Introduction

In the realm of modern engineering, few innovations capture the imagination quite like shape memory alloys (SMAs). These remarkable materials possess the unique ability to return to a predefined shape when subjected to specific temperature changes, making them ideal for a variety of applications. Among these, the shape memory alloy linear actuator stands out as a powerful tool in precision control systems.

The Magic of Shape Memory Alloys

Shape memory alloys are not just fascinating; they are revolutionizing how we think about movement and control in technology. By utilizing the properties of shape wire, these materials can exert significant force while maintaining compact sizes, which is essential in applications where space is at a premium. The magic lies in their ability to combine strength with flexibility, allowing engineers to design high precision linear actuators that outperform traditional methods.

Understanding Actuator Technologies

Actuators play a crucial role in transforming energy into motion across various devices and systems. Electric actuators, for instance, have gained popularity due to their efficiency and ease of integration into automated systems.

Why Precision Matters in Control

Precision is not merely an advantage; it’s often a necessity across industries ranging from robotics to aerospace. In environments where even slight inaccuracies can lead to catastrophic failures or inefficiencies, investing in high precision linear actuators becomes imperative. Therefore, understanding how to buy linear actuator systems that prioritize accuracy will ensure optimal performance and reliability for your projects.

What is a Shape Memory Alloy Linear Actuator

Shape memory alloy linear actuators (SMA linear actuators) are fascinating devices that utilize the unique properties of shape memory alloys to create motion. These actuators can return to a predefined shape when heated, making them ideal for applications where precision and reliability are paramount. In essence, they convert thermal energy into mechanical work, providing an innovative solution for various engineering challenges.

Definition and Functionality

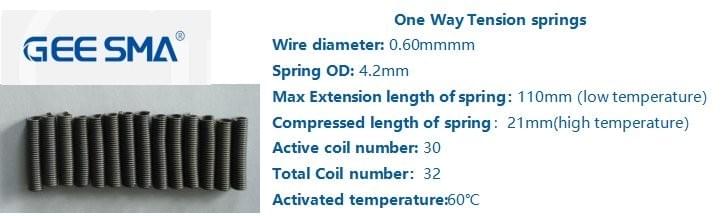

At its core, a shape memory alloy linear actuator is designed to produce controlled linear movement in response to temperature changes. When the actuator is heated above a specific transition temperature, the shape wire within it contracts or expands, leading to precise motion. This functionality makes SMA linear actuators particularly valuable in applications requiring high precision and minimal energy consumption.

The ability of these actuators to achieve significant force output while maintaining compact sizes sets them apart from traditional electric actuators. Their lightweight nature also allows for easier integration into various systems without adding substantial bulk or weight. As engineers look for ways to optimize performance while reducing size, the appeal of high precision linear actuators like SMA units continues to grow.

How Shape Wire Works

The magic behind shape memory alloys lies in their unique composition and molecular structure. Shape wire is typically made from materials like nickel-titanium (NiTi), which exhibit two distinct phases: martensite and austenite. When cooled below their transformation temperature, these alloys take on a flexible martensitic form; however, upon heating above this threshold, they revert to their original rigid austenitic form.

This phase transformation is what enables shape wire within SMA linear actuators to generate motion effectively. As the wire heats up—often through electrical resistance—it contracts rapidly when transitioning back into its stronger phase, producing movement that can be harnessed for various applications. This mechanism provides an incredibly efficient means of actuation compared to traditional electric actuator designs that rely on motors and gears.

Applications in Modern Technology

Shape memory alloy linear actuators are making waves across numerous industries due to their versatility and efficiency. In robotics and automation, these SMA units enable precise movements essential for tasks such as gripping or positioning components with accuracy unmatched by conventional systems. The ability of high precision linear actuators like SMAs allows robots not only to perform intricate tasks but also adapt quickly based on real-time feedback.

Moreover, medical devices have embraced SMA technology for surgical instruments that require delicate manipulation with minimal force application—perfectly aligning with the needs of modern healthcare practices focused on patient safety and efficacy during procedures. From stents that expand within blood vessels to robotic surgical arms capable of performing complex operations with extreme accuracy, the impact of shape memory alloy technology cannot be overstated.

In aerospace applications too, SMA linear actuators play crucial roles in systems ranging from wing morphing technologies that enhance aerodynamics during flight phases to deployable mechanisms used in satellite structures—demonstrating how far-reaching their influence truly is across sectors seeking innovative solutions for complex challenges.

