Introduction

Nitinol, a remarkable alloy of nickel and titanium, has captured the attention of various industries due to its unique properties and versatile applications. Understanding nitinol components is essential for anyone looking to harness the benefits of this extraordinary material in fields such as medicine and engineering. From nitinol wire used in innovative medical devices to specialized medical tubing, the possibilities are virtually endless.

Understanding Nitinol Components

Nitinol components are engineered to exhibit specific characteristics that set them apart from traditional metals. The unique combination of nickel and titanium allows these components to respond dynamically to temperature changes, enabling shape memory and superelasticity. This understanding is crucial for manufacturers seeking reliable solutions in high-performance applications, particularly in the realm of nitinol wire medical innovations.

The Unique Properties of Nitinol

The nitinol properties that make it so appealing include its ability to return to a predetermined shape when heated—a phenomenon known as the shape memory effect. Additionally, its superelasticity allows it to undergo significant deformation without permanent change, making it an ideal choice for various applications where flexibility and resilience are paramount. These unique characteristics not only enhance product performance but also improve patient outcomes in nitinol medical devices.

Applications of Nitinol in Various Industries

Nitinol's versatility extends across numerous industries beyond healthcare; from aerospace engineering to robotics, its applications are vast and varied. In the medical field, for instance, nitinol wire is often utilized in stents and guidewires due to its biocompatibility and mechanical properties—qualities that ensure safety and effectiveness within the human body. As more companies recognize the advantages provided by this innovative material, partnering with a reputable nitinol manufacturer becomes increasingly important for sourcing high-quality components tailored to specific needs.

What is Nitinol?

Nitinol, a remarkable alloy of nickel and titanium, has captured the attention of various industries due to its unique properties. This shape memory alloy can return to a predetermined shape when heated, making it invaluable in applications ranging from medical devices to robotics. Understanding what makes nitinol components so special is key to appreciating their widespread use.

Overview of Nitinol Composition

The composition of nitinol typically consists of approximately 50-60% nickel and 40-50% titanium. This specific ratio is crucial as it determines the alloy's distinctive properties, such as its ability to undergo phase transformations at different temperatures. When considering nitinol wire or medical tubing, it's essential to recognize how this unique blend contributes to the overall functionality and reliability of these materials.

The Science Behind Shape Memory Alloys

What sets nitinol apart from other materials is its fascinating behavior as a shape memory alloy (SMA). When deformed at lower temperatures, it can remember its original shape when heated above a certain transition temperature—this phenomenon is known as the shape memory effect. This characteristic allows for innovative designs in nitinol medical devices and applications that require precise movement or adjustment without mechanical parts.

Why Choose Nitinol Components

Choosing nitinol components for your projects offers numerous advantages that enhance performance and efficiency. The combination of biocompatibility and excellent mechanical properties makes nitinol wire an ideal choice for sensitive applications like surgical tools and stents. Moreover, partnering with a reputable nitinol manufacturer ensures access to high-quality materials tailored to meet specific needs in various industries.

Nitinol Wire: Versatile Applications

Nitinol wire is a remarkable material that has revolutionized the landscape of medical devices and beyond. Its unique properties, such as shape memory and superelasticity, make it a preferred choice for various applications in the healthcare sector. From stents to guidewires, nitinol components are at the forefront of medical innovation.

Uses in Medical Devices

Nitinol wire has found its niche in a myriad of medical devices due to its exceptional flexibility and biocompatibility. It is commonly used in applications like stents, catheters, and surgical tools where precision and reliability are paramount. The ability of nitinol wire to return to its original shape after deformation makes it ideal for devices that require minimal invasiveness and maximum effectiveness.

Nitinol Wire Medical Innovations

The innovations brought about by nitinol wire in the medical field are nothing short of groundbreaking. For instance, self-expanding stents made from nitinol components have transformed cardiovascular procedures by reducing recovery times and improving patient outcomes. Moreover, advancements such as nitinol guidewires allow for enhanced maneuverability through complex vascular systems, showcasing the versatile applications of this incredible material.

Advantages of Nitinol Wire

Choosing nitinol wire comes with several advantages that set it apart from other materials used in medical devices. First off, its unique properties—like shape memory—allow it to adapt to various conditions while maintaining structural integrity under stress. Additionally, being biocompatible ensures that nitinol components can be safely utilized within the human body without adverse reactions, making them a go-to choice for leading nitinol manufacturers looking to innovate in the healthcare industry.

