Introduction

Nitinol, a fascinating alloy of nickel and titanium, has garnered significant attention in various fields due to its unique properties and versatility. Understanding nitinol and its importance is crucial for grasping how this remarkable material can revolutionize industries, particularly in medical applications. As we delve into the science behind nitinol manufacturing, we will uncover the intricate processes involved in creating this alloy and explore its diverse applications in real life.

Understanding Nitinol and Its Importance

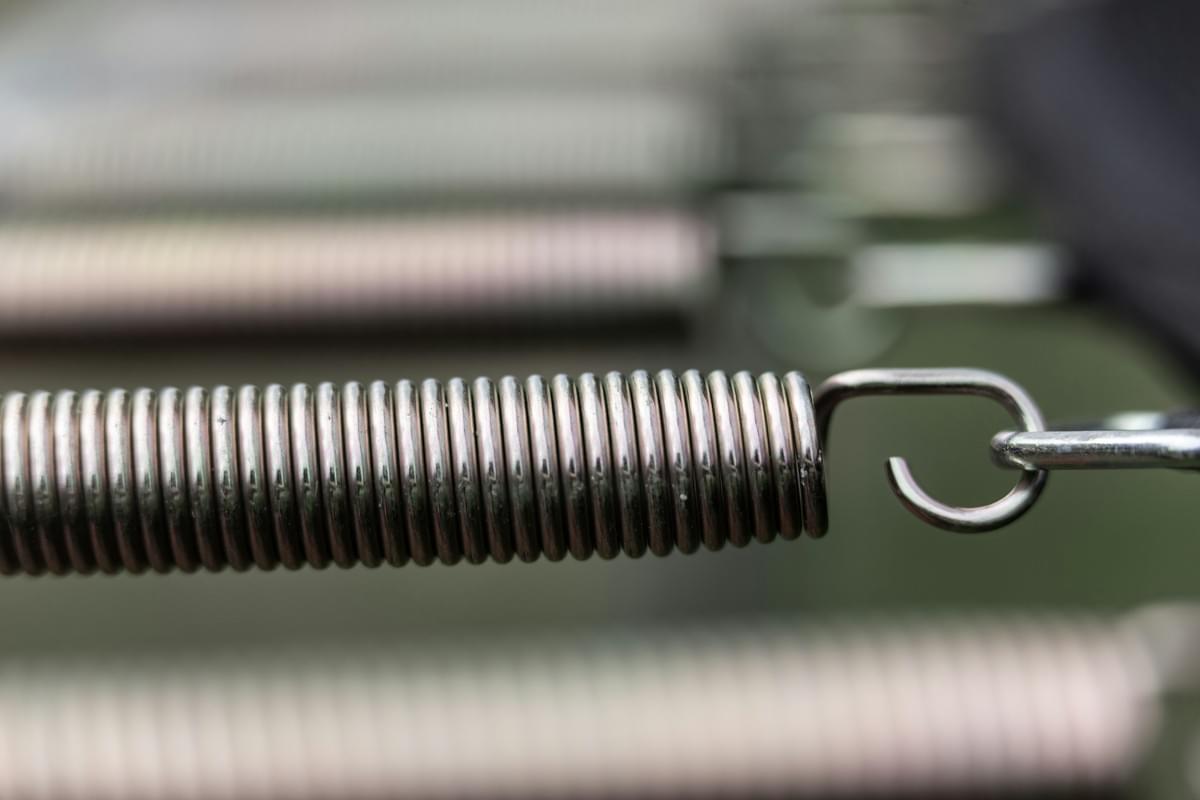

At its core, nitinol stands out for its shape memory effect and superelasticity, making it an invaluable resource across multiple sectors. The ability to return to a predetermined shape when heated is particularly vital in medical devices such as the nickel titanium archwire used in orthodontics. This innovative material not only enhances patient comfort but also ensures effective treatment outcomes, showcasing why understanding nitinol is essential for both manufacturers and consumers alike.

The Science Behind Nitinol Manufacturing

The manufacturing process of nitinol involves several complex steps that require precision and expertise. Knowing how to make nitinol starts with selecting the right alloy composition followed by careful heat treatment to achieve desired mechanical properties such as nitinol tensile strength. By mastering these processes, manufacturers can produce various nitinol components tailored for specific applications, ensuring optimal performance in everything from medical devices to aerospace engineering.