The Role of Electric Actuators

Electric actuators are becoming increasingly popular in various applications, thanks to their efficiency and ease of integration into modern systems. Unlike traditional pneumatic or hydraulic actuators, electric actuators offer precise control over movement and positioning, making them ideal for high precision linear actuator tasks. With advancements in technology, these devices can now achieve remarkable levels of performance while remaining compact and energy-efficient.

Advantages of Electric Actuators

One of the standout advantages of electric actuators is their ability to provide precise control over motion. This precision is crucial in applications requiring exact positioning, such as robotics and medical devices; it’s where the shape memory alloy linear actuator shines alongside electric options. Furthermore, electric actuators typically require less maintenance than their hydraulic counterparts because there are no fluids involved that could leak or degrade over time.

Another benefit includes energy efficiency; electric actuators often consume less power compared to other types like pneumatic systems. This characteristic not only reduces operational costs but also supports sustainability goals by lowering energy consumption across industries. Additionally, the simplicity of their design means that they can be easily integrated into existing systems without extensive modifications.

Finally, electric actuators tend to operate quietly compared to pneumatic or hydraulic alternatives, which can be essential in settings like hospitals or research laboratories where noise reduction is a priority. The smooth operation contributes to a more pleasant working environment while maintaining high performance standards expected from precision linear actuator technologies.

Comparing Electric Actuators to Other Types

When comparing electric actuators with other types like pneumatic and hydraulic systems, several factors come into play—namely cost-effectiveness, maintenance requirements, and operational efficiency. While pneumatic actuators might excel in speed for certain applications, they often fall short on precision when compared with an SMA linear actuator or a high precision linear actuator powered by electricity. Hydraulic systems may provide substantial force but at the cost of increased complexity and potential leakage issues.

Electric actuators stand out because they combine high torque output with exceptional accuracy—making them suitable for applications ranging from industrial automation to aerospace innovations. Their ability to maintain consistent performance without significant fluctuations sets them apart from conventional alternatives that may struggle under varying loads or conditions. Ultimately, the choice between these technologies depends on specific application needs; however, electric options frequently emerge as the most versatile solution for modern engineering challenges.

Moreover, advancements in actuator motor design have led to improved performance metrics across various sectors using electric actuation technology—further widening the gap between them and older methods like hydraulics or pneumatics. When considering a purchase decision about which type to buy linear actuator technology for your project needs careful evaluation based on these comparisons.

The Importance of Actuator Motor Design

The design of an actuator motor plays a pivotal role in determining how effectively an electric actuator functions within its intended application environment. High-quality motors ensure optimal torque output while minimizing energy wastage—a critical factor when aiming for efficient operation in both small-scale and large-scale projects alike. In particular, innovations surrounding shape wire technology have opened new avenues for achieving higher levels of performance within SMA linear actuation systems.

When selecting an actuator motor for your application needs—whether it’s a standard electric model or one designed specifically for use with shape memory alloy linear actuators—considerations should include size constraints as well as operational requirements such as load capacity and speed capabilities. A well-designed motor will allow seamless integration into existing setups while ensuring reliable long-term functionality even under demanding conditions typical across many industries today.

In conclusion, understanding how crucial effective actuator motor design is can help engineers make informed decisions regarding which type best suits their unique requirements—whether opting for traditional models or exploring cutting-edge solutions involving SMA technology combined with advanced electrical components aimed at achieving unparalleled levels of precision throughout various applications.

High Precision with SMA Linear Actuators

When it comes to precision engineering, the shape memory alloy linear actuator stands out due to its unique characteristics and capabilities. These actuators leverage the properties of shape wire, which can return to a predetermined shape when heated, allowing for precise movements that are essential in various applications. The integration of advanced actuator motor designs makes these high precision linear actuators not just effective but also reliable in demanding environments.

Mechanisms That Ensure Precision

The mechanisms behind the precision of SMA linear actuators are fascinating and rooted in their inherent material properties. Shape memory alloys can undergo phase transformations that allow them to exert significant force while maintaining tight tolerances, making them ideal for applications requiring exact movements. Additionally, the careful design of electric actuators that utilize these materials ensures that every movement is controlled with exceptional accuracy, enhancing their performance as precision linear actuators.

Case Studies in High Precision Applications

In real-world scenarios, high precision linear actuators have demonstrated their value across various industries. For instance, in robotics and automation, SMA linear actuators have been used to create robotic arms capable of delicate tasks like surgery or assembly line work where accuracy is paramount. Another notable example is in aerospace innovations where these actuators contribute to flight control systems that require exact positioning; here again, the role of actuator motors designed for high performance cannot be overstated.

