Introduction

Nitinol, a remarkable alloy of nickel and titanium, has garnered attention across various industries due to its unique properties and versatile applications. This shape memory alloy exhibits extraordinary behavior that allows it to return to a predetermined shape when heated, making it an ideal candidate for innovative projects. Whether in medical devices or aerospace components, the nitinol rod stands out as a game-changer in materials science.

Understanding Nitinol and Its Applications

Nitinol's intriguing capabilities stem from its classification as a shape memory alloy, which enables it to remember its original form after deformation. The applications of nitinol are extensive; from stents that expand within the human body to actuators in robotics, the possibilities are nearly endless. As industries seek lightweight yet durable materials, nitinol's unique properties make it an attractive choice for modern engineering challenges.

The Unique Properties of Nitinol Rod

The nitinol rod is characterized by super elasticity and exceptional resilience under stress, allowing it to perform effectively in demanding environments. This titanium alloy not only offers flexibility but also maintains structural integrity even when subjected to extreme conditions. Its ability to revert back to its original shape upon heating sets the nitinol wire apart from traditional materials, making it indispensable for innovative solutions.

Why Choose Nitinol for Your Projects

Choosing nitinol for your projects means opting for reliability and cutting-edge technology that can significantly enhance performance outcomes. The biocompatibility of this titanium material ensures safety in medical applications while its lightweight nature contributes to efficiency in aerospace designs. As industries evolve and demand more advanced materials, integrating super elastic nitinol wire into your projects can pave the way for future innovations.

The Science Behind Nitinol

Nitinol is a remarkable material that defies conventional properties, primarily due to its classification as a shape memory alloy (SMA). This unique category of metals can return to a predetermined shape when subjected to specific temperatures. Understanding the science behind nitinol rod and its properties opens the door to numerous innovative applications across various industries.

What is Shape Memory Alloy

Shape memory alloys are materials that can undergo significant deformation but revert to their original shape upon heating. Nitinol, composed of nickel and titanium, exemplifies this behavior with its ability to remember its original form after being deformed. This property makes nitinol wire an exceptional choice for applications requiring flexibility and resilience, as it can adapt and recover in dynamic environments.

The versatility of shape memory alloys extends beyond just mechanical applications; they also play a crucial role in medical devices where precision is paramount. For instance, when used in stents or guidewires, the super elastic nitinol wire can navigate complex anatomical structures before returning to its functional form. Ultimately, understanding what makes these materials tick gives engineers and designers an edge in creating innovative solutions.

Mechanisms of Shape Memory Metals

The functionality of shape memory metals like nitinol hinges on their unique crystallographic structure and phase transformation mechanisms. When cooled below a specific temperature known as the martensite finish temperature, nitinol adopts a more flexible phase known as martensite. Upon heating above this threshold, it transforms into its stronger austenite phase—this transition allows for the characteristic shape memory effect.

Moreover, super elasticity is another fascinating feature of nitinol wire that arises from this phase transformation process. Under stress at room temperature, the material can stretch significantly without permanent deformation—this property is particularly beneficial in applications where flexibility and strength are required simultaneously. The interplay between these mechanisms not only enhances performance but also opens up new avenues for technological advancements.

The Role of Titanium Alloys in Nitinol

Titanium alloys are integral to the composition and performance characteristics of nitinol rods; they provide essential attributes such as strength and corrosion resistance. The combination of titanium metal with nickel results in enhanced durability while maintaining lightweight properties—a critical factor for industries like aerospace and medical technology where every gram counts. As a result, titanium material contributes significantly to making nitinol one of the most sought-after materials for innovative engineering solutions.

Furthermore, titanium's biocompatibility complements nitinol's unique capabilities perfectly for use in medical devices implanted within the human body. This compatibility ensures minimal adverse reactions while allowing devices made from super elastic nitinol wire to perform effectively over extended periods inside biological environments. Thus, titanium alloys not only enhance performance but also ensure safety—a vital aspect when considering future innovations involving this remarkable material.

Advantages of Nitinol Rod

When it comes to materials that can revolutionize various industries, the nitinol rod stands out due to its remarkable properties. This unique shape memory alloy, primarily composed of titanium and nickel, offers advantages that traditional metals simply cannot match. From super elasticity to biocompatibility, the nitinol wire is quickly becoming a favorite for engineers and designers alike.

