Introduction

Welcome to the fascinating world of Nitinol, where science meets innovation in the most remarkable ways. This unique alloy, composed primarily of nickel and titanium, showcases extraordinary properties that make it a game-changer in various industries. Among its many applications, the NiTiFe Pipe Coupling stands out as a prime example of how shape memory alloys can revolutionize everyday life.

The Marvel of Nitinol Components

Nitinol components are nothing short of a marvel, exhibiting exceptional abilities that set them apart from traditional materials. With their unique niti properties, these shape memory metals can return to their original form after deformation when exposed to specific temperatures. This incredible feature not only enhances functionality but also opens doors to innovative designs across multiple sectors.

Understanding Shape Memory Alloys

At the heart of Nitinol's allure lies the concept of shape memory alloys (SMAs), which possess the ability to remember their original shape after being deformed. When discussing ni cu and its role in enhancing these alloys, it's important to note how temperature changes trigger this transformation. As we delve deeper into the mechanics behind SMAs, it becomes clear that understanding these properties is essential for harnessing their full potential in engineering and design.

Applications of Nitinol in Everyday Life

The applications of Nitinol are as diverse as they are impressive, impacting fields ranging from medical devices to aerospace technology. For instance, products like stents and guidewires leverage the unique characteristics of shape memory alloys for improved patient outcomes and enhanced performance. Additionally, consumer products utilizing Nitinol showcase its versatility—whether it's eyewear frames that adjust for comfort or innovative fasteners that adapt with temperature changes—this alloy is truly making waves in our daily lives.

What is Nitinol?

Nitinol, a remarkable alloy of nickel and titanium, is often hailed as a game-changer in various industries due to its unique properties. This shape memory alloy (SMA) exhibits extraordinary characteristics that differentiate it from traditional metals. Understanding the composition and structure of Nitinol helps illuminate why it plays such a pivotal role in modern technology, including applications like NiTiFe Pipe Coupling.

Composition and Structure

Nitinol consists primarily of nickel (Ni) and titanium (Ti), with some variations incorporating iron (Fe), resulting in the NiTiFe Pipe Coupling variant. The specific ratios of these elements can significantly influence the material's properties, making precise control during production essential. The crystal structure of Nitinol changes between two phases: austenite at high temperatures and martensite at low temperatures, which underpins its unique functionality.

Unique Nitinol Properties

The exceptional properties of Nitinol stem from its ability to undergo phase transformations between austenite and martensite, enabling it to return to its original shape after deformation—this is what we call the shape memory effect. Additionally, Nitinol displays superelasticity, allowing it to absorb significant stress without permanent deformation; this makes it invaluable for applications such as NiTiFe Pipe Coupling where flexibility is crucial. These niti properties make Nitinol not just another metal but a versatile solution for complex engineering challenges.

Importance of Shape Memory Effect

The shape memory effect is arguably the star feature that sets shape memory metals apart from their traditional counterparts. When subjected to specific temperature conditions, these alloys can remember their original form—a property that has vast implications in fields ranging from medical devices to aerospace engineering. For instance, in medical applications like stents or guidewires made from Nitinol, this effect allows for minimally invasive procedures while ensuring maximum efficacy once deployed inside the body.

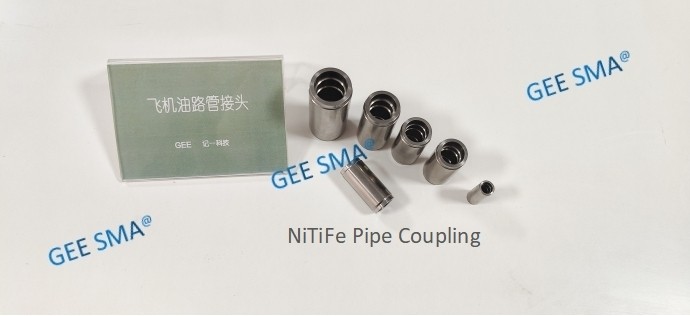

NiTiFe Pipe Coupling Explained

When it comes to modern piping solutions, the NiTiFe Pipe Coupling stands out as a remarkable innovation. This coupling utilizes the unique properties of shape memory alloys, specifically a combination of nickel (Ni), titanium (Ti), and iron (Fe), to deliver exceptional functionality. By leveraging the distinctive behavior of shape memory metals, these couplings can adapt to varying temperatures and pressures, ensuring a reliable connection in dynamic environments.

Functionality of NiTiFe Pipe Coupling

The functionality of NiTiFe Pipe Coupling is rooted in its ability to undergo phase transformations. At certain temperatures, this shape memory alloy can revert to its original shape after being deformed, providing a tight seal that is resistant to leaks. This characteristic makes it particularly useful in applications where traditional couplings might fail due to thermal expansion or contraction.

Additionally, the unique niti properties allow for self-tightening capabilities under stress, which means that these couplings can maintain their integrity even in fluctuating conditions. The adaptability of the NiTiFe Pipe Coupling reduces maintenance needs and enhances overall system durability. In industries where reliability is paramount, such as oil and gas or chemical processing, this innovative solution is invaluable.

