Introduction

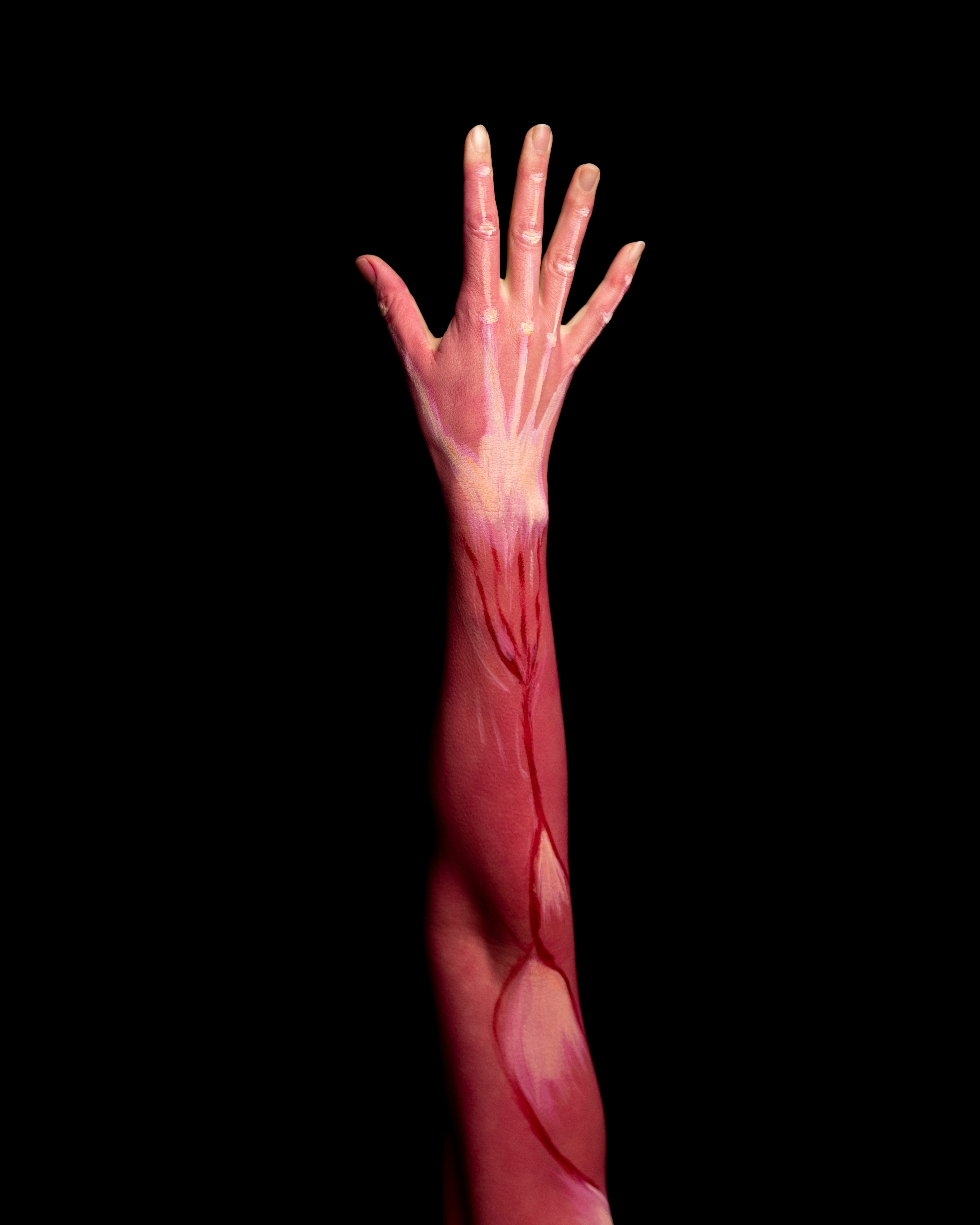

In the ever-evolving landscape of healthcare, the quest for improved vascular access methods has led to groundbreaking innovations that are transforming patient outcomes. Among these advancements, the introduction of specialized tools like the Niti guide wire medical stands out as a game-changer. By leveraging cutting-edge materials and technologies, we are witnessing a revolution in how medical professionals approach vascular procedures.