Super Elasticity in Nitinol Rod

One of the most impressive features of the nitinol rod is its super elasticity, which allows it to undergo significant deformation while returning to its original shape when stress is removed. This property makes super elastic nitinol wire an ideal choice for applications where flexibility and resilience are crucial. Imagine a material that can bend and twist without breaking—this is what sets nitinol apart from conventional titanium metal or other alloys.

This super elasticity arises from the unique phase transformation characteristics inherent in shape memory metals like nitinol. When subjected to varying temperatures, these materials can switch between two distinct crystalline structures, enabling them to return to their original form effortlessly. This means that products made from a nitinol rod can withstand extreme conditions without permanent deformation.

Biocompatibility of Titanium Material

Another compelling advantage of using a nitinol rod lies in the biocompatibility of titanium material itself. Unlike many other metals that may cause allergic reactions or adverse effects in biological environments, titanium alloys are known for their compatibility with human tissue. This makes nitrile rods particularly valuable in medical applications such as stents and orthopedic implants.

The biocompatible nature of titanium metal ensures that devices made with nitinol wire can be safely used within the body without causing inflammation or rejection by the immune system. As industries continue to prioritize safety and efficacy, this characteristic positions nitinol as a leading choice for medical device manufacturers looking for reliable materials. The integration of shape memory alloy technology further enhances these devices' functionality.

Durability of Nitinol Wire in Extreme Conditions

Durability is yet another feather in the cap for nitinol rods; they exhibit remarkable resistance to fatigue and corrosion even under extreme conditions. Whether facing high pressures in aerospace applications or exposure to harsh chemicals in industrial settings, super elastic nitinol wire has proven itself time and again as a robust solution. This durability stems from both its composition as a titanium alloy and its unique structural properties.

Nitinol's ability to maintain integrity over time means fewer failures and less downtime for critical systems—an essential factor across various industries including automotive, aerospace, and robotics. The longevity provided by this exceptional material translates into cost savings over time since replacements are less frequent compared to standard materials prone to wear and tear. As more engineers recognize these benefits, demand for components made from this extraordinary shape memory alloy will undoubtedly rise.

Industrial Uses of Nitinol

Nitinol, a remarkable shape memory alloy, is making waves across various industries due to its unique properties and versatility. Its applications range from aerospace to medical devices and even robotics, showcasing the adaptability of this titanium material. Let’s dive into some of the most exciting industrial uses of nitinol rod and other related components.

Aerospace Applications of Nitinol

In the aerospace sector, nitinol rods are revolutionizing design and functionality thanks to their super elasticity and lightweight characteristics. Aircraft components made from this titanium alloy can withstand extreme temperatures and pressures while returning to their original shapes after deformation, which is crucial during flight conditions. The use of nitinol wire in actuators allows for compact designs that save space without compromising performance, leading to more efficient aircraft systems.

Medical Devices Utilizing Nitinol

The medical industry has embraced nitinol for its biocompatibility and shape memory capabilities, making it an ideal choice for various devices like stents and guidewires. These products leverage the unique properties of shape memory metals to adapt to body temperature, expanding or contracting as needed within the human body. Additionally, super elastic nitinol wire provides flexibility during procedures while maintaining strength—essential for navigating complex anatomical structures.

Nitinol in Robotics and Automation

In robotics, nitinol's ability to change shape in response to temperature makes it a game-changer for actuators and sensors that require precise movements without bulky mechanisms. Robots equipped with nitinol rods can perform intricate tasks with enhanced control while being lighter than traditional materials made from titanium metal or other alloys. Furthermore, the durability of nitinol wire ensures that robotic applications can endure harsh environments without failure—a critical factor in automation processes.

