Introduction

In the realm of advanced materials, Nitinol has carved out a niche that is both fascinating and functional. This unique alloy, composed primarily of nickel and titanium, is renowned for its extraordinary properties as a shape memory alloy. Its ability to return to a predetermined shape when heated makes it invaluable across various industries, prompting many to consider where to buy nitinol wire for their innovative projects.

Understanding Nitinol and Its Importance

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, is more than just a catchy name; it's a game-changer in material science. The importance of this alloy lies in its remarkable characteristics—most notably, its shape memory effect and superelasticity—which allow it to perform under conditions that would render other metals ineffective. As industries push the envelope of technology, understanding Nitinol's unique capabilities becomes crucial for harnessing its potential.

The Role of Nickel in Nitinol Wire

Nickel plays a pivotal role in defining the properties of Nitinol wire. This element not only contributes to the alloy's strength but also influences its phase transformation temperatures—key factors that determine how effectively it can function as a shape memory metal. With varying nickel content impacting performance metrics like flexibility and resilience, manufacturers must carefully consider these elements when selecting materials for applications ranging from medical devices to automotive components.

Applications of Nitinol in Various Industries

The versatility of Nitinol extends across multiple sectors, showcasing its adaptability and innovative spirit. In aerospace engineering, nitinol springs are utilized for their lightweight yet durable properties; meanwhile, the medical field leverages this alloy’s unique characteristics in devices such as stents and guidewires. As businesses continue exploring new frontiers with nitinol nickel titanium products, understanding where to source quality materials—and at what price—remains essential for staying competitive.

What is Nitinol Wire?

Nitinol wire is a remarkable alloy primarily composed of nickel and titanium, known for its unique properties that make it a standout among materials. This shape memory alloy (SMA) can return to a predetermined shape when heated, making it invaluable in various applications. From medical devices to aerospace innovations, the versatility of nitinol wire continues to capture the imagination of engineers and researchers alike.

Properties of Nitinol Wire

The properties of nitinol wire are what set it apart from conventional metals. One of its most notable features is its ability to undergo significant deformation while still returning to its original shape upon heating, thanks to the shape memory effect. Additionally, nitinol exhibits superelasticity at body temperature, allowing it to endure considerable stress without permanent deformation—qualities that make it ideal for applications like nitinol springs in medical devices.

Another fascinating property is its biocompatibility; the titanium material in nitinol ensures that it's safe for use within the human body. This makes nitinol wire an excellent choice for implants and stents used in various surgical procedures. With such impressive characteristics, it's no wonder that industries are eager to buy nitinol wire for their innovative projects.

The Science Behind Shape Memory Alloys

At the heart of nitinol's capabilities lies the science behind shape memory alloys (SMAs). These materials can exist in two different phases: austenite and martensite, which correspond to high-temperature and low-temperature states respectively. When cooled into the martensitic phase, nitinol can be easily deformed; however, when heated back into the austenitic phase, it remembers its original configuration.

The transformation between these phases occurs at specific temperatures determined by the alloy's composition—particularly the ratio of nickel to titanium. This clever interplay allows engineers to tailor SMAs like nitinol for specific applications by adjusting their chemical makeup accordingly. Understanding this science not only enhances our appreciation for these materials but also drives further innovations across multiple sectors.

Comparing Nitinol to Other Metals

When comparing nitinol with other metals, particularly traditional options like stainless steel or aluminum alloys, several distinct advantages emerge due to its unique properties as a shape memory metal. For instance, while stainless steel is strong and durable, it lacks the ability to return to an original form after deformation—something that sets nitinol apart dramatically in terms of functionality.

Moreover, when considering weight-to-strength ratios or biocompatibility factors essential in medical applications, titanium material shines brightly alongside nickel content found in Nitinol alloys. As industries increasingly seek lightweight yet robust solutions—especially in aerospace or automotive sectors—the demand for buying high-quality nitinol wire continues on an upward trajectory due to these compelling benefits.

