Introduction

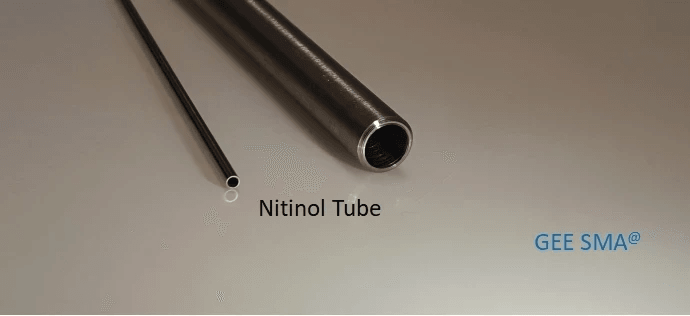

Nitinol alloys are a fascinating blend of science and engineering, capturing the imagination of many industries with their unique properties and capabilities. These remarkable materials, primarily composed of nickel and titanium, exhibit extraordinary characteristics that set them apart from traditional metals like aluminum alloy material and titanium alloys. As we delve deeper into the world of nitinol alloy rods, we uncover their versatility and applications across various sectors.

Understanding Nitinol Alloys

At its core, a nitinol alloy rod is an advanced material that combines the elements nickel and titanium in a specific ratio to create a metal with unique functionalities. Unlike precious metals or even conventional titanium alloy materials, nitinol exhibits both shape memory effect and superelasticity, making it an exceptional choice for demanding applications. This understanding lays the groundwork for exploring how these alloys differ from other metallic options available on the market.

The Unique Properties of Nitinol

One of the standout features of nitinol is its shape memory effect; when deformed at a lower temperature, it can return to its original shape upon heating. This property allows nitinol alloy rods to perform effectively in environments where traditional materials like aluminum alloy material might fail or not provide adequate performance under stress. Additionally, the superelasticity characteristic enables these rods to absorb significant amounts of energy without permanent deformation—qualities that make them indispensable in various applications.

Applications of Nitinol Alloy Rods

The applications for nitinol alloy rods are as diverse as they are impressive, spanning industries such as medical devices, aerospace, and consumer products. In medicine, for instance, nitinol is used in stents and guidewires due to its biocompatibility and ability to return to predefined shapes within the human body. Meanwhile, aerospace manufacturers leverage this innovative material for components requiring lightweight yet durable solutions—showcasing how nitinol surpasses traditional options like titanium alloys in certain scenarios.

What is a Nitinol Alloy Rod?

Nitinol alloy rods are fascinating materials that combine unique properties with practical applications across various industries. Composed primarily of nickel and titanium, these rods exhibit remarkable characteristics that set them apart from traditional metals like aluminum alloy material and titanium alloy. Understanding the definition and composition of nitinol alloy rods is essential to appreciate their versatility and effectiveness in diverse applications.

Definition and Composition

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, is a shape memory alloy that consists of approximately 50-60% nickel and 40-50% titanium. This specific composition allows nitinol to exhibit its signature shape memory effect, where it can return to its original form after deformation when exposed to heat. Unlike precious metals or other alloys, nitinol’s unique blend of elements enables it to undergo significant changes in shape at different temperatures, making it an exceptional choice for various engineering solutions.

How Nitinol Differs from Titanium Alloys

While both nitinol and titanium alloys share some similarities—like their lightweight nature—their functionalities diverge significantly. Titanium alloy materials are primarily known for their strength-to-weight ratio and corrosion resistance but lack the dynamic properties found in nitinol alloys. The ability of a nitinol alloy rod to remember its original shape when heated is a game-changer in applications where adaptability is crucial, setting it apart from traditional titanium alloys.

Common Uses in Various Industries

Nitinol alloy rods have carved out a niche across numerous sectors due to their unique properties. In the medical field, they are instrumental in creating stents and guidewires that adapt seamlessly within the human body—a feat not achievable with conventional aluminum or titanium materials alone. Beyond healthcare, industries such as aerospace utilize these rods for components requiring high reliability under extreme conditions, showcasing how versatile this remarkable material truly is.

How Does Nitinol Work?

Nitinol alloy rods are fascinating materials that operate on principles unlike those found in traditional metals. Their unique behavior stems from the shape memory effect, which allows them to return to a predetermined shape when heated after being deformed. This characteristic is what sets nitinol apart from other materials, including aluminum alloy materials and titanium alloys, making it a go-to choice in various innovative applications.

Shape Memory Effect Explained

The shape memory effect is the cornerstone of how nitinol alloy rods function. When these rods are heated above a certain temperature, they remember their original shape and revert back to it, even after being bent or twisted into different forms. This remarkable property is primarily due to the material's crystalline structure, which can change between two distinct phases: martensite and austenite. While aluminum alloy materials may exhibit some flexibility, they lack this transformative capability that makes nitinol so special.

