Introduction

In the ever-evolving world of materials science, NiTiFe alloys stand out for their unique properties and versatile applications. These remarkable materials, composed of nickel, titanium, and iron, exhibit shape memory and superelasticity, making them invaluable in various industries. As demand grows for innovative solutions that leverage these characteristics, understanding the role of GEE SMA becomes crucial.

Understanding NiTiFe Alloys

NiTiFe alloys are a fascinating blend of metals that offer exceptional performance under stress and temperature variations. Their unique composition allows them to return to a predetermined shape when heated or deformed, which opens up a world of possibilities in engineering and design. With applications ranging from medical devices to aerospace components, the importance of NiTiFe alloys cannot be overstated.

The Role of GEE SMA in the Market

GEE SMA has positioned itself as a key player in the production and distribution of NiTiFe alloys, catering to diverse market needs with precision and expertise. Their commitment to innovation ensures that they remain at the forefront of technological advancements in this field. By providing high-quality NiTiFe materials tailored for specific applications, GEE SMA plays an essential role in driving industry progress.

Why Choose GEE SMA for Your Needs

Their focus on customer satisfaction ensures that clients receive not just products but comprehensive support throughout their projects. With a dedication to excellence and continuous improvement, GEE SMA is your go-to partner for all things related to NiTiFe.

What Are NiTiFe Alloys?

NiTiFe alloys, also known as nickel-titanium-iron alloys, are fascinating materials that blend the unique properties of shape memory and superelasticity. These alloys are primarily composed of nickel (Ni), titanium (Ti), and iron (Fe), which work together to create a remarkable combination of strength and flexibility. The addition of iron enhances the mechanical properties of NiTiFe, making it a preferred choice in various demanding applications.

Composition and Characteristics

The composition of NiTiFe alloys is crucial to their performance traits. Typically, these alloys consist of approximately 50% nickel, 50% titanium, with varying amounts of iron added—usually around 5-10%. This specific ratio not only grants these materials their characteristic phase transformation but also contributes to their ability to return to a predetermined shape when heated or deformed.

One standout characteristic of NiTiFe is its impressive ability to undergo significant deformation while still returning to its original form upon heating. This property makes it particularly valuable in applications where reliability and resilience are paramount. Additionally, NiTiFe exhibits excellent corrosion resistance due to its alloying elements, ensuring durability even in harsh environments.

Applications Across Industries

NiTiFe alloys find themselves at home in a wide array of industries due to their unique properties. In the aerospace sector, these materials are used for actuators and components that require lightweight yet strong solutions capable of enduring extreme conditions. Similarly, in the medical field, NiTiFe is often employed in stents and guidewires where flexibility and shape memory capabilities can significantly improve patient outcomes.

The automotive industry has also embraced NiTiFe alloys for applications like active suspension systems and safety features that require precise responses during operation. Their versatility extends even further into consumer electronics where they contribute to innovative designs that demand both functionality and aesthetic appeal. Clearly, the adaptability of NiTiFe makes it an essential material across various sectors.

Benefits of Using NiTiFe Alloys

Utilizing NiTiFe alloys provides numerous advantages that can elevate product performance across different applications. One major benefit is their ability to operate effectively under varying temperature conditions without losing functionality—an essential trait for industries like aerospace or medical devices where environmental fluctuations are common.

Additionally, the lightweight nature combined with high strength means that products made from NiTiFe can be designed more efficiently without compromising on quality or safety standards. Lastly, using these advanced materials can lead to cost savings over time by reducing maintenance needs and enhancing product longevity—a win-win situation for manufacturers looking for reliable solutions.

GEE SMA: A Leader in NiTiFe Production

With a rich history and a robust commitment to innovation, the company has established itself as a trusted provider of high-quality NiTiFe alloys. This section delves into GEE SMA's journey, its unwavering dedication to quality assurance, and the exciting advancements it brings to alloy development.

Company History and Expertise

GEE SMA began its journey several decades ago with a vision to revolutionize the materials landscape through advanced alloys like NiTiFe. Over the years, the company has garnered extensive expertise in metallurgy, allowing it to refine its production processes continually. This historical foundation not only enhances their credibility but also positions them as leaders in providing state-of-the-art NiTiFe solutions for diverse applications.

The team at GEE SMA comprises seasoned professionals who bring years of experience and knowledge in alloy technology. Their collective expertise facilitates innovative approaches that keep pace with industry demands while ensuring that each batch of NiTiFe alloy meets stringent standards. As a result, clients can trust that they are receiving products developed by experts who understand both the science and application of these unique materials.

