Understanding Niti Rods

Niti rods, made from the remarkable nitinol nickel titanium alloy, are at the forefront of innovative materials in various industries. These shape memory alloys exhibit unique properties that set them apart from traditional metals and alloys. Understanding what makes nitinol special is key to appreciating its transformative potential.

What is Nitinol?

Nitinol, a contraction of Nickel Titanium Naval Ordnance Laboratory, is a unique alloy primarily composed of nickel and titanium. This shape memory alloy has gained prominence due to its ability to return to a pre-defined shape when heated above a certain temperature. The fascinating aspect of nitinol wire lies in its dual phase structure: it can exist in both austenite (the high-temperature phase) and martensite (the low-temperature phase), allowing it to perform extraordinary feats.

Properties of Nickel Titanium Alloys

Nickel titanium alloys like nitinol possess several distinctive properties that make them highly desirable for various applications. Firstly, they exhibit excellent elasticity and flexibility, which means they can be deformed significantly without permanent damage—a trait that's crucial for many engineering applications. Additionally, nitinol's corrosion resistance ensures longevity in harsh environments, making it an ideal candidate for medical devices and aerospace components alike.

How Shape Memory Alloys Function

The magic of shape memory nitinol wire lies in its ability to remember shapes through thermal activation. When cooled below its transformation temperature, the alloy can be easily manipulated into different configurations; however, once heated above this threshold, it returns to its original shape with remarkable force and speed. This unique behavior stems from the ni ti shape memory alloy's crystalline structure changes during heating and cooling cycles—an attribute that opens doors for innovative uses across diverse fields like robotics and medical technology.

Why Niti Rods Are Game Changers

Niti rods, composed primarily of nitinol nickel titanium, are revolutionizing various industries with their unique properties and capabilities. The exceptional characteristics of shape memory alloys allow these rods to return to a predetermined shape when heated, making them incredibly versatile. With applications ranging from medical devices to aerospace innovations, the impact of nitinol alloys is profound and far-reaching.

Unique Shape Memory Characteristics

One of the standout features of the ni ti shape memory alloy is its ability to remember a specific shape after being deformed. This means that when a shape memory nitinol wire is subjected to heat, it can revert back to its original configuration, providing unparalleled functional benefits in various applications. This unique characteristic allows for innovative designs that would be impossible with traditional materials like steel or plastic.

The mechanism behind this transformation relies on phase changes within the nitinol alloys at specific temperatures. When cooled below its transformation temperature, the niti rod can be easily manipulated into different shapes; upon heating above this threshold, it returns to its memorized form. This remarkable property not only enhances usability but also opens up new avenues for creative engineering solutions across multiple sectors.

Enhanced Durability and Flexibility

Nitinol wire boasts impressive durability and flexibility compared to conventional nickel alloys or other metals typically used in manufacturing. Its inherent ability to withstand significant deformation without permanent damage makes it an ideal choice for applications requiring resilience under stress or changing conditions. This durability ensures that products made from niti rods can endure harsh environments while maintaining their functionality over time.

Moreover, the flexibility of nitinol alloys allows for intricate designs that can adapt seamlessly during operation without compromising structural integrity. For instance, in medical devices such as stents or guidewires, the combination of strength and flexibility provided by shape memory nitinol wire leads to improved patient outcomes and reduced complications during procedures. Thus, utilizing these advanced materials not only enhances product performance but also contributes significantly to overall safety.

Applications in Aerospace and Medical Fields

The aerospace industry has eagerly adopted niti rods due to their lightweight yet robust nature combined with excellent thermal properties—making them perfect candidates for components that require both strength and reduced weight. From actuators in aircraft systems to components in satellite technology, nitinol's unique attributes help engineers design more efficient systems while minimizing fuel consumption and improving performance metrics across various platforms.

In the medical field, the applications are equally compelling; shape memory alloys have transformed how surgical tools are designed and utilized—enabling minimally invasive procedures with enhanced precision thanks to their adaptability during use. Nitinol's biocompatibility further expands its utility within healthcare settings; devices such as stents benefit from both mechanical performance and patient safety due to this remarkable material's properties.

As we continue exploring innovative uses for these extraordinary materials like niti rods made from nitinol nickel titanium, it's clear they are game changers across numerous domains—ushering in a new era of engineering possibilities that were once thought impossible.

The Science Behind Nitinol

Nitinol, a remarkable alloy of nickel and titanium, is often hailed for its unique properties that set it apart from traditional materials. This ni ti shape memory alloy exhibits extraordinary characteristics, particularly its ability to return to a predetermined shape when exposed to certain temperatures. Understanding the science behind nitinol wire and its mechanical properties is crucial for harnessing its potential in various applications.

