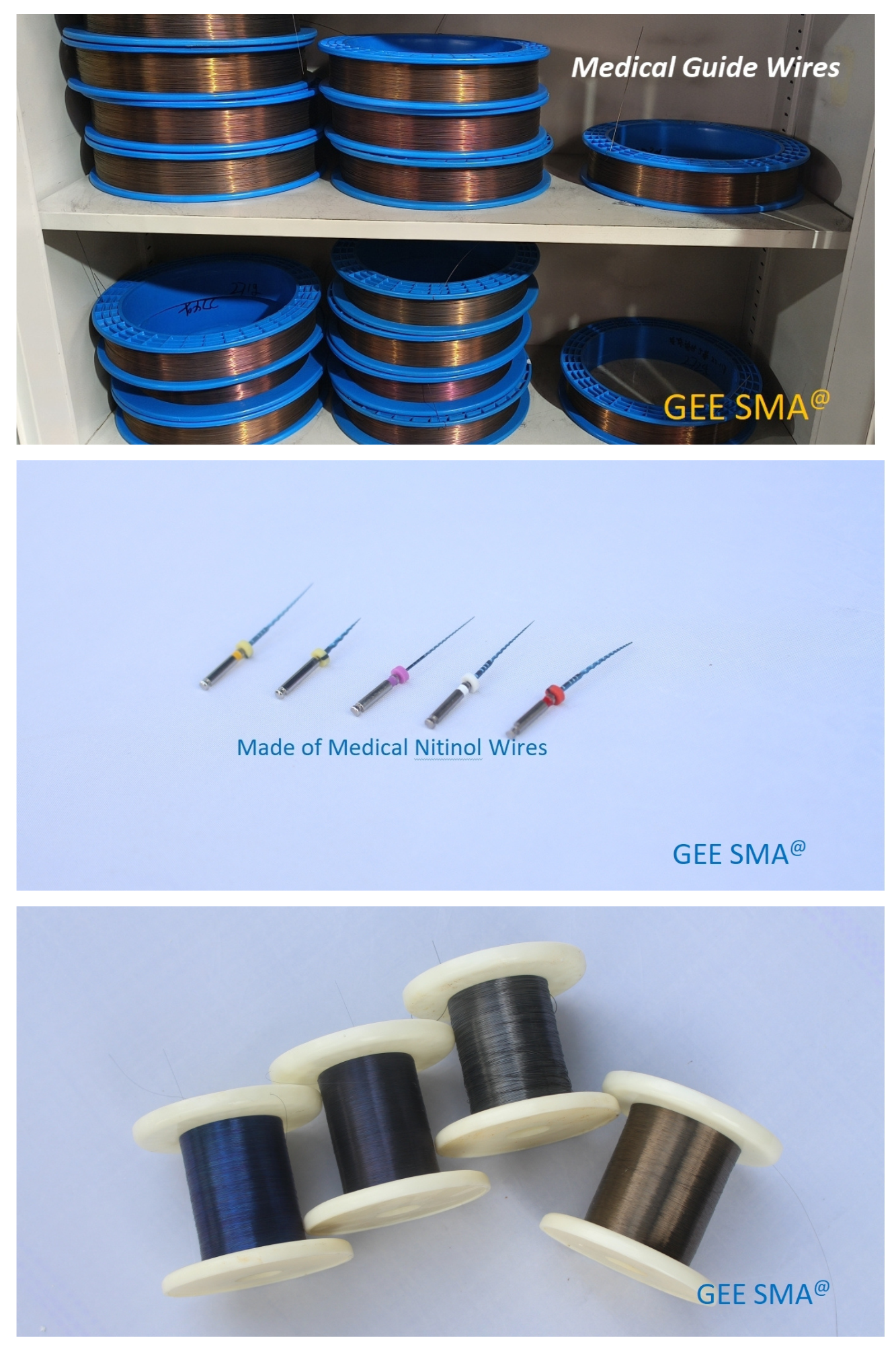

GEE SMA: A Leader in Nitinol Production

When it comes to the realm of nitinol production, GEE SMA stands out as a formidable leader. With a steadfast commitment to quality and innovation, the company has made significant strides in harnessing the unique properties of nitinol shape memory alloys. Their dedication not only enhances product performance but also pushes the boundaries of what is possible with this remarkable material.

Commitment to Quality and Innovation

At GEE SMA, quality is not just a buzzword; it's a core principle that drives every aspect of their operations. The team employs rigorous testing and quality assurance protocols to ensure that every batch of nitinol wire medical applications meets the highest standards. This commitment to excellence allows them to consistently deliver superelastic nitinol products that exceed customer expectations.

Innovation is equally crucial at GEE SMA, where research and development are at the forefront of their mission. By investing in cutting-edge technology and exploring new applications for nitinol properties, they remain ahead of industry trends. This proactive approach ensures that GEE SMA continues to lead in providing advanced solutions that leverage the unique characteristics of this extraordinary material.

Role in Space Missions

GEE SMA's contributions extend beyond terrestrial applications; they play an essential role in space missions as well. The superelastic nitinol developed by GEE SMA has been utilized in various aerospace projects, showcasing its ability to withstand extreme conditions while maintaining functionality. The unique properties of nitinol shape memory make it an ideal candidate for components that require resilience under pressure.

In addition to its mechanical advantages, using nitinol material in space missions can lead to weight savings—an invaluable asset when launching payloads into orbit. The lightweight nature combined with high strength makes this alloy a favorite among engineers looking for innovative solutions for aerospace challenges. As space exploration continues to evolve, GEE SMA remains committed to providing reliable materials that help propel humanity further into the cosmos.