Revolutionizing Vascular Access with Innovation

The realm of vascular access is undergoing significant transformation, driven by the need for precision and efficiency in medical interventions. Innovations such as the ASTM F2063 Medical Grade Nitinol Guide Wire exemplify how modern engineering can enhance traditional practices. These advancements not only improve procedural success rates but also minimize patient discomfort and recovery times.

The Role of Nitinol in Medical Guidewires

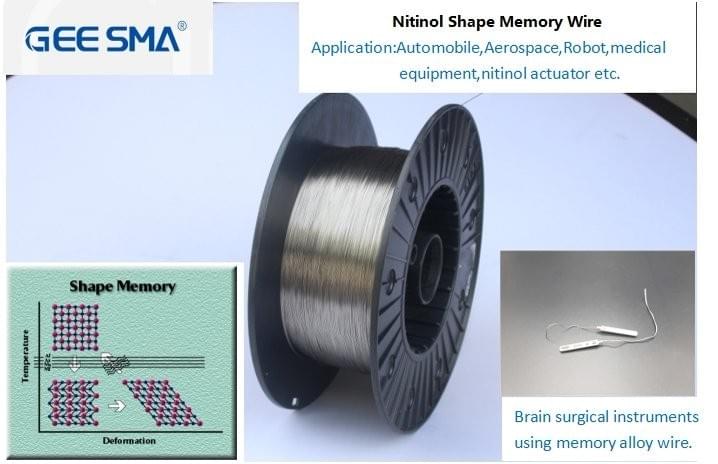

Nitinol, a unique nickel-titanium alloy known for its remarkable shape memory and flexibility, plays a pivotal role in the functionality of medical guidewires. The incorporation of nitinol into devices like the Niti guide wire medical allows for superior maneuverability within complex vascular structures, ensuring that healthcare providers can navigate with confidence. This material's ability to return to its original shape after deformation makes it an ideal choice for crafting reliable and resilient medical guidewires.

Importance of Quality in Medical Devices

In an industry where lives are at stake, quality cannot be compromised; it is paramount that every component meets rigorous standards. The ASTM F2063 Medical Grade Nitinol Guide Wire is designed not only to perform effectively but also to adhere strictly to safety regulations and quality assurance protocols. Ensuring top-notch quality in medical devices fosters trust between manufacturers and healthcare providers while ultimately enhancing patient care outcomes.

The Evolution of Vascular Access Technologies

The landscape of vascular access technologies has undergone a remarkable transformation over the decades. From rudimentary methods to sophisticated innovations, medical guidewires have played a pivotal role in enhancing procedural efficiency and patient outcomes. This evolution reflects not only technological advancements but also a deeper understanding of patient needs and safety protocols.

Historical Overview of Medical Guidewires

Medical guidewires have been integral to vascular procedures since their inception, evolving from simple metal rods to complex devices crafted from advanced materials like ASTM F2063 Medical Grade Nitinol Guide Wire. Early guidewires were often rigid and limited in their application, posing challenges for clinicians navigating intricate vascular pathways. However, the introduction of flexible and shape-memory alloys revolutionized the field, allowing for greater maneuverability and precision in accessing blood vessels.

Throughout the years, various innovations have emerged that enhanced the functionality of medical guidewires, including improved coatings to reduce friction and enhance biocompatibility. The development of nitinol-based guide wires marked a significant turning point; these wires could return to their original shape after deformation, making them incredibly versatile for various clinical applications. As we look back at this historical journey, it's clear that each advancement has paved the way for safer and more effective vascular access techniques.

Advances in Vascular Access Techniques

The advances in vascular access techniques are largely attributable to improvements in medical guidewire technology. With the introduction of nitinol-based products like the niti guide wire medical, healthcare professionals can now navigate challenging anatomical structures with unprecedented ease. These innovations allow for minimally invasive procedures that reduce recovery time and improve overall patient satisfaction.