Applications of Nitinol in Real Life

Nitinol's unique properties have led it to be utilized extensively across various industries beyond just medicine. For instance, it plays a crucial role in creating durable products like nitinol alloy rods used in robotics or automotive systems that demand flexibility without compromising strength. Additionally, questions such as is nitinol magnetic? often arise as researchers explore new possibilities for this innovative material, further expanding its potential applications across different fields.

What is Nitinol?

Nitinol, a unique alloy composed primarily of nickel and titanium, possesses remarkable properties that set it apart from traditional metals. This alloy is known for its shape memory effect and superelasticity, making it incredibly versatile in various applications. Understanding the composition and characteristics of Nitinol is essential for appreciating its wide-ranging uses, especially in fields such as medicine and engineering.

Overview of Nitinol Alloy Composition

Nitinol's composition typically consists of approximately 55% nickel and 45% titanium, although these percentages can vary slightly depending on the specific application. The precise balance between nickel and titanium affects the alloy's mechanical properties, including its tensile strength and phase transformation temperatures. When exploring how to make nitinol, it's crucial to ensure accurate ratios during the manufacturing process to achieve desired performance characteristics.

Unique Properties of Nitinol

One of the standout features of Nitinol is its ability to return to a predetermined shape when heated above a certain temperature—this is known as the shape memory effect. Additionally, nitinol exhibits superelasticity at temperatures above its transformation range; this means it can undergo significant deformation without permanent change or damage. These unique properties make nitinol components ideal for applications like orthodontics, where flexibility combined with strength—such as with nickel titanium archwire—is essential for effective treatment.

Distinction Between Nitinol Types

There are generally two primary types of Nitinol: one optimized for shape memory applications and another designed for superelastic behavior. Shape memory nitinol is often used in devices that require movement or actuation when subjected to heat, while superelastic nitinol finds use in areas requiring flexibility without permanent deformation—like niti arch wire in orthodontic treatments. Understanding these distinctions helps manufacturers choose the right type based on their specific needs, ensuring optimal performance across various industries.

How is Nitinol Made?

Nitinol, a remarkable nickel-titanium alloy, undergoes a fascinating manufacturing process that transforms raw materials into the unique components we rely on today. Understanding how to make nitinol involves several intricate steps that ensure its special properties are preserved and enhanced. From melting to shaping, each phase of production plays a crucial role in determining the final quality and application of nitinol products.

Detailed Manufacturing Process

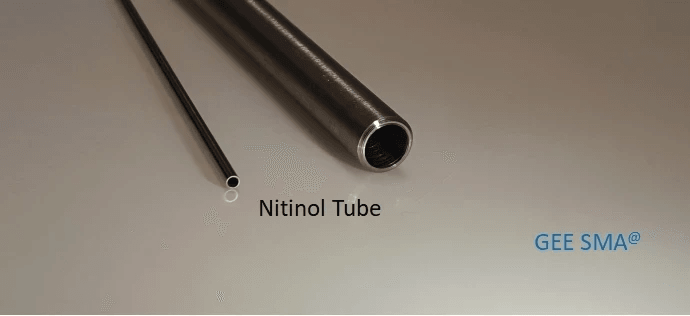

The manufacturing process of nitinol begins with the careful selection and preparation of nickel and titanium in specific ratios, typically around 50% nickel and 50% titanium by atomic percentage. These metals are melted together in a vacuum or inert atmosphere to prevent oxidation, resulting in a homogeneous alloy known as nitinol alloy rod. Once cooled, this alloy can be processed into various forms such as wires or sheets, which are essential for applications ranging from medical devices to automotive components.

After forming the initial shapes, manufacturers often employ techniques like cold working or hot working to enhance the mechanical properties of nitinol components further. This is where the magic happens—through deformation processes, manufacturers can manipulate the material's structure to achieve desired characteristics such as improved tensile strength or flexibility. The final stage involves cutting and finishing these components to meet precise specifications required for their intended use.

Role of Heat Treatment in Nitinol Production

Heat treatment is a pivotal step in how is nitinol made; it allows manufacturers to unlock the unique shape memory effect that makes this alloy so desirable in various applications. By subjecting the formed nitinol parts to controlled heating cycles at specific temperatures, producers can induce phase transformations within the material's crystalline structure. This process not only enhances properties like ductility but also enables features such as superelasticity—qualities that are particularly beneficial when creating products like niti arch wire used in orthodontics.

The heat treatment process also influences nitinol tensile strength significantly; properly treated materials exhibit superior performance under stress compared to untreated counterparts. As temperature changes affect its behavior dramatically, understanding these thermal effects is crucial for engineers designing components intended for diverse environments—from body temperature conditions in medical applications to extreme temperatures encountered in aerospace engineering.

