Introduction

In the ever-evolving landscape of materials science, Nitinol tubes stand out as a remarkable innovation that combines unique properties with versatile applications. Composed primarily of nitinol nickel titanium, these shape memory alloys offer not only exceptional mechanical performance but also the ability to revert to predefined shapes when subjected to specific temperatures. This intriguing characteristic makes Nitinol strip an essential component in various industries, from medical devices to aerospace engineering.

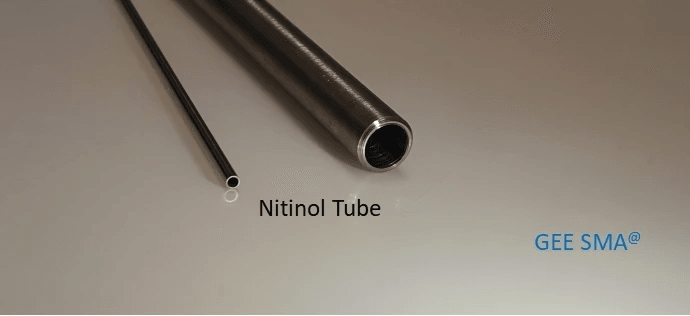

Understanding Nitinol Tubes

Nitinol tubes are crafted from a specialized titanium alloy known for its unique shape memory and superelastic properties. This means that when deformed at room temperature, they can return to their original form upon heating, making them ideal for applications requiring precision and reliability. The integration of shape memory metals into design processes opens up new avenues for innovation in product development and manufacturing.

Importance of Trim Development

Trim development is crucial in optimizing the performance and functionality of Nitinol products, particularly in complex applications such as medical devices and robotics. Effective trim strategies ensure that components are manufactured with precision while minimizing waste and production time. By focusing on efficient trim development processes, manufacturers can enhance the overall quality of Nitinol strip products while maintaining cost-effectiveness.

Overview of Cost Efficiency

Cost efficiency is a significant consideration in the production of Nitinol tubes, especially given the advanced technology required for their manufacture. Analyzing the cost structure reveals opportunities for reducing expenses without compromising quality or performance. Through innovative approaches and streamlined processes, companies can leverage nitinol nickel titanium's advantages while achieving substantial long-term savings.

What is Nitinol and Its Uses?

Nitinol, a fascinating alloy primarily composed of nickel and titanium, is celebrated for its unique properties that set it apart in various industries. This shape memory alloy can return to a predetermined shape when heated above a certain temperature, making it incredibly versatile. With applications ranging from medical devices to robotics, the use of Nitinol strips has revolutionized many sectors.

Defining Nitinol and its Alloys

Nitinol is an abbreviation derived from its composition: Nickel Titanium Naval Ordnance Laboratory, where it was first developed. The alloy typically consists of approximately 55% nickel and 45% titanium, but variations exist to enhance specific properties for different applications. These alloys can be tailored further by adjusting the ratios or incorporating additional elements to improve characteristics like corrosion resistance or strength.

Key Applications in Medical Devices

In the medical field, Nitinol strips are indispensable due to their biocompatibility and ability to perform under varying conditions within the human body. Commonly found in stents, guidewires, and surgical tools, this shape memory metal adapts seamlessly to physiological changes while maintaining structural integrity. Its lightweight nature contributes significantly to patient comfort without compromising performance or efficacy.

The Role of Shape Memory Metals

Shape memory metals like Nitinol exhibit remarkable behavior that allows them to remember their original form after deformation when subjected to heat. This property is particularly useful in applications requiring precise movement or deployment mechanisms—think of stents expanding within arteries or robotic arms mimicking human motion. As industries continue exploring innovative uses for shape memory alloys, the potential for Nitinol remains expansive and exciting.

Advantages of Nitinol Tubes in Manufacturing

Nitinol tubes represent a remarkable advancement in manufacturing, particularly due to their unique properties and versatile applications. These tubes are crafted from a specialized nitinol nickel titanium alloy, which combines the best of both metals to create a material that is not only strong but also highly adaptable. When it comes to shape memory metals, the Nitinol Strip stands out for its ability to return to a predetermined shape when subjected to specific temperature changes, making it invaluable in various industries.

