Introduction

In the realm of modern engineering, few materials capture the imagination quite like shape memory alloys (SMAs). These remarkable materials possess the ability to return to a pre-defined shape when subjected to specific temperatures, allowing for innovative applications that were once confined to the pages of science fiction. Among these applications, the shape memory alloy linear actuator stands out as a game-changer in revolutionizing linear motion with unparalleled precision and efficiency.

The Fascinating World of Shape Memory Alloys

Shape memory alloys are not just another engineering curiosity; they represent a paradigm shift in how we approach movement and actuation. Composed primarily of nickel and titanium, these alloys can remember their original form after being deformed, making them incredibly versatile for various applications. From medical devices to aerospace technology, the unique properties of SMAs enable engineers to design systems that are lighter, more efficient, and capable of performing complex tasks with minimal input.

Revolutionizing Linear Motion with Precision

The advent of shape memory alloy linear actuators has transformed traditional concepts of linear motion by introducing a level of precision previously unattainable with conventional systems. Unlike traditional linear motor actuators that rely on electric motors or hydraulic systems, SMAs operate through thermal activation, which allows for smoother and quieter operation. This innovation not only enhances performance but also reduces energy consumption—making it an attractive option for industries seeking sustainable solutions.

The Role of GEE SMA in Advanced Technology

At the forefront of this technological revolution is GEE SMA, a pioneer in developing advanced nitinol alloys tailored for specific applications. Their commitment to quality and customization ensures that each shape memory alloy linear actuator meets stringent industry standards while delivering exceptional performance. As GEE SMA continues to push the boundaries of what’s possible with SMAs, they play an essential role in advancing technologies across sectors such as aerospace and robotics.

Understanding Shape Memory Alloys

Shape memory alloys (SMAs) are materials that possess a remarkable ability to return to a predefined shape when subjected to specific thermal conditions. This unique property stems from their crystalline structure, which can undergo phase transformations between two distinct forms: the martensite phase at lower temperatures and the austenite phase at higher temperatures. Such versatility makes SMAs particularly appealing for applications in linear motion, where precise control and movement are essential.

What Makes Them Unique

What sets shape memory alloys apart from traditional materials is their ability to remember their original configuration after deformation. When heated, they revert to this shape, generating significant force in the process—ideal for use in a shape memory alloy linear actuator. This characteristic not only allows for efficient energy conversion but also means that these materials can be compactly designed, saving space while delivering high performance.

Another fascinating aspect of SMAs is their tunable properties; by adjusting the alloy composition and processing methods, manufacturers can fine-tune characteristics such as transformation temperature and mechanical strength. This customization is crucial for linear actuator manufacturers who need specific performance metrics tailored to different applications. As industries increasingly demand precision engineering solutions, the unique attributes of shape memory alloys position them as front-runners in innovative design.

