Introduction

Shape memory alloys (SMAs) are fascinating materials that can remember their original shape after being deformed, returning to it when exposed to specific stimuli, typically temperature changes. This unique property makes them invaluable in various industries, leading to innovative applications ranging from aerospace to medical devices and civil engineering. As the demand for advanced materials grows, understanding the properties and uses of shape memory alloys is crucial for harnessing their full potential.

Overview of Shape Memory Alloys

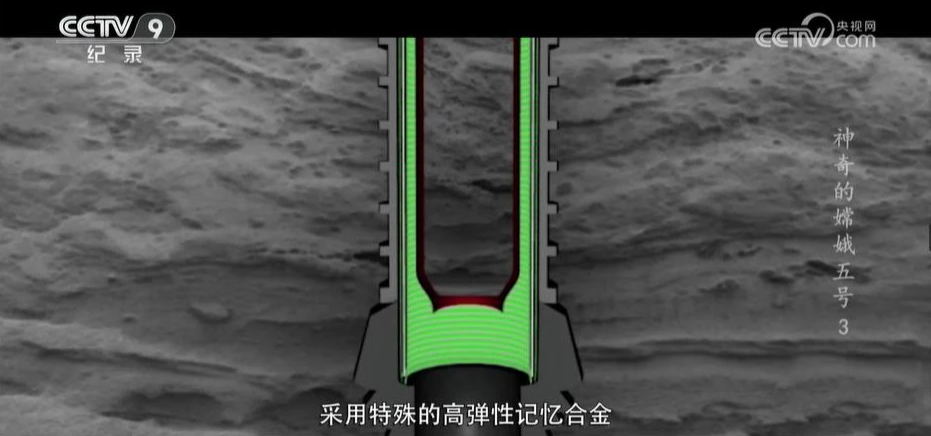

At the heart of shape memory alloys is a remarkable mechanism that allows these materials to undergo a phase transformation when subjected to heat or stress. This transformation enables them to revert back to their pre-deformed shapes, showcasing exceptional elasticity and resilience. The diverse types of SMAs include nickel-titanium (Nitinol), copper-aluminum-nickel, and iron-based alloys, each with distinct thermal and mechanical properties that cater to different applications.

Significance of Nitinol in Industry

Nitinol stands out among shape memory alloys due to its impressive combination of strength, flexibility, and biocompatibility, making it particularly significant in medical applications such as stents and surgical tools. Its unique characteristics allow for minimally invasive procedures that enhance patient safety and recovery times. Beyond healthcare, Nitinol's applications extend into aerospace and automotive industries where its shape memory capabilities contribute to innovative designs and improved performance.

GEE SMA's Role in Shape Memory Alloys

GEE SMA plays a pivotal role in advancing the field of shape memory alloys through research and development focused on enhancing their properties and expanding their uses across various sectors. By innovating new formulations of SMAs like Nitinol, GEE SMA aims to push the boundaries of what these materials can achieve in challenging environments such as space exploration or earthquake-resistant structures in civil engineering projects. Their commitment not only drives technological progress but also underscores the importance of sustainable practices within the industry.

Understanding Shape Memory Alloys Properties

Shape memory alloys (SMAs) are fascinating materials that exhibit unique properties, allowing them to return to a predetermined shape when subjected to specific thermal conditions. This remarkable behavior is primarily due to the phase transformation between two distinct structural forms: the austenite and martensite phases. The unique mechanism of shape memory not only underpins their functionality but also opens doors for diverse applications across various industries.

Unique Mechanism of Shape Memory

The core of the unique mechanism in shape memory alloys lies in their ability to undergo a reversible phase change. When heated above a certain temperature, the alloy transforms from its martensitic state, which is more pliable and can be deformed, into its austenitic state, which is rigid and exhibits its original shape. This transition allows for numerous shape memory alloys uses, particularly in fields where precise movements or adjustments are essential.

The mechanism also enables these materials to remember their original form after deformation, providing significant advantages in applications ranging from aerospace engineering to medical devices. For instance, in stents used in minimally invasive surgeries—one of the prominent shape memory alloys in medical applications—this property ensures that they expand correctly once placed inside the body at body temperature. The ability to revert back effortlessly makes SMAs indispensable across various sectors.

Thermal and Mechanical Properties

Thermal properties play a crucial role in determining how effectively shape memory alloys can be utilized across different applications. These materials typically have high thermal expansion coefficients and can undergo significant changes in volume with temperature variations, enhancing their responsiveness. Furthermore, their mechanical properties include excellent fatigue resistance and strength-to-weight ratios that make them ideal candidates for innovative designs.

