Introduction

Nitinol alloy rods have become a cornerstone in modern engineering design, thanks to their unique properties that set them apart from traditional nickel alloys. These remarkable materials, composed primarily of nickel and titanium, exhibit extraordinary characteristics such as the shape memory effect and superelasticity. Understanding how nitinol alloys can be effectively utilized in various applications is crucial for engineers looking to push the boundaries of innovation.

Understanding Nitinol Alloys in Design

At the heart of many groundbreaking designs lies an understanding of nitinol alloys, particularly how they differ from conventional nickel materials. Nitinol's unique composition allows for significant deformation while retaining its original shape when subjected to heat, making it an ideal choice for dynamic applications. This understanding not only enhances mechanical design but also opens doors to creative solutions that were previously unimaginable.

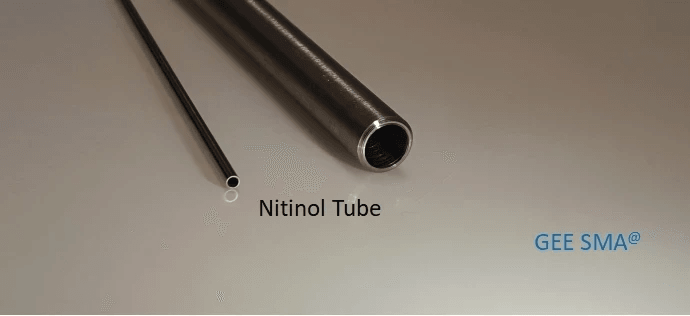

The Versatility of Nitinol Alloy Rod

The versatility of nitinol alloy rods cannot be overstated; they serve multiple functions across various industries due to their remarkable properties. Whether used in medical devices or aerospace components, these nickel alloy rods adapt seamlessly to different environments and requirements. Their ability to withstand extreme conditions while providing reliable performance makes them a favorite among engineers and designers alike.

Applications That Benefit from Nitinol Properties

Numerous applications benefit from the exceptional properties of nitinol alloys, showcasing their potential across sectors like healthcare and robotics. In medical devices, for instance, nitinol sheets are utilized in stents that expand within the body at specific temperatures, demonstrating their practical utility. Similarly, in robotics and aerospace engineering, nitinol rods are employed to create lightweight yet durable components that enhance overall system efficiency.

What is Nitinol Alloy?

Nitinol, a fascinating nickel-titanium alloy, has captured the attention of engineers and designers alike for its unique properties and versatile applications. The name Nitinol is derived from its composition—Nickel Titanium Naval Ordnance Laboratory—where it was first discovered. This alloy stands out in the world of materials science due to its ability to undergo significant deformation while returning to its original shape when heated, making it a prime candidate for various innovative uses.

A Dive into Nickel Materials

Nickel materials are renowned for their excellent corrosion resistance and mechanical strength, which makes them ideal for a wide range of applications. When combined with titanium, these nickel alloys form nitinol alloys that exhibit remarkable characteristics not found in traditional metals. The synergy between nickel and titanium creates a material that is not only strong but also lightweight, enhancing the performance of products like nitinol rods and sheets.

In particular, the nickel content in nitinol alloys contributes significantly to their unique thermal properties. The balance between nickel and titanium allows these alloys to exhibit both shape memory effect (SME) and superelasticity—two attributes that are highly sought after in engineering design. As industries continue to explore the capabilities of these materials, understanding the role of nickel becomes essential for leveraging nitinol properties effectively.

Unique Characteristics of Nitinol Alloys

Nitinol alloys are celebrated for their distinctive features that set them apart from conventional materials. One key characteristic is their shape memory effect; this allows a nitinol alloy rod or sheet to return to its pre-deformed shape upon heating above a specific temperature. This property opens doors for creative engineering solutions across various fields such as robotics, aerospace, and medical devices.

Another remarkable aspect of nitinol is its superelasticity—a phenomenon where the material can undergo considerable deformation without permanent change when subjected to stress below a certain threshold temperature. This quality makes nitinol particularly valuable in applications requiring flexibility without compromising strength or integrity. Furthermore, the fatigue resistance inherent in nitinol ensures that components maintain performance over extended use cycles.

In addition to these mechanical properties, nitinol exhibits excellent biocompatibility, making it an ideal choice for medical implants and devices like stents or orthodontic wires. The versatility offered by these unique characteristics positions nitinol as an indispensable material in modern engineering design.

Comparison with Traditional Alloys

When comparing nitinol alloys with traditional alloys such as steel or aluminum, several differences become apparent that highlight why engineers often prefer using nitinol alloy rods or sheets in advanced applications. Traditional materials typically lack the shape memory effect found in nitinol; they cannot revert back to an original configuration after deformation unless they are physically reshaped through machining processes—an often labor-intensive task.