Nitinol Components in Different Industries

Nitinol components find their way into an array of industries due to their exceptional properties derived from how they are made and treated. In healthcare, for instance, nickel titanium archwire has revolutionized orthodontic treatments by providing gentle yet effective forces on teeth while maintaining flexibility without breaking—an impressive feat considering traditional wires often lack such resilience. Beyond medicine, industries like robotics utilize nitinol actuators because they can convert thermal energy into mechanical motion efficiently.

Moreover, sectors such as aerospace benefit from using lightweight yet strong materials like nitinol alloy rods for critical applications where reducing weight without compromising integrity is vital. The versatility of these components highlights why understanding how to make nitinol—and mastering its production techniques—is essential across multiple fields today.

Nitinol in Medical Applications

Nitinol has made significant strides in the medical field, primarily due to its unique properties and versatility. One of the most notable applications is in orthodontics, where nickel titanium archwire plays a crucial role. The combination of shape memory and superelasticity allows for more effective tooth movement while minimizing discomfort for patients.

Use of Nickel Titanium Archwire in Orthodontics

The use of nickel titanium archwire, often referred to as niti arch wire, has revolutionized orthodontic treatments. These wires can exert gentle, continuous forces on teeth, promoting smoother and more efficient alignment over time. Additionally, their ability to return to a predetermined shape enhances treatment outcomes while reducing the number of adjustments needed by orthodontists.

Orthodontists appreciate how easy it is to work with nitinol components like these archwires because they are less likely to break compared to traditional stainless steel wires. This durability means fewer emergencies for patients and less frustration for practitioners. With ongoing advancements in how nitinol is made, we can expect even more refined options that cater to diverse patient needs.

Advantages of Nitinol in Medical Devices

Nitinol's unique properties extend beyond orthodontics into a variety of medical devices where flexibility and strength are paramount. Its tensile strength makes it an ideal material for stents and guidewires used in minimally invasive surgeries, allowing them to navigate complex anatomical pathways without compromising integrity. Moreover, the biocompatibility of nitinol ensures that these devices can be safely implanted within the body.

One standout feature is that nitinol retains its shape under stress and can return to its original form when heated or cooled—an attribute essential for many surgical tools. This adaptability leads to better patient outcomes as devices conform more closely to biological structures during procedures. As manufacturers continue exploring how to make nitinol components with even greater precision, we anticipate further innovations that will enhance surgical techniques.

Future Trends in Nitinol Medical Applications

The future looks bright for nitinol in medical applications as research continues into new uses and improved manufacturing processes. Innovations may include enhanced versions of current devices or entirely new applications leveraging nitinol's unique characteristics—such as self-expanding stents that adapt dynamically within blood vessels based on physiological conditions.

Additionally, ongoing developments aim at addressing common concerns like the magnetic properties of nitinol; understanding is nitinol magnetic could lead researchers toward novel applications where magnetism plays a role in functionality or diagnostics. As we explore these possibilities further, it's clear that choosing the right nitinol alloy rod or component will become increasingly important for tailored medical solutions.

Nitinol's Mechanical Properties

Nitinol, a remarkable nickel-titanium alloy, exhibits unique mechanical properties that set it apart from traditional metals. Understanding these properties is essential for various applications, especially in fields like medicine and engineering. In this section, we will delve into nitinol's tensile strength, compare it to conventional metals, and explore how temperature influences its behavior.

Understanding Nitinol Tensile Strength

Nitinol boasts impressive tensile strength, making it suitable for demanding applications such as orthodontics and robotics. The alloy’s ability to return to its original shape after deformation is a significant aspect of its strength profile. This characteristic is particularly beneficial when using nitinol components like the niti arch wire in braces, where flexibility and resilience are crucial.

The tensile strength of nitinol can vary based on its composition and heat treatment process during manufacturing—essentially answering the question of how to make nitinol effectively. Manufacturers often adjust these variables to achieve desired performance characteristics tailored for specific applications. Thus, understanding nitinol tensile strength not only highlights its capabilities but also informs manufacturers about optimizing their production methods.

Comparison to Traditional Metals

When compared to traditional metals like stainless steel or aluminum, nitinol often outshines in terms of flexibility and shape memory effects. While stainless steel might have higher tensile strength in some cases, it lacks the unique ability of nitinol to revert back to a predetermined shape after deformation—a property that can be game-changing in various scenarios. For instance, when utilizing a nitinol alloy rod in medical devices or tools, the advantages become abundantly clear: reduced risk of breakage and enhanced durability.

