Introduction

In the realm of innovative materials, few can match the versatility and intrigue of nitinol muscle wire. This remarkable shape memory metal has captured the attention of creators across various fields, from robotics to medicine, due to its unique ability to return to a predetermined shape when exposed to specific temperatures. Understanding how nitinol wire functions and its myriad applications is essential for anyone looking to harness the power of this extraordinary material.

What is Nitinol Muscle Wire?

Nitinol muscle wire is a type of shape memory alloy wire made primarily from nickel and titanium, which possesses an astonishing ability to remember its original form. When heated, this muscle wire undergoes a phase transformation that allows it to contract or expand dramatically, mimicking muscle movement in a way that traditional materials cannot achieve. This unique characteristic makes nitinol an exciting option for engineers and artists alike who seek dynamic solutions in their creations.

The Science Behind Shape Memory Metal

At the heart of nitinol's functionality lies its fascinating science as a shape memory metal or alloy. The material exists in two distinct phases: martensite at lower temperatures, which allows for flexibility and deformation, and austenite at higher temperatures, where it regains its predefined shape. This transition between phases enables nitinol wire not only to perform mechanical work but also opens up new avenues for innovation across different industries.

Applications of Nitinol Wire in Creation

The applications of nitinol wire are virtually limitless due to its unique properties as a shape memory alloy nitinol. In robotics, it can be used for actuators that mimic natural movements without bulky motors or gears; in medical devices, it serves as stents or guidewires that adapt seamlessly within the human body; while in aerospace innovations, it contributes lightweight solutions that enhance performance without compromising strength. As creators continue exploring new uses for muscle wire, the potential impact on technology and design remains profound.

Understanding Nitinol Muscle Wire

Nitinol muscle wire is an extraordinary material that has captivated engineers and creators alike. This shape memory metal, primarily composed of nickel and titanium, exhibits unique properties that allow it to return to a predetermined shape when heated. Understanding the journey of shape memory alloys (SMAs), how muscle wire operates, and the specific characteristics that make nitinol so remarkable is essential for anyone looking to harness its potential.

The Journey of Shape Memory Alloy

The story of shape memory alloy begins in the 1960s when researchers first discovered the intriguing properties of nitinol wire. Originally developed for military applications, this innovative material quickly found its way into various industries due to its remarkable ability to remember shapes after deformation. As creators began experimenting with nitinol muscle wire, they realized its potential beyond just functionality; it became a game-changer in design and engineering.

Over time, advancements in manufacturing processes have made nitinol more accessible and versatile. Today, shape memory alloy wires are utilized in everything from robotics to medical devices, showcasing their adaptability across different fields. The journey from a niche military application to widespread use illustrates how far nitinol has come as a staple in modern technology.

How Muscle Wire Works

At the core of how muscle wire functions lies the principle of phase transformation within the material structure of nitinol wire. When cooled below a certain temperature, known as the martensitic phase, nitinol can be easily deformed into various shapes. However, once heated above this threshold—typically around 70°C (158°F)—the wire transitions back to its original configuration due to its unique crystalline structure.

This transformation is what makes SMA wire so fascinating; it allows for precise control over movement without relying on traditional motors or actuators. By applying electrical current or heat directly to the muscle wire, creators can manipulate its form with impressive accuracy and speed. This capability opens up endless possibilities for innovative designs and applications across multiple sectors.

Properties That Make Nitinol Unique

Nitinol's uniqueness stems from several key properties that set it apart from other materials used in engineering and design projects. First and foremost is its exceptional shape memory effect—this allows nitinol muscle wire not only to return to a predefined shape but also enables it to exert significant force during this transition process. This means that even small amounts of SMA wire can accomplish tasks typically reserved for larger mechanical systems.

Another standout feature is superelasticity; when subjected to stress beyond typical elastic limits at certain temperatures, nitinol can deform significantly without permanent damage or failure—returning effortlessly back to its original form once released from stress conditions. Additionally, resistance against corrosion makes nitinol an ideal candidate for long-lasting applications in challenging environments such as medical implants or aerospace components.

In summary, understanding how these properties work together equips creators with valuable insights into leveraging nitinol effectively within their projects while showcasing why this extraordinary material continues gaining traction across various industries.

Applications Across Industries

Nitinol muscle wire, a remarkable shape memory metal, is revolutionizing various industries with its unique properties and capabilities. From robotics to medical devices and even aerospace innovations, the versatility of nitinol wire is nothing short of astounding. Let's dive into how this extraordinary shape memory alloy wire is making waves across different sectors.