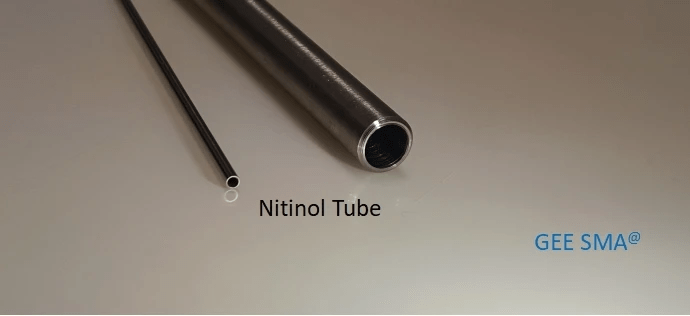

Nitinol Medical Tubing: A Game Changer

Nitinol medical tubing is revolutionizing the healthcare sector with its unique properties and versatility. This specialized tubing is made from nitinol components, a nickel-titanium alloy known for its remarkable shape memory and superelastic characteristics. As advancements in medical devices continue to evolve, the role of nitinol tubing becomes increasingly significant, offering solutions that were once deemed impossible.

Exploring Medical Applications

The applications of nitinol medical tubing span a wide range of medical devices, from stents to guidewires and beyond. Its ability to return to a predetermined shape when heated makes it ideal for use in minimally invasive surgeries, where flexibility and strength are paramount. Additionally, nitinol wire medical innovations are paving the way for breakthroughs in cardiovascular procedures and orthopedic implants, highlighting the importance of these specialized components in modern medicine.

Benefits of Nitinol Tubing

One of the standout benefits of using nitinol tubing is its exceptional biocompatibility; this means it can be safely used within the human body without adverse reactions. The unique thermal properties of nitinol allow it to perform effectively even under varying body temperatures, making it suitable for a variety of applications. Moreover, its superelasticity ensures that nitinol components can withstand significant deformation without losing their original shape—an essential feature for any reliable medical device.

Leading Nitinol Manufacturers

When sourcing quality nitinol components, partnering with reputable nitinol manufacturers is crucial. Companies like GEE SMA specialize in producing high-quality nitinol wire and tubing tailored to meet specific medical needs while adhering to stringent industry standards. By choosing a trusted nitinol company like GEE SMA, you gain access to custom solutions that leverage the latest advancements in material science—ensuring your projects benefit from the best that nitinol has to offer.

Nitinol Properties: Why They Matter

When it comes to nitinol components, understanding their unique properties is essential for leveraging their full potential, especially in medical applications. Nitinol, a nickel-titanium alloy, exhibits remarkable characteristics that set it apart from traditional materials. This section delves into the unique shape memory capabilities of nitinol, its biocompatibility factors, and its thermal and mechanical properties.

Unique Shape Memory Characteristics

One of the standout features of nitinol wire is its shape memory effect, which allows it to return to a predetermined shape when heated above a certain temperature. This property makes nitinol components incredibly useful in various medical devices where precision and reliability are paramount. For instance, in nitinol medical devices like stents and guidewires, this ability enhances performance by enabling them to adapt seamlessly within the human body.

The transformation between two distinct phases—martensite and austenite—enables these unique characteristics. When cold-formed into one shape (martensite), heating allows it to revert to its original form (austenite). This remarkable property not only improves functionality but also opens doors for innovative designs in nitinol wire medical applications.

Biocompatibility Factors

Biocompatibility is crucial for materials used in medical applications; fortunately, nitinol boasts excellent biocompatibility factors that make it suitable for implantation within the human body. The alloy's composition minimizes adverse reactions with bodily tissues while promoting healing processes—a key consideration for any nitinol manufacturer aiming to produce safe medical tubing or devices.

Moreover, the corrosion resistance of nitinol enhances its longevity inside the body, reducing the risk of complications associated with material degradation over time. This reliability makes it an attractive choice for various applications in healthcare settings where patient safety is paramount.

Thermal and Mechanical Properties

Nitinol components are not just about shape memory; they also exhibit impressive thermal and mechanical properties that contribute significantly to their effectiveness in demanding environments. The alloy can withstand extreme temperatures without losing its structural integrity—a vital characteristic for both surgical instruments and implantable devices made from nitinol wire or tubing.

Additionally, the superelastic behavior of nitinol allows it to endure significant deformation without permanent change—a feature highly beneficial during procedures requiring flexibility and resilience from medical devices. These thermal and mechanical properties position nitinol as a superior choice among other materials available on the market today.

