Introduction

In the realm of materials science, few innovations capture the imagination quite like shape memory alloys (SMAs). These remarkable metallic compounds possess the unique ability to return to a predetermined shape when subjected to specific temperature changes. This fascinating property not only showcases the wonders of material behavior but also opens doors to a myriad of applications across various industries.

What Are Shape Memory Alloys?

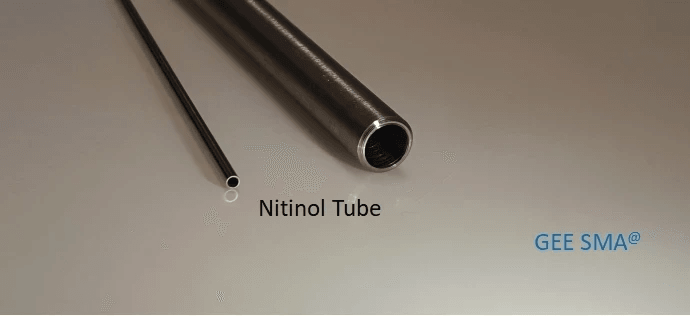

Shape memory alloys are special materials that can remember their original form after being deformed. When heated above a certain temperature, they revert to their pre-deformed shape, demonstrating an extraordinary physical phenomenon known as the shape memory effect. Commonly utilized in various forms, including wires and sheets, these alloys are primarily made from nickel and titanium, collectively known as Nitinol.

The Science Behind Shape Memory Alloys

The science behind shape memory alloys involves intricate phase transformations at the atomic level. When cooled below a critical temperature, SMAs exist in a low-temperature phase that allows them to be easily deformed; upon heating, they transition into a high-temperature phase where they regain their original structure. This transformation is not just an impressive trick; it’s rooted in solid-state physics and crystallography, making SMAs an exciting area of study for engineers and scientists alike.

Applications of Shape Memory Alloys

Shape memory alloys find themselves at home in numerous applications ranging from medical devices to aerospace engineering. In medicine, for example, SMA actuators are used in stents that expand at body temperature or surgical tools that can change shape during procedures. Beyond healthcare, industries such as robotics and automotive also leverage SMAs for components like sensors and actuators due to their reliability and efficiency.

Overview of Shape Memory Alloys

Shape memory alloys (SMAs) are fascinating materials that can remember their original shape after being deformed. These unique alloys undergo a phase transformation in response to temperature changes, allowing them to revert to their pre-deformed state when heated. This remarkable property makes SMAs an ideal choice for various applications, including medical devices, robotics, and aerospace engineering.

Definition and Characteristics

At the core of shape memory alloys is their ability to undergo a reversible phase change between two distinct crystal structures: the martensite phase and the austenite phase. When cooled below a certain temperature, SMAs become malleable and can be easily deformed; upon heating, they return to their original configuration with impressive force. This characteristic not only defines SMAs but also sets them apart from conventional materials, making them indispensable in modern technology.

Types of Shape Memory Alloys

There are several types of shape memory alloys, with nickel-titanium (Nitinol) being the most widely recognized due to its excellent performance and biocompatibility. Other notable SMAs include copper-aluminum-nickel and iron-based alloys, each offering unique properties suited for specific applications. The choice of SMA often depends on factors like thermal stability, mechanical strength, and environmental resistance.

Advantages of Using Shape Memory Alloys

One of the primary advantages of using shape memory alloys is their lightweight nature combined with high strength-to-weight ratios, making them perfect for applications where minimizing weight is crucial. Additionally, SMAs operate without requiring complex systems or motors; they can convert thermal energy directly into mechanical work through simple heating methods. This efficiency not only simplifies designs but also reduces costs associated with maintenance and energy consumption in devices like Shape Memory Alloy (SMA) actuators.

How Shape Memory Alloy (SMA) Actuators Work

Shape Memory Alloy (SMA) actuators are fascinating devices that leverage the unique properties of shape memory alloys to perform mechanical tasks. By undergoing phase transformations in response to temperature changes, these actuators can convert thermal energy into mechanical work. This remarkable ability allows them to return to a predetermined shape after being deformed, making them ideal for various applications.

Mechanism of Action

The mechanism of action for SMA actuators involves two primary phases: the austenite and martensite phases. When heated above a specific temperature, the SMA transitions from the martensite phase, which is pliable and can be easily deformed, to the rigid austenite phase. This transformation releases stored energy, allowing the actuator to return to its original shape and exert force in the process.

This unique behavior is not just limited to heating; cooling also plays a role in shaping an actuator's performance. As it cools down, it reverts back to its more flexible martensitic form, ready for another cycle of deformation and actuation when required. This cyclical process enables SMAs to function efficiently in dynamic environments where precision movement is crucial.

Design and Functionality

Designing Shape Memory Alloy (SMA) actuators involves careful consideration of their intended application and performance requirements. These actuators can be customized in terms of size, shape, and operating temperature ranges based on their specific use cases—ranging from robotics to aerospace applications. The compact nature of SMA actuators allows for integration into tight spaces where traditional motors might struggle.