Unique Properties of Nitinol Strip

The Nitinol Strip boasts several unique properties that set it apart from traditional materials. One of its most notable features is its exceptional elasticity; it can undergo significant deformation without permanent damage, allowing for innovative designs that were previously unimaginable with other titanium alloys. Additionally, this shape memory alloy has excellent fatigue resistance and corrosion resistance, making it an ideal choice for demanding applications in medical devices and aerospace components.

Furthermore, the transformation temperatures of nitinol nickel titanium can be precisely engineered during manufacturing processes, enabling designers to tailor the material’s behavior for specific applications. This adaptability means that engineers can create complex geometries while maintaining structural integrity—something that standard metals simply cannot achieve. In essence, the unique properties of the Nitinol Strip empower manufacturers to push boundaries and explore new horizons in product design.

Impact on Design Flexibility

The impact of Nitinol tubes on design flexibility cannot be overstated; they allow engineers and designers unprecedented freedom when conceptualizing products. With their ability to return to a pre-defined shape after deformation, these tubes facilitate intricate designs that would otherwise require multiple components or additional assembly steps with conventional materials. This flexibility not only enhances creativity but also streamlines production processes by reducing part counts.

Moreover, thanks to the lightweight nature of nitinol nickel titanium compared to other metals like stainless steel or aluminum alloys, designers can achieve more efficient designs without compromising strength or performance. The integration of shape memory metals into manufacturing processes enables rapid prototyping and iterative design improvements—allowing teams to innovate quickly while minimizing costs associated with traditional machining techniques. Ultimately, this design flexibility translates into products that are not only aesthetically pleasing but also functionally superior.

Reduced Weight for Enhanced Performance

One major advantage of utilizing Nitinol tubes is their reduced weight compared to other materials like conventional titanium alloys or stainless steels. This weight reduction is crucial across various industries where every gram counts—especially in aerospace and medical applications where performance directly correlates with efficiency and safety margins. By incorporating nitinol nickel titanium into their designs, manufacturers can enhance overall performance without sacrificing structural integrity.

Additionally, lighter components lead directly to improved fuel efficiency in aerospace applications and reduced fatigue on medical devices used within patients' bodies over extended periods—both critical factors for success in these fields. The use of shape memory alloys further complements this benefit by allowing devices made from Nitinol Strip not only to be lighter but also more responsive under varying conditions such as temperature changes or mechanical stresses encountered during operation.

In conclusion, embracing the advantages offered by Nitinol tubes leads manufacturers toward innovative solutions that prioritize performance while maintaining cost-effectiveness over time.

Streamlining Trim Development Processes

In the fast-paced world of Nitinol tube production, streamlining trim development processes is crucial for maintaining a competitive edge. By focusing on efficiency, manufacturers can significantly reduce lead times and enhance overall productivity. This section explores various techniques and innovations that can optimize the development of Nitinol strips and their applications in industries such as medical devices and aerospace.

Techniques to Minimize Development Time

Minimizing development time for Nitinol strips involves implementing strategic planning and advanced methodologies. One effective approach is employing rapid prototyping techniques that allow for quick iterations of design concepts using nitinol nickel titanium alloys. Additionally, utilizing simulation software can help predict performance outcomes early in the design phase, reducing the need for extensive physical testing later on.

Another technique is to adopt a modular design philosophy, where components are designed to be easily interchangeable. This not only speeds up the assembly process but also allows for greater flexibility in manufacturing different shapes or configurations of shape memory metals. By integrating these strategies into the trim development process, companies can achieve faster turnaround times without compromising quality.

Incorporating Automation in Nitinol Tube Production

The integration of automation into Nitinol tube production has revolutionized how manufacturers approach efficiency and precision. Automated systems can handle repetitive tasks with remarkable accuracy, allowing skilled workers to focus on more complex challenges related to titanium alloy fabrication. As a result, automation not only accelerates production rates but also enhances consistency across batches of shape memory alloys.