Sourcing Quality Nitinol Components

When it comes to sourcing quality nitinol components, the choice of manufacturer can significantly impact the performance and reliability of your products. With a growing array of nitinol companies in the market, it’s crucial to evaluate their experience, capabilities, and reputation. Selecting the right nitinol manufacturer ensures that you receive high-quality materials that meet industry standards for applications such as nitinol wire and medical tubing.

Choosing the Right Nitinol Company

Choosing the right nitinol company requires careful consideration of several factors, including their production processes and quality control measures. Look for manufacturers with a proven track record in producing reliable nitinol components that exhibit desirable nitinol properties like shape memory and superelasticity. Additionally, customer testimonials and case studies can provide insights into how well a company meets specific needs in creating innovative nitinol medical devices.

A reputable company should also be transparent about their sourcing of raw materials and manufacturing techniques. This transparency is vital to ensure that the nitinol wire or medical tubing you receive is not only effective but also safe for its intended applications. Ultimately, investing time in selecting a reputable supplier will pay dividends in product performance and longevity.

GEE SMA: A Trusted Nitinol Manufacturer

GEE SMA stands out as a trusted nitinol manufacturer known for its commitment to quality and innovation in producing various nitinol components. With extensive experience in crafting high-performance nitinol wire and medical tubing, GEE SMA has established itself as a leader in the field. Their rigorous testing protocols ensure that every batch meets stringent industry standards while maintaining exceptional mechanical properties.

What sets GEE SMA apart is their dedication to understanding customer needs; they work closely with clients to develop tailored solutions that leverage advanced nitinol properties effectively. Whether you need standard or custom-sized products, GEE SMA's expertise allows them to deliver precisely what you require for your projects involving nitinol medical devices or other applications. Trusting GEE SMA means aligning yourself with a partner who prioritizes quality at every step of the manufacturing process.

Custom Solutions for Your Needs

In today's competitive landscape, having access to custom solutions is often essential for success when working with nitinol components like wire or tubing. Many leading manufacturers now offer bespoke services tailored specifically to meet unique project requirements—GEE SMA being one of them. Their ability to customize products ensures that clients receive exactly what they need without compromising on quality or performance.

Customization can range from adjusting dimensions based on specific application criteria to modifying material properties through advanced processing techniques—making it possible for businesses across various industries to innovate with confidence using advanced materials like those produced by GEE SMA’s state-of-the-art facilities. By choosing a manufacturer willing to adapt their offerings based on your input, you not only enhance your product development process but also strengthen your market position.

In conclusion, sourcing high-quality nitinol components from reputable manufacturers like GEE SMA ensures optimal performance across diverse applications—from cutting-edge medical devices utilizing specialized forms of nitinol wire to robust medical tubing designed for safety and effectiveness. By carefully evaluating potential suppliers' capabilities while considering customization options available today, businesses can pave the way toward successful outcomes rooted firmly within modern technological advancements.

Conclusion

In summary, nitinol components have transformed the landscape of modern medicine, offering innovative solutions that enhance patient care and treatment outcomes. The unique properties of nitinol, including its shape memory and superelasticity, make it an ideal choice for a range of medical applications. As we continue to explore the potential of nitinol wire and tubing in medical devices, it’s clear that this remarkable material will play a pivotal role in advancing healthcare.

Nitinol's Role in Modern Medicine

Nitinol wire and tubing are at the forefront of numerous medical innovations, from stents to guidewires, underscoring their significance in modern healthcare. The biocompatibility and flexibility of these nitinol components ensure they can be safely used within the human body without adverse reactions. Moreover, as the demand for minimally invasive procedures grows, the versatility of nitinol medical devices becomes increasingly critical to meeting patient needs.

The Future of Nitinol Components

Looking ahead, the future of nitinol components appears bright as ongoing research continues to unlock new applications across various industries beyond just medicine. Innovations in manufacturing processes promise to enhance the performance characteristics of nitinol wire and tubing even further. As technology advances and more companies recognize the advantages offered by these materials, we can expect an expansion in their use—potentially revolutionizing fields such as robotics and aerospace alongside medicine.

Partnering with GEE SMA for Success

When it comes to sourcing high-quality nitinol components tailored for your specific needs, partnering with a reputable nitinol manufacturer like GEE SMA is essential. With expertise in producing advanced nitinol wire medical products and specialized tubing solutions, GEE SMA stands out as a trusted partner for businesses seeking reliable materials. Their commitment to customer satisfaction ensures that you receive not only superior products but also custom solutions that drive success in your projects.