Introduction

In the world of advanced materials and actuators, nitinol actuators stand out for their remarkable capabilities. These unique devices leverage the properties of shape memory alloys to create motion in response to temperature changes. Understanding how nitinol wire operates opens doors to innovative applications across various industries, from robotics to medical devices.

Understanding Nitinol Actuators

Nitinol actuators are a fascinating blend of engineering and material science, utilizing nitinol wire to achieve movement without traditional electrical input. Unlike conventional linear actuators that rely on motors or pneumatic systems, these electrical actuators harness thermal energy to trigger motion through a process known as shape setting. The result is a compact and efficient actuator spring that can perform tasks with impressive precision and reliability.

The Science Behind Shape Memory Alloys

At the heart of nitinol’s functionality lies its classification as a shape memory alloy (SMA), which means it can return to a predetermined shape when heated above a specific temperature threshold. This property is not merely theoretical; it allows nitinol wire to undergo significant deformation while maintaining its ability to revert back, making it an ideal candidate for actuator applications. By understanding the science behind these materials, engineers can design more effective nitinol spring actuators tailored for diverse operational needs.

Exploring Real-World Applications

The versatility of nitinol actuators is evidenced by their growing presence in real-world applications, ranging from intricate medical devices like stents and surgical tools to robotics where precise movements are crucial. As industries seek more efficient alternatives to traditional systems, the demand for these innovative solutions continues to rise. With ongoing advancements in technology, we can expect even broader utilization of nitinol wire in future designs that push the boundaries of what's possible.

What is a Nitinol Actuator?

Nitinol actuators are fascinating devices that leverage the unique properties of nitinol, a nickel-titanium alloy known for its shape memory and superelastic capabilities. These actuators function by converting thermal energy into mechanical motion, allowing them to contract or expand in response to temperature changes. This makes nitinol actuators particularly useful in applications where precise movement is required without the need for complex electrical systems.

Definition and Functionality

At its core, a nitinol actuator is a type of linear actuator that utilizes nitinol wire to achieve motion through thermal activation. When heated above a specific temperature, the wire remembers its pre-defined shape and contracts, creating movement or force. This functionality allows nitinol actuators to perform tasks typically assigned to traditional electrical actuators but with added benefits like reduced complexity and weight.

Comparison with Traditional Actuators

When comparing nitinol actuators with traditional electrical actuators, several key differences emerge. Traditional actuators often rely on motors and gears to create motion, which can be bulky and require significant power input; in contrast, nitinol spring actuators are compact and only need heat to operate effectively. Additionally, while electrical systems can be susceptible to failure due to wear over time, the robustness of nitinol wire ensures longevity under various conditions.

Advantages of Using Nitinol

The advantages of using nitinol in actuator designs are numerous and compelling. First off, their lightweight nature makes them ideal for applications where space is limited or weight is critical—think aerospace or medical devices. Furthermore, the inherent ability of nitinol shape setting allows these actuators to maintain their performance over time without extensive maintenance needs, making them not just efficient but also cost-effective in the long run.

The Mechanics of Nitinol Wire

Nitinol wire is a fascinating component that underpins the functionality of nitinol actuators. This unique alloy, primarily composed of nickel and titanium, exhibits remarkable properties that allow it to change shape in response to temperature variations. Understanding how nitinol wire works is crucial for grasping the mechanics behind various applications, from medical devices to robotics.

How Nitinol Wire Works

At its core, a nitinol actuator leverages the shape memory effect and superelasticity inherent in nitinol wire. When heated above a specific transformation temperature, the wire reverts to its pre-set shape, enabling it to perform work as an electrical actuator or linear actuator would. This property allows for precise control and movement within systems where traditional actuators might fall short.

The beauty of nitinol wire lies not just in its ability to remember shapes but also in how it responds elastically under stress. Unlike conventional materials that may deform permanently after exceeding yield strength, nitinol can return to its original form once the stress is removed—making it an ideal choice for actuator springs in dynamic applications. This combination of traits makes nitinol wire a game-changer across various industries.