Robotic arms equipped with specialized tools can streamline processes such as cutting, bending, and assembling Nitinol strips into desired shapes or configurations. Furthermore, automated quality control systems continuously monitor production lines to ensure that every piece meets stringent specifications before it leaves the facility. This level of oversight reduces waste and improves overall product reliability in applications ranging from medical devices to robotics.

Best Practices for Quality Control

Quality control is paramount when dealing with advanced materials like nitinol nickel titanium; any defects could compromise performance in critical applications such as surgical instruments or aerospace components. Implementing best practices begins with establishing robust testing protocols at every stage of production—from raw material inspection through final product evaluation.

Utilizing non-destructive testing methods ensures that each Nitinol strip maintains its unique properties while adhering to industry standards for safety and functionality. Regular training sessions for staff members involved in quality assurance further bolster these efforts by keeping them informed about emerging technologies and methodologies related to shape memory metals. Ultimately, a commitment to rigorous quality control practices leads not only to superior products but also fosters customer trust.

Cost-Effective Nitinol Tube Solutions

When it comes to manufacturing, cost-effectiveness is the name of the game, especially in industries that rely on advanced materials like Nitinol. Understanding the cost structure of Nitinol manufacturing can provide insights into how to optimize production without sacrificing quality. This section will explore the intricacies of this cost structure, highlight GEE SMA's competitive advantages, and discuss how investing in Nitinol innovation can lead to long-term savings.

Analyzing the Cost Structure of Nitinol Manufacturing

The cost structure of Nitinol manufacturing is influenced by several factors, including raw material prices and processing techniques. Nitinol nickel titanium alloys are generally more expensive than conventional metals due to their unique properties and specialized production processes. However, when you break down costs associated with shape memory metals like Nitinol Strip, you'll find that their exceptional performance often justifies the investment.

Labor costs also play a significant role in overall expenses; thus, streamlining operations can lead to substantial savings. By incorporating efficient techniques for shaping and forming titanium alloy components, manufacturers can reduce waste and enhance productivity. Ultimately, a thorough analysis of these elements reveals that while initial investments may be high, the benefits provided by Nitinol far outweigh these costs in many applications.

GEE SMA's Competitive Edge

GEE SMA stands out in the crowded field of Nitinol manufacturers through its commitment to innovation and quality assurance. With years of experience working with shape memory alloys, they have developed proprietary processes that lower production costs while maintaining the integrity of their products. Their expertise in crafting high-quality nitinol tubes allows them to offer competitive pricing without compromising on performance or reliability.

Moreover, GEE SMA leverages state-of-the-art technology for automation throughout its production line—reducing labor costs and minimizing human error significantly. This efficiency translates into faster turnaround times for clients who require precision-engineered components made from nitinol nickel titanium alloys. The combination of advanced technology and skilled craftsmanship positions GEE SMA as a leader in providing cost-effective solutions across various industries.

Long-term Savings through Nitinol Innovation

Investing in innovative technologies related to shape memory metals like Nitinol Strip offers organizations long-term financial benefits that extend beyond initial expenditures. For instance, products made from titanium alloy exhibit enhanced durability and reduced maintenance requirements compared to traditional materials—leading to decreased lifecycle costs over time. Companies utilizing these advanced materials often find themselves reaping rewards from fewer replacements or repairs due to their reliability.

Furthermore, as industries increasingly adopt sustainable practices, using materials like nitinol becomes an attractive option due to their recyclability and energy-efficient properties during production processes. By choosing GEE SMA’s solutions rooted in innovation and sustainability principles, businesses not only save money but also contribute positively towards environmental stewardship—a win-win situation!

In summary, understanding the nuances behind cost-effective solutions involving nitinol tube manufacturing reveals significant opportunities for companies willing to invest wisely today for greater returns tomorrow.

Case Studies of Successful Nitinol Applications

Nitinol, a remarkable shape memory alloy made primarily from nickel and titanium, has found its way into various industries due to its unique properties. In this section, we will explore how GEE SMA has successfully utilized Nitinol in aerospace missions, medical device innovations, and robotics applications. Each case study highlights the versatility and effectiveness of Nitinol strips in real-world scenarios.

