Introduction

In the ever-evolving world of technology, the emergence of nitinol cable stands out as a game-changer. This remarkable material, a type of shape memory alloy, combines the unique properties of titanium and nickel to create wires that can return to their original shape when heated. As we delve deeper into the fascinating realm of nitinol wire and its capabilities, it becomes clear why this innovative metal is poised to redefine various cable applications.

Understanding Nitinol Cable Basics

Nitinol cable is not your average wiring; it’s a sophisticated blend of titanium nickel alloy that exhibits extraordinary characteristics. The most notable feature is its shape memory effect, which allows the metal nitinol to revert back to a predetermined shape when subjected to specific temperatures. This property enables nitinol alloys to be used in diverse applications, from medical devices to robotics, making them indispensable in modern engineering.

Why Nitinol is the Future of Cables

The future of cables lies in materials that offer more than just conductivity; they need durability and adaptability—qualities inherent in nitinol cable. Unlike traditional cables that may succumb to wear and tear over time, nitinol wire boasts remarkable resistance to corrosion and fatigue, ensuring longevity even in challenging environments. With its lightweight nature combined with strength, it's no wonder that industries are increasingly turning towards this innovative solution for their wiring needs.

Applications of Nitinol Cable

The versatility of nitinol cable opens up a plethora of applications across various sectors. In the medical field, for instance, it’s used in stents and guidewires due to its ability to navigate complex pathways while maintaining structural integrity. Beyond healthcare, industries such as aerospace and robotics are harnessing the unique properties of shape memory metals like nitinol for advanced systems where reliability and performance are paramount.

What is Nitinol?

Nitinol, a remarkable type of shape memory alloy, has gained significant attention in various industries due to its unique properties and capabilities. The term Nitinol itself is derived from its composition—Nickel Titanium Naval Ordnance Laboratory—highlighting the blend of titanium and nickel that gives rise to its extraordinary characteristics. This section will delve into the fascinating world of nitinol wire, exploring what makes it a standout among metal nitinol variants.

Overview of Shape Memory Alloys

Shape memory alloys (SMAs) like nitinol are materials that can remember their original shapes after being deformed when subjected to specific temperature changes. When heated above a certain temperature, nitinol cable returns to its pre-deformed configuration, showcasing an impressive ability known as the shape memory effect. This property makes SMAs particularly useful in applications ranging from medical devices to robotics, where precision and reliability are paramount.

The Science Behind Nitinol Wire

The science behind nitinol wire lies in its unique structure at the atomic level, which allows it to exhibit both superelasticity and shape memory behavior. When cooled below a specific transformation temperature, the titanium nickel alloy undergoes a phase change that enables it to deform significantly without permanent damage. Upon reheating, this metal nitinol reverts back to its original form with remarkable speed and efficiency—a phenomenon that has opened doors for innovative uses across various fields.

Unique Properties of Nitinol Alloys

Nitinol alloys possess several unique properties that set them apart from traditional metals like steel or aluminum. Their lightweight nature combined with exceptional durability makes them ideal candidates for applications where weight savings are crucial without sacrificing strength. Additionally, these titanium nickel alloys demonstrate impressive resistance to corrosion and fatigue, ensuring longevity even in harsh environments—making nitinol cable an attractive option for industries such as aerospace and biomedical engineering.

How Nitinol Cable Works

Nitinol cable operates on fascinating principles that set it apart from traditional wiring solutions. At its core, the remarkable shape memory effect is what gives nitinol wire its unique capabilities, allowing it to return to a predetermined shape after being deformed. This property, combined with the inherent characteristics of metal nitinol, makes it an exciting prospect for a variety of applications.

Shape Memory Effect Explained

The shape memory effect is a phenomenon where certain materials can remember their original shape and return to it when subjected to specific conditions, such as temperature changes. In the case of nitinol cables, when heated above a certain threshold, the titanium nickel alloy undergoes a phase transformation that enables it to revert to its pre-set configuration. This ability not only enhances functionality but also offers innovative solutions in robotics and medical devices, showcasing the versatility of shape memory alloys.