In terms of mechanical performance, SMAs exhibit superelasticity—a phenomenon where they can withstand large strains without permanent deformation when loaded above their transformation temperature. This characteristic is particularly beneficial for civil engineering applications like seismic protection systems where structures must endure dynamic loads without compromising integrity. By leveraging these thermal and mechanical properties effectively, engineers can design systems that adapt dynamically while ensuring long-term reliability.

Material Composition and Types

The composition of shape memory alloys significantly influences their performance characteristics and suitability for specific uses. Commonly used SMAs include nickel-titanium (Nitinol), copper-aluminum-nickel (Cu-Al-Ni), and iron-based alloys—each offering distinct advantages tailored for particular applications within aerospace or medical fields among others. Nitinol is particularly popular due to its superior biocompatibility and excellent mechanical properties that have made it a staple in many medical devices.

Different types of SMAs are engineered with varying compositions to optimize attributes such as transformation temperatures or corrosion resistance depending on the intended application environment—be it space exploration or surgical procedures. The diversity in material composition allows researchers and engineers alike to explore innovative solutions while addressing specific challenges associated with each industry’s demands concerning shape memory alloys advantages.

Shape Memory Alloys Uses in Aerospace

Shape memory alloys (SMAs) have carved out a niche for themselves in the aerospace industry, showcasing their remarkable properties and applications. These materials exhibit unique behaviors that allow them to return to a predetermined shape when subjected to specific thermal conditions. In this section, we will explore the various uses of shape memory alloys in aerospace, highlighting their significance in space exploration, satellite technology innovations, and contributions from GEE SMA.

Applications in Space Exploration

The applications of shape memory alloys in space exploration are nothing short of revolutionary. SMAs can be found in actuators for deployable structures such as solar panels and antennas, which are critical for spacecraft functionality. Their ability to change shape with temperature variations allows for reliable performance under the extreme conditions of space, making them essential components for successful missions.

In addition to structural applications, shape memory alloys are also employed in mechanisms that require precise movement and positioning. For example, they can be used in robotic arms or gripping devices intended for planetary exploration or sample collection on celestial bodies. The unique properties of SMAs ensure that these mechanisms operate effectively even when subjected to the harsh vacuum and temperature fluctuations of outer space.

Furthermore, ongoing research into advanced SMA composites is paving the way for even more innovative uses within aerospace applications. As scientists continue to explore the potential of these materials, we can expect groundbreaking developments that will enhance our capabilities in exploring distant planets and asteroids.

Innovations in Satellite Technology

Shape memory alloys are at the forefront of innovations within satellite technology as well. Their lightweight nature combined with high strength makes them ideal candidates for various satellite components where weight reduction is crucial without compromising performance. SMAs enable sophisticated designs that maximize functionality while minimizing mass—an essential requirement for any spacecraft.

One notable innovation involves using SMAs in deployable structures like antennas and solar arrays on satellites. The ability of these materials to return to a specific shape upon heating allows engineers to design compact systems that expand once deployed into orbit—enhancing communication capabilities significantly without adding unnecessary bulk during launch.

Moreover, advancements involving smart materials like shape memory alloys are leading towards more autonomous satellite systems capable of self-repairing or adapting their configuration based on environmental conditions encountered during operation. Such innovations could revolutionize how satellites function and interact with their surroundings while improving reliability and longevity.

GEE SMA’s Contributions to Space Missions

GEE SMA has been instrumental in advancing the role of shape memory alloys within space missions through pioneering research and development efforts focused on optimizing material properties specifically tailored for aerospace applications. By leveraging their expertise, GEE SMA has contributed significantly by providing innovative solutions that address challenges faced by engineers designing spacecraft components.

Their contributions include developing specialized SMA actuators designed explicitly for deployment mechanisms used on satellites—ensuring robust performance under varying thermal conditions experienced during launch and operation phases alike. This commitment not only enhances mission success rates but also promotes greater efficiency across multiple projects involving international collaborations focused on deep-space exploration initiatives.

Additionally, GEE SMA continues pushing boundaries by exploring new combinations of materials aimed at improving overall durability while maintaining lightweight characteristics essential for modern aerospace engineering standards today—a testament to how vital shape memory alloys' uses are becoming across diverse fields beyond just medical applications or civil engineering endeavors!

Shape Memory Alloys in Medical Applications

Shape memory alloys (SMAs) have revolutionized the medical field, offering innovative solutions that enhance patient care and surgical outcomes. Their unique properties allow them to revert to a predetermined shape upon heating, making them ideal for various medical applications. From stents to surgical devices, the versatility of shape memory alloys uses is transforming how healthcare professionals approach treatment.