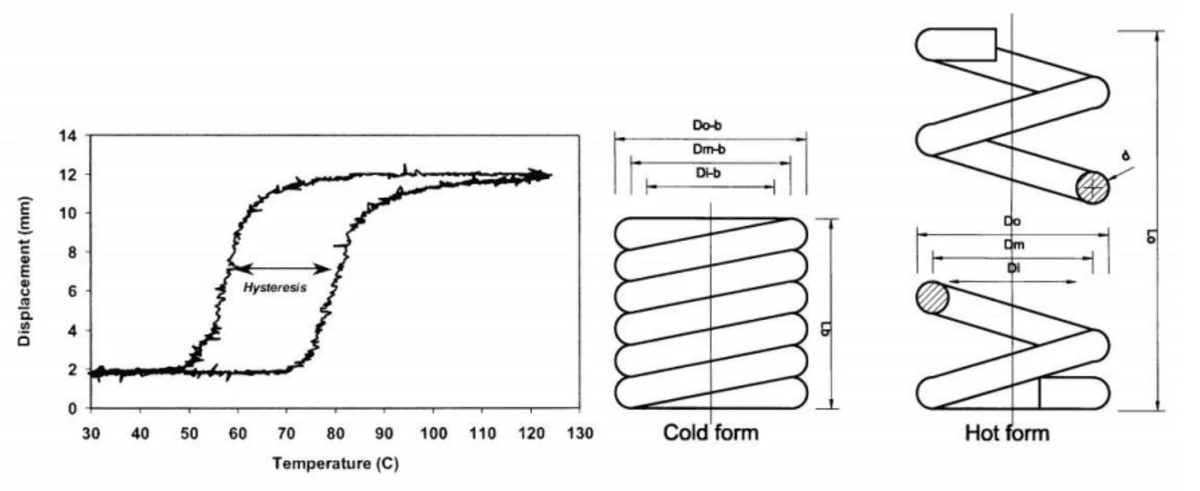

How They Respond to Temperature

The response of shape memory alloys to temperature changes is nothing short of spectacular. When cooled below a certain threshold, SMAs enter the martensitic state, allowing them to be easily deformed without permanent damage—a feature that enables their use in various linear motor actuators. Once heated above this critical point, they transition back into the austenitic state and regain their original form with impressive force output.

This temperature-dependent behavior allows for dynamic actuation capabilities; by simply varying the temperature applied to the SMA component within a linear actuator system, users can achieve precise control over movement and positioning. The ability of SMAs to operate effectively across various thermal environments makes them suitable for applications ranging from medical devices to aerospace technologies where reliable linear motion is paramount.

Moreover, understanding how these materials respond under different conditions helps engineers design smarter systems that leverage this unique thermal responsiveness while minimizing energy consumption—an attractive feature for many modern applications.

Applications in Various Industries

Shape memory alloys have found diverse applications across numerous industries due to their exceptional properties and adaptability in design—especially within sectors requiring advanced actuation solutions like aerospace and robotics. In aerospace missions, SMAs are utilized in mechanisms such as deployable structures or active control surfaces where space constraints demand lightweight yet powerful solutions like shape memory alloy linear actuators.

In robotics, these materials enable precise movements with minimal energy expenditure; robotic arms equipped with SMAs can perform intricate tasks while maintaining high efficiency levels thanks to effective linear motion capabilities inherent in these alloys. Additionally, automotive manufacturers are increasingly incorporating SMAs into safety systems such as seatbelt retractors or airbag deployment mechanisms—highlighting how versatile these materials are across various applications.

The potential of shape memory alloys continues expanding as researchers explore new uses—from smart textiles that adapt based on environmental conditions to innovative medical devices capable of minimally invasive surgeries utilizing SMA-driven actuation systems—underscoring an exciting future ahead for both industries and consumers alike.

The Mechanics of Linear Actuation

In the ever-evolving landscape of technology, the mechanics behind linear actuation are becoming increasingly sophisticated. At the heart of this innovation lies the shape memory alloy linear actuator, a device that leverages unique materials to convert thermal energy into mechanical motion. This transformation enables precise control over linear motion, making it an invaluable tool in numerous applications.

Shape Memory Alloy Linear Actuator Explained

A shape memory alloy linear actuator utilizes materials that can remember their original shape after being deformed, thanks to temperature changes. When heated above a certain threshold, these alloys revert to their pre-deformed structure, generating movement in a controlled manner. This mechanism allows for efficient and reliable linear motion without the complexity often associated with traditional actuators.

The operation of these actuators is relatively straightforward yet fascinating: they expand or contract in response to temperature fluctuations, creating forceful linear movements. This capability makes them ideal for applications requiring precision and reliability, such as robotics and aerospace systems. Their compact design and lightweight nature further enhance their appeal among linear actuator manufacturers looking to optimize performance without compromising on size or weight.