Robotics and Automation

In the realm of robotics and automation, nitinol muscle wire is a game-changer. Its ability to contract and expand in response to temperature changes allows for precise movements that are essential in robotic applications. Engineers are increasingly incorporating SMA wire into robotic designs, enabling lighter, more efficient systems that can mimic natural motion with an elegance previously thought impossible.

Moreover, the compactness of nitinol wire means that it can be integrated into tight spaces within robotic structures without sacrificing functionality. This space-saving quality not only enhances design efficiency but also reduces overall weight—crucial for mobile robots operating in dynamic environments. As we continue to explore the boundaries of what robots can do, shape memory alloy nitinol will undoubtedly play a pivotal role in advancing automation technology.

Medical Devices and Implants

The medical field has embraced nitinol muscle wire for its incredible properties that cater specifically to patient needs. One notable application is in stents and guidewires, where the shape memory capabilities allow these devices to navigate complex pathways within the body before expanding to their functional form once positioned correctly. This adaptability makes procedures less invasive while improving patient outcomes significantly.

Additionally, nitinol's biocompatibility ensures that it can safely reside within the human body without adverse reactions—an essential factor when creating implants such as orthopedic devices or dental tools made from shape memory alloy wire. The future looks bright as researchers continue to innovate new applications for this remarkable material in medicine, paving the way for smarter medical devices that enhance healing processes.

Aerospace Innovations with Nitinol

In aerospace engineering, where every ounce counts and reliability is paramount, nitinol muscle wire stands out as an invaluable asset. Its lightweight nature combined with strength makes it ideal for components like actuators or control surfaces in aircraft designs—allowing engineers to achieve greater fuel efficiency without compromising performance or safety standards. The use of SMA wire contributes significantly to innovations aimed at reducing overall aircraft weight while increasing operational efficiency.

Furthermore, shape memory alloy nitinol offers unique solutions for deployable structures such as antennas or solar panels on spacecraft; these components can be compacted during launch but easily expand once they reach their intended environment thanks to the properties of this exceptional material. As aerospace technology continues evolving towards more sustainable solutions, leveraging nitinol will be crucial in achieving groundbreaking advancements.

Choosing the Right Nitinol Wire

Selecting the right nitinol muscle wire is crucial for ensuring that your project meets its intended design and functional goals. With various options available, it's essential to understand the properties of shape memory metal and how they can affect performance. By considering specific factors, you can make an informed choice that enhances your creation.

Factors to Consider for Creators

When choosing nitinol wire, several critical factors come into play. First and foremost is the operating temperature range; different grades of shape memory alloy wire respond to heat at various temperatures, which directly influences their functionality in applications. Additionally, consider the wire's diameter and tensile strength, as these characteristics will determine how well it can handle stress during operation.

Another important factor is the activation mechanism—how you plan to trigger the shape memory effect in your design. Some creators prefer electrical stimulation while others opt for thermal activation. Understanding these dynamics will help ensure that your muscle wire operates effectively within its intended environment.

Lastly, think about the specific application of your project: whether it's a delicate medical device or a robust robotic component will significantly impact your choice of nitinol muscle wire. The unique properties of each type of shape memory alloy nitinol will dictate its suitability for different tasks.