Use in Stents and Surgical Devices

One of the most prominent shape memory alloys applications in medical devices is in stents, which are used to keep arteries open after balloon angioplasty. Nitinol, a type of SMA, is especially favored due to its ability to expand at body temperature while maintaining flexibility during insertion. This capability significantly improves the efficacy of stenting procedures and reduces complications associated with traditional rigid stents.

In addition to stents, SMAs are increasingly used in other surgical devices such as guidewires and catheters. These tools benefit from the unique properties of shape memory materials, allowing for easier navigation through complex vascular systems during minimally invasive procedures. The adaptability and reliability of SMAs make them essential components in modern surgical practices.

Advantages in Minimally Invasive Surgery

The advantages of using shape memory alloys in minimally invasive surgery are substantial. By leveraging their unique properties, surgeons can perform complex procedures with smaller incisions, leading to reduced recovery times and less postoperative pain for patients. This shift towards less invasive techniques aligns perfectly with current trends emphasizing patient comfort and quicker return to daily activities.

Moreover, the flexibility provided by SMAs allows for greater maneuverability within tight anatomical spaces without compromising device integrity or performance. As a result, these materials not only enhance surgical precision but also minimize trauma to surrounding tissues—an essential aspect when considering long-term patient outcomes. The growing reliance on shape memory alloys applications underscores their pivotal role in advancing surgical methodologies.

Biocompatibility and Safety

When discussing shape memory alloys advantages in medical applications, biocompatibility is paramount. Nitinol exhibits excellent compatibility with human tissue; it does not provoke significant immune responses or adverse reactions when implanted within the body. This property ensures that devices made from SMAs can remain safely inside patients over extended periods without causing complications.

Safety considerations extend beyond biocompatibility; they also encompass device functionality under physiological conditions. Shape memory alloys maintain their mechanical properties even after repeated stress cycles within the body—an important factor for long-term reliability in medical devices like stents and implants. As healthcare continues evolving towards more effective treatments, understanding both the benefits and limitations of shape memory alloys will guide future innovations.

Shape Memory Alloys Applications in Civil Engineering

Shape memory alloys (SMAs) are revolutionizing civil engineering with their unique properties and innovative applications. Their ability to return to a predetermined shape when subjected to specific thermal conditions makes them ideal for various structural applications. In this section, we will explore the diverse uses of shape memory alloys in civil engineering, focusing on seismic protection systems, smart structures and actuators, and their long-term performance and reliability.

Seismic Protection Systems

One of the most significant shape memory alloys uses in civil engineering lies in seismic protection systems. These systems leverage the unique properties of SMAs to absorb and dissipate energy during an earthquake, thereby enhancing a structure's resilience against seismic forces. By integrating SMAs into building designs, engineers can create structures that not only withstand earthquakes but also adapt dynamically to changing conditions.

The advantages of using shape memory alloys in these applications include reduced damage during seismic events and lower repair costs afterward. Moreover, SMAs can be designed to activate automatically when triggered by ground motion, offering a proactive approach to earthquake safety. This innovative use of shape memory materials positions them as critical components in future-proofing infrastructure against natural disasters.

Smart Structures and Actuators

Incorporating smart structures into modern engineering is another exciting application for shape memory alloys. These materials enable the development of actuators that can respond intelligently to environmental stimuli such as temperature or stress changes. By utilizing SMAs in these systems, engineers can create structures that adjust themselves automatically—think buildings that can flex or bend to accommodate wind loads or shifting foundations.

The benefits of employing shape memory alloys for smart structures extend beyond mere adaptability; they also improve overall safety and efficiency. For instance, bridges equipped with SMA-based actuators can self-correct minor misalignments over time without manual intervention or costly repairs. This level of automation represents a significant advancement in civil engineering practices while showcasing the versatility of shape memory alloys applications.

Long-term Performance and Reliability

When evaluating the long-term performance and reliability of materials used in construction, shape memory alloys stand out due to their durability and fatigue resistance. Unlike traditional materials that may degrade over time under constant stress or environmental exposure, SMAs retain their functionality through numerous cycles of deformation without losing their unique properties. This longevity makes them ideal candidates for critical infrastructure projects where reliability is paramount.

Furthermore, ongoing research into improving SMA formulations continues to enhance their properties for civil engineering applications—leading to even more robust solutions for various challenges faced by modern infrastructure projects today. The combination of superior performance characteristics with innovative design possibilities solidifies the role of shape memory alloys as essential components within the field of civil engineering moving forward.