Customer-Centric Approach

At GEE SMA, understanding customer needs is paramount; they pride themselves on a customer-centric approach that fosters collaboration and responsiveness. By actively engaging with clients from diverse industries—including medical devices and aerospace—they can tailor their offerings based on specific requirements involving nitinol wire medical applications or other uses of superelastic nitinol products. This level of customization ensures clients receive precisely what they need without compromising on quality or performance.

Moreover, GEE SMA's dedication doesn't end with product delivery; they offer ongoing support and consultation services throughout the lifecycle of their products. Whether customers need technical assistance or insights into optimizing their use of nitinol properties, GEE SMA stands ready to help them succeed with innovative solutions tailored just for them. This unwavering focus on client satisfaction solidifies their reputation as a trusted partner across multiple sectors.

Future of Nitinol Shape Memory Alloys

The future of nitinol shape memory alloys is bright, with innovations on the horizon that promise to revolutionize various industries. As research continues to unlock the full potential of nitinol properties, we can expect advancements that enhance its applications and performance. From medical devices to aerospace technology, the versatility of this remarkable material is paving the way for exciting developments.

Emerging Technologies and Trends

Emerging technologies are rapidly reshaping our understanding and utilization of nitinol materials. One significant trend is the integration of smart materials into everyday products, where superelastic nitinol plays a crucial role in creating adaptive structures that respond to environmental changes. The development of advanced manufacturing techniques, such as 3D printing with nitinol wire medical applications, allows for customized designs that enhance functionality and reduce production costs.

Moreover, researchers are exploring nanostructured nitinol alloys that could lead to enhanced shape memory effects and improved mechanical properties. These innovations are not just theoretical; they have real-world implications in fields ranging from biomedicine to consumer electronics. As these trends continue to evolve, we can anticipate a surge in applications that leverage the unique characteristics of nitinol shape memory alloys.

Nitinol in Robotics and Aerospace

Nitinol's unique properties make it an ideal candidate for robotics and aerospace applications where lightweight materials with high strength are essential. In robotics, superelastic nitinol can be used for actuators that mimic human muscle movement or create flexible joints in robotic limbs without sacrificing durability or performance. This adaptability allows robots to operate more efficiently in dynamic environments while minimizing energy consumption.

In aerospace engineering, the ability of nitinol shape memory alloys to return to a predetermined shape under specific conditions opens up new possibilities for aircraft design and functionality. For instance, components made from nitinol could adjust their shapes during flight based on aerodynamic pressures or temperatures, enhancing fuel efficiency and safety measures significantly. With ongoing research into its application within these sectors, it's clear that nitinol will play a pivotal role in shaping the future of technology.

Potential Environmental Applications

As sustainability becomes increasingly vital across industries, the potential environmental applications of nitinol shape memory alloys are gaining attention. The energy-efficient properties inherent in superelastic nitinol allow it to be utilized in systems designed for renewable energy generation and storage solutions. For example, incorporating nitinol materials into solar panels could improve their efficiency by enabling them to adapt dynamically based on sunlight intensity.

Additionally, researchers are investigating how nitrogen-based alloys can contribute to waste reduction through innovative recycling methods or biodegradable products without sacrificing performance characteristics associated with traditional metals. By harnessing the unique attributes of this remarkable material, industries can move towards more sustainable practices while maintaining high standards in quality and functionality.

Conclusion

Nitinol, a remarkable shape memory alloy, has proven to be an incredibly versatile material in various fields, especially in medicine and technology. Its unique nitinol properties allow it to return to its original shape after deformation, making it invaluable for applications requiring reliability and precision. From stents that expand within arteries to innovative robotics, the adaptability of nitinol material is nothing short of astonishing.

The Versatility of Nitinol Material

The versatility of nitinol material stems from its dual ability to exhibit both shape memory and superelasticity. This means that not only can it revert to a predetermined shape when heated, but it can also withstand significant deformation without permanent change at room temperature. These characteristics make nitinol wire medical applications particularly advantageous as they enhance patient safety and device performance in critical situations.

In addition to medical uses, the versatility of nitinol extends into various industrial sectors where flexibility and strength are paramount. Its lightweight nature combined with high fatigue resistance allows for innovative designs in aerospace components and consumer products alike. As industries continue to explore new possibilities, the role of nitinol will undoubtedly expand even further.

Innovations Driving Nitinol's Future

Innovations surrounding nitinol shape memory alloys are rapidly evolving, driven by advancements in technology and materials science. Researchers are exploring new methods for enhancing the properties of superelastic nitinol through alloying techniques and manufacturing processes that yield even more resilient forms of this remarkable metal. As these innovations unfold, we can expect an increasing array of applications across sectors such as robotics, automotive engineering, and even environmental technologies.

Moreover, collaborations between academia and industry are fostering breakthroughs that could revolutionize how we utilize nitinol properties in everyday life. With ongoing research focused on optimizing performance characteristics while maintaining cost-effectiveness, the future looks bright for this extraordinary material. The potential for novel applications is limited only by our imagination—and perhaps a little bit of engineering prowess.

Why Nitinol is Here to Stay

Nitinol's unique combination of properties ensures its relevance well into the future; it's not just a passing trend but a foundational element shaping modern innovation. The growing demand for advanced medical devices highlights how essential nitinol wire medical applications have become in improving patient outcomes worldwide—this trend shows no signs of slowing down anytime soon! Additionally, as industries seek sustainable alternatives with superior performance capabilities, the advantages offered by nitinol will keep it firmly entrenched in technological advancements.

The ongoing exploration into environmental applications further cements why nitinol is here to stay; its adaptability makes it suitable for developing eco-friendly solutions that align with global sustainability goals. As we continue pushing boundaries with this incredible material—whether through enhanced manufacturing techniques or ingenious design concepts—the future promises exciting developments that will redefine what we thought possible with alloys like nitinol.