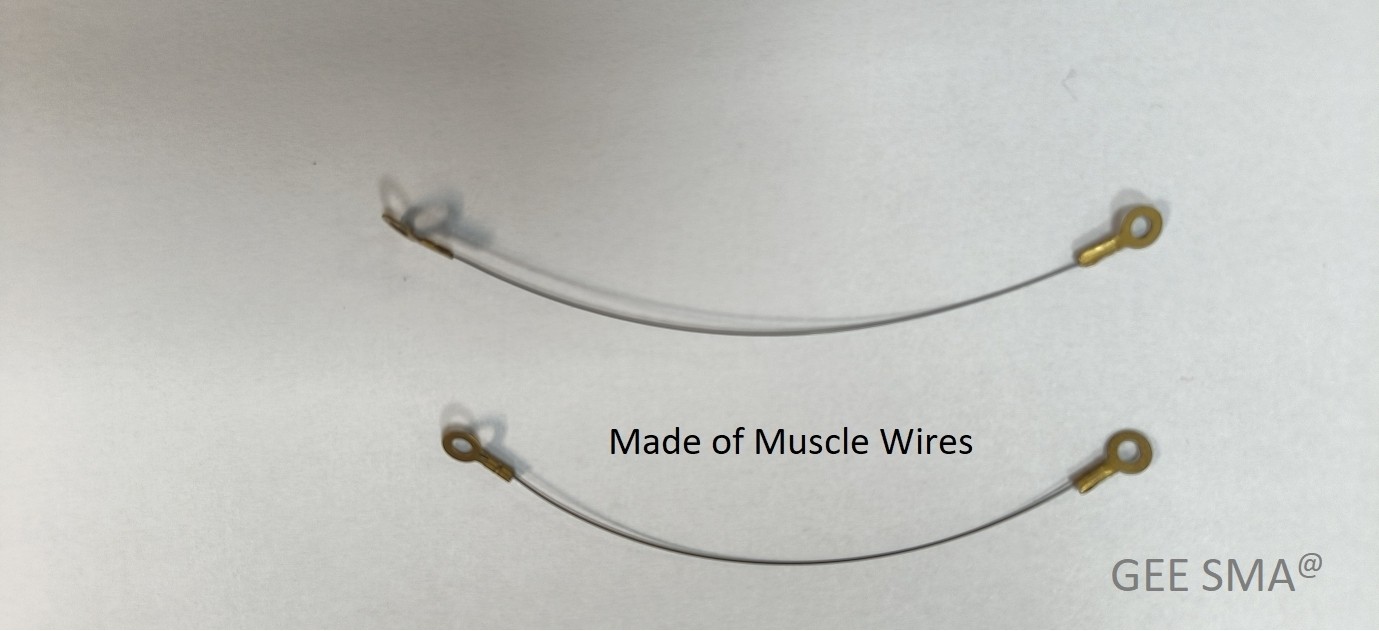

GEE SMA: A Trusted Supplier

When it comes to sourcing high-quality nitinol wire, GEE SMA stands out as a trusted supplier in the industry. Known for their commitment to excellence, they offer a wide range of options tailored specifically for creators looking to harness the power of shape memory metals. Their expertise ensures that you receive only top-grade materials that meet rigorous standards.

GEE SMA provides detailed specifications for their nitinol muscle wire products, including information on transformation temperatures and mechanical properties, making it easier to select what best suits your project needs. Plus, their customer service team is always ready to assist with any questions or custom requirements you might have regarding shape memory alloy wire.

Choosing GEE SMA not only guarantees quality but also fosters innovation as they continuously explore new advancements in SMA technology. Partnering with them means you're equipped with reliable resources as you push boundaries in your creative endeavors using nitinol muscle wire.

Tailoring Nitinol for Specific Projects

Tailoring nitinol muscle wire for specific projects involves understanding both its capabilities and limitations thoroughly. Different applications may require modifications in terms of size or treatment processes like annealing or cold working—methods that can enhance performance based on project demands and environmental conditions.

For instance, if you're developing a medical implant that requires biocompatibility alongside functionality, selecting a specific grade of shape memory alloy nitinol designed for such applications is vital. Similarly, if you're working on robotics where rapid response times are essential, you'll want to focus on wires with quicker actuation capabilities.

Working with Nitinol Muscle Wire

When working with nitinol muscle wire, understanding its unique properties and behavior is crucial for successful applications. This shape memory metal can be a bit temperamental, but with the right techniques and precautions, it can become an invaluable tool in your creative arsenal. Here’s how to make the most of your experience with nitinol wire.

Tips for Handling and Crafting

Handling nitinol wire requires a gentle touch and some finesse. First, always ensure you are working in a clean environment to prevent contamination; dirt or oils can affect the performance of this shape memory alloy wire. When crafting, use appropriate tools like pliers designed for fine work to avoid damaging the delicate structure of the muscle wire.

Another tip is to preheat your nitinol muscle wire before bending or shaping it; this helps activate its shape memory properties more effectively. Additionally, remember that when you cool down the wire after shaping it, it will retain that new form until heated again—this is where its magic lies! Experimenting with different temperatures can lead to exciting results as you learn how the material responds.

Lastly, keep in mind that patience is key when working with shape memory alloy nitinol. Allow yourself ample time for trial and error as you familiarize yourself with how this remarkable metal behaves under different conditions.

Common Mistakes to Avoid

Even seasoned creators can stumble when using nitinol muscle wire if they're not careful about certain pitfalls. One common mistake is applying too much force during bending; remember that this shape memory metal has specific limits—exceeding them could lead to permanent deformation or breakage of the wire. Always approach shaping tasks gently and incrementally.

Another mistake often made involves neglecting temperature considerations; forgetting to heat or cool properly can result in disappointing outcomes when trying to achieve desired shapes or movements from your muscle wire projects. Be sure to have a reliable method for monitoring temperatures during your processes.

Lastly, failing to account for fatigue life is another issue many encounter when working with SMA (shape memory alloy) wires like nitinol muscle wire. Over time and repeated use, these wires may lose their effectiveness if not handled properly; thus, keeping track of usage cycles will help maintain their performance over time.