Exploring the Ni Ti Shape Memory Alloy

The ni ti shape memory alloy, commonly known as nitinol, is a fascinating material that has captured the attention of scientists and engineers alike. Its distinct ability to remember shapes makes it an ideal candidate for innovative applications across multiple fields. When deformed at lower temperatures, this nickel titanium alloy can revert to its original form upon heating, showcasing the remarkable phenomenon of shape memory.

This property stems from the unique crystalline structure of nitinol alloys, which undergoes a phase transformation between two different structures: martensite and austenite. At lower temperatures, nitinol exists in a softer martensitic state that allows deformation; however, once heated above its transformation temperature, it transitions into the stronger austenitic state. This transition not only enables the functionality of devices like stents and actuators but also illustrates why niti rods are game changers in technology.

Transformation Temperatures and Their Importance

Understanding transformation temperatures is paramount when working with nitinol wire since they dictate how and when the material will exhibit its shape memory effect. These critical temperatures vary based on composition and processing methods used during manufacturing; thus, tailoring them can enhance performance in specific applications. For instance, medical devices often require precise control over these temperatures to ensure optimal operation within the human body.

The transformation temperature range typically includes both the forward transformation (from martensite to austenite) and reverse transformation (from austenite back to martensite). By adjusting these parameters through careful design choices with nickel alloys like nitinol, manufacturers can create products tailored for specific environments or stresses they may encounter during use. Consequently, understanding these nuances helps developers maximize efficiency while minimizing risk associated with thermal fatigue or failure.

Mechanical Properties of Nitinol Wire

The mechanical properties of nitinol wire contribute significantly to its versatility across various industries including aerospace and medical fields. Notably known for high strength-to-weight ratios coupled with excellent fatigue resistance, this shape memory alloy can endure repeated cycles without significant degradation over time—an essential trait for components subjected to dynamic loading conditions. Additionally, its superelastic behavior allows it to absorb considerable energy while maintaining structural integrity under stress.

Furthermore, the unique combination of flexibility and durability found in niti rods makes them suitable for intricate designs that traditional materials simply cannot achieve without compromising performance or safety standards. For example, surgical tools made from nitinol wire can navigate complex anatomical structures more effectively than rigid counterparts due to their ability to flex without breaking under pressure—leading ultimately toward better patient outcomes overall! As research continues into enhancing these properties further through innovative processing techniques or composite formulations involving nickel titanium alloys like those seen today; we are likely only scratching the surface regarding their full potential.

Niti Rod Applications in Real Life

Niti rods, crafted from the remarkable nitinol nickel titanium alloy, are revolutionizing various industries with their unique properties and versatile applications. From medical devices to aerospace innovations, the shape memory alloy's ability to return to a predetermined shape makes it an invaluable asset in modern technology. Let's delve into how these incredible materials are making waves across different fields.

Medical Devices and Surgical Tools

In the realm of healthcare, nitinol wire is nothing short of a game changer. Its flexibility and strength make it ideal for creating intricate surgical tools and medical devices that require precision and reliability. For instance, shape memory nitinol wire is commonly used in stents, allowing them to expand once placed within the body, providing crucial support for blood vessels without causing trauma.

Moreover, the unique properties of nitinol alloys enable the development of advanced orthopedic implants that can adapt to changing physiological conditions. This adaptability not only enhances patient outcomes but also reduces recovery times significantly. With continuous advancements in biomedical engineering, the future holds even more promise for innovative applications of niti rods in surgery and rehabilitation.

Robotics and Automation

The robotics sector has also embraced the versatility of niti rods due to their exceptional durability and lightweight nature. Nitinol's shape memory characteristics allow robots to perform complex movements with greater efficiency than traditional materials could provide. As a result, robotic systems utilizing shape memory alloys can operate in environments where flexibility and strength are paramount.

Additionally, nitinol wire is being integrated into soft robotics—an emerging field focused on creating adaptable machines that mimic biological forms. These soft robots can navigate challenging terrains or perform delicate tasks without risking damage to themselves or their surroundings. The incorporation of ni ti shape memory alloy into robotic designs promises a future filled with smarter, more capable automation solutions.

Aerospace Innovations with Nitinol

Aerospace engineering is yet another domain where niti rods shine brightly due to their lightweight yet robust nature. The use of nitinol alloys enables aircraft components to withstand extreme temperatures while maintaining structural integrity—a critical requirement for high-performance aviation applications. Shape memory alloys are particularly useful for components that need to change shapes during operation or respond dynamically under varying conditions.

Furthermore, innovative designs incorporating nitinol wire are paving the way for next-generation spacecraft technologies that require minimal maintenance while maximizing efficiency during flight missions. As space exploration continues to advance rapidly, incorporating these advanced materials will be essential for developing reliable systems capable of enduring harsh environments beyond Earth’s atmosphere. With ongoing research into new applications for niti rods in aerospace technologies, we can expect exciting developments on the horizon.