Future Trends in Precision Linear Actuators

Looking ahead, the future trends for shape memory alloy linear actuators point toward even greater advancements in technology and application scope. With ongoing research into new materials and smarter actuator motor designs, we can expect enhanced performance metrics such as speed and efficiency alongside precision improvements. As industries continue to seek out innovative solutions for automation challenges, those looking to buy linear actuators will find an expanding range of options tailored specifically for high-precision needs.

Choosing the Right Linear Actuator

Selecting the ideal linear actuator can feel like navigating a maze, especially with so many options available. Whether you're leaning towards a shape memory alloy linear actuator or an electric actuator, understanding your specific needs is crucial. This section will guide you through the essential factors to consider and highlight the features that define high-performance models.

Factors to Consider When You Buy Linear Actuator

When you decide to buy a linear actuator, start by evaluating the load capacity and stroke length required for your application. Different applications demand different specifications; for instance, a high precision linear actuator might be necessary in robotics, while simpler tasks may only require basic functionality. Additionally, consider environmental factors such as temperature and humidity—some actuators are more resilient than others in challenging conditions.

Another critical aspect is speed and response time; how quickly do you need your actuator to respond? For applications requiring rapid adjustments, an electric actuator might be preferable due to its quick action capabilities compared to traditional systems. Finally, think about power requirements—some actuators operate on standard AC power while others may need specialized setups.

Key Features of High Performance Models

High performance models of shape memory alloy linear actuators often come equipped with advanced features that set them apart from standard options. One standout characteristic is their ability to deliver exceptional precision through finely-tuned control mechanisms; this is paramount in applications where every millimeter counts. Furthermore, many high-performance SMA linear actuators utilize innovative designs that enhance efficiency while minimizing energy consumption.

Another important feature is durability; look for models constructed from high-quality materials that can withstand wear and tear over time without compromising performance. The integration of smart technology also plays a significant role; some modern actuators come with built-in sensors and feedback systems for real-time monitoring of performance parameters. These features not only improve reliability but also contribute greatly to achieving optimal operation in demanding environments.

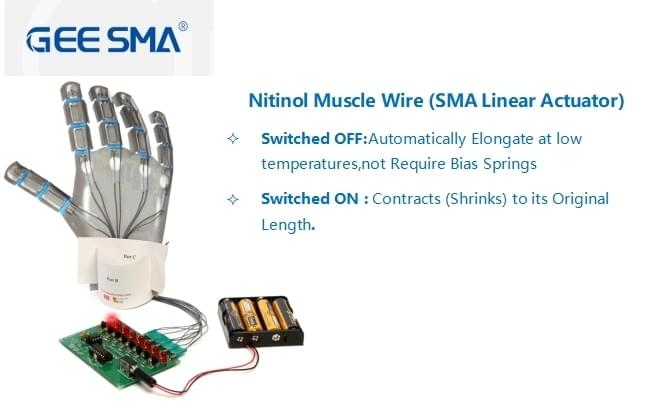

The Importance of Quality Manufacturers like GEE SMA

Investing in a quality manufacturer can make all the difference when it comes to shape memory alloy linear actuators or any type of electric actuator. Companies like GEE SMA are renowned for their commitment to quality control and innovation within their product lines, ensuring that customers receive reliable solutions tailored for various applications. Partnering with reputable manufacturers provides peace of mind knowing that your chosen actuator has been rigorously tested under various conditions.

Moreover, established brands often offer comprehensive support services including technical assistance and warranty options which can prove invaluable post-purchase. With cutting-edge research backing their products, companies like GEE SMA consistently push the boundaries of what’s possible in precision linear actuation technology—a key factor if you're looking for long-term reliability in your projects. Ultimately, choosing a trusted manufacturer ensures you get not just an ordinary actuator but one designed for excellence.

Real-World Applications of SMA Actuators

Shape Memory Alloy (SMA) linear actuators are making waves in various industries thanks to their unique properties and capabilities. Their ability to change shape in response to temperature variations allows them to perform tasks that traditional electric actuators might struggle with, particularly in terms of precision and control. This adaptability makes SMA linear actuators ideal for applications where space is limited and reliability is paramount.

Robotics and Automation

In the realm of robotics and automation, the use of shape memory alloy linear actuators has revolutionized how machines operate. These high precision linear actuators can mimic biological movements, enabling robots to perform delicate tasks with incredible accuracy. Whether it's in assembly lines or robotic arms, the actuator motor's responsiveness ensures seamless integration into automated systems, enhancing productivity while reducing operational costs.

Moreover, SMA technology allows for lightweight designs that don't compromise on strength or efficiency—an essential factor in modern robotics. As manufacturers look to buy linear actuators for their projects, the appeal of SMA solutions continues to grow due to their compactness and high performance. Ultimately, the fusion of robotics with SMA technology paves the way for smarter automation solutions across various sectors.