The Significance of Nickel in Nitinol

Nickel plays a pivotal role in the composition of Nitinol, which is an alloy made primarily of nickel and titanium. This unique combination results in a shape memory alloy known for its remarkable ability to return to a predetermined shape when subjected to specific temperatures. Understanding nickel's contribution helps clarify why Nitinol is favored across various industries, from aerospace to medical devices.

Nickel's Role in Nitinol Alloys

In Nitinol alloys, nickel serves not just as a filler but as a crucial element that influences the overall properties of the material. The balance between nickel and titanium determines the transformation temperatures and mechanical characteristics of the alloy, allowing it to exhibit its famous shape memory effect. As such, when you buy nitinol wire, you're essentially investing in an advanced material that harnesses the unique properties provided by nickel.

Effects of Nickel Content on Properties

The content of nickel within Nitinol significantly affects its performance attributes such as elasticity, strength, and thermal response. Higher nickel concentrations can enhance the alloy’s ability to recover its shape after deformation, making it ideal for applications requiring high reliability and durability. Conversely, too much nickel can lead to brittleness; thus, finding the right balance is essential for optimizing nitinol wire price while ensuring quality.

Advantages of Nickel Wire in Industrial Applications

Nickel wire offers distinct advantages when utilized in industrial applications involving shape memory metals like Nitinol springs or other components made from titanium material. Its excellent corrosion resistance and thermal stability make it suitable for challenging environments found in aerospace or medical devices where reliability is paramount. By choosing high-quality nickel wire for your projects, you ensure enhanced performance while potentially lowering long-term costs associated with maintenance or replacements.

Industrial Applications of Nitinol Wire

Nitinol wire, a remarkable alloy of nickel and titanium, has carved out a niche in various industries due to its unique properties. Its shape memory capability and superelasticity make it an ideal candidate for innovative applications across aerospace, medical devices, and automotive sectors. As industries increasingly recognize the benefits of nitinol, the demand to buy nitinol wire continues to rise.

Aerospace Innovations using Nitinol

In the aerospace sector, nitinol's lightweight nature combined with its strength makes it an attractive material for advanced engineering solutions. Shape memory alloys are utilized in actuators and control surfaces, allowing for more efficient aircraft designs that can adapt dynamically during flight. By implementing nitinol springs in landing gear mechanisms, engineers can enhance reliability while reducing weight—an essential factor when every gram counts in aviation.

Medical Devices Leveraging Shape Memory Metals

The medical field has seen a surge in the use of shape memory metals like nitinol due to their biocompatibility and versatility. From stents that expand within blood vessels to guidewires that navigate complex anatomical pathways, nitinol wire plays a critical role in improving patient outcomes. As hospitals seek high-quality materials at competitive prices, buying nitinol wire becomes a strategic decision for manufacturers aiming to stay ahead in this fast-evolving industry.

Automotive Uses of Nitinol Springs

Automotive applications have also embraced the benefits of nitinol springs for their ability to return to their original shapes after deformation—a feature that's invaluable for suspension systems and other components requiring flexibility and resilience. The combination of nickel titanium allows these springs to absorb shocks effectively while maintaining performance under varying loads. With advancements in technology driving innovation, automakers are increasingly looking into how they can buy nickel wire or invest in nitinol components to enhance vehicle durability and efficiency.

Scientific Discoveries with Nitinol

The world of scientific research has been significantly impacted by the unique properties of nitinol, a nickel-titanium shape memory alloy. Researchers are constantly exploring new applications and innovations that harness the remarkable abilities of nitinol wire. From aerospace to medical devices, the advancements in shape memory metals have opened doors to groundbreaking technologies.