Applications in Industry

NiTiFe Pipe Couplings find diverse applications across various sectors due to their robust performance characteristics. In the oil and gas industry, for instance, they are used extensively for connecting pipelines that transport high-pressure fluids safely and efficiently. Their resilience against corrosion further extends their usability in harsh environments where traditional materials might corrode or degrade over time.

Moreover, these couplings are also making waves in aerospace applications where weight savings without compromising strength are critical factors. The lightweight nature of shape memory alloys makes them ideal for use in aircraft systems requiring reliable fluid transfer under extreme conditions. Beyond aerospace and energy sectors, you’ll find NiTiFe Pipe Couplings being employed in automotive applications as well—think fuel lines designed for high efficiency!

Advantages Over Traditional Couplings

The advantages of using NiTiFe Pipe Couplings over traditional coupling methods are compelling enough to make engineers reconsider their choices. First off, the inherent flexibility provided by shape memory metals allows these couplings to accommodate thermal fluctuations without losing their sealing capability—something traditional metal couplings often struggle with under similar conditions.

Additionally, thanks to their self-tightening feature derived from unique niti properties, maintenance becomes significantly less frequent compared to conventional options that may require regular inspections and adjustments. Finally, with improved resistance against wear and corrosion due to their material composition—specifically with nickel enhancing durability—NiTiFe Pipe Couplings not only save time but also cut down costs long-term by reducing replacement frequencies.

Braiding Techniques for Nitinol

Nitinol, with its remarkable properties as a shape memory alloy, offers exciting possibilities in various applications. Among these are advanced braiding techniques that enhance the utility of Nitinol components. This section delves into the methods of braiding Nitinol, the benefits it brings, and how GEE SMA stands at the forefront of this innovation.

Overview of Braiding Methods

Braiding techniques for Nitinol involve intertwining strands of this unique material to create durable and flexible structures. There are several approaches to braiding, including traditional three-dimensional braiding and more complex multi-layered methods that optimize strength and flexibility. These processes leverage the distinct niti properties of Nitinol, allowing for intricate designs that can be tailored to specific applications like NiTiFe Pipe Coupling.

The choice of braiding method significantly impacts the final product's performance characteristics, such as elasticity and shape retention. By combining different braid patterns or integrating other materials like ni cu (Nickel-Copper) alloys, manufacturers can achieve desired mechanical properties while retaining the essential shape memory effect integral to Nitinol's functionality. This versatility makes braided Nitinol an attractive option for industries looking to innovate.

Benefits of Braided Nitinol Components

Braided Nitinol components offer several advantages over their non-braided counterparts, primarily due to their enhanced flexibility and strength-to-weight ratio. The unique structure created through braiding allows these components to withstand significant stress while maintaining their ability to return to a predetermined shape after deformation—a hallmark of shape memory metals. This feature is particularly beneficial in applications such as NiTiFe Pipe Coupling where reliability under pressure is crucial.

Moreover, braided configurations can improve fatigue resistance compared to solid forms of Nitinol or other materials used in similar applications. The ability to absorb energy during operation means that products made from braided Nitinol can endure repeated cycles without failure, making them ideal for dynamic environments such as aerospace or medical devices. Additionally, these components often exhibit improved thermal conductivity due to their design, further enhancing their performance in various settings.

GEE SMA’s Expertise in Braiding

GEE SMA has positioned itself as a leader in the development and production of braided Nitinol components thanks to its commitment to innovation and quality craftsmanship. With extensive experience in utilizing shape memory alloys like nitinol combined with advanced manufacturing techniques, GEE SMA excels at creating bespoke solutions tailored specifically for client needs—whether that's enhancing NiTiFe Pipe Coupling designs or developing new consumer products utilizing these remarkable materials.

Their state-of-the-art facilities enable precision control over every aspect of the braiding process, ensuring that each product meets stringent industry standards while maximizing performance characteristics inherent in niti properties such as fatigue resistance and temperature responsiveness. Furthermore, GEE SMA’s team continuously explores new methodologies and technologies within the realm of shape memory metals ensuring they remain at the cutting edge of this evolving field.

Forming Processes for Nitinol

Nitinol, a unique shape memory alloy primarily composed of nickel and titanium, showcases remarkable properties that enable it to return to its original shape when heated. The forming processes for Nitinol are critical in shaping this material into functional components that leverage its extraordinary characteristics. Understanding these processes not only enhances the utility of Nitinol in various applications but also paves the way for innovations like the NiTiFe Pipe Coupling.

Techniques for Shaping Nitinol

Shaping Nitinol involves several specialized techniques tailored to exploit its unique properties, including its ability to undergo significant deformation while retaining memory of its original form. Common methods include hot working, cold working, and a variety of thermal treatments that help achieve desired geometries and mechanical properties. Additionally, advanced techniques such as laser cutting and electroforming are gaining traction, allowing manufacturers to create intricate designs that enhance the functionality of products like NiTiFe Pipe Couplings.