Commitment to Quality Assurance

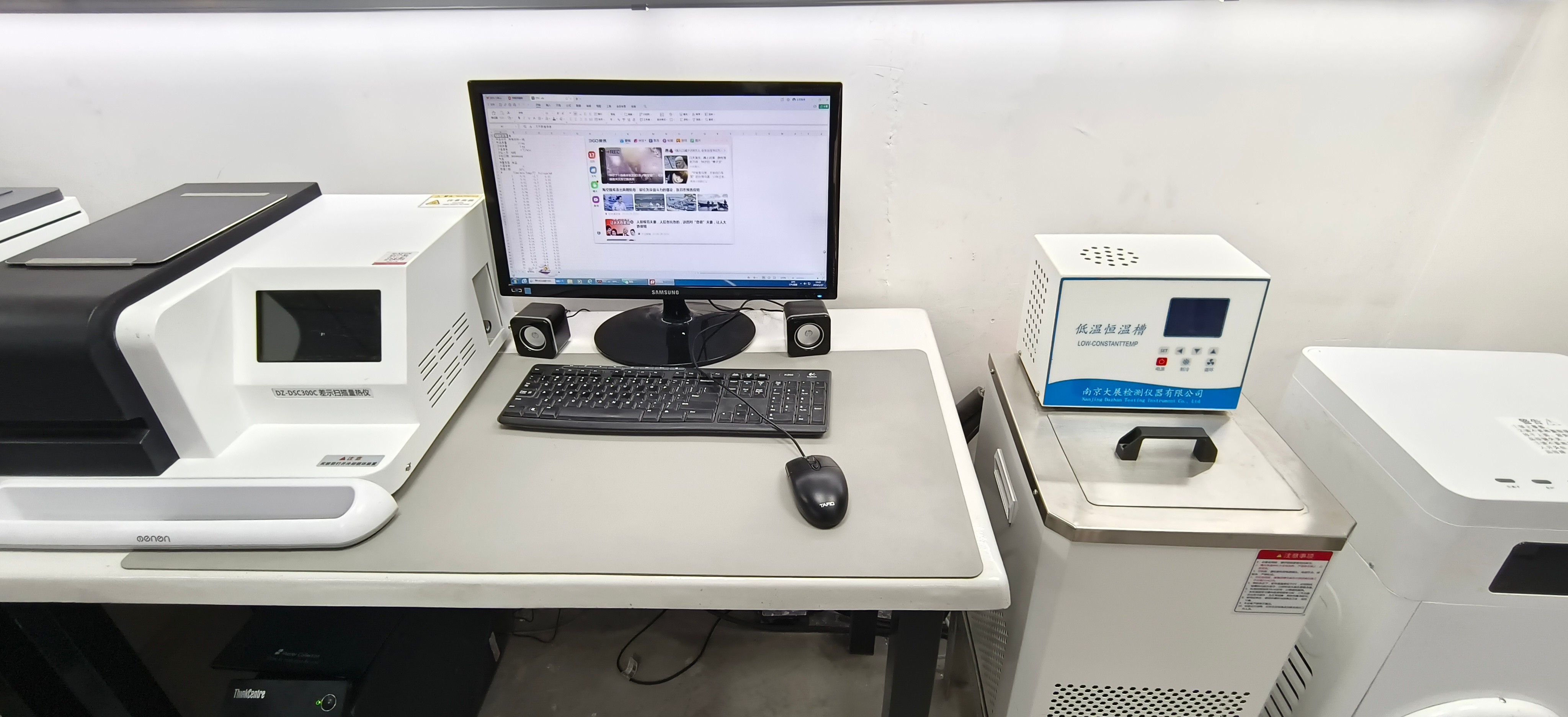

At GEE SMA, quality assurance is not just an afterthought; it's woven into every aspect of their operations. The company employs rigorous testing protocols for all its NiTiFe products, ensuring they meet or exceed industry specifications before reaching customers' hands. This commitment guarantees that whether used in aerospace components or medical devices, each piece delivers reliability and performance.

Moreover, GEE SMA continuously invests in state-of-the-art technology for quality control throughout the production process. From raw material selection to final inspections, every step is meticulously monitored by skilled technicians dedicated to upholding the highest standards of excellence in NiTiFe manufacturing. This unwavering focus on quality ensures that clients can confidently integrate GEE SMA’s products into their projects without concerns about material integrity.