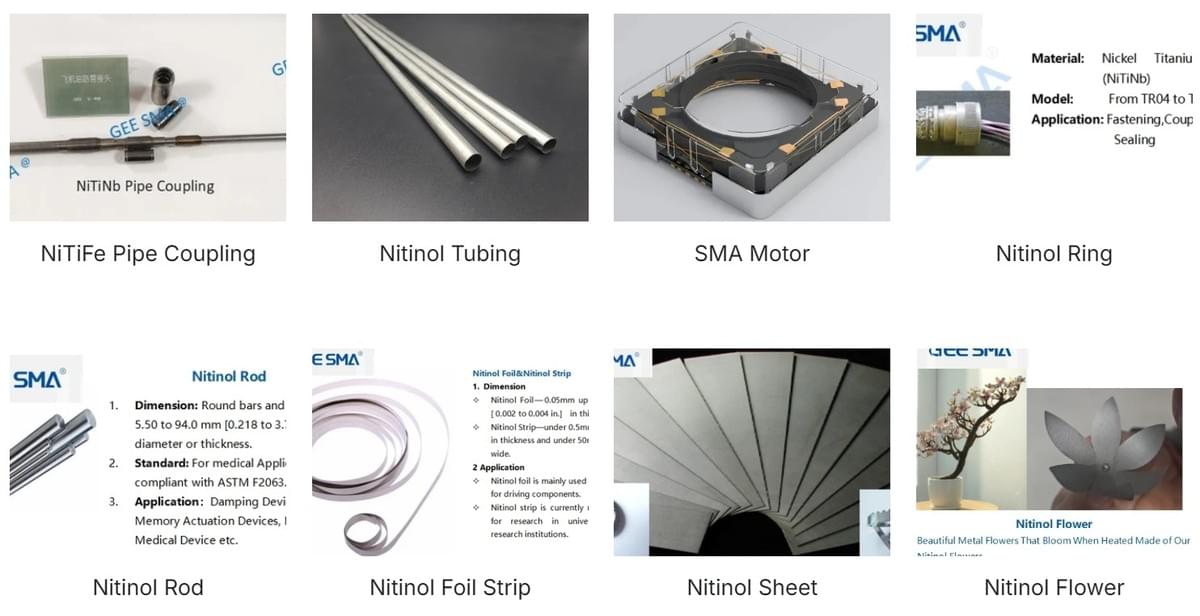

GEE SMA: Leaders in Nitinol Production

In the ever-evolving landscape of materials science, GEE SMA stands out as a pioneering force in the production of nitinol. With a focus on innovation, they harness the remarkable properties of shape memory alloys and titanium alloys to create solutions that push the boundaries of engineering. Their commitment to quality and performance ensures that every nitinol rod and wire produced meets the highest standards, making them a trusted partner across various industries.

Overview of GEE SMA’s Innovations

GEE SMA has consistently led the charge in developing cutting-edge technologies related to nitinol wire and shape memory metals. Their research teams are dedicated to exploring new applications for titanium material, resulting in groundbreaking advancements that enhance product functionality. By leveraging super elastic nitinol wire, GEE SMA has created components that can adapt under stress while maintaining their original form, revolutionizing how engineers approach design challenges.

Nitinol in Space Exploration Projects

The aerospace industry is one of the most demanding fields for materials science, and GEE SMA's contributions to space exploration projects are nothing short of extraordinary. Utilizing nitinol rods and wires, they have developed mechanisms that can withstand extreme temperatures and pressures encountered beyond Earth's atmosphere. The unique properties of shape memory alloys allow these components to perform reliably in environments where traditional materials might fail, making them invaluable for satellite deployment systems and spacecraft mechanisms.

Custom Solutions with Nitinol Components

Understanding that every project presents unique challenges, GEE SMA excels at providing custom solutions featuring nitinol components tailored to specific needs. Their expertise in working with titanium metal allows them to engineer specialized products such as actuators or connectors designed for optimal performance under varying conditions. With their extensive knowledge of super elastic nitinol wire behavior, they can create bespoke solutions that not only meet but exceed client expectations across diverse applications.

Future Trends in Nitinol Technology

The future of nitinol technology is bright and full of potential, driven by ongoing innovations in titanium metal processing and the expanding applications of shape memory alloys. As industries continue to explore the unique properties of nitinol rods, we can expect a surge in demand for these remarkable materials. With advancements in manufacturing techniques, the versatility and functionality of nitinol will only grow, paving the way for exciting new uses.

Advances in Titanium Metal Processing

Recent developments in titanium metal processing are revolutionizing how we utilize titanium alloys, particularly in creating super elastic nitinol wire. Enhanced techniques such as additive manufacturing and advanced heat treatment processes allow for more precise control over material properties, resulting in superior performance characteristics. This means that manufacturers can produce nitinol rods that exhibit improved shape memory effects and elasticity, making them even more suitable for a wide range of applications.