Safety Precautions when Using SMA Wire

Safety should always be at the forefront when handling any materials—including nitinol muscle wire—especially since it operates under varying temperatures that could pose risks if mishandled. Always wear protective gloves while working with heated wires; even brief contact can lead to burns due to high temperatures involved in activating shape memory properties.

Additionally, ensure proper ventilation in your workspace if you're using tools that produce fumes or heat while manipulating SMA wires like nitinol—this keeps air quality safe while you work on your projects! It's also wise to keep flammable materials away from heat sources during crafting sessions involving nitinol muscle wires.

Finally, familiarize yourself thoroughly with all equipment used alongside shape memory alloy nitinol so you're prepared for any potential hazards they may present during operation—from sharp edges on tools used for cutting or shaping wires—to electric shock risks from soldering devices employed in assembly processes!

The Future of Shape Memory Alloys

The future of shape memory alloys, particularly nitinol muscle wire, is brimming with possibilities that could revolutionize various industries. As research continues to delve deeper into the properties of shape memory metals, we can expect innovations that enhance performance and expand applications. With advancements in technology and material science, nitinol wire is poised to become even more integral in shaping our future.

Innovations on the Horizon

Emerging technologies are set to reshape how we utilize nitinol muscle wire, particularly in areas like robotics and biomedical applications. Researchers are exploring new alloys and processing techniques that could improve the functionality of shape memory alloy wire, making it lighter and more responsive. These innovations will not only enhance existing applications but also pave the way for entirely new uses of SMA wire across various fields.

Additionally, smart materials incorporating nitinol are being developed for use in wearables and soft robotics. Imagine clothing that adjusts to body temperature or devices that adapt their form based on user needs—this is where the future lies with shape memory alloy nitinol! As these advancements unfold, creators will have unprecedented tools at their disposal to innovate further.

Environmental Impact of Nitinol

While exploring the future of nitinol wire, it's essential to consider its environmental impact as well. Nitinol is known for its durability and longevity; thus, products made from this shape memory metal often require less frequent replacement than traditional materials. This characteristic could lead to a reduction in waste over time—a significant advantage as industries strive for sustainability.

Moreover, ongoing research aims to improve the recyclability of SMA wire and other related materials. By developing processes that allow for easier recycling or repurposing of used nitinol muscle wire, we can mitigate some environmental concerns associated with manufacturing and disposal. Embracing these sustainable practices will ensure that creators not only push boundaries but do so responsibly.

How Creators Can Push Boundaries

Creators looking to harness the potential of shape memory alloys must embrace experimentation and collaboration across disciplines. By integrating knowledge from engineering, design, biology, and other fields with their understanding of muscle wire properties, innovators can unlock new applications previously thought impossible. The key lies in thinking outside conventional frameworks—imagine combining nitinol's unique characteristics with cutting-edge technologies like 3D printing!

Furthermore, sharing insights within communities dedicated to SMA wire can foster collective growth and discovery. Engaging with fellow creators through forums or workshops can spark ideas that lead to groundbreaking projects utilizing shape memory alloy nitinol in ways no one has yet imagined! The future is bright for those willing to explore uncharted territories with this versatile material.

Conclusion

As we wrap up our exploration of nitinol muscle wire and its fascinating applications, it’s clear that the power of shape memory metal is not just a novelty but a transformative technology. From robotics to medical devices, the potential of nitinol wire is vast and continually expanding. Harnessing this innovative material allows creators to push boundaries and develop solutions previously thought impossible.

Harnessing the Power of Nitinol Wire

The unique properties of shape memory alloy wire make nitinol muscle wire an incredible resource for engineers and designers alike. By understanding how this remarkable material responds to temperature changes, creators can design intricate systems that mimic natural movement or respond dynamically to their environment. The ability to harness the power of nitinol opens up new possibilities in fields ranging from art installations to advanced robotics.

The Versatility of Shape Memory Metals

Nitinol's versatility as a shape memory alloy nitinol makes it suitable for a variety of applications across diverse industries. Whether it's providing precise actuation in robotic limbs or enabling self-expanding stents in medical treatments, muscle wire proves its worth time and again. This adaptability is what sets shape memory metals apart; they can be tailored for specific needs while maintaining their fundamental characteristics.

Why GEE SMA is Your Best Bet

When it comes to sourcing high-quality nitinol wire, GEE SMA stands out as a trusted supplier committed to excellence and innovation. Their extensive range of products ensures that creators have access to the right type of shape memory alloy wire for any project, whether it’s industrial or artistic in nature. With GEE SMA, you’re not just purchasing materials; you’re investing in a partnership that empowers your creative endeavors with reliable support and expertise.