Innovations in Alloy Development

Innovation is at the heart of GEE SMA’s mission as they strive to push boundaries within the realm of NiTiFe alloys. The company actively engages in research and development initiatives aimed at enhancing alloy properties such as strength, flexibility, and thermal responsiveness—key attributes that make NiTiFe ideal for various applications across industries.

By collaborating with academic institutions and industry leaders, GEE SMA stays ahead of emerging trends while fostering an environment where creativity thrives within their teams. These innovations not only lead to improved product offerings but also help clients solve complex challenges by providing tailored solutions using advanced NiTiFe technologies.

In conclusion, GEE SMA's leadership position stems from its rich history rooted in expertise, steadfast commitment to quality assurance practices, and relentless pursuit of innovation within alloy development—especially regarding their exceptional range of NiTiFe products.

Applications of NiTiFe Alloys

NiTiFe alloys, known for their unique shape memory and superelastic properties, have carved a niche across various industries. Their versatility makes them indispensable in applications ranging from aerospace to medical devices and automotive innovations. Let's dive into how these remarkable materials are being utilized today.

Aerospace and Defense Uses

In the aerospace sector, NiTiFe alloys are celebrated for their ability to withstand extreme temperatures and stress while maintaining structural integrity. These materials are often employed in critical components such as actuators, couplings, and sensors, where reliability is non-negotiable. The shape memory effect allows for lightweight designs that can significantly enhance fuel efficiency in aircraft.

Additionally, the defense industry benefits from NiTiFe's resilience under harsh conditions. Components made from these alloys can adapt to varying environmental stresses without compromising performance. As a result, they play a pivotal role in the development of advanced military equipment and systems.

Medical Device Advancements

Their biocompatibility combined with superelastic properties makes them ideal for a range of applications including stents, guidewires, and orthopedic implants. These devices can undergo significant deformation during insertion but return to their original shape once deployed within the body.

Moreover, the use of NiTiFe in minimally invasive surgical tools has transformed patient care by reducing recovery times and improving outcomes. The ability to tailor these alloys for specific medical applications ensures that healthcare providers have access to cutting-edge technology that meets patient needs effectively. Thus, NiTiFe continues to pave the way for innovation in medical device engineering.

Automotive Innovations

The automotive industry is another area where NiTiFe alloys shine brightly due to their unique properties that contribute to safety and performance enhancements. From active suspension systems that improve ride comfort to smart seatbelt mechanisms that adapt during collisions—these materials offer solutions that were previously unimaginable.

Furthermore, manufacturers are increasingly integrating NiTiFe into engine components where high temperature resistance is crucial for performance optimization. This not only leads to more efficient engines but also reduces emissions—a win-win situation for both automakers and environmentally conscious consumers alike.

How GEE SMA Supports Your Projects

When it comes to NiTiFe alloys, GEE SMA is not just a supplier; we are your strategic partner. Our focus is on providing comprehensive support that aligns with your project goals, ensuring that you receive exactly what you need when you need it. Whether you're looking for custom solutions or rapid responses, our commitment to excellence in NiTiFe production shines through every aspect of our service.

Custom Solutions and Tailored Products

Understanding that each project is unique, GEE SMA specializes in crafting custom solutions tailored specifically to your requirements. Our team works closely with clients to develop NiTiFe alloys that meet precise specifications, whether for aerospace applications or cutting-edge medical devices. This bespoke approach ensures optimal performance and reliability in every product we deliver.

In addition to standard offerings, we also provide tailored products designed to fit niche applications within various industries. By leveraging our extensive knowledge of NiTiFe materials and their properties, we can engineer solutions that enhance functionality while maintaining cost-effectiveness. With GEE SMA by your side, you can trust that your project will benefit from the most suitable alloy configurations available.

Rapid Response to Customer Needs

In today’s fast-paced market, timing is everything—and GEE SMA understands this better than anyone else when it comes to NiTiFe projects. We pride ourselves on our ability to respond quickly and efficiently to customer inquiries and requests for assistance. Our streamlined processes ensure that whether you need a quick quote or urgent delivery of specialized alloys, we're ready to meet those demands without compromising quality.

Our dedicated customer service team is always on standby, prepared to address any questions or concerns regarding your order or project specifications involving NiTiFe alloys. This proactive approach allows us not only to react swiftly but also anticipate potential challenges before they arise—keeping your project on track and within budget.