Medical Devices and Surgical Applications

The medical field is another area where shape memory alloy linear actuators are making significant impacts. From minimally invasive surgical tools to advanced prosthetics, these precision linear actuators provide reliable motion control that is critical during surgical procedures. The unique properties of shape wire enable devices to adapt seamlessly within a patient’s body while ensuring maximum safety and efficacy.

Additionally, SMA technology can be used in drug delivery systems that require precise actuation for optimal results—ensuring medication is administered accurately when needed most. As healthcare professionals increasingly seek innovative solutions, the demand for high precision linear actuators within medical devices continues to rise dramatically. With quality manufacturers like GEE SMA leading the charge, we can expect even more groundbreaking advancements in this field.

Aerospace Innovations and Industry Examples

Aerospace applications have also embraced shape memory alloy linear actuators due to their exceptional performance under extreme conditions. These lightweight yet robust components play a crucial role in controlling wing flaps or landing gear mechanisms—where reliability is non-negotiable! The actuator motor’s ability to respond quickly and efficiently contributes significantly to aircraft safety and performance metrics.

Furthermore, as aerospace technology evolves toward more efficient designs, integrating SMA technology helps reduce overall weight without sacrificing functionality—a key factor when every gram counts during flight operations! Companies looking at futuristic aircraft designs are increasingly inclined to consider these innovative solutions when planning their next project or upgrade; after all, who wouldn't want a competitive edge? In summary, the aerospace industry stands at the forefront of adopting high precision linear actuator technologies that promise enhanced safety features while pushing boundaries further than ever before.

Conclusion

As we wrap up our exploration of shape memory alloy (SMA) technology and its applications in linear actuators, it’s clear that these innovative devices offer a unique blend of functionality and precision. The ability of SMA linear actuators to respond to temperature changes allows for remarkable adaptability in various environments, making them indispensable in fields like robotics, aerospace, and medical devices. With their compact design and lightweight properties, shape memory alloy linear actuators are paving the way for future advancements in actuator technologies.

Evaluating the Benefits of SMA Technology

The benefits of using shape memory alloy linear actuators are manifold. First and foremost, their high precision capabilities allow for exceptional control in applications where accuracy is paramount; think surgical robots or aerospace mechanisms where even a slight deviation can lead to significant consequences. Additionally, SMA technology offers simplicity in design since these actuators do not require complex electric motors or gears, thereby reducing potential points of failure.

Moreover, the energy efficiency associated with SMA linear actuators is another key advantage; they consume power only when changing states rather than continuously like some electric actuators. This feature not only extends battery life but also contributes positively to sustainability efforts across industries. Ultimately, evaluating the benefits of SMA technology reveals that it stands out as a smart choice for high precision applications.

The Future of Linear Actuators

Looking ahead, the future of linear actuators appears bright with ongoing innovations in materials science and actuator motor design. As industries demand greater efficiency and precision from their equipment, we can expect further integration of advanced technologies into both shape memory alloy linear actuators and electric actuator systems alike. Developments such as improved shape wire compositions could enhance performance characteristics while reducing costs – making these technologies more accessible than ever before.

Furthermore, with the rise of automation and smart systems across various sectors, there will be an increasing need for reliable high precision linear actuators that can seamlessly integrate into complex networks. The convergence of artificial intelligence with actuator technology could also lead to smarter control systems capable of adapting on-the-fly based on real-time data inputs. In essence, the future holds immense potential for both shape memory alloys and electric actuation technologies as they evolve alongside emerging trends.

Why GEE SMA Stands Out in the Market

When it comes to choosing where to buy linear actuators or seeking quality manufacturers in this field, GEE SMA consistently emerges as a top contender due to its commitment to excellence and innovation. Their focus on producing high-performance models ensures that customers receive reliable products designed specifically for demanding applications requiring precise motion control – an essential factor when selecting a supplier for your next project involving high precision linear actuators.

Additionally, GEE SMA's expertise extends beyond just manufacturing; they actively engage with clients to understand their unique needs while providing tailored solutions that leverage cutting-edge shape wire technology effectively within each actuator design produced by them. Their reputation is built upon years spent refining processes aimed at delivering unparalleled quality alongside competitive pricing strategies – making them an ideal partner for anyone looking into advanced actuator solutions today.

In conclusion, whether you're exploring options among electric or shape memory alloy linear actuators or simply seeking insights into future trends within this exciting industry landscape—the information presented here should empower you toward making informed decisions about your next purchase!