Introduction

In the ever-evolving world of engineering, few innovations capture the imagination quite like shape memory alloys (SMAs). These remarkable materials have the unique ability to return to a predetermined shape when heated, making them perfect candidates for applications that require precision and adaptability. Among their many uses, the shape memory alloy linear actuator stands out as a game-changer in various fields, combining efficiency with a compact design.

Understanding Shape Memory Alloys

Shape memory alloys are metallic materials that possess an extraordinary property: they can remember their original shapes after being deformed. This phenomenon occurs due to specific crystallographic changes that happen when these alloys are subjected to heat. In essence, when an SMA is heated above a certain temperature, it undergoes a transformation that restores its initial form, which is a fascinating aspect of material science.

The Magic of Linear Actuators

Linear actuators are devices that create motion in a straight line and are essential in countless applications across industries. The magic happens when you combine these actuators with shape memory alloys; you get an SMA linear actuator that offers unique advantages over traditional systems. With their ability to convert thermal energy into mechanical motion efficiently, SMA linear actuators can perform tasks with precision and reliability.

Applications of SMA Linear Actuators

The versatility of shape memory alloy linear actuators opens doors to numerous innovative applications across various sectors. From aerospace engineering where lightweight components are crucial to medical devices requiring precise movements for patient care, SMAs are paving the way for advancements we once considered science fiction. Additionally, in robotics and automation enhancements, these actuators provide solutions that were previously unattainable with conventional technologies.

What is a Shape Memory Alloy?

Shape Memory Alloys (SMAs) are fascinating materials that can remember their original shape after being deformed. When subjected to a specific temperature, these alloys revert to their pre-deformed shape, demonstrating remarkable properties that make them ideal for various applications, including the innovative design of a shape memory alloy linear actuator. Understanding SMAs is crucial for grasping how they function in practical devices and systems.

The Science Behind SMA

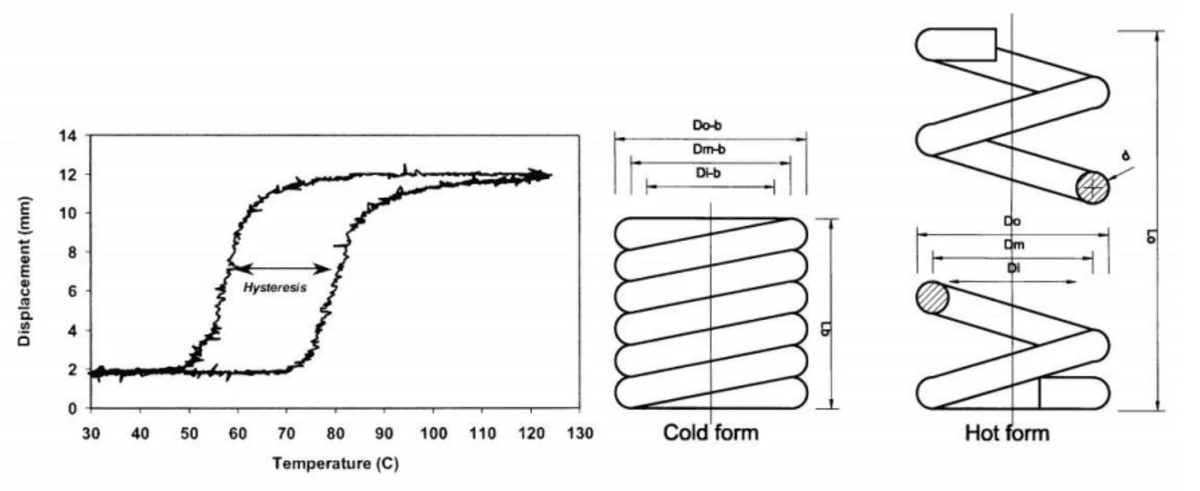

At the heart of Shape Memory Alloys is a unique phase transformation that occurs between two solid phases: martensite and austenite. When heated above a certain temperature, the SMA transitions from martensite (a low-temperature phase) to austenite (a high-temperature phase), resulting in significant changes in shape and mechanical properties. This transformation enables SMA linear actuators to produce motion without the need for complex mechanical systems, making them an efficient choice for various engineering challenges.