When you think about how this works in practice, imagine bending a nitinol wire into an intricate design; once heated, it springs back into its original form like magic! The dynamic nature of these cables allows them to perform complex tasks without losing structural integrity over time. This remarkable characteristic truly sets nitinol cables apart from conventional options.

The Role of Titanium Nickel Alloy

At the heart of every nitinol cable is the titanium nickel alloy that gives these wires their extraordinary properties. The unique composition not only contributes to the shape memory effect but also ensures high strength and resilience under various environmental conditions. This combination makes titanium wire an ideal choice for applications requiring durability and adaptability.

Moreover, the alloy's ability to withstand fatigue means that nitinol cables can endure repeated cycles of deformation without succumbing to wear and tear—a common issue with standard metal wires. As industries increasingly demand lightweight yet strong materials for their projects, titanium nickel alloy emerges as a frontrunner in meeting those needs effectively. The synergy between these elements creates opportunities for innovation across diverse sectors.

Practical Examples of Nitinol in Action

Nitinol cable isn't just theoretical; it's already making waves in various fields! One prominent example lies within medical devices—think stents or guidewires that expand upon reaching body temperature thanks to their shape memory properties. These applications not only improve patient outcomes but also highlight how nitinol alloys can revolutionize healthcare technology.

In aerospace engineering, engineers utilize nitinol wires for deployable structures due to their lightweight nature and ability to withstand extreme temperatures during flight missions. Additionally, robotics has seen an influx of innovations powered by this incredible material—robotic arms made from nitinol cable can mimic human-like movements due to their flexibility and strength combined with intelligent design features.

With practical implementations spanning such critical areas as medicine and space exploration, it's clear that nitinol technology is paving new paths toward efficiency and effectiveness across multiple industries.

Benefits of Using Nitinol Cable

When it comes to modern materials, few can rival the unique advantages offered by nitinol cable. This remarkable shape memory alloy, composed primarily of titanium and nickel, presents a blend of lightweight and durable characteristics that make it ideal for a variety of applications. Whether you're designing aerospace components or medical devices, the benefits of using nitinol wire are hard to ignore.

Lightweight and Durable Characteristics

One of the standout features of nitinol alloys is their impressive strength-to-weight ratio. Unlike traditional cables made from heavier metals, a nitinol cable provides exceptional durability without adding unnecessary weight to your projects. This lightweight nature not only enhances performance but also contributes to energy efficiency in applications ranging from robotics to automotive engineering.

Moreover, the durability of metal nitinol is noteworthy; it can endure significant stress and strain while maintaining its original form thanks to its unique shape memory effect. When subjected to deformation, a nitinol wire can return to its predetermined shape upon heating, making it incredibly reliable for dynamic applications. In essence, this combination of lightness and resilience positions nitinol cable as a game-changer in various fields.

Resistance to Corrosion and Fatigue

Nitinol's resistance to corrosion is another compelling benefit that sets it apart from conventional cables made from other metals. The titanium nickel alloy composition forms a protective oxide layer that shields against environmental factors such as moisture and chemicals—an essential feature for components exposed to harsh conditions or corrosive environments. This inherent corrosion resistance means less maintenance over time, ultimately reducing costs for manufacturers.

Additionally, metal nitinol exhibits remarkable fatigue resistance compared to traditional materials; this means that even after repeated cycles of deformation and recovery, a nitinol wire maintains its integrity without succumbing to wear or failure. This characteristic is particularly beneficial in applications where cables are subjected to constant movement or stress—think robotics or aerospace mechanisms where reliability is paramount. By choosing nitinol cable, industries can enjoy longer-lasting solutions that minimize downtime due to equipment failure.

Versatile Applications Across Industries

The versatility of nitinol cable extends far beyond just aerospace or medical uses; it's making waves across various industries thanks to its unique properties as a shape memory metal. From consumer electronics where compact design matters most, to innovative robotics that require flexible yet strong connections—nitinol alloys are proving their worth everywhere you look! Engineers are increasingly turning towards these advanced materials because they open up new possibilities for design and functionality.