Moreover, while conventional metals may offer high tensile strength or durability individually, they do not combine those traits with superelasticity like nitrogen does when heated above certain temperatures; this dual functionality allows designers more freedom when creating complex shapes without sacrificing performance attributes. For instance, using a nitinol rod can lead to lighter structures compared to heavier steel components while still achieving desired strength levels.

Lastly, cost considerations must also be taken into account: although initial investments may be higher when sourcing from a specialized nitinol manufacturer compared with traditional metal suppliers due mainly because of processing requirements involved during production stages; long-term benefits often outweigh upfront costs through reduced maintenance needs over time due largely thanks again attributed back towards enhanced fatigue resistance exhibited by these innovative alloys.

The Role of Nitinol Alloy Rods in Engineering

Nitinol alloy rods are revolutionizing the landscape of mechanical design, offering unique properties that traditional materials simply cannot match. These remarkable nickel alloys exhibit exceptional flexibility and strength, making them indispensable in various engineering applications. As industries evolve, the role of nitinol alloy rods continues to expand, proving their worth as essential components in innovative designs.

Their Importance in Mechanical Design

In mechanical design, nitinol alloy rods provide engineers with a robust solution for applications requiring both strength and adaptability. The inherent properties of nitinol alloys allow for designs that can withstand extreme conditions while maintaining functionality. This adaptability is particularly crucial in fields like aerospace and robotics, where performance and reliability are paramount.

Moreover, the lightweight nature of nitinol rod enhances efficiency without compromising structural integrity. This advantage leads to reduced energy consumption and improved overall performance of engineered products. As designers increasingly recognize the value of these materials, nitinol alloy rods are becoming a staple in modern engineering practices.

Advantages Over Conventional Materials

When compared to conventional materials such as steel or aluminum, nitinol alloys stand out for their unique characteristics that enhance performance across various applications. The shape memory effect is one such advantage; it allows components made from nitinol to return to a predetermined shape when subjected to specific temperatures or stress levels. This property not only simplifies design but also reduces the need for complex mechanisms typically required by traditional materials.

Additionally, the corrosion resistance associated with nickel material makes nitinol an ideal choice for environments prone to degradation over time. Its ability to perform reliably under challenging conditions means less maintenance and longer service life for engineered products using nitinol sheets or rods. Consequently, industries can enjoy significant cost savings through reduced downtime and replacement needs.

Case Studies in Modern Applications

Numerous case studies illustrate how nitinol alloy rods have been successfully integrated into modern engineering projects across diverse sectors. In medical devices, for instance, stents crafted from these nickel alloys have transformed cardiac procedures by providing flexible yet strong support within arteries while adapting seamlessly to body temperatures. This innovation has significantly improved patient outcomes and minimized recovery times.

In the realm of robotics, companies are harnessing the advantages of nitinol properties by developing actuators that mimic natural muscle movements more effectively than traditional motors could achieve alone. These advancements lead to more agile robots capable of performing complex tasks with precision and efficiency—an essential quality as automation becomes increasingly prevalent across industries.

Furthermore, aerospace applications benefit from lightweight yet durable structures made possible through nitinol manufacturing techniques that yield high-performance components resistant to fatigue and wear over time. This integration showcases how leveraging advanced materials like nitinol can drive innovation forward while enhancing safety standards within critical fields.

Shape Memory Effect and Its Applications

The shape memory effect is one of the most fascinating phenomena exhibited by nitinol alloys, particularly when considering their applications in various fields. This unique property allows materials like nitinol alloy rods to return to a predetermined shape when heated above a certain temperature, making them incredibly versatile in design and function. The process involves a phase transformation that occurs within the nickel material, enabling the nitinol properties to be harnessed for innovative solutions.

What is the Shape Memory Effect?

At its core, the shape memory effect refers to the ability of certain alloys, such as nickel-titanium (commonly known as nitinol), to remember their original shapes after deformation. When a nitinol rod is deformed at lower temperatures, it can be manipulated into various forms; however, once heated above its transformation temperature, it reverts back to its original configuration. This remarkable characteristic stems from the unique molecular structure of nitinol alloys, which allows them to undergo reversible phase changes—an aspect that sets them apart from traditional nickel alloys.

Practical Uses in Medical Devices

The medical field has eagerly embraced the advantages of nitinol properties due to their reliability and efficiency. Nitinol alloy rods are commonly utilized in stents and guidewires because they can expand and contract with body temperature changes while maintaining structural integrity. Additionally, nitinol sheets are used in surgical tools where precise movement is critical; these devices take advantage of the shape memory effect for minimally invasive procedures that require less trauma during operation.

Nitinol in Robotics and Aerospace

Beyond healthcare, nitinol's unique characteristics have made significant strides in robotics and aerospace applications as well. In robotics, engineers leverage nitinol alloy rods for actuators that mimic natural muscle movements due to their ability to contract and expand efficiently under thermal stimuli. Meanwhile, aerospace manufacturers are increasingly integrating nitinol components into systems where lightweight materials with high strength-to-weight ratios are essential—further showcasing how versatile this nickel material can be across industries.

