Introduction

Nitinol, a remarkable alloy of nickel and titanium, has taken the world by storm with its unique properties and versatile applications. Known for its ability to undergo significant shape changes in response to temperature variations—thanks to the nitinol transition temperature—this material is at the forefront of innovation across various industries. From medical devices that save lives to robotics that enhance efficiency, understanding Nitinol and its applications is essential for grasping how this alloy is shaping our future.

Understanding Nitinol and Its Applications

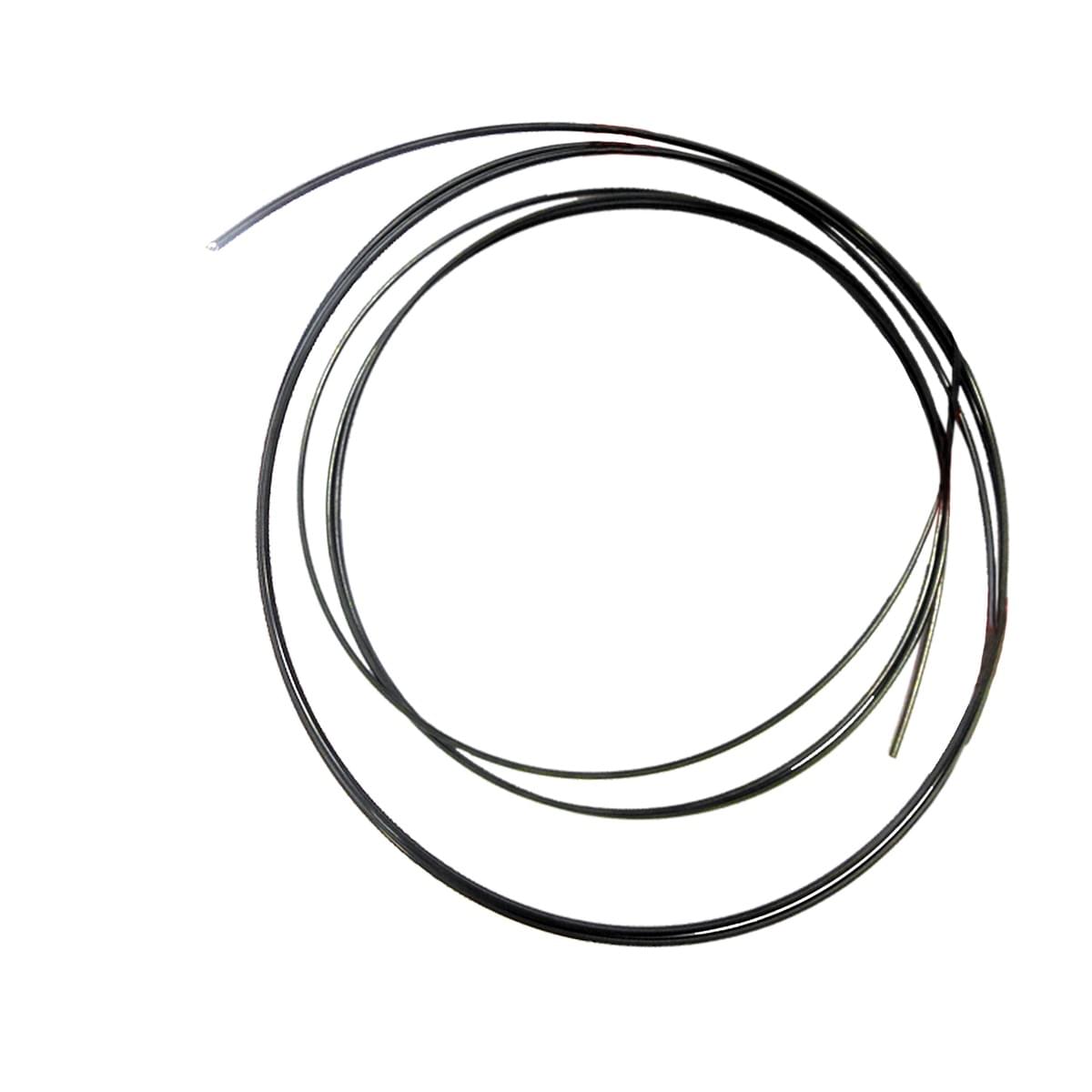

Nitinol wire has become a staple in the medical field, particularly in stents and guidewires due to its biocompatibility and flexibility. Beyond healthcare, Nitinol's unique characteristics are being leveraged in aerospace, automotive, and even consumer products, showcasing its adaptability. The magic lies not just in its composition but also in how it transforms under different conditions—making it a game-changer for engineers and designers alike.