In addition, custom solutions utilizing titanium wire have emerged in specialized sectors like telecommunications and automotive engineering where specific requirements must be met without compromising on performance or reliability. The adaptability offered by these cables allows manufacturers the freedom they need when developing cutting-edge technology tailored precisely for their needs. As more industries discover the advantages offered by metal nitinol, we can expect an explosion of innovative applications in the near future!

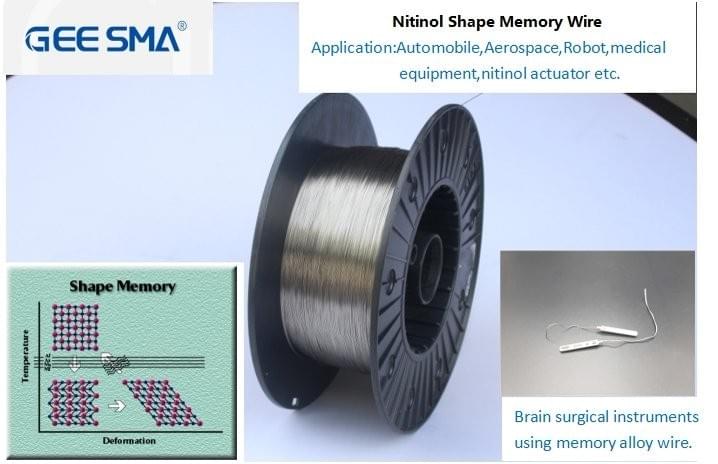

Exploring GEE SMA and Nitinol Innovations

Nitinol innovations are spearheaded by companies like GEE SMA, which has established itself as a leader in the development of shape memory alloys. These pioneering efforts have transformed the landscape of nitinol cable applications, making them more accessible and versatile across various industries. By harnessing the unique properties of titanium nickel alloy, GEE SMA has unlocked new frontiers for nitinol wire technology.

Pioneers in Nitinol Shape Memory Alloys

GEE SMA stands at the forefront of nitinol shape memory alloy advancements, pushing boundaries with innovative designs and applications. Their commitment to research and development has led to breakthroughs that enhance the performance of nitinol alloys in diverse settings—from medical devices to robotics. By focusing on the unique characteristics of metal nitinol, they continue to refine their products for maximum efficiency and reliability.

The company's expertise also extends to producing specialized nitinol wire that meets stringent industry standards while maintaining flexibility and strength. This dedication positions GEE SMA as a critical player in shaping the future landscape of shape memory metals, ensuring that their contributions remain pivotal for years to come. Ultimately, their pioneering spirit drives other innovators to explore new possibilities within this dynamic field.

Contributions to Space Missions

Nitinol cable technology plays a crucial role in space missions, where reliability and performance are non-negotiable attributes. Companies like GEE SMA have contributed significantly by developing specialized components made from titanium nickel alloy, which withstand extreme temperatures and pressures encountered during space travel. These innovations not only ensure mission success but also pave the way for future explorations beyond our planet.

In particular, nitinol's shape memory effect allows for mechanisms that can adapt dynamically during flight or landing phases—an invaluable asset when precision is essential. The use of metal nitinol in spacecraft systems enhances durability while reducing weight compared to traditional materials, thereby improving overall efficiency on long-duration missions. As we venture deeper into space exploration, advancements in nitinol cable technology will undoubtedly play a vital role in overcoming challenges faced by astronauts.

Custom Solutions for Specialized Needs

The versatility of nitinol alloys makes them ideal candidates for custom solutions tailored to meet specialized needs across various sectors. From aerospace engineering to medical devices, companies like GEE SMA provide innovative designs utilizing nitinol wire that cater specifically to client requirements without sacrificing quality or performance. This adaptability is key when addressing unique challenges posed by different industries.

For instance, medical applications often require precise control over movement—something that can be achieved through tailored design using shape memory metals like metal nitinol. Similarly, automotive manufacturers benefit from customized solutions involving lightweight yet durable materials such as titanium wire which contribute positively towards fuel efficiency without compromising safety standards. With ongoing research into new methodologies surrounding these technologies, it’s clear that custom solutions will continue evolving alongside industry demands.