Research Innovations in Shape Memory Alloys

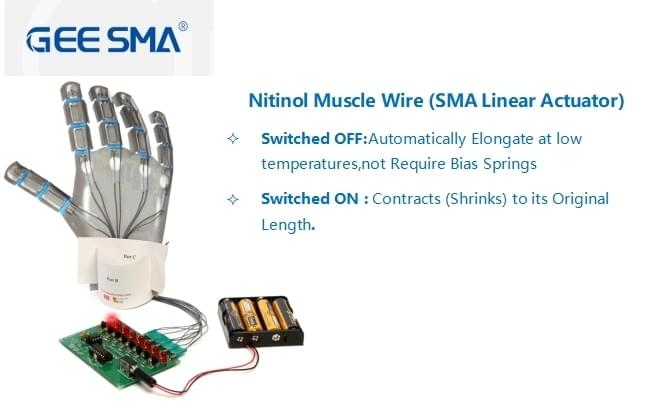

In recent years, the field of shape memory alloys has seen a surge in innovative research focused on enhancing the properties and applications of nitinol. Scientists are delving into ways to optimize nickel content within nitinol nickel titanium alloys, aiming to improve their performance in extreme environments. These innovations not only make it easier for industries to buy nitinol wire but also lead to more efficient designs in critical applications, such as robotics and biomedical devices.

Research has also highlighted how adjustments in processing techniques can enhance the characteristics of nitinol springs. By fine-tuning heat treatments and mechanical processes, researchers can create custom shapes that respond better under specific conditions. These discoveries pave the way for more versatile uses of shape memory metals across various sectors.

Case Studies of Nitinol in High-Tech Projects

Case studies showcasing successful implementations of nitinol wire illustrate its transformative potential across high-tech projects. One notable example is its use in soft robotics, where engineers leverage the unique properties of shape memory alloys to create flexible actuators that mimic natural movement. The ability to control these actuators using simple thermal inputs demonstrates how far we've come with titanium material innovations.

Another fascinating case is found within minimally invasive surgical tools, where nitinol's elasticity and strength allow for intricate designs that reduce patient recovery times significantly. Medical professionals have reported enhanced surgical outcomes thanks to devices made from this remarkable alloy, proving that investing in quality nickel wire leads to life-changing solutions for patients worldwide.

The automotive industry is also tapping into these advancements; manufacturers are increasingly integrating nitinol springs into their designs for enhanced performance and durability under varying conditions. This adaptability showcases just how integral shape memory alloys have become across diverse fields.

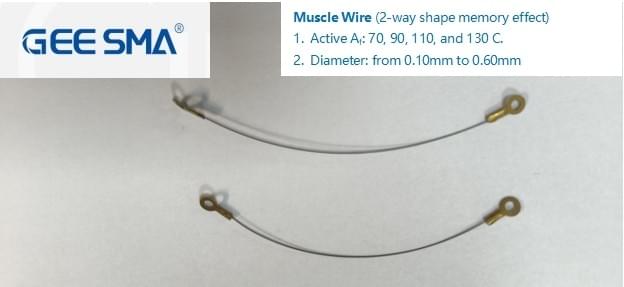

GEE SMA's Contributions to Scientific Advancements

GEE SMA stands at the forefront of scientific advancements involving shape memory alloys like nitinol wire, leading innovative research efforts aimed at pushing boundaries further than ever before. Their commitment to developing new formulations and processing techniques ensures that industries can access high-quality materials tailored for specific applications—making it easier than ever to buy nitinol wire suited for unique needs.

Moreover, GEE SMA actively collaborates with universities and research institutions on projects aimed at uncovering novel uses for niitinol nickel titanium materials beyond traditional applications. This partnership fosters an environment ripe for innovation while ensuring that cutting-edge findings reach commercial markets promptly.

Their contributions extend beyond mere product development; GEE SMA prioritizes sustainability by exploring eco-friendly production methods for their titanium material-based products. As they continue paving new paths in scientific discovery related to shape memory metals, we can expect exciting developments that will reshape industries worldwide.

How to Buy Nitinol Wire

Navigating the world of Nitinol wire can feel like a daunting task, especially if you're not familiar with the nuances of this unique material. Whether you're looking to buy Nitinol wire for industrial applications or innovative projects, understanding the key factors involved in your purchase is essential. This section will guide you through considerations that can help you make an informed decision.