The Science Behind the Nitinol Transition Temperature

At the heart of Nitinol’s functionality is the nitinol transition temperature—a critical point where the alloy shifts between two distinct phases: martensite and austenite. This phase transformation allows Nitinol to remember shapes, enabling it to revert back when heated or cooled appropriately. Understanding this transition is vital for harnessing Nitinol's full potential in applications ranging from actuators to precision instruments.

Key Characteristics of Nitinol Alloys

Nitinol alloys are distinguished by their superelasticity and shape memory effects, both stemming from their unique crystalline structure. This means that when deformed at lower temperatures (in martensite form), they can return to their original shape upon heating above their nitinol transition temperature. Additionally, features like corrosion resistance and fatigue endurance make Nitinol plates an excellent choice for various industrial uses—from medical implants to innovative engineering solutions.

The Magic of Nitinol Transition Temperature

Nitinol, the remarkable alloy of nickel and titanium, possesses a unique property known as the nitinol transition temperature. This temperature is critical because it dictates whether the material exhibits its shape memory effect or superelasticity. Understanding this transition is essential for engineers and innovators who harness Nitinol's capabilities in various applications, from medical devices to robotics.

What is Nitinol Transition Temperature?

The nitinol transition temperature refers to the specific temperature range at which Nitinol transitions between two distinct phases: martensite and austenite. In its martensite form, Nitinol wire can be easily deformed, while upon heating above this transition temperature, it reverts to its austenitic state and returns to its original shape. This fascinating behavior not only allows for innovative designs but also opens doors to countless applications where precision and reliability are paramount.

Temperature Variations in Nitinol Alloys

Temperature variations in nitinol alloys can significantly affect their performance characteristics. Different compositions of Nitinol will yield different transition temperatures, which can be fine-tuned based on specific application requirements—think of it like customizing your favorite dish with just the right spices! For instance, by adjusting the nickel-to-titanium ratio within the alloy, engineers can create specialized grades of Martensite Nitinol that function optimally in varying thermal environments.

Impact of Transition Temperature on Performance

The impact of nitinol transition temperature on performance cannot be overstated; it essentially defines how effectively an application will utilize the unique properties of Nitinol wire or plates. When designed correctly for their intended use—whether that's in medical devices requiring precise movements or aerospace components needing lightweight durability—the right transition temperature enhances overall functionality and reliability. Thus, understanding these nuances is vital for anyone looking to innovate with Shape setting Nitinol or explore new frontiers in superelasticity.

Exploring Martensite Nitinol

Martensite Nitinol is a fascinating phase of the Nitinol alloy that exhibits unique characteristics and properties, making it a standout material in various applications. This phase occurs at lower temperatures and is known for its ability to undergo significant deformation while retaining its original shape upon heating. Understanding the properties of Martensite Nitinol is crucial, especially when considering its use in high-performance applications such as medical devices.

Characteristics of Martensite Nitinol

Martensite Nitinol has a distinctive crystalline structure that allows it to exhibit remarkable flexibility and resilience. The nitinol transition temperature plays a vital role in determining when the alloy will switch between its martensitic and austenitic phases, influencing its performance in different environments. Furthermore, this form of Nitinol can be easily deformed at room temperature, making it ideal for applications where shape memory effects are desired.

The ability to revert back to its original shape when heated makes Martensite Nitinol particularly useful in various engineering fields. Its transformation can be finely tuned by adjusting the composition of the alloy, allowing for customized performance based on specific requirements. This adaptability is why engineers are increasingly turning to Martensite Nitinol for innovative solutions across multiple industries.

Applications in Medical Devices

One of the most impactful uses of Martensite Nitinol lies within the realm of medical devices, where its unique properties are leveraged for patient benefit. For instance, it is commonly used in stents and guidewires due to its ability to return to a predetermined shape after being deformed during delivery into the body. The combination of nitinol superelasticity and shape memory effect ensures that these devices perform reliably within complex biological environments.

Beyond stents, Martensite Nitinol finds application in orthopedic implants and surgical instruments, where flexibility without compromising strength is paramount. These devices often require precise movements or adjustments once implanted; thus, using materials that can adapt under varying conditions becomes essential. As research continues into this remarkable material's capabilities, we can expect even more innovative uses within healthcare.