Shape Setting Process

The shape setting process for nitinol involves careful heating and cooling cycles that define the final configuration of the material. Initially, the wire is deformed into a desired shape at elevated temperatures; then it's cooled down while maintaining this form until it reaches room temperature—this establishes its memorized state. Upon reheating above the transition temperature, the wire will revert back to this preset shape with remarkable force.

This process isn’t just about creating any old configuration; precision is key when designing components like nitinol spring actuators used in delicate environments such as surgical instruments or aerospace applications. Each step must be meticulously controlled to ensure reliability and performance when deployed in real-world scenarios.

Moreover, understanding this process sheds light on why nitinol actuators are increasingly favored over traditional options—they can be tailored specifically for their intended application without compromising functionality or efficiency. The versatility offered by customized shape setting makes these materials indispensable in modern engineering solutions.

Thermal Properties and Response

Thermal properties play a pivotal role in how effectively a nitinol actuator performs its functions. The ability of nitinol wire to respond rapidly to changes in temperature means that these actuators can operate with minimal delay when activated by heat sources or electrical currents—an essential characteristic for applications requiring quick responses like robotics or automated systems.

As temperatures fluctuate, so does the mechanical response of nitinol wire; this dynamic behavior allows engineers to design systems with enhanced control capabilities compared to traditional linear actuators or electrical actuators that may not react as swiftly or efficiently under similar conditions. Furthermore, understanding thermal properties helps optimize energy consumption within devices utilizing these innovative materials.

In summary, mastering the thermal response characteristics of nitinol enables developers and engineers alike to push boundaries within various fields—from advanced manufacturing techniques using custom-designed actuator springs all the way through complex surgical devices requiring precision movements driven by nimble mechanisms like those found in cutting-edge nitinol spring actuators.

Nitinol Spring Actuator Innovations

Nitinol spring actuators are at the forefront of innovation, blending advanced materials with cutting-edge technology. These actuator springs leverage the unique properties of nitinol wire, enabling them to perform tasks that traditional linear actuators simply cannot match. The recent advancements in nitinol shape setting have opened up new avenues for applications across various industries, making these devices more efficient and versatile than ever before.

Recent Developments in Actuator Springs

The evolution of actuator springs has seen significant improvements thanks to the integration of nitinol wire technology. Recent developments focus on enhancing the responsiveness and durability of these nitinol actuators, allowing for quicker actuation times and greater reliability under various conditions. Innovations such as optimized shape setting processes have enabled manufacturers to create custom spring configurations that meet specific performance requirements while minimizing weight and maximizing strength.

In addition to mechanical enhancements, researchers are exploring ways to integrate smart technologies into nitinol spring actuators. By combining electrical actuator capabilities with traditional mechanical functions, these hybrid systems can achieve unprecedented levels of control and precision. This convergence is particularly beneficial in fields like robotics, where nimble movements and adaptability are crucial for success.

Case Studies of Nitinol in Action

One notable case study involves the use of nitinol actuators in medical devices, specifically in minimally invasive surgical instruments. Surgeons have reported improved outcomes thanks to the precise control offered by these actuator springs, which can adapt their shape based on temperature changes during procedures. The ability to manipulate instruments with such finesse has revolutionized surgical techniques and patient recovery times.

Another compelling example is found within aerospace applications where lightweight materials are paramount. Nitinol wire has been utilized in deploying mechanisms for satellite components due to its remarkable strength-to-weight ratio combined with its shape memory properties. These innovations not only enhance functionality but also contribute significantly to fuel efficiency by reducing overall spacecraft weight.

Future Trends in Nitinol Technology

Looking ahead, we can expect a surge in research focused on enhancing the thermal properties of nitinol actuators further. As scientists delve deeper into understanding how temperature affects nitinol wire behavior, they aim to develop more responsive systems that can react faster under varying environmental conditions—essentially creating smarter actuator springs that can adapt on-the-fly without external input.