The science behind SMAs also involves thermodynamics and crystallography, which explain how these materials respond to temperature changes. By manipulating these properties through alloy composition and processing techniques, researchers have developed increasingly sophisticated SMAs with enhanced performance characteristics tailored for specific uses in linear actuators.

Common Types of Shape Memory Alloys

There are several types of Shape Memory Alloys commonly used in engineering applications today, each with distinct properties and advantages. The most prevalent SMAs include Nickel-Titanium (NiTi), Copper-Aluminum-Nickel (Cu-Al-Ni), and Copper-Zinc-Aluminum (Cu-Zn-Al). Among these, NiTi stands out due to its biocompatibility and excellent fatigue resistance, making it particularly suitable for medical devices as well as SMA linear actuators.

Each type of SMA has unique characteristics that can be leveraged based on application requirements—from temperature ranges to mechanical strength. For instance, while NiTi is often favored in aerospace applications due to its lightweight nature and reliability under extreme conditions, Cu-based alloys might be chosen for cost-effective solutions where performance can be slightly compromised.

Innovations in Material Science

The field of material science has witnessed significant innovations concerning Shape Memory Alloys over recent years. Advances in processing techniques have led to the development of new SMA variants with improved functionality—such as higher transformation temperatures or enhanced energy efficiency—making them even more appealing for use in linear actuators.

Researchers are also exploring ways to integrate smart technologies with SMAs by embedding sensors or control systems within the material itself, creating responsive systems capable of adapting their behavior based on environmental stimuli or user input. These innovations promise not only to enhance the capabilities of traditional linear actuators but also open up new avenues for automation across diverse industries.

How Does an SMA Linear Actuator Work?

When it comes to understanding how a shape memory alloy linear actuator operates, one must first appreciate the unique properties of shape memory alloys (SMAs). These materials can undergo phase transformations in response to temperature changes, allowing them to return to a predetermined shape after deformation. This remarkable ability is harnessed in SMA linear actuators, which convert thermal energy into mechanical motion with impressive efficiency.

Mechanism of Action

The mechanism of action for an SMA linear actuator is rooted in the principles of thermodynamics and material science. When electrical current is applied, the SMA heats up and transitions from its low-temperature phase (martensite) to its high-temperature phase (austenite), causing it to expand and create linear motion. Once the current is removed and the actuator cools down, it contracts back to its original form, returning to its initial position—this cycle can be repeated many times without significant wear.

This unique mechanism allows for precise control over movement, making SMA linear actuators ideal for applications where space and weight are at a premium. By leveraging this thermal-responsive behavior, engineers can design compact systems that deliver robust performance across various environments. The inherent simplicity of this design also means fewer moving parts compared to traditional actuators, leading to increased reliability.

Key Components of SMA Linear Actuators

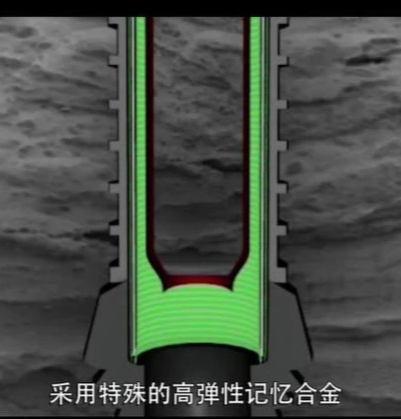

A typical shape memory alloy linear actuator consists of several key components that work together seamlessly. At its core lies the SMA wire or ribbon that performs the actual actuation; this material is critical as it dictates the performance characteristics such as response time and force output. Surrounding this are housing elements designed to protect the SMA from environmental factors while allowing for efficient heat dissipation during operation.

Other essential components include sensors for feedback control and electronic circuitry that regulates power supply based on demand. Together, these elements create a highly efficient system capable of producing significant force relative to its size—an advantage that traditional actuators often struggle with due to their bulkier construction. Ultimately, these components work harmoniously within an SMA linear actuator to deliver reliable motion in compact packages.