Advantages of Martensite Nitinol

The advantages offered by Martensite Nitinol are numerous and compelling for engineers looking for high-performance materials. For starters, its excellent biocompatibility ensures safety when used inside human bodies—an essential factor when developing medical devices like stents or orthopedic implants made from nitinol plates or wires. Additionally, this alloy's lightweight nature combined with high strength makes it an attractive option compared to traditional materials like stainless steel.

Another significant advantage lies in the material's ability to withstand extreme conditions without losing functionality—ideal for applications exposed to varying temperatures or mechanical stressors over time. Moreover, with advancements in manufacturing techniques such as shape setting nitinol processes becoming more accessible, creating tailored components that meet specific demands has never been easier! This versatility positions Martensite Nitinol at the forefront of innovation across multiple sectors beyond just medicine.

Superelasticity: The Nitinol Advantage

Nitinol superelasticity is one of the most fascinating properties of this unique alloy, allowing it to undergo significant deformation and return to its original shape without permanent damage. This remarkable characteristic is closely tied to the nitinol transition temperature, which dictates when the material shifts between its austenite and martensite phases. Understanding these principles not only showcases the versatility of nitinol wire but also highlights its potential in various applications.

Principles of Nitinol Superelasticity

At the core of nitinol superelasticity lies a phenomenon known as stress-induced martensitic transformation. When subjected to stress at temperatures above the nitinol transition temperature, the material can deform significantly while remaining in its austenitic phase. Once the stress is removed, it reverts back to its original shape, demonstrating an impressive ability to absorb energy without permanent deformation—an ideal trait for many engineering applications.

The transformation from austenite to martensite occurs reversibly, meaning that even after extensive cycling through deformation, nitinol maintains its integrity. This behavior contrasts sharply with traditional metals that may suffer fatigue or break under similar circumstances. The combination of high strength and flexibility makes Nitinol superelasticity particularly valuable in sectors where reliability and durability are paramount.

Real-World Applications of Nitinol Superelasticity

Nitinol superelasticity finds practical use across various industries, especially in medical devices where precision and resilience are crucial. For example, stents made from nitinol wire can expand within blood vessels without losing their shape or structural integrity over time—a feature that significantly enhances patient outcomes. Additionally, dental archwires crafted from nitinol provide orthodontists with effective tools for adjusting teeth alignment while minimizing discomfort for patients.

Beyond healthcare, this property also shines in robotics and aerospace applications where lightweight yet strong materials are essential. Components designed with nitinol plates can withstand extreme conditions while maintaining their functionality—think flexible wing structures or adaptive robotic grippers that respond dynamically to their environment. As industries continue innovating around these capabilities, we can expect even more groundbreaking uses for Nitinol superelasticity.

Comparison Between Superelasticity and Shape Memory Effect

While both superelasticity and shape memory effect stem from the unique properties of Nitinol alloys, they operate under different principles and conditions. Superelasticity occurs when materials experience significant deformation above their nitinol transition temperature without retaining any changes once stress is removed; it's all about flexibility on demand! In contrast, the shape memory effect allows materials to return to a predetermined shape when heated or triggered by specific stimuli after being deformed below this critical temperature.

Martensite Nitinol plays a crucial role in both phenomena but behaves differently depending on external forces like heat or pressure applied during operation. While both features have distinct advantages—superelastic components excel in dynamic environments requiring constant adjustments—shape setting Nitinol proves beneficial for applications needing precise control over final shapes at lower temperatures. Understanding these differences allows engineers and designers alike to choose wisely based on project requirements!

Shape Setting Nitinol

Shape setting Nitinol is a fascinating process that enables this unique alloy to retain a specific shape when subjected to certain conditions. This method takes advantage of the material's inherent properties, particularly its ability to undergo phase transformations between martensite and austenite states based on the nitinol transition temperature. By carefully controlling the temperature and mechanical stresses during processing, manufacturers can create components that respond predictably to changes in temperature or stress.

The Process of Shape Setting Nitinol

The shape-setting process begins with heating Nitinol wire or other forms of the alloy above its nitinol transition temperature, allowing it to transform into the austenitic phase. Once in this state, the material is deformed into a desired shape and then cooled down, which causes it to revert back to its martensite form while memorizing this new configuration. When subsequently heated again above the transition temperature, the shape-setting effect kicks in, causing the material to return to its original shape—an incredible demonstration of Nitinol superelasticity.

This technique not only enhances performance but also ensures that components can withstand significant deformation without permanent damage. In essence, shape setting allows engineers and designers to leverage Nitinol’s unique characteristics effectively while creating reliable products for various applications.