GEE SMA and Its Impact on Nitinol Innovation

GEE SMA stands at the forefront of innovation in the realm of nitinol alloys, leveraging its deep expertise in nickel materials to push boundaries in engineering applications. As a leading nitinol manufacturer, GEE SMA has honed its capabilities to produce high-quality nitinol alloy rods and sheets that meet diverse industry requirements. Their commitment to research and development ensures that they remain a pivotal player in the evolving landscape of nitinol properties.

Overview of GEE SMA's Expertise

With years of experience specializing in nickel alloys, GEE SMA has developed a comprehensive understanding of nitinol materials and their unique characteristics. This expertise allows them to innovate effectively, creating products that harness the remarkable shape memory effect inherent in nitinol alloys. By focusing on quality control and advanced manufacturing techniques, GEE SMA consistently delivers superior nitinol products that cater to various sectors.

Nitinol Products for Space Mission Success

In the demanding field of space exploration, reliability is paramount, and GEE SMA's nitinol alloy rods have proven invaluable for mission success. These rods are designed to withstand extreme temperatures and stresses encountered during space missions while maintaining their exceptional mechanical properties. The use of nitinol sheets further enhances their adaptability, making them ideal for critical components such as actuators and connectors.

Custom Solutions Tailored for Diverse Needs

Recognizing that one size does not fit all, GEE SMA prides itself on offering custom solutions tailored specifically to client needs involving nickel material applications. Whether it’s a specialized nitinol rod or a bespoke sheet design, they work closely with clients to ensure optimal performance under unique operational conditions. This customer-centric approach not only solidifies their reputation as a trusted nitinol manufacturer but also drives innovation across various industries.

Challenges and Future of Nitinol Alloys

While the potential of nitinol alloys is vast, they are not without their challenges. One significant limitation of nitinol properties is their relatively high cost compared to traditional nickel alloys, which can deter some manufacturers from adopting them in large-scale production. Additionally, the unique characteristics that make nitinol alloy rods so appealing—such as the shape memory effect—can also lead to complexities in fabrication and processing that require specialized knowledge and equipment.

Limitations of Nitinol Properties

Nitinol's remarkable properties come with a few caveats that can impact its practicality in certain applications. For instance, while nitinol rods exhibit excellent fatigue resistance, they can be susceptible to stress-induced transformations that may limit their performance under extreme conditions. Furthermore, the variability in mechanical properties based on temperature changes can pose challenges for engineers designing components that must function reliably across a range of environments.

Ongoing Research and Development

To address these limitations, ongoing research into nitinol alloys is focused on enhancing their performance while reducing costs. Researchers are experimenting with various compositions of nickel materials to improve the stability and durability of nitinol sheets and rods. This innovation aims not only to optimize existing products but also to develop new applications where these unique nickel alloy features can shine—think medical devices or aerospace components designed with precision.

The Future Landscape of Nitinol Applications

Looking ahead, the future landscape for nitinol applications appears promising as industries continue to recognize its potential benefits over conventional materials. With advancements in manufacturing techniques by leading nitinol manufacturers, we may see a rise in affordable options for using these remarkable alloys across various sectors—from robotics to automotive engineering. As ongoing research unlocks new capabilities within nitinol properties, we could witness an explosion of innovative designs utilizing nitinol alloy rods that were previously thought impossible.

Conclusion

The journey through the world of nitinol alloys has revealed their transformative potential in engineering and design. Nitinol alloy rods, with their unique properties and versatility, are paving the way for innovations across various industries. As we embrace these remarkable nickel materials, we can expect to see even more groundbreaking applications that leverage their distinctive characteristics.

Nitinol Alloy Rods: Transforming Engineering

Nitinol alloy rods are not just another addition to the toolbox of engineers; they are revolutionizing how we approach mechanical design. These nickel alloys exhibit incredible flexibility and resilience, allowing designers to create components that can adapt to dynamic environments. From aerospace to medical devices, the integration of nitinol properties into engineering solutions is a game-changer that enhances performance while reducing weight and complexity.

The Essential Role of Shape Memory Alloys

At the heart of many innovations lies the fascinating concept of shape memory alloys (SMAs), with nitinol being a prime example. These materials can remember their original shapes after deformation, making them invaluable in applications where precision and reliability are paramount. The essential role of nitinol sheets and rods in creating responsive systems cannot be overstated; they provide engineers with tools that respond intelligently to changing conditions.

Future Prospects in Mechanical Design and Innovation

Looking ahead, the future prospects for nitinol alloys in mechanical design seem exceptionally bright. Ongoing research by innovative nitinol manufacturers is continually uncovering new applications and enhancing existing ones, ensuring that these materials will remain at the forefront of technological advancement. As industries increasingly recognize the benefits of incorporating nitinol rod solutions into their designs, we can anticipate a wave of creative breakthroughs driven by this extraordinary nickel material.