Additionally, modern imaging technologies complement these advancements by providing real-time feedback during procedures—ensuring that clinicians can make informed decisions on-the-fly while utilizing medical guidewires effectively. Training programs have also evolved alongside these technologies; today’s healthcare providers are better equipped with knowledge about how to leverage these tools for optimal outcomes. Consequently, patients benefit from faster procedures with fewer complications thanks to these refined techniques.

Emerging Trends in Vascular Device Manufacturing

As we move further into the 21st century, emerging trends in vascular device manufacturing signal exciting possibilities for future developments in medical guidewire technology. One notable trend is the increasing focus on personalized medicine; manufacturers are exploring ways to customize devices like ASTM F2063 Medical Grade Nitinol Guide Wire based on individual patient anatomy or specific clinical scenarios. This level of customization could lead to even better performance during procedures.

Another trend is sustainability within manufacturing processes—companies are beginning to prioritize eco-friendly materials and practices without compromising product quality or efficacy. Innovations such as 3D printing technology also hold promise for creating highly specialized nitinol products tailored precisely for unique procedural needs or anatomical challenges faced by clinicians today. As these trends continue to unfold, they will undoubtedly shape the future landscape of vascular access technologies.

Understanding the Niti Guide Wire Medical Advantage

The Niti Guide Wire Medical stands out in the crowded field of medical guidewires due to its unique composition and design. Crafted from ASTM F2063 medical grade nitinol, this guide wire offers an unparalleled combination of flexibility and strength, making it a go-to choice for healthcare professionals. Its innovative properties not only enhance procedural outcomes but also improve patient safety, establishing it as a pivotal tool in vascular access.

What Makes Niti Guide Wire Special?

What truly sets the Niti Guide Wire Medical apart is its remarkable shape memory and superelastic properties derived from nitinol. This allows the guide wire to navigate complex vascular pathways with ease, reducing the risk of vessel trauma during insertion. Additionally, its ability to return to a pre-defined shape after deformation enhances reliability during critical procedures, ensuring that healthcare providers can trust their instruments under pressure.

The unique design of the Niti Guide Wire also facilitates precise maneuverability within challenging anatomies, making it ideal for various interventional procedures. Its responsiveness to body temperature further aids in achieving optimal performance during use. Ultimately, these features combine to create a medical guidewire that not only meets but exceeds industry standards for patient care.

Key Features of ASTM F2063 Medical Grade Nitinol Guide Wire

The ASTM F2063 medical grade nitinol guide wire boasts several key features that underscore its superiority in clinical applications. First and foremost is its exceptional biocompatibility; being made from nitinol ensures that it integrates well within the human body without eliciting adverse reactions. This characteristic is crucial for long-term implantation scenarios where compatibility can significantly affect patient outcomes.

Moreover, this guide wire's thin profile and enhanced torque response allow for superior navigation through tortuous vessels while minimizing friction against vessel walls. The result? A smoother procedure with less resistance and improved precision during catheter placement or other interventions involving vascular access points. Additionally, its corrosion resistance further guarantees durability over time—vital attributes when considering equipment longevity in busy healthcare environments.

Benefits of Using Nitinol in Medical Applications

Utilizing nitinol in medical applications like those seen with the Niti Guide Wire Medical provides numerous benefits that enhance both efficiency and effectiveness during procedures. The material's superelasticity translates into reduced risk of kinking or breakage under stress—a common concern with traditional materials used in medical guidewires. This resilience leads to greater confidence among clinicians when navigating delicate anatomical structures.

Furthermore, the lightweight nature of nitinol contributes positively to maneuverability without compromising strength or performance capabilities—an essential balance for any successful interventional procedure involving vascular access devices like those employing an ASTM F2063 medical grade nitinol guide wire. Patients benefit as well; faster recovery times are often achievable due to minimized trauma associated with more traditional approaches.

In summary, choosing the Niti Guide Wire Medical means opting for innovation backed by rigorous standards set forth by organizations such as ASTM International—ensuring quality at every turn while enhancing overall patient care outcomes across diverse clinical settings.