Advantages over Traditional Actuators

Shape memory alloy linear actuators boast several advantages compared to traditional actuators like electric motors or pneumatic systems. Firstly, they offer significant weight savings due to their compact design and absence of bulky components typically found in conventional systems. Additionally, they operate silently and smoothly, which is particularly advantageous in environments where noise reduction is essential.

Another key benefit is their simplicity; with fewer moving parts than most traditional options, maintenance requirements are minimized while reliability is maximized. Furthermore, these actuators can achieve high force outputs relative to their size—an impressive feat that enhances their effectiveness across various applications. As more industries recognize these advantages, demand for shape memory alloy linear actuators continues to grow among leading linear actuator manufacturers.

Key Industries Utilizing Linear Actuators

The versatility of shape memory alloy linear actuators has led them to be embraced by a wide array of industries seeking innovative solutions for complex challenges. In aerospace engineering, for instance, these actuators are employed in mechanisms that require precise positioning under extreme conditions—think flaps on aircraft wings or satellite deployments in space! Their ability to perform reliably under varying temperatures makes them indispensable in this field.

Similarly, robotics has seen a surge in the use of shape memory alloy technologies due to their responsiveness and precision capabilities during operations such as gripping or movement articulation. Medical devices also benefit from this technology; surgical instruments that require delicate handling often integrate these advanced actuators for improved control and safety during procedures. As industries continue exploring new frontiers with innovative designs powered by shape memory alloys, we can expect even broader adoption across sectors.