Moreover, sustainability will play a pivotal role in future innovations involving nitinol technology as industries increasingly prioritize eco-friendly practices. Manufacturers will likely explore recycling methods for used nitinol wire while developing new alloys that maintain performance standards without compromising environmental integrity. With ongoing advancements, we stand on the brink of a new era where nitinol spring actuators could redefine efficiency across multiple sectors.

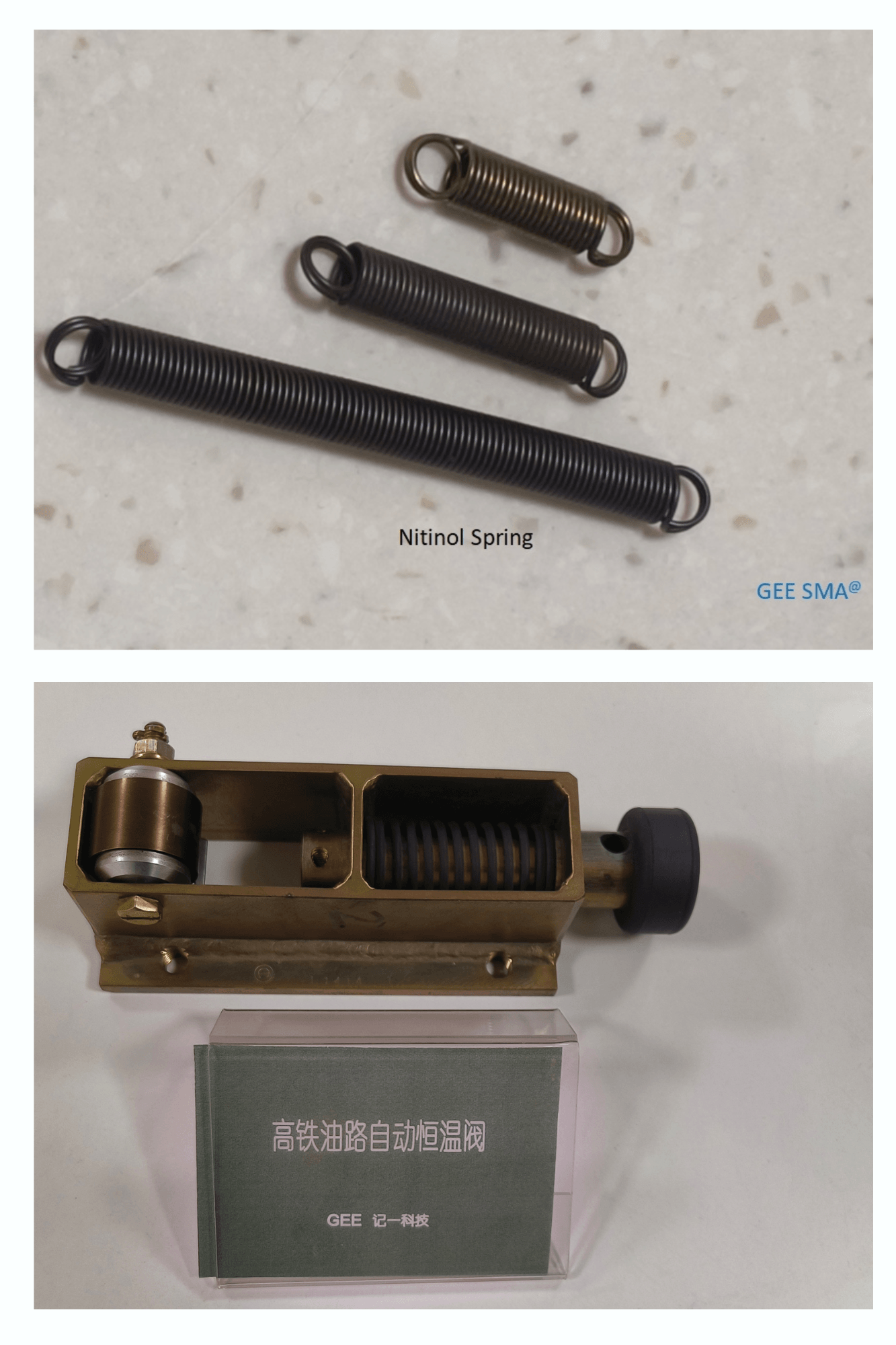

GEE SMA: Pioneering Nitinol Solutions

In the realm of advanced manufacturing and innovative engineering, GEE SMA stands out as a leader in the development of nitinol solutions. With a focus on nitinol actuators and actuator springs, GEE SMA has carved a niche for itself by providing cutting-edge technology that meets diverse industry needs. Their commitment to quality and performance ensures that every product, from linear actuators to specialized nitinol wire applications, is designed to exceed expectations.

Overview of GEE SMA's Offerings

GEE SMA offers an impressive range of products centered around nitinol shape memory alloys, including both electrical actuators and linear actuators tailored for specific applications. Their nitinol spring actuator designs are particularly noteworthy, showcasing the versatility and efficiency of this unique material. By leveraging advanced manufacturing techniques, GEE SMA ensures that their offerings not only meet stringent industry standards but also push the boundaries of what’s possible with nitinol technology.

One area where GEE SMA excels is in customizing solutions to fit unique project requirements. Whether it's developing specialized actuator springs or optimizing the shape setting process for specific uses, their team works closely with clients to deliver tailored solutions. This dedication to customization sets them apart in a competitive landscape filled with one-size-fits-all approaches.

Nitinol Shape Memory Alloys in Space Exploration

Nitinol shape memory alloys have found an exciting application in space exploration through innovative projects led by GEE SMA. The adaptability and lightweight nature of nitinol actuators make them ideal candidates for use in spacecraft systems where reliability is paramount. From deploying solar panels to adjusting antennas, these electrical actuators provide precise movement without adding excessive weight—crucial for successful missions beyond our atmosphere.