Case Studies: Successful Collaborations

To illustrate how GEE SMA successfully supports projects involving NiTiFe alloys, let's look at some notable collaborations we've had across industries. One example includes a partnership with an aerospace company where we developed a specialized NiTiFe alloy used in actuators for advanced flight control systems. The result was enhanced performance metrics and significant weight savings—demonstrating the transformative impact of our tailored solutions.

Another case involved working with a medical device manufacturer needing a unique alloy for stents designed for minimally invasive procedures. By customizing the properties of the NiTiFe material used in their devices, we helped them achieve improved flexibility and biocompatibility while ensuring compliance with stringent regulatory standards.

These case studies exemplify how GEE SMA not only meets but exceeds client expectations through innovation and collaboration in the realm of NiTiFe alloys.

The Future of NiTiFe Alloys

The future of NiTiFe alloys is not just bright; it’s positively glowing with potential. As industries evolve and demand for advanced materials increases, the versatility and unique properties of NiTiFe are set to play a pivotal role in various applications. With ongoing research and development, we can expect exciting innovations that will further enhance the capabilities of these remarkable alloys.

Emerging Trends in Material Science

Material science is witnessing a renaissance, with NiTiFe alloys at the forefront of several emerging trends. One significant trend is the increasing interest in smart materials that respond to environmental changes, making NiTiFe an ideal candidate due to its shape memory and superelastic properties. Additionally, sustainability is becoming paramount; researchers are exploring eco-friendly production methods for NiTiFe alloys that minimize environmental impact while maintaining performance.

Another noteworthy trend is the integration of artificial intelligence (AI) and machine learning in material design processes. These technologies help optimize alloy compositions, leading to improved performance characteristics tailored for specific applications. As these trends continue to evolve, the adaptability of NiTiFe will ensure its relevance across multiple sectors.

The Impact of Technology Advancements

Technological advancements are revolutionizing how we produce and utilize NiTiFe alloys. Innovations such as additive manufacturing (3D printing) allow for more complex geometries and designs that were previously unattainable with traditional methods. This capability not only enhances functionality but also reduces material waste, aligning with contemporary sustainability goals.

Moreover, advancements in characterization techniques enable scientists to better understand the behavior of NiTiFe under various conditions, paving the way for improved reliability and performance in critical applications like aerospace and medical devices. As technology continues to advance at breakneck speed, we can anticipate even more groundbreaking developments that will push the boundaries of what’s possible with NiTiFe alloys.

GEE SMA’s Vision for Tomorrow

At GEE SMA, our vision for tomorrow revolves around harnessing the full potential of NiTiFe alloys through innovation and collaboration. We are committed to staying ahead by investing in research initiatives that explore new alloy formulations and processing techniques tailored to meet future demands across industries. Our goal is not just to adapt but to lead in creating cutting-edge solutions that leverage the unique properties of NiTiFe.

We also envision fostering partnerships with academic institutions and industry leaders to drive forward-thinking projects focused on sustainable practices in alloy production. By aligning our efforts with emerging trends in material science, GEE SMA aims to ensure that our clients benefit from state-of-the-art products designed for tomorrow's challenges today. Together, we can shape a future where NiTiFe alloys play an integral role across diverse sectors.

Conclusion

In the ever-evolving landscape of materials science, NiTiFe alloys stand out as a beacon of innovation and versatility. Their unique properties make them indispensable across various industries, from aerospace to medical devices. As we look to the future, understanding and utilizing NiTiFe alloys will be crucial for businesses seeking a competitive edge.

Why NiTiFe Alloys Matter Today

NiTiFe alloys are not just another entry in the materials handbook; they represent a significant leap forward in performance and application potential. Their shape memory and superelastic properties open doors to solutions that were previously thought impossible. With industries increasingly focusing on efficiency and reliability, the importance of NiTiFe alloys has never been more pronounced.

Choosing GEE SMA for Quality and Reliability

When it comes to sourcing NiTiFe alloys, GEE SMA emerges as a trusted partner with a proven track record of excellence. Our commitment to quality assurance ensures that every product meets stringent industry standards, providing peace of mind for our clients. By choosing GEE SMA, you’re not just selecting an alloy supplier; you’re opting for a partner dedicated to your success.

Getting Started with GEE SMA Products

Embarking on your journey with GEE SMA is straightforward and tailored to meet your specific needs regarding NiTiFe products. We offer custom solutions designed around your project requirements, ensuring optimal performance in real-world applications. Connect with us today to explore how our innovative offerings can elevate your projects into new realms of possibility.