GEE SMA: The Backbone of Quality Manufacturing

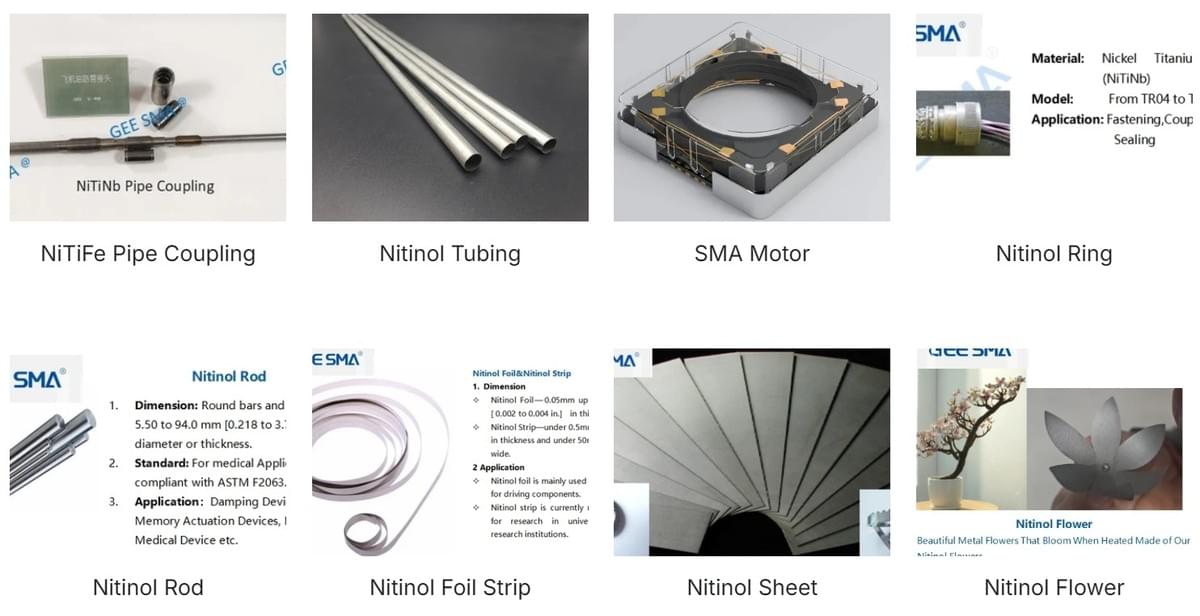

In the realm of vascular access, GEE SMA stands out as a cornerstone of quality manufacturing. With a focus on innovation and precision, GEE SMA has positioned itself as a leader in the production of advanced medical devices, including the ASTM F2063 Medical Grade Nitinol Guide Wire. Their commitment to excellence ensures that healthcare providers have access to reliable tools that enhance patient care.

Introduction to GEE SMA and Its Expertise

Founded with a vision to revolutionize medical device manufacturing, GEE SMA has built a reputation for expertise in developing cutting-edge technologies. Their team comprises skilled professionals who understand the complexities involved in producing high-quality medical guidewires tailored for various applications. By leveraging their knowledge and experience, they continuously push the boundaries of what’s possible with products like the niti guide wire medical.

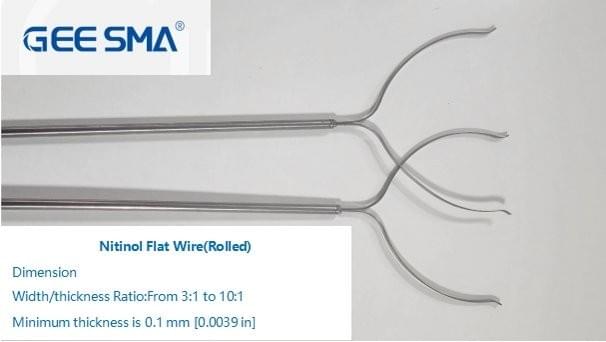

Role of GEE SMA in Nitinol Shape Memory Alloys

GEE SMA plays an instrumental role in harnessing the unique properties of nitinol shape memory alloys for medical applications. Nitinol's remarkable ability to return to its original shape after deformation makes it ideal for creating flexible yet durable guidewires, such as those used in vascular procedures. With their expertise, GEE SMA ensures that each ASTM F2063 Medical Grade Nitinol Guide Wire meets stringent performance standards essential for successful clinical outcomes.