Advantages and Disadvantages of Shape Memory Alloys

Shape memory alloys (SMAs) are fascinating materials that bring a unique blend of benefits and challenges to various industries. Understanding the advantages and disadvantages of shape memory alloys is crucial for their effective application, especially in fields such as aerospace, medicine, and civil engineering. By examining these aspects, we can better appreciate how shape memory alloys can revolutionize technology while also acknowledging the hurdles they present.

Benefits of Using Shape Memory Alloys

One of the standout characteristics of shape memory alloys is their ability to return to a predetermined shape when subjected to specific thermal conditions, making them highly versatile in numerous applications. In medical applications, for instance, SMAs are utilized in stents that expand at body temperature, providing a minimally invasive solution for patients with vascular issues. Additionally, in civil engineering, shape memory alloys applications include seismic protection systems that automatically adapt to changes in environmental conditions, enhancing structural resilience.

Furthermore, the lightweight nature of shape memory materials contributes significantly to their appeal in aerospace applications where reducing weight can lead to improved fuel efficiency and overall performance. Another advantage is their biocompatibility; this property ensures that SMAs can be safely used within the human body without causing adverse reactions. The combination of these benefits makes shape memory alloys an attractive choice across various sectors.

Limitations and Challenges Faced

Despite their many advantages, there are limitations associated with the use of shape memory alloys that must be addressed. One significant challenge is their relatively high cost compared to traditional materials; this factor can limit widespread adoption in some industries where budget constraints are critical. Additionally, while SMAs offer impressive mechanical properties under certain conditions, they may not perform well under extreme stress or fatigue over time.

Another limitation lies in the complexity involved in processing these materials; achieving consistent results often requires specialized techniques and equipment that may not be readily available everywhere. Furthermore, understanding shape memory alloys properties requires extensive research and development efforts which can add time and expense to projects involving these innovative materials. Addressing these challenges is essential for maximizing the potential of SMAs across various applications.

Evaluating Cost vs. Performance

When considering any material for industrial use—especially one as specialized as a shape memory alloy—evaluating cost versus performance becomes paramount. While initial investments might be higher due to manufacturing complexities or material costs associated with SMAs, long-term savings could be realized through reduced maintenance needs or enhanced operational efficiencies in applications like aerospace or civil engineering structures.

For instance, although implementing shape memory alloys in medical devices may seem costly upfront compared to conventional alternatives, their unique properties often lead to better patient outcomes and lower overall healthcare costs due to fewer complications during procedures like minimally invasive surgeries. Therefore, it's vital for stakeholders across industries—including those involved with shape memory alloys uses—to weigh both immediate financial implications against potential long-term benefits when making decisions about adopting SMA technologies.

In summary, while exploring the advantages and disadvantages of shape memory alloys reveals compelling reasons for their use across multiple fields—from medical innovations like stents to civil engineering solutions—the challenges they present cannot be overlooked either. Balancing cost with performance will ultimately determine how widely these remarkable materials will reshape our world.

Conclusion

In conclusion, shape memory alloys (SMAs) are revolutionizing various industries by harnessing their unique properties and applications. From aerospace to medicine and civil engineering, the versatility of SMAs is evident in their diverse uses. As we look to the future, the potential for further innovation in shape memory materials continues to grow, promising exciting developments across multiple fields.

Transforming Industries with Shape Memory Alloys

Shape memory alloys are transforming industries by introducing innovative solutions that enhance performance and efficiency. In medical applications, for instance, the use of SMAs in stents has significantly improved patient outcomes through minimally invasive procedures. Similarly, in civil engineering, shape memory alloys applications have led to advancements in seismic protection systems that better safeguard structures during earthquakes.

Future Trends in Shape Memory Materials

The future of shape memory materials looks bright as researchers explore new compositions and manufacturing techniques to expand their capabilities. Emerging trends include the development of more environmentally friendly SMAs that maintain high performance while reducing ecological impact. Additionally, advancements in smart technologies will likely lead to even more sophisticated applications of shape memory alloys across various sectors.

GEE SMA’s Commitment to Innovation

GEE SMA is at the forefront of this exciting evolution, dedicated to pushing the boundaries of what shape memory alloys can achieve. Their commitment to innovation ensures that they remain a key player in both existing markets and emerging opportunities within medical and civil engineering fields. By continuously investing in research and development, GEE SMA exemplifies how companies can leverage the advantages of shape memory alloys while addressing some disadvantages through improved material formulations.