Moreover, these advances facilitate the production of lighter yet stronger components from titanium material, which is crucial for industries like aerospace and medical devices. As processing methods become more efficient and cost-effective, we can anticipate a broader adoption of nitinol wire across various sectors. Ultimately, improved titanium metal processing will enhance the overall quality and reliability of products made from this exceptional shape memory alloy.

Emerging Applications of Shape Memory Alloys

Shape memory alloys are gaining traction beyond traditional uses due to their unique capabilities—particularly with materials like nitinol rod leading the charge. Industries are now exploring innovative applications ranging from automotive systems to consumer electronics where responsive materials can provide significant advantages. For instance, imagine car parts that automatically adjust based on temperature or wearable tech that conforms perfectly to body shapes; all made possible by advancements in shape memory metals.

Additionally, researchers are investigating new ways to integrate super elastic nitinol wire into smart textiles that respond dynamically to environmental changes or user input. This could revolutionize clothing design by offering enhanced comfort and adaptability while maintaining durability through advanced titanium alloy properties. The exploration of these emerging applications highlights just how versatile shape memory alloys have become across multiple fields.

The Evolution of Nitinol Wire Solutions

The evolution of nitinol wire solutions reflects an ongoing commitment to innovation within industries reliant on this remarkable material. Manufacturers are continuously refining their approaches to create more resilient versions of super elastic nitinol wire that can withstand extreme conditions without compromising performance or integrity. As research progresses into optimizing the microstructure of these wires through advanced manufacturing techniques, we can expect even greater enhancements in durability and functionality.

Furthermore, customization options for nitinol rods will expand as companies seek tailored solutions for specific industry needs—from medical devices requiring precise biocompatibility features to aerospace components demanding lightweight strength without sacrificing reliability. This evolution not only improves existing products but also opens doors for entirely new designs that leverage the unique characteristics offered by titanium alloys as they relate to shape memory effects.

As we look ahead at these trends shaping the future landscape of Nitinol technology—it's clear: innovation is at our doorstep!

Conclusion

In summary, the potential of the nitinol rod is truly remarkable, combining advanced technology with practical applications across various industries. Its unique properties as a shape memory alloy and titanium material make it an invaluable resource for engineers and innovators alike. As we look to the future, the role of nitinol wire in shaping new solutions will only continue to grow.

Key Benefits of Nitinol Rod

The nitinol rod stands out due to its exceptional super elasticity, allowing it to return to its original shape after deformation. This characteristic makes it ideal for applications where flexibility and resilience are paramount, particularly in challenging environments. Additionally, the biocompatibility of titanium alloy ensures that these rods can be safely used in medical devices without adverse reactions.

Moreover, durability is another key benefit of using nitinol wire; it can withstand extreme conditions that would typically compromise other materials. This durability stems from the inherent strength of titanium metal combined with the innovative design principles behind shape memory metals. Ultimately, choosing a nitinol rod means investing in a product that promises longevity and reliability.

GEE SMA’s Impact on Industries

GEE SMA has positioned itself as a leader in nitinol production by pushing boundaries and fostering innovation across multiple sectors. Their commitment to research has led to breakthroughs that enhance aerospace applications significantly through lightweight yet robust designs utilizing nitinol wire. Furthermore, their contributions extend into medical devices where precision and reliability are critical; GEE SMA's products consistently meet these demands.

The company's involvement in space exploration projects showcases how nitinol can revolutionize engineering challenges encountered beyond our atmosphere. By developing custom solutions with titanium material tailored for specific needs, GEE SMA demonstrates an unparalleled understanding of market requirements and technological advancements. Their impact on industries not only highlights their expertise but also sets new standards for what is possible with shape memory alloys.

Choosing Nitinol for Future Innovations

As we venture further into an era defined by rapid technological advancement, selecting materials like nitinol rod becomes essential for fostering innovation. The unique features of this shape memory alloy open up avenues previously thought impossible—whether it's enhancing robotic systems or creating cutting-edge medical instruments using super elastic nitinol wire.

Investing in titanium alloys ensures that projects benefit from both strength and adaptability while remaining at the forefront of modern engineering practices. Ultimately, choosing nitinol means embracing a future where possibilities are limited only by imagination—making it a vital component for anyone looking to innovate boldly.