Quality Assurance and Customer Satisfaction at GEE SMA

Quality assurance is at the heart of everything GEE SMA does; they employ rigorous testing protocols to ensure that every niti guide wire medical product is safe and effective for use in patients. Their dedication extends beyond just meeting regulatory requirements; they strive for customer satisfaction by incorporating feedback from healthcare professionals into their design processes. This commitment not only enhances product reliability but also fosters trust among clinicians who rely on these vital tools during procedures.

Clinical Applications and Case Studies

The clinical landscape is continually evolving, and the introduction of the Niti Guide Wire Medical has significantly impacted vascular access procedures. This innovative medical guidewire has been successfully employed in a variety of clinical scenarios, demonstrating its versatility and effectiveness in enhancing patient outcomes. By examining successful procedures, we can better understand how this ASTM F2063 Medical Grade Nitinol Guide Wire is transforming the way healthcare professionals approach vascular access.

Successful Procedures Using Niti Guide Wire Medical

The Niti Guide Wire Medical has been instrumental in a range of successful procedures, including percutaneous coronary interventions and peripheral vascular interventions. Its unique properties allow for improved navigation through complex vascular pathways, making it an indispensable tool for interventional cardiologists and radiologists alike. With its combination of flexibility and strength, this medical guidewire has facilitated numerous successful catheter placements that were previously challenging.

In one notable case study, a patient with severe arterial blockage underwent an angioplasty where the Niti guide wire medical was employed to navigate through tortuous anatomy. The procedure was completed with minimal complications, showcasing the wire's ability to maintain shape while providing excellent torque response. Such successes underscore the critical role that high-quality materials like ASTM F2063 Medical Grade Nitinol Guide Wire play in achieving optimal patient outcomes during intricate procedures.

Real-World Impact on Patient Care

The real-world impact of utilizing the Niti Guide Wire Medical extends beyond just technical success; it reflects positively on overall patient care and recovery times. Patients benefit from reduced procedure durations due to the guide wire’s superior navigational capabilities, which can lead to shorter hospital stays and quicker recoveries. This translates into less time under anesthesia and fewer post-operative complications—factors that are crucial for both patients and healthcare providers.

Moreover, healthcare teams have reported increased confidence when using this advanced medical guidewire during complex interventions. The reliability of the ASTM F2063 Medical Grade Nitinol Guide Wire ensures that clinicians can focus more on patient care rather than worrying about equipment performance issues. Ultimately, this results in enhanced trust between patients and their healthcare providers as they witness firsthand the benefits brought about by innovative technologies like the Niti guide wire medical.

Testimonials from Healthcare Professionals

Healthcare professionals across various specialties have praised the transformative effects of incorporating the Niti Guide Wire Medical into their practice routines. Surgeons frequently highlight its ease of use and adaptability during demanding cases where precision is paramount for successful outcomes. One interventional cardiologist noted that the flexibility of this medical guidewire allows me to navigate even the most challenging anatomies without hesitation.

Additionally, nurses assisting in these procedures have expressed appreciation for how streamlined operations become when using high-quality tools like ASTM F2063 Medical Grade Nitinol Guide Wire. They report less time spent troubleshooting equipment-related issues, allowing them to devote more attention to patient comfort and safety during interventions. Overall feedback emphasizes not only improved procedural success rates but also a significant boost in team morale as they utilize cutting-edge technology such as niti guide wire medical.

The Future of Vascular Access with Nitinol Technology

The future of vascular access is bright, especially with the continued integration of innovative technologies like Nitinol. As healthcare evolves, so do the tools and techniques used to enhance patient care, particularly in vascular procedures. The transformative potential of the Niti Guide Wire Medical is at the forefront of this evolution, promising to improve outcomes and streamline processes.