GEE SMA: Pioneers in Nitinol Alloys

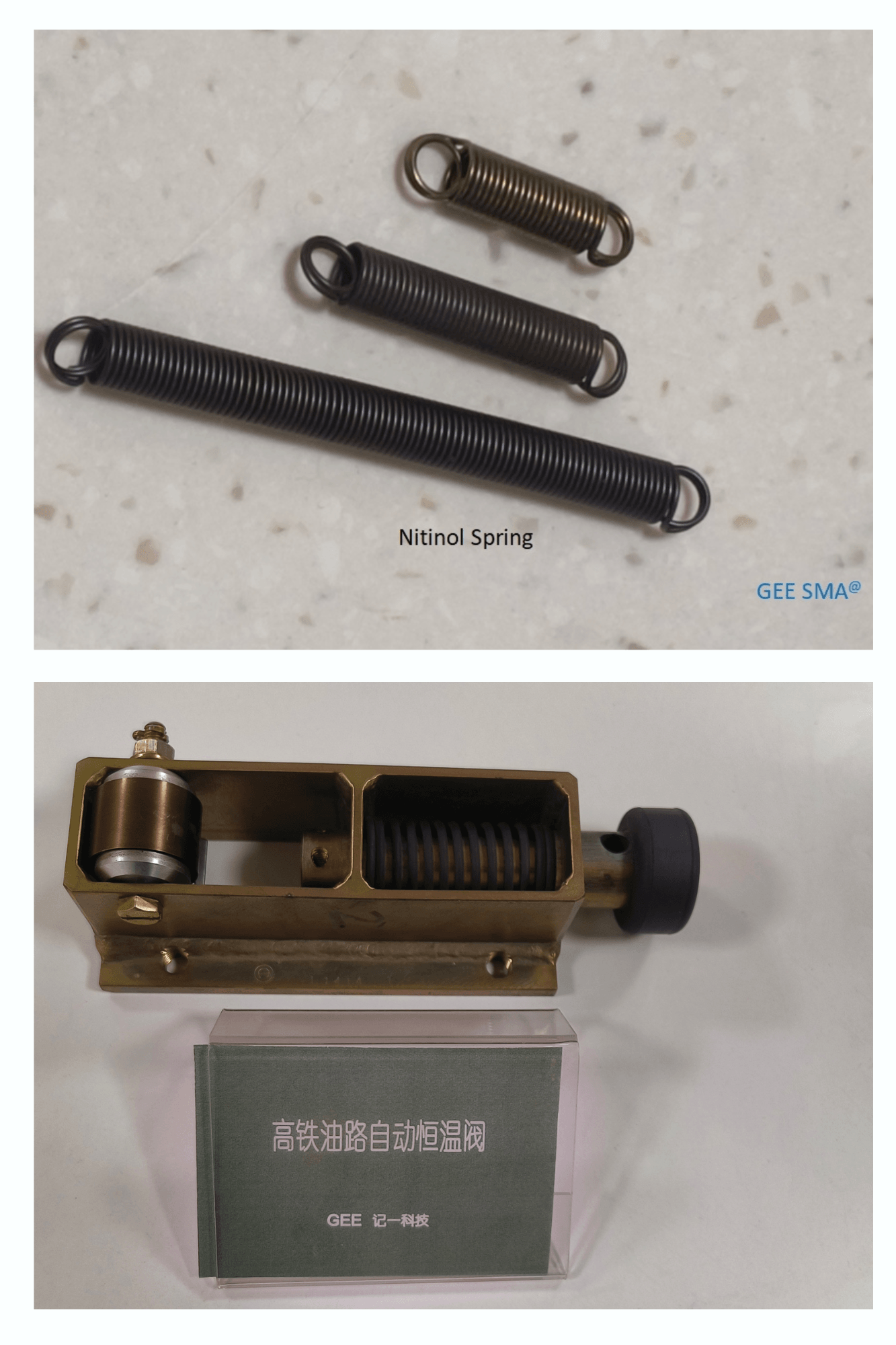

GEE SMA stands at the forefront of innovation in the realm of shape memory alloys, particularly with their groundbreaking work on Nitinol. This unique alloy, known for its remarkable ability to return to a pre-defined shape when heated, has opened new doors in the field of linear motion. By harnessing the properties of shape memory alloys, GEE SMA has developed advanced linear motor actuators that are transforming industries across the board.

Overview of GEE SMA's Innovations

GEE SMA has pioneered several innovations that have redefined what’s possible with shape memory alloy linear actuators. Their cutting-edge research and development focus on enhancing performance, efficiency, and reliability in various applications. By combining state-of-the-art manufacturing techniques with deep material science knowledge, they ensure that their linear actuator offerings are not only robust but also highly effective for diverse industrial needs.

The company's commitment to innovation is evident in its custom solutions tailored to specific applications within aerospace and robotics. These advancements allow GEE SMA to create specialized products that meet rigorous industry standards while pushing the boundaries of what traditional actuators can achieve. With a focus on continuous improvement and adaptation, GEE SMA remains a trailblazer among linear actuator manufacturers.

The Importance of Quality and Customization

In an industry where precision is paramount, GEE SMA places a significant emphasis on quality control throughout its production processes. Each shape memory alloy linear actuator undergoes rigorous testing to ensure it meets strict performance specifications before it reaches customers. This dedication to quality not only enhances product lifespan but also instills confidence in clients relying on these actuators for critical applications.

Customization is another cornerstone of GEE SMA's approach; they understand that one size does not fit all when it comes to engineering solutions. By offering tailored designs based on specific client requirements, they enable businesses to optimize their operations significantly—whether it's adjusting force output or modifying response times for unique tasks. This flexibility ensures that every customer receives an actuator perfectly suited to their needs.

Impact on Aerospace Missions

The impact of GEE SMA's innovations extends far into aerospace missions where reliability and precision are non-negotiable requirements. Their shape memory alloy linear actuators are utilized in various aerospace applications ranging from satellite deployment systems to adaptive wing technologies—demonstrating versatility across high-stakes environments. As aerospace missions become increasingly complex, having dependable actuation systems powered by advanced materials like Nitinol is essential for success.

Moreover, these advanced actuators contribute significantly by reducing weight while maintaining high force output—an essential factor when designing aircraft or spacecraft where every gram counts against fuel efficiency and payload capacity. The integration of GEE SMA's technology into aerospace systems showcases how modern engineering can leverage material properties for enhanced performance and safety during missions beyond our atmosphere. As more industries recognize these benefits, we can expect a growing demand for innovative solutions from leading linear actuator manufacturers like GEE SMA.