Significance of Forming in Product Development

The forming processes for Nitinol are vital in product development because they directly influence the performance and reliability of the final product. By carefully controlling how Nitinol is shaped, manufacturers can optimize its mechanical properties, ensuring that it performs effectively under varying conditions—especially important for applications involving shape memory metals in medical devices or aerospace components. Furthermore, effective forming techniques can lead to cost savings and improved efficiency during production stages.

Examples of Formed Nitinol Products

Numerous innovative products utilize formed Nitinol components across various industries due to their unique properties. In medicine, stents made from this shape memory alloy expand at body temperature, providing life-saving interventions with minimal invasiveness. Similarly, the automotive sector benefits from formed Nitinol parts used in actuators and sensors; meanwhile, NiTiFe Pipe Couplings exemplify how this technology can revolutionize traditional coupling methods by providing flexibility and strength under pressure.

Real-World Applications of Nitinol

Nitinol, with its remarkable properties and versatility, has found a plethora of applications across various industries. From medical devices that save lives to innovative aerospace solutions and even consumer products that enhance daily living, the impact of this shape memory alloy is profound. Let's dive into some of the fascinating ways Nitinol is shaping our world.

Nitinol in Medical Devices

One of the most significant contributions of Nitinol lies in the medical field, where its unique properties are harnessed to create life-saving devices. Surgical tools, stents, and guidewires made from this shape memory metal exhibit incredible flexibility and strength, allowing for minimally invasive procedures. The shape memory effect ensures that these devices can return to their original form after deformation, making them ideal for complex anatomical structures.

Moreover, the biocompatibility of Nitinol makes it a preferred choice for implants and prosthetics. For instance, NiTiFe Pipe Coupling systems are being explored for use in orthopedic applications due to their ability to adapt under stress while maintaining structural integrity. As research continues to unveil more about Nitinol's ni cu composition and its benefits in medical technology, we can expect even more groundbreaking innovations on the horizon.

Aerospace Innovations with Nitinol

In the aerospace sector, Nitinol is revolutionizing how we think about materials used in flight technology. Its lightweight nature combined with high strength allows aircraft components to be both durable and efficient—crucial factors when every ounce counts in aviation design. Shape memory alloys like Nitinol can also be utilized in actuators that adjust wing configurations during flight or adapt landing gear mechanisms based on varying conditions.

The unique niti properties allow engineers to design systems that respond dynamically to environmental changes without heavy mechanical components. This adaptability not only improves performance but also enhances safety features within aircraft systems. As aerospace companies continue exploring new applications for NiTiFe Pipe Coupling technologies, we may soon see more efficient air travel options emerging from these innovations.

Consumer Products Utilizing Nitinol

Beyond industrial applications, everyday consumer products are also benefiting from the incorporation of Nitinol’s remarkable characteristics. From self-heating coffee mugs that adjust temperature based on your preferences to eyeglass frames that return to their original shape after bending—the possibilities seem endless! The use of shape memory metals provides an innovative twist on traditional designs while enhancing functionality.

Additionally, some fashion brands have started utilizing braided Nitinol components in jewelry and accessories due to their unique aesthetic appeal paired with resilience against wear and tear. These products not only showcase modern design but also highlight how far we've come in integrating advanced materials into our daily lives—thanks largely to advancements like those offered by GEE SMA’s expertise in braiding techniques. With ongoing research into ni cu compositions and further enhancements on existing technologies like NiTiFe Pipe Couplings, it's clear that our relationship with this extraordinary alloy will only deepen over time.

Conclusion

In conclusion, the future of Nitinol applications is bright and brimming with potential. As industries continue to explore the remarkable capabilities of shape memory alloys, we can expect innovative solutions that leverage the unique properties of NiTiFe pipe coupling and other Nitinol components. From medical devices to aerospace technologies, the versatility of shape memory metals promises to transform how we approach engineering challenges.

The Future of Nitinol Applications

The future of Nitinol applications is poised for exponential growth as researchers and engineers uncover new uses for this extraordinary material. With its unique niti properties, particularly its shape memory effect, Nitinol is likely to play a pivotal role in sectors like robotics and smart materials. Imagine a world where NiTiFe pipe coupling systems enhance fluid transport efficiency or where shape memory alloys revolutionize consumer products like self-healing electronics—this is only the beginning.

GEE SMA’s Role in Advancing Nitinol Technology

GEE SMA stands at the forefront of advancing Nitinol technology, continually pushing boundaries with innovative solutions that harness the power of shape memory alloys. Their expertise in developing high-quality NiTiFe pipe coupling products exemplifies their commitment to enhancing industrial applications while ensuring reliability and performance. By investing in research and development, GEE SMA not only enhances existing technologies but also pioneers new methods for integrating niti properties into everyday life.

Key Takeaways on Nitinol and Its Impact

Nitinol's impact on various industries cannot be overstated; it has redefined expectations for what materials can achieve. The combination of its unique properties—especially in terms of shape memory effect—alongside innovations like NiTiFe pipe coupling makes it a game-changer across multiple fields from healthcare to aerospace engineering. As we look ahead, understanding these advancements will be crucial for leveraging shape memory metals effectively and sustainably.