Functionality-wise, SMA actuators are often used in systems requiring precise control over motion or force generation without needing bulky components or complex mechanisms. Their inherent simplicity makes them attractive for engineers looking for innovative solutions that are both lightweight and reliable while still delivering substantial power output when activated by heat or electrical stimuli.

Real-World Examples

Real-world applications of Shape Memory Alloy (SMA) actuators span multiple industries due to their versatility and efficiency. For instance, they are extensively used in medical devices such as stents that expand within blood vessels at body temperature—demonstrating both life-saving capabilities and smart engineering principles at work. Similarly, they find application in robotics where precise movements are essential; robotic grippers utilizing SMA technology can open or close with remarkable speed based on thermal activation.

Moreover, aerospace has seen innovations with SMAs being integrated into adaptive wing structures that change shape during flight for improved aerodynamics—a testament to how far this technology has come since its inception! As we continue exploring advancements in Shape Memory Alloy foil production techniques, we can expect even more groundbreaking uses that will reshape our understanding of movement and control across various fields.

The Process of Shape Memory Alloy Foil Production

The production of Shape Memory Alloy (SMA) foils is a fascinating journey that begins with careful material selection and ends with stringent quality control. These foils are essential components in various applications, from medical devices to aerospace technology, where their unique properties can be fully utilized. Understanding the intricacies of this process is crucial for anyone interested in the world of shape memory alloys.

Material Selection for Foils

Choosing the right materials for Shape Memory Alloy foil production is paramount to achieving optimal performance. Typically, nickel-titanium (Nitinol) is the alloy of choice due to its remarkable shape memory effect and biocompatibility. The exact composition can vary, but it often includes varying ratios of nickel and titanium, which influence the alloy's transformation temperatures and mechanical properties.

In addition to Nitinol, other alloys may be explored depending on specific application requirements; however, Nitinol remains a leader in this field due to its versatility. Factors like cost-effectiveness, availability, and desired performance characteristics play a significant role in material selection as well. Ultimately, selecting the right materials sets the foundation for successful Shape Memory Alloy foil production.

Manufacturing Techniques

Once materials have been selected for Shape Memory Alloy foil production, various manufacturing techniques come into play to create high-quality foils that meet industry standards. Common processes include cold rolling and hot working, which help achieve desired thicknesses while preserving the unique properties of SMAs. These techniques allow manufacturers to produce foils with specific shapes and dimensions tailored to their intended applications.

Another critical aspect involves heat treatment processes that enable the shape memory effect by controlling phase transformations within the alloy structure. This step ensures that when subjected to specific temperature changes or mechanical stresses, the SMA will return to its predetermined shape efficiently—an essential feature for SMA actuators in practical applications. The combination of these manufacturing techniques contributes significantly to achieving reliable and effective Shape Memory Alloy products.

Quality Control in Production

Quality control is an indispensable part of Shape Memory Alloy foil production that ensures each batch meets stringent specifications before reaching end-users. This process involves rigorous testing methods such as tensile strength assessments and thermal analysis to evaluate each foil's performance characteristics thoroughly. Additionally, non-destructive testing methods help identify any potential defects without compromising product integrity.

Manufacturers often implement standardized procedures throughout production lines for consistent quality assurance across all batches produced—this not only enhances reliability but also fosters trust among customers relying on these materials for critical applications like surgical instruments or actuators in robotics systems using SMAs. By maintaining high-quality standards during every stage—from material selection through manufacturing techniques—producers can ensure optimal outcomes while paving the way for innovative advancements within shape memory alloy technology.

Innovations in Shape Memory Alloy Technology

Shape memory alloys (SMAs) are experiencing a renaissance, with groundbreaking innovations propelling their use across various sectors. These advancements not only enhance the performance of existing applications but also pave the way for entirely new uses of SMAs. As industries seek more efficient and responsive materials, the spotlight is firmly on shape memory alloys, showcasing their versatility and adaptability.

Recent Developments in SMA

Recent developments in shape memory alloys have focused on optimizing their mechanical properties and expanding their operational capabilities. Research has led to the creation of new alloy compositions that improve fatigue resistance and thermal stability, making SMAs even more suitable for demanding environments. Moreover, advancements in manufacturing techniques for shape memory alloy foil production have enabled thinner, lighter foils that maintain high performance, opening doors to innovative applications in aerospace and robotics.

Another exciting area of development is the integration of smart technology with shape memory alloy actuators. By incorporating sensors and control systems into SMA devices, engineers can create more responsive systems that adapt to changing conditions in real-time. This synergy between SMAs and smart technology has great potential to revolutionize fields such as healthcare, where precise movements are critical.