Comparison with Traditional Actuators

When comparing shape memory alloy linear actuators with traditional alternatives like electric or pneumatic cylinders, several distinct advantages emerge. Traditional actuators often rely on complex mechanical systems involving gears or pistons that add weight and increase failure points; in contrast, an SMA linear actuator offers a more streamlined approach with fewer moving parts. This simplicity not only enhances reliability but also contributes significantly to lower manufacturing costs over time.

Additionally, while electric actuators require bulky motors and pneumatic systems depend on compressed air sources—both demanding more space—SMA linear actuators excel in confined spaces thanks to their compact design and lightweight nature. Moreover, they are known for their ability to operate effectively under extreme conditions without sacrificing performance—a feat that many traditional options cannot claim easily due to their reliance on external power sources or specific environmental conditions.

In summary, when evaluating different actuation technologies, it's clear that shape memory alloy linear actuators present compelling benefits over conventional methods by offering efficiency without compromising on strength or reliability.

Advantages of Shape Memory Alloy Linear Actuators

Shape Memory Alloy (SMA) linear actuators are revolutionizing various industries with their unique advantages. These actuators utilize the remarkable properties of shape memory alloys to deliver exceptional performance in compact designs. Let’s dive into the key benefits that make SMA linear actuators stand out from traditional options.

Compact Design and Efficiency

One of the most striking features of shape memory alloy linear actuators is their compact design, which allows them to fit into tight spaces where traditional linear actuators may falter. This sleekness doesn’t come at the cost of efficiency; in fact, SMA linear actuators often outperform larger counterparts by delivering precise movements without bulky mechanisms. Their ability to convert thermal energy into mechanical work with minimal components enhances not only their efficiency but also reduces maintenance needs, making them a favorite in modern engineering.

High Power-to-Weight Ratio

When it comes to power-to-weight ratio, shape memory alloy linear actuators truly shine. These devices can generate significant force relative to their weight, making them ideal for applications where every ounce counts—think aerospace or portable medical devices. The lightweight nature combined with high output means that engineers can design lighter systems without sacrificing performance, leading to innovations that push boundaries further than ever before.

Reliability in Extreme Conditions

Reliability is paramount when selecting any actuator for critical applications, and SMA linear actuators do not disappoint even in extreme conditions. They exhibit excellent performance across a wide range of temperatures and environments, ensuring consistent operation whether in high-altitude aerospace settings or harsh medical environments. This resilience makes shape memory alloy linear actuators an attractive choice for industries requiring dependable solutions that stand the test of time.

Real-World Applications of SMA Linear Actuators

Shape memory alloy linear actuators are making waves across various industries, showcasing their versatility and innovative potential. From aerospace to medical devices and robotics, these actuators are revolutionizing the way we approach design and functionality. Their unique properties allow for compact solutions that maintain performance under demanding conditions.

Aerospace Engineering Innovations

In aerospace engineering, the need for lightweight and efficient components is paramount, making shape memory alloy linear actuators an ideal choice. These SMA linear actuators can enable morphing wing designs that adapt to changing flight conditions, enhancing aerodynamic efficiency. Furthermore, their ability to operate reliably in extreme temperatures makes them perfect for applications in space exploration and high-altitude flights.

The integration of a shape memory alloy linear actuator into aircraft systems not only reduces weight but also simplifies maintenance routines due to fewer moving parts compared to traditional mechanisms. This innovation is paving the way for more fuel-efficient aircraft designs that could significantly lower operational costs over time. As engineers continue to explore new horizons with SMA technology, we can expect even more groundbreaking advancements in aviation.

Medical Device Advancements

The medical field is another area where shape memory alloy linear actuators shine brightly, particularly in minimally invasive surgical tools and prosthetics. These SMA linear actuators provide precise movements while being compact enough to fit within small instruments used during surgeries. Their biocompatibility also ensures that they can be safely used in devices that interact directly with human tissues.

Moreover, advancements in SMA technology have led to the development of smart prosthetics that mimic natural limb movement more effectively than ever before. By utilizing a shape memory alloy linear actuator, these devices can respond dynamically to user inputs or environmental changes, providing a more intuitive experience for users. The future of medical devices looks promising as researchers continue refining these technologies.