Factors to Consider for Nitinol Wire Price

When it comes to purchasing Nitinol wire, price is often a primary concern. Several factors influence the nitinol wire price, including alloy composition, diameter, and specific properties required for your application. Additionally, fluctuations in the market price of nickel and titanium materials can also impact overall costs; therefore, keeping an eye on these trends can save you money in the long run.

Another crucial factor is the quantity you're looking to buy. Bulk purchases typically come with discounts; however, ensure that you are not compromising on quality just for a lower price tag. It's always wise to balance cost with performance characteristics—after all, investing in high-quality nitinol nickel titanium products can lead to better outcomes in your projects.

Lastly, consider any additional costs associated with shipping or handling when evaluating prices from different suppliers. Some companies may offer competitive base prices but add hidden fees that could inflate your total expenditure significantly. By doing thorough research and comparing multiple quotes, you'll be better positioned to find a fair deal without sacrificing quality.

Where to Source Quality Nitinol and Nickel Alloys

Finding reliable sources for quality nitinol and nickel alloys might seem like searching for a needle in a haystack—but it doesn't have to be! Start by exploring specialized suppliers who focus solely on shape memory metals; they often have extensive inventories and expertise tailored specifically for this niche market. Online marketplaces dedicated to industrial materials also provide options where you can compare various sellers side by side.

Another great avenue is industry trade shows or conferences where manufacturers showcase their latest innovations and products—including nitinol springs and other shape memory alloys. Networking at these events could lead you directly to reputable suppliers while giving you insights into new technologies on display. Plus, meeting face-to-face allows you to ask questions that might clarify your purchasing decisions.

Don't forget about online reviews and testimonials when sourcing materials; they serve as valuable indicators of supplier reliability and product quality! A supplier's reputation within the industry can significantly affect your project's success—so take time researching before committing yourself financially.

Evaluating Suppliers for Your Needs

Once you've identified potential suppliers for buying nitinol wire or other nickel titanium products, it's vital to evaluate them based on several criteria before making any commitments. Start by checking their certifications—reputable suppliers should adhere strictly to international standards regarding material quality and safety regulations related specifically to shape memory alloys.

Next up: customer service! A responsive supplier who addresses inquiries promptly demonstrates their commitment not just during sales but throughout your entire project lifecycle—from order placement through delivery challenges that may arise later down the road! Building relationships with such partners fosters trust which ultimately leads both parties toward mutual success!

Finally, don’t hesitate asking about warranty policies or return procedures should issues arise post-purchase; knowing how they handle such situations provides peace of mind as well as insight into their overall business practices! Taking these steps ensures that when it’s time for you buy nitinol wire again (and trust us—you will!), you'll know exactly where best fits YOUR needs!

Conclusion

As we wrap up our exploration of Nitinol wire, it’s clear that this remarkable material holds immense promise for the future. With ongoing advancements in technology and materials science, the applications of nitinol nickel titanium are set to expand even further. Whether in aerospace, medical devices, or automotive innovations, the versatility of shape memory alloys will continue to inspire new designs and functionalities.

Exploring the Future of Nitinol Wire

The future of nitinol wire looks bright as researchers and engineers strive to unlock its full potential. Innovations in manufacturing processes are likely to enhance the quality and reduce the nitinol wire price, making it more accessible for various industries. As demand grows for lightweight yet durable materials, investing in nitinol springs and other shape memory metals will undoubtedly become a strategic advantage for many businesses.

The Impact of Shape Memory Alloys in Technology

Shape memory alloys like nitinol are revolutionizing how we think about design and functionality in technology. Their unique properties allow them to return to a predetermined shape when heated, opening doors for innovative applications across multiple sectors. From self-healing structures to advanced robotics, the impact of these materials is profound and far-reaching.

Choosing the Right Nitinol Provider for Your Project

When considering where to buy nitinol wire, it's essential to evaluate suppliers based on quality and reliability. Look for providers who specialize in nitinol nickel titanium products and have a solid reputation within your industry. By selecting a trusted source for nickel wire or titanium material, you can ensure that your projects benefit from high-quality shape memory metals tailored to your specific needs.