The Role of Temperature in Performance

Temperature plays a critical role in the performance of nitinol alloy rods; it's essentially the conductor of their magic trick! Below a specific transformation temperature, nitinol behaves like any other metal—flexible yet somewhat rigid—allowing for easy manipulation during manufacturing processes. However, once exposed to heat above this threshold, it activates its shape memory effect and returns to its predetermined form with remarkable speed and reliability—qualities not commonly found in titanium alloys or aluminum alloy materials.

Comparison with Aluminum Alloy Materials

When comparing nitinol alloy rods with aluminum alloy materials and titanium alloys, several distinct differences emerge that highlight why nitinol is often preferred for specialized applications. While aluminum alloys are lightweight and corrosion-resistant, they do not possess the same ability to remember shapes or respond dynamically to temperature changes as nitinol does. Moreover, titanium alloys offer strength but fall short on functionality when subjected to varying temperatures; they lack the versatility that makes nitinol such an exciting material for industries ranging from medical devices to aerospace engineering.

What Industries Use Nitinol Alloy Rods?

Nitinol alloy rods have carved a niche for themselves across various industries, thanks to their unique properties and versatility. From medical devices to aerospace applications, the demand for these remarkable materials continues to grow. Let’s delve into the specific sectors that benefit from nitinol alloy rods and explore how they are revolutionizing traditional practices.

Medical Applications and Devices

In the medical field, nitinol alloy rods shine brightly due to their shape memory effect and biocompatibility. These properties make them ideal for use in stents, guidewires, and other critical devices that require precision and reliability. Unlike titanium alloys or aluminum alloy materials, nitinol can return to its original shape after deformation when exposed to body temperature, significantly improving patient outcomes.

Moreover, nitinol's flexibility allows for minimally invasive procedures, reducing recovery time for patients. Surgeons appreciate its ability to navigate complex anatomical structures without causing damage—something precious metals simply can't match in terms of functionality. As a result, many leading medical device manufacturers are turning to nitinol as their material of choice.

Aerospace and Defense Utilization

The aerospace industry has also embraced nitinol alloy rods due to their lightweight nature combined with high strength—qualities that are essential in aviation technology. When compared with titanium alloy materials, nitinol offers enhanced performance in extreme conditions such as high temperatures and varying pressures encountered during flight. This makes it an invaluable resource for components like actuators and control surfaces.

Defense applications similarly benefit from the unique attributes of nitinol; its durability ensures reliable performance in demanding environments where failure is not an option. The ability of nitinol alloys to revert back to predetermined shapes can be utilized in specialized military equipment designed for rapid deployment and adaptability on the battlefield. As a result, both commercial aviation companies and defense contractors are increasingly sourcing from reputable nitinol manufacturers.

Consumer Products Featuring Nitinol

You might be surprised at just how many consumer products utilize nitinol alloy rods! From eyeglass frames that maintain their shape after bending to innovative gadgets that respond dynamically based on temperature changes—nitinol is making waves beyond industrial applications. Its lightweight nature gives designers more freedom compared with traditional materials like aluminum alloys or even titanium alloys.

One standout example is smart jewelry that adjusts fit based on temperature changes or user input—a perfect blend of style and functionality made possible by this incredible material. Additionally, some high-end automotive parts incorporate nitinol for improved performance without adding unnecessary weight—a win-win situation! With its growing popularity among designers looking for cutting-edge solutions, it's clear that the future of consumer products will continue embracing this remarkable material.

How is Nitinol Manufactured?

Nitinol, a unique alloy of nickel and titanium, undergoes a meticulous manufacturing process that ensures its exceptional properties are preserved. This production involves several stages, including melting, casting, and forming the alloy into various shapes like nitinol alloy rods. Understanding this process is crucial for appreciating the quality and performance of these materials in various applications.

Overview of the Production Process

The journey of creating a nitinol alloy rod begins with the careful selection of raw materials, primarily nickel and titanium. These precious metals are combined in precise ratios to form the desired alloy composition, which is then melted in a vacuum or inert atmosphere to prevent contamination. Once melted, the molten metal is cast into ingots or directly formed into rods through processes like hot working or cold drawing; each method plays a vital role in achieving optimal material properties.

After forming, these nitinol rods undergo heat treatment to induce specific phase transformations essential for their shape memory effect. The controlled cooling and heating cycles are crucial; they determine how well the nitinol will perform under varying temperature conditions compared to traditional aluminum alloy materials and titanium alloys. The entire production process is designed to ensure that every nitinol manufacturer can deliver products that meet stringent industry standards.

Quality Control in Nitinol Manufacturing

Quality control is paramount in the manufacturing of nitinol alloy rods due to their specialized applications across industries such as medical devices and aerospace. Rigorous testing protocols are implemented at every stage of production to ensure consistency in mechanical properties and performance characteristics. This includes checking for impurities from precious metals used during production and verifying that each batch meets established specifications.

Advanced techniques such as metallography help manufacturers analyze microstructural features while mechanical testing assesses strength, ductility, and fatigue resistance against other materials like titanium alloys or aluminum alloys. Any deviation from quality standards can lead to significant failures in application; thus, manufacturers invest heavily in quality assurance measures throughout their processes. By adhering strictly to these protocols, they guarantee that their products maintain reliability even under extreme conditions.