Future Trends in SMA Applications

Looking ahead, the future trends for shape memory alloys suggest a significant expansion into new markets driven by technological advancements. One promising area is biomedical engineering; SMAs are increasingly being utilized in minimally invasive surgical tools due to their ability to change shape at body temperature. Additionally, as renewable energy technologies gain traction, there’s potential for SMAs to play a crucial role in energy harvesting systems through their unique thermal-to-mechanical energy conversion capabilities.

Furthermore, we can expect enhanced collaborations between academia and industry focused on developing more sustainable production methods for shape memory alloy foil production. This shift will not only reduce environmental impact but also lower costs associated with SMA manufacturing processes. As awareness grows regarding the benefits of SMAs across various sectors, we may witness an explosion of innovative products designed around these remarkable materials.

Case Studies of Successful Implementations

Several case studies highlight successful implementations of shape memory alloys that underscore their transformative potential across industries. For instance, NASA has explored using SMAs in space missions due to their lightweight nature and ability to operate under extreme conditions—making them ideal candidates for deployable structures like solar panels or antennae that need reliable actuation mechanisms when exposed to varying temperatures.

Another compelling example comes from the automotive sector where manufacturers have integrated shape memory alloy actuators into active suspension systems for vehicles. These systems adjust automatically based on road conditions and driving behavior—enhancing comfort while improving safety features significantly. Such implementations showcase how versatile SMAs can be when applied creatively within existing frameworks.

In conclusion, innovations surrounding shape memory alloys continue to reshape our understanding of material capabilities while expanding application horizons across diverse fields—from aerospace engineering to medical devices and beyond!

GEE SMA: A Leader in Nitinol Production

In the competitive landscape of shape memory alloy production, GEE SMA stands out as a leader, particularly known for its expertise in Nitinol, a unique alloy of nickel and titanium. With a commitment to innovation and quality, GEE SMA has developed advanced manufacturing processes that ensure the highest standards in shape memory alloy foil production and actuator performance. Their state-of-the-art facilities are equipped with cutting-edge technology that allows for precise control over material properties and product specifications.

Overview of GEE SMA’s Capabilities

GEE SMA boasts extensive capabilities in the design and production of shape memory alloys tailored to meet diverse industry needs. The company specializes in creating high-performance Shape Memory Alloy (SMA) actuators that can be utilized across various applications, from medical devices to aerospace components. By leveraging their deep understanding of material science and engineering, GEE SMA consistently delivers products that not only meet but exceed customer expectations.

Key Projects and Collaborations

Throughout its history, GEE SMA has been involved in numerous key projects that showcase its leadership in shape memory alloy technology. One notable collaboration was with a leading medical device manufacturer to develop innovative surgical tools utilizing Shape Memory Alloy actuators, enhancing precision and reducing recovery times for patients. These partnerships underscore GEE SMA's commitment to pushing the boundaries of what is possible with shape memory alloys while addressing real-world challenges.

Commitment to Quality and Customer Needs

Quality is at the forefront of GEE SMA’s operations; every step from material selection to shape memory alloy foil production is meticulously monitored to ensure optimal performance. The company employs rigorous quality control measures that guarantee each product meets stringent industry standards while being responsive to customer feedback for continuous improvement. This dedication not only fosters trust among clients but also solidifies GEE SMA's reputation as a reliable partner in developing cutting-edge solutions using shape memory alloys.

Conclusion

As we wrap up our exploration of shape memory alloys, it's clear that these remarkable materials are not just a scientific curiosity but a cornerstone of innovation in various industries. The future of shape memory alloys looks incredibly promising, with ongoing research and development paving the way for even more sophisticated applications. From medical devices to aerospace engineering, the versatility and unique properties of Shape Memory Alloy (SMA) actuators will undoubtedly play a pivotal role in shaping the technologies of tomorrow.

The Future of Shape Memory Alloys

Looking ahead, the future of shape memory alloys is bright and full of potential. Researchers are delving into advanced compositions and processing techniques to enhance the performance and expand the capabilities of SMAs, particularly in high-stress environments. This evolution will likely lead to more efficient Shape Memory Alloy foil production methods, enabling manufacturers to create lighter and stronger components that can adapt dynamically to their surroundings.

Why Choose GEE SMA for Your Projects

When it comes to selecting a partner for your projects involving shape memory alloys, GEE SMA stands out as an industry leader. Their expertise in producing high-quality SMAs ensures that clients receive reliable materials tailored to specific applications. With a commitment to innovation and customer satisfaction, GEE SMA is well-equipped to support your vision with cutting-edge solutions in Shape Memory Alloy (SMA) actuators.

Exploring the Impact of Shape Memory Alloys

The impact of shape memory alloys on various sectors cannot be overstated; they are revolutionizing how we approach engineering challenges today. From enhancing surgical procedures with minimally invasive tools to improving energy efficiency in automotive designs, SMAs are making waves across multiple fields. As we continue exploring their capabilities through advanced Shape Memory Alloy foil production techniques, we can expect even greater contributions from this fascinating technology.