GEE SMA: Leading the Nitinol Revolution

When it comes to pioneering advancements in the field of nitinol, GEE SMA stands at the forefront, showcasing an unwavering commitment to excellence. The company's high-quality production of nitinol alloys has set a benchmark in the industry, making them a preferred choice for various applications. With a focus on innovation, GEE SMA is transforming how industries utilize the unique properties of nickel titanium and shape memory alloys.

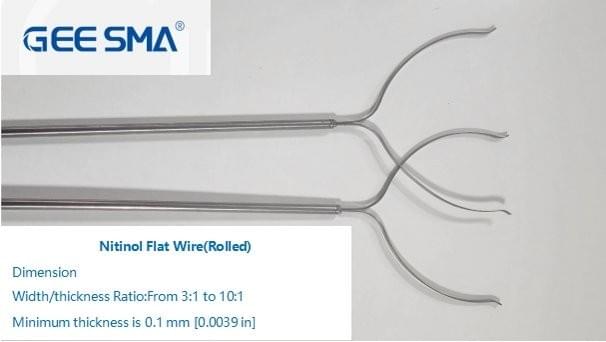

High-Quality Production of Nitinol Alloys

GEE SMA employs state-of-the-art technology to produce top-tier nitinol wire that meets stringent quality standards. Their expertise in crafting nitinol nickel titanium allows for precise control over mechanical properties and transformation temperatures, ensuring optimal performance in end products. This meticulous approach results in shape memory nitinol wire that can withstand demanding conditions while retaining its unique shape memory characteristics.

The production process at GEE SMA emphasizes sustainability and efficiency, reducing waste while maximizing output quality. By harnessing advanced manufacturing techniques, they ensure that each niti rod produced exhibits consistent reliability and durability. This dedication to high-quality production not only enhances product lifespan but also contributes positively to cost efficiency across industries.

Contributions to Space Missions

GEE SMA's contributions extend beyond traditional applications; they play a crucial role in aerospace innovations as well. The lightweight yet durable nature of their nitinol alloys makes them ideal for space missions where every gram counts and reliability is paramount. From actuators to structural components, the use of ni ti shape memory alloy technology enables engineers to design more efficient spacecraft with enhanced functionality.

In recent collaborations with space agencies, GEE SMA has provided custom solutions using their exceptional range of nitinol wire products tailored specifically for aerospace challenges. These applications showcase how shape memory alloys can adapt under extreme conditions while offering unparalleled performance metrics compared to conventional materials like nickel alloy alternatives. As missions grow more ambitious, so too does the reliance on innovative materials like those produced by GEE SMA.

Custom Solutions for Diverse Industries

One size does not fit all when it comes to industrial needs; that's why GEE SMA excels at providing custom solutions tailored specifically for diverse sectors ranging from medical devices to robotics and beyond. Their ability to manipulate the properties of nitinol alloys means they can create specialized niti rods designed for specific applications—be it surgical tools or robotic grippers requiring precise movement and flexibility.

The versatility of shape memory nitinol wire allows engineers across various fields to push boundaries previously thought unattainable with traditional materials alone. Clients benefit from collaborative partnerships where expertise meets creativity; together they develop innovative solutions that address unique challenges faced by modern manufacturing processes today. As industries evolve rapidly towards automation and advanced technologies, GEE SMA remains committed to being a key player in this exciting landscape through their exceptional offerings.

Conclusion

In the rapidly evolving landscape of technology, Niti rods are poised to become pivotal components across various industries. Their unique properties, derived from nitinol nickel titanium alloys, are not just pushing boundaries but also redefining what is possible with materials science. As we look ahead, the potential for these shape memory alloys in advancing innovation seems limitless.

The Future of Niti Rods in Technology

The future of niti rods appears bright as their applications continue to expand into new realms of technology. With ongoing research into nitinol wire and its capabilities, we can expect breakthroughs that will enhance performance in fields like robotics and aerospace. As industries embrace the ni ti shape memory alloy's versatility, we're likely to witness revolutionary changes that could transform everyday products and solutions.

Nitinol's Impact on Cost Efficiency

One of the standout features of nitinol alloys is their ability to reduce costs while maintaining high performance standards. By utilizing shape memory nitinol wire in manufacturing processes, companies can streamline production and minimize waste due to its unique properties that allow for complex shapes without extensive tooling. This cost efficiency not only benefits manufacturers but also translates into savings for consumers as innovative products become more accessible.

Embracing Nitinol in Modern Manufacturing

Modern manufacturing is on the brink of a transformation powered by the adoption of nitinol materials like niti rods. As industries increasingly recognize the advantages offered by nickel alloy innovations, they are integrating these advanced materials into their production lines with enthusiasm. Embracing nitinol in manufacturing not only enhances product functionality but also paves the way for sustainable practices that prioritize efficiency and durability.