Innovations on the Horizon

Exciting advancements are on the horizon for medical guidewires powered by ASTM F2063 Medical Grade Nitinol. Researchers and manufacturers are exploring new designs that incorporate advanced imaging capabilities directly into guidewires, allowing for real-time visualization during procedures. Additionally, there’s a push towards developing smart guidewires that can communicate data back to medical devices or mobile applications for enhanced decision-making in critical situations.

Moreover, innovations in surface coatings and materials promise to reduce friction and enhance biocompatibility even further. These developments could lead to smoother insertion experiences and lower risks of complications such as thrombosis or infection. As these innovations materialize, they will position the Niti Guide Wire Medical as an indispensable tool in modern vascular access.

Potential Challenges and Solutions

Despite these promising advancements, challenges remain in fully realizing the potential of Nitinol technology in vascular access devices. One significant hurdle is ensuring consistent manufacturing quality across various production batches; maintaining compliance with ASTM F2063 standards is crucial for safety and efficacy. To tackle this challenge, companies must invest heavily in quality assurance protocols and robust testing methodologies that ensure every guide wire meets or exceeds industry benchmarks.

Additionally, there may be resistance from healthcare professionals who are accustomed to traditional methods; change often comes with skepticism. Education plays a vital role here—demonstrating through clinical studies how using a Niti Guide Wire Medical can improve patient outcomes will be paramount in gaining acceptance among practitioners. By addressing these challenges head-on with strategic solutions focused on education and quality control, the future looks promising for nitinol-based vascular access technologies.

How Niti Guide Wire Medical Can Adapt to Market Needs

To remain competitive in an evolving market landscape, Niti Guide Wire Medical must stay agile and responsive to emerging trends and customer feedback. This adaptability involves not only investing in R&D but also fostering strong relationships with healthcare providers to understand their needs better—after all, they are on the front lines using these devices daily. By actively engaging with clinicians about their experiences with medical guidewires, manufacturers can identify areas for improvement or innovation.

Furthermore, embracing digital transformation can significantly enhance operational efficiency while also improving product offerings; think telemedicine consultations combined with advanced imaging systems integrated into guidewires! This holistic approach ensures that products align closely with market demands while enhancing patient care quality overall. Ultimately, by being proactive rather than reactive to market shifts and clinician input, Niti Guide Wire Medical can solidify its position as a leader in vascular access solutions.

Conclusion

In conclusion, the advancements in vascular access technologies, particularly through the use of the Niti Guide Wire Medical, have significantly transformed how medical professionals approach vascular procedures. The innovative properties of ASTM F2063 Medical Grade Nitinol Guide Wire not only enhance procedural efficiency but also improve patient outcomes. As healthcare continues to evolve, these innovations will play a crucial role in shaping future practices.

Transformative Impact on Vascular Procedures

The introduction of the Niti Guide Wire Medical has revolutionized vascular procedures by providing unmatched flexibility and strength. Its unique design allows for easier navigation through complex vascular pathways, reducing procedure times and enhancing overall safety for patients. This transformative impact is evident in numerous clinical applications where successful outcomes have been achieved thanks to its superior performance.

The Critical Need for Quality in Medical Devices

Quality assurance is paramount when it comes to medical devices, especially those involved in critical procedures like vascular access. The ASTM F2063 Medical Grade Nitinol Guide Wire exemplifies this necessity by adhering to stringent manufacturing standards that ensure reliability and safety during use. As healthcare providers increasingly rely on advanced technologies, maintaining high-quality benchmarks becomes essential for fostering trust and efficacy within the medical community.

Looking Ahead: The Future of Vascular Access Solutions

Looking ahead, the future of vascular access solutions appears promising with continuous innovations on the horizon. The adaptability of Niti Guide Wire Medical ensures that it can meet evolving market needs while addressing potential challenges associated with new technologies. By prioritizing quality and innovation, we can anticipate a significant leap forward in patient care and procedural success rates.