Key Players in the Nitinol Market, including GEE SMA

The market for nitinol alloy rods has seen considerable growth due to increasing demand across various sectors; key players have emerged as leaders within this niche industry. Companies like GEE SMA have established themselves as prominent nitinol manufacturers known for their innovative approaches and high-quality products tailored for specific applications—medical devices being a prime focus area where precision matters most.

In addition to GEE SMA, several other companies contribute significantly by offering diverse product lines ranging from simple wires to complex components made from nitinol alloys designed specifically for challenging environments compared with conventional titanium alloy materials or aluminum alloys. As competition increases within this market segment, continuous advancements in manufacturing techniques will likely enhance product capabilities further while driving down costs—a win-win scenario for consumers seeking durable solutions.

What are the Benefits of Nitinol Alloy Rods?

Nitinol alloy rods present a unique combination of benefits that make them stand out in various industries. Their remarkable durability, lightweight nature, and exceptional performance under extreme conditions set them apart from traditional materials like aluminum alloy and titanium alloys. As industries seek more innovative materials, nitinol manufacturers are stepping up to meet the demand for advanced solutions.

Durability and Reliability in Design

One of the most significant advantages of nitinol alloy rods is their durability and reliability in design. Unlike precious metals, which can be costly and may not offer the same structural integrity, nitinol provides a robust solution that can withstand considerable stress without compromising its shape or function. This makes it an ideal choice for critical applications where failure is not an option, such as in medical devices or aerospace components.

Moreover, nitinol's ability to return to its original shape after deformation (thanks to its shape memory effect) adds another layer of reliability that other materials like titanium alloy or aluminum alloy materials simply can't match. This resilience ensures that products made with nitinol can endure challenging environments while maintaining their performance over time. As industries continue to innovate, the demand for durable materials like nitinol will only grow.

Lightweight Alternatives to Titanium Alloys

When it comes to weight considerations in engineering and design, nitinol alloy rods shine brightly as lightweight alternatives to titanium alloys. While titanium is known for its strength-to-weight ratio, nitinol takes this concept further by offering similar strength but at a reduced weight—making it easier to handle and implement in various applications. This characteristic is especially beneficial in fields such as aerospace, where every ounce counts toward efficiency.

Additionally, using lighter materials can lead to enhanced fuel efficiency in vehicles and aircraft when employing nitinol components instead of heavier titanium alloy material or aluminum alloy material alternatives. The lightweight nature of nitinol does not compromise its strength; rather, it allows engineers greater flexibility when designing structures that require both robustness and reduced weight. Ultimately, this balance between lightness and strength positions nitinol as a compelling choice for modern engineering challenges.

Enhanced Performance in Extreme Conditions

Nitinol alloy rods are renowned for their enhanced performance under extreme conditions—whether it's temperature fluctuations or high-stress environments typical in aerospace or medical applications. The unique properties inherent to these alloys allow them to maintain functionality even when exposed to drastic temperature changes that would typically challenge other metals like aluminum alloys or traditional titanium alloys.

This adaptability makes nitinol particularly valuable in applications where precision is crucial; think surgical tools that must perform reliably regardless of environmental variations during procedures or components used in space exploration facing harsh conditions outside Earth's atmosphere. Moreover, the combination of durability with superior thermal responsiveness means products made from nitinol can adapt dynamically while ensuring consistent performance—a feat not easily achieved with many conventional materials.

Conclusion

In wrapping up our exploration of nitinol alloys, it’s clear that these remarkable materials hold a promising future across multiple industries. As advancements in technology continue to evolve, the demand for nitinol alloy rods is likely to increase due to their unique properties and versatility. With ongoing research and development, we can anticipate even more innovative applications that leverage the incredible capabilities of this shape memory alloy.

The Future of Nitinol Alloys

The future of nitinol alloys looks bright, especially with the growing interest in lightweight yet durable materials in sectors such as aerospace and medical devices. As industries increasingly prioritize efficiency and performance, nitinol alloy rods are poised to replace heavier alternatives like titanium alloy materials and aluminum alloy materials. Furthermore, ongoing innovations from leading nitinol manufacturers will likely lead to enhanced processes that improve the quality and performance of these precious metals.

Key Takeaways on Nitinol Benefits

Nitinol offers a unique blend of benefits that set it apart from traditional materials such as titanium alloys or aluminum alloy material. Its shape memory effect allows for design flexibility not found in other metals, resulting in lightweight solutions without sacrificing strength or reliability. Additionally, the ability to perform under extreme conditions makes nitinol alloy rods an attractive choice for various applications including medical devices and aerospace components.

Exploring GEE SMA's Innovations in Nitinol

GEE SMA stands out as a key player in the nitinol market with its commitment to innovation and quality control in manufacturing processes. Their focus on developing advanced nitinol alloys ensures that they meet the evolving needs of industries that rely on precision-engineered components like nitinol alloy rods. By continuously pushing the boundaries of what’s possible with titanium and alloys, GEE SMA is shaping a future where these extraordinary materials become even more integral to modern technology.