GEE SMA's contributions extend beyond just functionality; they also bring a level of resilience that is essential in the harsh conditions of space. The ability of nitinol wire to return to its pre-defined shape after deformation allows for mechanisms that can withstand extreme temperatures and vacuum conditions without failure. This reliability not only enhances mission success rates but also opens up new possibilities for future space technologies.

As we look toward future explorations on Mars or beyond, the role of nitinol spring actuators becomes increasingly significant. Innovations developed by GEE SMA could very well be at the forefront of robotic systems designed for planetary exploration or even human habitats on other celestial bodies.

Commitment to Quality and Customization

At GEE SMA, quality isn't just a buzzword; it’s embedded into every aspect of their operations—from research and development through production processes involving nitinol wire and actuator springs. Their rigorous testing protocols ensure that each product meets high-performance standards before it reaches clients' hands. This commitment guarantees that when customers choose GEE SMA’s offerings like linear or electrical actuators, they are investing in durable solutions backed by reliable performance.

Moreover, customization remains at the heart of what they do; understanding that each application has its own set of challenges means offering tailored solutions rather than generic fixes. Whether it's modifying an existing design or creating something entirely new from scratch using advanced nitinol shape setting techniques, their engineering team is ready to tackle any challenge head-on.

This approach not only fosters strong client relationships but also drives innovation within industries as diverse as aerospace, medical devices, and robotics—showing how versatile and impactful nitinol technology can be when paired with dedicated craftsmanship.

Applications Across Diverse Industries

Nitinol actuators are making waves across various sectors, showcasing their versatility and effectiveness. From medical devices to robotics and aerospace, the unique properties of nitinol wire are revolutionizing how we think about actuation. Let's dive into the exciting applications of nitinol in these industries.