Robotics and Automation Enhancements

Robotics is undergoing a transformation thanks to the integration of shape memory alloy linear actuators into various systems designed for automation and precision tasks. These SMA linear actuators offer unparalleled flexibility and adaptability for robotic joints, enabling smoother movements without bulky motors or gears disrupting their sleek designs. This compactness allows robots equipped with such technology to navigate tighter spaces while maintaining high levels of efficiency.

In manufacturing environments where automation is key, implementing a shape memory alloy linear actuator can enhance productivity by allowing machines to adjust rapidly without compromising on power or reliability. Additionally, their resilience against wear makes them suitable for long-term use in demanding industrial settings where traditional solutions might falter over time. With ongoing research focusing on improving these systems further, the future looks bright for robotics powered by SMA innovations.

Choosing the Right SMA Linear Actuator

Selecting the right shape memory alloy linear actuator can feel like trying to find a needle in a haystack, but fear not! With a little guidance, you can navigate through the options available and make an informed decision that suits your needs. Factors such as performance requirements, size constraints, and environmental conditions will play crucial roles in determining which SMA linear actuator is right for you.

Factors to Consider

When choosing an SMA linear actuator, it’s essential to consider several factors that impact performance and suitability. First off, think about the load capacity; whether you need it for delicate applications or heavy-duty tasks will significantly influence your choice. Additionally, temperature ranges and response times are vital—some applications may require quick actuation while others can tolerate slower movements.

Another factor is the actuator's size and weight; compact designs can be advantageous in space-constrained environments. Furthermore, understanding the specific application requirements—like stroke length and power consumption—will help narrow down your options efficiently. Ultimately, balancing these factors ensures that your chosen linear actuator meets both functional demands and logistical constraints.