Future Trends in Nitinol Technology

The future of nitinol technology is bright, with numerous advancements on the horizon that promise to revolutionize various industries. As the demand for more efficient and adaptable materials grows, innovations in shape memory metals are paving the way for exciting developments. From improved manufacturing techniques to enhanced performance characteristics, the potential of nitinol cable and its applications is only just beginning to be realized.

Advancements in Shape Memory Metals

Recent breakthroughs in shape memory metals are transforming how we think about materials like nitinol wire and titanium nickel alloy. Researchers are developing advanced processing methods that enhance the properties of these alloys, leading to stronger, lighter, and more responsive cables. These advancements not only improve the performance of nitinol cables but also expand their usability across diverse fields such as robotics, aerospace, and medical devices.

Moreover, the integration of smart technologies with shape memory alloys is set to create a new generation of products that can adapt dynamically to environmental changes. Imagine a nitinol cable that can change its shape or stiffness based on temperature or stress—this isn't science fiction; it's rapidly becoming a reality! Such innovations will make titanium wire applications even more versatile and efficient.

Potential New Applications of Nitinol Cable

As research continues to unveil new properties of metal nitinol, we can expect an explosion of potential applications for nitinol cable beyond current uses. One promising area is in soft robotics where lightweight and flexible cables could lead to more dexterous robotic limbs capable of delicate tasks. The unique characteristics of shape memory alloys allow for designs that mimic biological movements more closely than traditional rigid components.

In addition, industries such as automotive could benefit significantly from incorporating nitinol wires into their systems—think self-adjusting components that enhance fuel efficiency by adapting on-the-fly! With ongoing innovation driving down production costs while enhancing functionality, it’s likely we’ll see these applications become mainstream sooner rather than later.

Sustainability and Nitinol Production

Sustainability is becoming increasingly important across all sectors; thus, it’s crucial to consider how nitinol production aligns with eco-friendly practices. The manufacturing processes for titanium nickel alloy have evolved significantly over recent years to reduce waste and energy consumption while maintaining high quality standards. This commitment not only benefits manufacturers but also positions metal nitinol as an environmentally conscious choice in material selection.

Furthermore, researchers are exploring recycling methods specifically tailored for shape memory alloys like those used in nitinol cables—ensuring they remain viable long after their initial use. By creating closed-loop systems where old materials can be repurposed into new products without losing integrity or performance, we can contribute positively toward a sustainable future while embracing innovative solutions offered by this remarkable alloy.

Conclusion

As we wrap up our exploration of nitinol cable and its remarkable properties, it's clear that this innovative material is more than just a trend—it's paving the way for the future of wiring solutions. Nitinol wire, with its unique shape memory alloy characteristics, offers unparalleled advantages in various applications, from medical devices to aerospace technology. The lightweight yet durable nature of nitinol alloys positions them as an ideal choice for industries seeking efficient and reliable materials.

Key Takeaways about Nitinol Cable

Nitinol cable stands out due to its incredible shape memory effect, which allows it to return to a predetermined shape when heated. This property is rooted in the titanium nickel alloy composition that gives nitinol wire its strength and flexibility. Moreover, the resistance to corrosion and fatigue makes these cables a long-lasting solution compared to conventional materials.

The Growing Importance of Nitinol

The significance of nitinol cannot be overstated; as industries evolve and demand more sophisticated materials, nitinol's unique properties make it increasingly relevant. With advancements in shape memory metals technology, applications are expanding into fields such as robotics and renewable energy systems. This growth highlights not only the versatility of metal nitinol but also its potential role in addressing future challenges across multiple sectors.

Embracing Nitinol for Innovative Solutions

To stay ahead in a rapidly changing technological landscape, embracing innovations like nitinol cable is essential for businesses aiming for sustainability and efficiency. Custom solutions utilizing titanium wire and other forms of nitinol alloys can lead to breakthroughs that redefine industry standards. By investing in these cutting-edge materials today, companies can position themselves at the forefront of tomorrow's advancements.