Applications in Robotics and Aerospace

Shape setting Nitinol finds numerous applications across industries like robotics and aerospace due to its remarkable properties. In robotics, actuators made from shape-set Nitinol can provide lightweight solutions for movement mechanisms that require precise control and flexibility without adding excessive weight—an essential factor for robotic designs where efficiency is key. Similarly, in aerospace applications, components made from shape-setting Nitinol plates can adapt dynamically under changing conditions such as pressure variations or thermal fluctuations.

Moreover, these applications benefit from the inherent resilience of Martensite Nitinol during operation; they can endure extreme conditions while maintaining their functionality over time. This adaptability makes them invaluable for systems requiring high reliability under demanding circumstances.

Benefits of Shape Setting in Engineering

The benefits of utilizing shape-setting techniques in engineering are manifold and transformative for product design and functionality. First off, incorporating shape-set Nitinol allows for lighter designs without sacrificing strength or durability—ideal for industries like automotive or aerospace where every gram counts towards efficiency goals. Additionally, components designed with this technology exhibit excellent fatigue resistance due to their ability to revert back after deformation—a critical factor when considering long-term performance.

Furthermore, integrating Nitinol plates into engineering solutions opens up avenues for innovative designs that were previously unimaginable with traditional materials alone. The combination of lightweight properties with superelasticity leads not only to enhanced product life cycles but also fosters creative approaches toward solving complex engineering challenges.

Nitinol Plates and Their Versatility

Nitinol plates are becoming increasingly popular in various industries due to their unique properties, particularly their ability to undergo significant deformation while maintaining strength. The nitinol transition temperature plays a crucial role in the functionality of these plates, allowing them to revert to a predetermined shape upon heating. This versatility opens doors for innovative applications across sectors such as aerospace, robotics, and medical devices.

Usage of Nitinol Plates in Industry

In the industrial landscape, nitinol plates are utilized for their remarkable superelasticity and shape memory characteristics. Industries such as automotive and aerospace benefit from the lightweight nature of nitinol wire and plates, which contribute to fuel efficiency and performance enhancement. Furthermore, Martensite Nitinol is often employed in medical devices where biocompatibility is essential, showcasing how these materials can meet diverse industry needs.

How Nitinol Plates Enhance Product Design

The incorporation of nitinol plates into product design not only enhances functionality but also provides aesthetic appeal through sleek designs that traditional materials may lack. With their ability to return to a specific shape after deformation, these plates allow engineers more freedom when creating innovative solutions that require resilience under stress or impact. Moreover, the unique properties of shape setting Nitinol enable designers to create components that can adapt dynamically based on temperature changes or mechanical forces.

Future Perspectives for Nitinol Plates

Looking ahead, the potential applications for nitinol plates continue to expand as research uncovers new ways to exploit their properties further. Future advancements could lead to even more refined control over the nitinol transition temperature, resulting in tailored solutions for specific challenges across industries like robotics or wearable technology. As we explore these possibilities, it’s clear that nitinol plates will play an essential role in driving innovation forward.

Conclusion

In conclusion, Nitinol has proven itself to be a remarkable material that significantly advances technology across various fields. Its unique properties, particularly the nitinol transition temperature and its ability to transform between different phases, have opened up innovative avenues in engineering and medicine. As we continue to explore the capabilities of Nitinol wire, we can expect it to play an even more pivotal role in future applications.

Nitinol's Role in Advancing Technology

Nitinol's role in advancing technology cannot be overstated; it has revolutionized numerous industries with its unique characteristics. The nitinol transition temperature allows for specific applications that leverage the shape memory effect, making it indispensable in medical devices such as stents and guidewires. Furthermore, Martensite Nitinol showcases exceptional flexibility and strength, proving vital in sectors that demand durable yet lightweight materials.

The Future of Nitinol Materials

The future of Nitinol materials looks promising as researchers continue to develop new alloys and enhance existing ones for better performance. With advancements in understanding the nitinol transition temperature and its implications for superelasticity, we can anticipate even broader applications across industries like aerospace and robotics. Moreover, innovations such as shape setting Nitinol are paving the way for more complex designs that can adapt dynamically to their environments.

Innovative Applications on the Horizon

Looking ahead, innovative applications utilizing Nitinol plates are emerging rapidly across various sectors. From advanced robotics employing shape setting Nitinol to medical devices benefiting from enhanced superelasticity properties, the potential is vast and exciting. As industries recognize the advantages of Martensite Nitinol and its unique characteristics, we will likely witness a surge in groundbreaking technologies that harness these extraordinary materials.