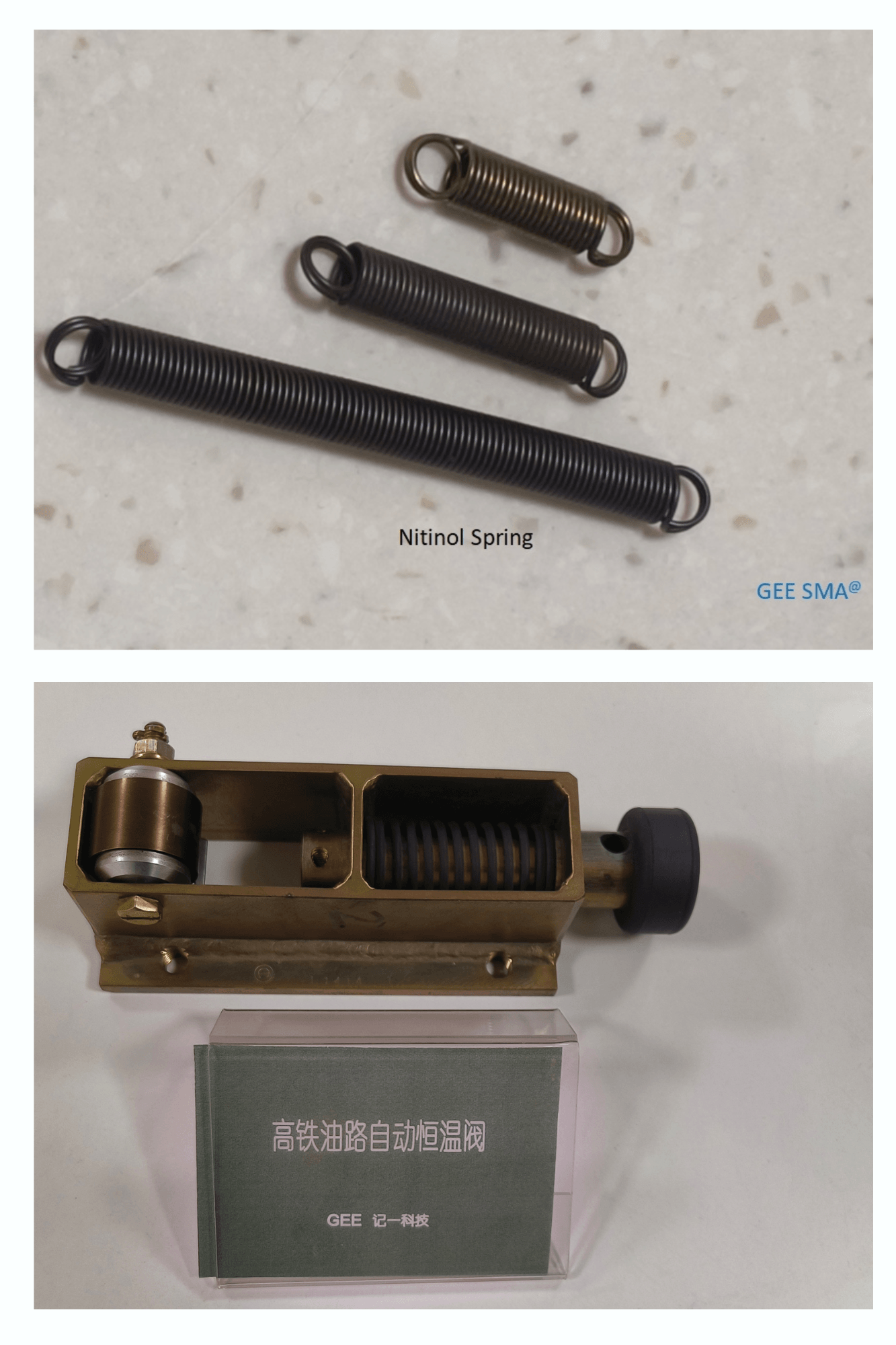

Leading Manufacturers like GEE SMA

When it comes to reliable manufacturers of shape memory alloy linear actuators, GEE SMA stands out as a leader in innovation and quality. They offer a diverse range of SMA linear actuators tailored for various industries—from aerospace to medical devices—ensuring that you find just what you need. Their commitment to research and development means they consistently push the boundaries of what's possible with shape memory alloys.

GEE SMA’s products are not only known for their high performance but also for their durability under extreme conditions which is critical in many applications. Moreover, they provide excellent customer support throughout the selection process, helping clients choose the best solution for their specific needs. With GEE SMA at your side, you're not just buying an actuator; you're investing in a partnership focused on success.

Customization for Specific Applications

Customization is where things get really exciting with shape memory alloy linear actuators! Many manufacturers—including GEE SMA—offer tailored solutions designed specifically for unique applications or challenges faced by engineers today. Whether it's altering dimensions to fit into tight spaces or adjusting actuation speed based on operational requirements, customization opens up endless possibilities.

Furthermore, customization extends beyond just physical attributes; software integrations can also be adapted to ensure compatibility with existing systems or technologies used within your project framework. This level of flexibility allows engineers to harness the full potential of SMA technology without compromising on design integrity or functionality. When selecting an SMA linear actuator, don’t hesitate to explore these custom options—they might just provide that perfect fit!

Conclusion

In wrapping up our exploration of shape memory alloys and their application in linear actuators, it’s clear that these remarkable materials are poised to revolutionize various industries. The future of shape memory alloy linear actuators is bright, with ongoing innovations promising enhanced performance and versatility. As engineers continue to unlock the potential of SMAs, we can expect exciting advancements that will redefine how we think about motion and control.

The Future of Shape Memory Alloys

The future of shape memory alloys is brimming with possibilities, particularly in the realm of SMA linear actuators. Researchers are continually discovering new compositions and manufacturing techniques that enhance the capabilities of these materials. With advancements such as improved thermal response times and greater resilience under extreme conditions, we can anticipate a wave of innovative applications across diverse sectors.

Impact on Engineering and Design

Shape memory alloy linear actuators are set to have a profound impact on engineering and design principles moving forward. Their unique properties allow for more compact designs without sacrificing performance, enabling engineers to create sleeker products that fit into tighter spaces. This shift toward miniaturization not only enhances aesthetic appeal but also contributes to energy efficiency—an essential factor in modern engineering practices.

Why GEE SMA Leads the Way

GEE SMA stands at the forefront of this technological evolution, leading the charge in developing cutting-edge shape memory alloy linear actuators. Their commitment to quality and innovation has established them as a trusted name among manufacturers in this niche market. By focusing on customization options tailored to specific applications, GEE SMA ensures that customers receive solutions that meet their precise needs while pushing the boundaries of what’s possible with SMA technology.