Medical Devices and Surgical Instruments

In the realm of medical devices, nitinol actuators shine brightly due to their biocompatibility and reliability. Nitinol shape setting allows for precise movements in surgical instruments, enabling minimally invasive procedures with greater efficiency. With actuator springs made from this remarkable alloy, surgeons can perform intricate tasks with enhanced dexterity and control.

Moreover, nitinol wire's ability to return to a predetermined shape when heated plays a crucial role in stents and guidewires used during surgeries. These devices benefit from the strength and flexibility of nitinol, ensuring they can navigate complex anatomical pathways without causing damage. As the demand for advanced medical technology grows, the integration of nitinol actuators will undoubtedly lead to groundbreaking innovations in healthcare.

Robotics and Automation

The robotics industry is another area where nitinol actuators are making significant contributions. With their lightweight nature and high strength-to-weight ratio, linear actuators made from nitinol are ideal for robotic applications that require both power and precision. This unique combination allows robots to perform complex tasks that were once thought impossible.

Nitinol spring actuators provide an innovative solution for creating responsive movements in robotic limbs or grippers, allowing them to mimic human-like dexterity more closely than traditional electrical actuators could achieve alone. The adaptability of these systems means they can be customized for specific tasks while maintaining energy efficiency—a critical factor in automation processes. As robotics continues to advance, the use of nitinol wire is set to play an even more prominent role in enhancing functionality.

Aerospace and Defense

In aerospace and defense applications, reliability is paramount—and that's where nitinol comes into play with its robust performance characteristics. Nitinol actuators are utilized in various systems such as deployable structures or control surfaces on aircraft due to their ability to withstand extreme conditions while maintaining functionality through shape memory effects. This capability ensures that components respond accurately under varying temperatures encountered at high altitudes.

Additionally, actuator springs crafted from nitinol offer weight savings that are crucial for fuel efficiency in aviation technology—every gram counts when it comes to flying! The potential uses extend beyond just aircraft; satellites equipped with precision engineering using nitinol wire can achieve better deployment mechanisms for solar panels or antennas as well. As we push towards more innovative aerospace designs, the importance of integrating materials like Nitinol cannot be overstated.

Conclusion

In summary, nitinol actuators represent a remarkable fusion of innovation and functionality, showcasing their versatility across a myriad of applications. These unique devices leverage the properties of nitinol wire to deliver precise movements that can revolutionize industries ranging from medical devices to aerospace. The adaptability of nitinol spring actuators makes them an essential component in modern engineering, ensuring they are not just a passing trend but a staple in advanced manufacturing.

The Versatility of Nitinol Actuators

The versatility of nitinol actuators is evident in their ability to function as both linear and electrical actuators, offering solutions tailored to various needs. Unlike traditional actuator springs, which often rely on mechanical components that can wear down over time, nitinol’s shape memory capabilities provide durability and reliability. This flexibility allows engineers to design compact systems that respond dynamically to thermal stimuli while maintaining high performance across diverse environments.

Driving Future Innovations with Nitinol

As we look ahead, the potential for driving future innovations with nitinol is immense. Researchers are continually exploring new methods for enhancing the efficiency and responsiveness of nitinol wire technology, paving the way for smarter actuator systems that can adapt in real-time. With advancements in nitinol shape setting techniques and material science, we are likely to see even more sophisticated applications emerge—pushing the boundaries of what’s possible in robotics and automation.

Why Nitinol Matters in Advanced Manufacturing

Nitinol matters significantly in advanced manufacturing due to its unique properties that combine strength with lightness—a perfect match for today’s demands for efficiency and sustainability. The incorporation of nitinol actuators into production processes not only streamlines operations but also reduces energy consumption compared to conventional systems. As industries continue to evolve towards more sustainable practices, the role of nitinol spring actuators will be crucial in shaping a smarter future.