The comparison doesn't end there; nitinol components are also lighter than many traditional metals while maintaining similar or superior performance metrics. This lightweight nature makes them ideal for applications where weight savings are critical without compromising on functionality or safety standards. As industries continue exploring innovative uses for materials like nickel titanium archwire in orthodontics and beyond, understanding how these materials stack up against traditional options becomes increasingly important.

Impact of Temperature on Nitinol Behavior

Temperature plays a pivotal role in determining the mechanical properties of nitinol; this is where things get particularly interesting! The unique phase transformation behavior of this alloy means that changes in temperature can lead to dramatic shifts in its physical state—from flexible at lower temperatures to rigid at higher ones. This characteristic allows engineers and designers not only to utilize the material effectively but also provides opportunities for creative solutions across multiple industries.

For example, when considering whether is nitinol magnetic, one must factor in temperature as well—the magnetic properties may vary based on thermal conditions affecting the atomic structure within the alloy itself! Such insights are essential when designing products that rely on precise behaviors under varying environmental conditions—think medical devices that operate within fluctuating body temperatures or aerospace components exposed to extreme conditions during flight.

In summary, understanding how temperature impacts nitinol behavior enhances our ability to harness this remarkable material’s full potential while ensuring optimal performance across diverse applications.

Is Nitinol Magnetic?

When discussing the properties of materials, one might wonder about the magnetic characteristics of nitinol. This unique nickel-titanium alloy exhibits intriguing behavior in terms of magnetism, which can be surprising given its wide array of applications. Understanding whether nitinol is magnetic or not helps clarify its uses and potential in various industries.

Exploring the Magnetic Properties of Nitinol

Nitinol is generally classified as a non-magnetic material, primarily due to its specific alloy composition and structure. The nickel-titanium blend does not possess ferromagnetic properties, which means it won't be attracted to magnets like iron or cobalt. However, under certain conditions—such as extreme temperatures—niti arch wire and other nitinol components can display weak magnetic responses, but this is not typical for most applications.

Applications that Benefit from Nitinol's Magnetism

Despite being mostly non-magnetic, there are niche applications where the slight magnetic properties of nitinol can be advantageous. For example, in certain medical devices that require precise positioning or stabilization, understanding the minimal magnetism can enhance their functionality. Additionally, researchers are exploring how to make nitinol components that could interact with external magnetic fields for innovative uses in robotics and smart materials.

Common Misconceptions About Nitinol

One common misconception about nitinol is that it must be magnetic due to its metal composition; however, this couldn't be further from the truth! Many people mistakenly assume that all metals exhibit strong magnetism when they don't realize how unique nickel titanium archwire actually is. By clarifying these misunderstandings around how is nitinol made and its properties, we can better appreciate its role in modern technology without falling prey to myths.

Conclusion

In wrapping up our exploration of Nitinol, it's evident that this remarkable material has carved a niche in both industrial and medical fields. Innovations in Nitinol manufacturing continue to push the boundaries of what is possible with this unique alloy, making it essential for future advancements. As we look ahead, understanding how to make Nitinol and its various applications will be crucial for harnessing its full potential.

Innovations in Nitinol Manufacturing

The process of how is Nitinol made has evolved significantly over the years, incorporating advanced techniques that enhance its properties and usability. Manufacturers are now utilizing cutting-edge methods to create more consistent and high-quality nitinol components, such as nickel titanium archwire and nitinol alloy rods. These innovations not only improve the performance of these materials but also lower production costs, making them more accessible across various industries.

The Future of Nitinol in Technology

Looking forward, the future of Nitinol in technology appears bright as researchers explore new applications beyond traditional uses. From robotics to aerospace engineering, the unique characteristics of nitinol—like its shape memory effect—are being harnessed for innovative solutions that were previously unimaginable. As industries continue to investigate how to make nitinol even more versatile, we can expect groundbreaking developments that will redefine standards across multiple sectors.

Choosing the Right Nitinol Components for Your Needs

When it comes to selecting the right nitinol components for your project or application, understanding their specific properties is key. For instance, if you require flexibility and strength in orthodontics, opting for a high-quality niti arch wire can be critical due to its superior nitinol tensile strength compared to traditional materials. Additionally, being aware of whether or not is nitinol magnetic can influence your choice depending on your project's requirements; some applications may benefit from this property while others might not.