GEE SMA in Aerospace Missions

In the aerospace sector, GEE SMA has leveraged the unique characteristics of Nitinol strips to enhance mission capabilities significantly. These shape memory metals can withstand extreme temperatures and pressures while maintaining their structural integrity, making them ideal for components in aircraft and spacecraft. For instance, Nitinol's ability to return to a predetermined shape after deformation is invaluable for actuators and couplings that must function reliably under varying conditions.

One notable project involved the use of nitinol nickel titanium components in deployable structures for satellite systems. The lightweight nature of titanium alloys combined with the shape memory effect allowed engineers to design more efficient mechanisms that save space during launch and expand once in orbit. This innovative approach not only improved performance but also reduced overall mission costs—showcasing how effective trim development processes can be when applied to Nitinol manufacturing.

Medical Device Innovations Using Nitinol

The medical field is one of the most significant beneficiaries of advancements in nitinol technology. Medical devices incorporating nitinol strips have revolutionized treatments by providing superior flexibility and biocompatibility compared to traditional materials. Shape memory alloys are particularly useful in stents and guidewires where precise control is essential; they can navigate complex vascular pathways while expanding safely once positioned.

Moreover, innovations using nitinol nickel titanium have led to breakthroughs such as self-expanding stents that adapt seamlessly within blood vessels without compromising patient safety or comfort. The lightweight properties of these titanium alloys also contribute to reduced fatigue on surrounding tissues during procedures—a critical factor for patient recovery times. As manufacturers continue streamlining trim development processes for these devices, we can expect even greater advancements in medical technology driven by Nitinol's unique capabilities.

Nitinol's Role in Robotics

Robotics is another field where nitinol shines brightly due to its remarkable attributes as a shape memory metal. Engineers are increasingly integrating nitinol strips into robotic systems that require precise movements or adaptations based on environmental changes. For example, soft robotics often utilizes these materials because they allow for dynamic motion without bulky actuators or motors—resulting in lighter-weight designs that mimic natural movement.

A fascinating application includes robotic grippers designed with nitinol components that can adjust their grip strength according to the object being handled—whether fragile or heavy—ensuring optimal performance across various tasks. Additionally, researchers are investigating how combining nitinol with other materials could lead to hybrid systems capable of even more complex functions while maintaining energy efficiency through reduced weight from titanium alloys' incorporation into designs. Overall, as robotics continues evolving, so too will the role of shape memory metals like nitinol.

Conclusion

In wrapping up our exploration of Nitinol, it’s clear that this remarkable material, primarily composed of nitinol nickel titanium, offers a plethora of benefits across various industries. From its unique properties as a shape memory alloy to its lightweight nature, Nitinol strips are revolutionizing manufacturing processes and product designs. The versatility and efficiency of shape memory metals make them indispensable in applications ranging from medical devices to aerospace engineering.

Summary of Nitinol Benefits

Nitinol's standout features include its ability to return to a predetermined shape when heated, which is the hallmark of shape memory alloys. This property not only enhances functionality but also allows for innovative designs that were previously unimaginable with traditional materials like titanium alloy. Moreover, the reduced weight of Nitinol strips translates into improved performance metrics and energy savings in numerous applications.

Future Trends in Nitinol Manufacturing

Looking ahead, the future trends in Nitinol manufacturing are set to be driven by advancements in automation and material science innovations. As production techniques evolve, we can expect even more refined nitinol nickel titanium alloys that enhance performance while reducing costs significantly. The integration of smart technologies will likely lead to next-generation shape memory metals that adapt dynamically to their environment, opening new avenues for application.

How GEE SMA Exceeds Customer Expectations

GEE SMA stands out by not only providing high-quality Nitinol strips but also by ensuring customer satisfaction through tailored solutions and innovative practices. Their commitment to understanding client needs enables them to deliver competitive edge products that consistently outperform expectations in both performance and cost-effectiveness. With a focus on long-term partnerships and continuous improvement, GEE SMA exemplifies how excellence in service can complement superior material offerings.