Precision and Force in Actuation

In the realm of engineering, precision and force are paramount, especially when it comes to actuation technologies. Shape memory alloy linear actuators have emerged as game-changers in this domain, offering unique capabilities that traditional methods simply cannot match. By harnessing the properties of shape memory alloys, these actuators provide both high force output and remarkable precision, making them indispensable in various applications.

Achieving High Force Output

One of the standout features of shape memory alloy linear actuators is their ability to produce significant force while maintaining a compact size. This high force output is primarily due to the unique phase transformation that occurs within the material when exposed to specific temperature changes. As a result, linear actuator manufacturers are increasingly adopting these alloys for applications where space constraints and power efficiency are critical.

The capacity for a shape memory alloy linear actuator to generate substantial force makes it ideal for demanding environments such as aerospace and robotics. For instance, when deployed in robotic arms or aircraft control surfaces, these actuators can deliver precise movements without compromising on strength or reliability. This combination of compactness and power is revolutionizing how we think about linear motion in advanced technologies.

Enhancing Precision with Shape Memory Alloys

Precision is another hallmark of shape memory alloy linear actuators that sets them apart from conventional options. The inherent responsiveness of shape memory alloys allows for fine-tuned control over movement dynamics, enabling engineers to achieve exact positioning with minimal error margins. This level of accuracy is essential in fields like robotics where even slight deviations can lead to significant operational failures.

Moreover, the ability to customize the properties of shape memory alloys means that engineers can tailor their performance characteristics according to specific application needs. Linear motor actuators using these materials can be designed to respond quickly or slowly based on task requirements, providing flexibility that traditional systems often lack. Such enhancements not only improve performance but also open up new possibilities for innovation across various industries.

Case Studies in Aerospace and Robotics

To illustrate the transformative impact of shape memory alloy linear actuators, let's delve into some compelling case studies from aerospace and robotics sectors. In aerospace applications, companies have successfully integrated these actuators into wing morphing technologies—allowing aircraft wings to change shape during flight for improved aerodynamics and fuel efficiency. The use of shape memory alloy technology has led to lighter designs without sacrificing performance or safety.

In robotics, consider a scenario where robotic surgical instruments utilize shape memory alloy linear actuators for precision cutting or suturing tasks within tight confines inside the human body. The ability to achieve high levels of control while exerting necessary forces enhances both efficacy and safety during procedures—demonstrating how crucial these innovations are becoming in medical technology as well as other fields requiring precision engineering.

These examples showcase how leading linear actuator manufacturers are leveraging advancements in material science through shape memory alloys not just for improved functionality but also for pioneering new applications that were once thought impossible.

Challenges and Future Prospects

The world of shape memory alloys (SMAs) is indeed captivating, but it does come with its own set of challenges. While shape memory alloy linear actuators promise revolutionary advancements in linear motion, there are limitations that need to be addressed for broader adoption. These limitations include issues related to response time, thermal efficiency, and the complexity of integrating SMAs into existing systems.

Limitations of Current Technology

One of the primary limitations of current shape memory alloy technology is its relatively slow response time compared to traditional linear motor actuators. This delay can hinder applications requiring rapid actuation, particularly in dynamic environments like robotics and aerospace. Moreover, the thermal management required for these alloys can complicate designs, making it challenging for engineers to optimize performance without overheating or damaging components.

Another significant hurdle lies in the durability and fatigue resistance of shape memory alloys. While they exhibit remarkable properties under specific conditions, prolonged use can lead to degradation over time. This raises concerns among linear actuator manufacturers regarding reliability and maintenance costs associated with SMA-based systems.

Future Developments in Linear Motor Actuators

Looking ahead, future developments in linear motor actuators are poised to address many current limitations through innovative engineering solutions. Researchers are exploring advanced materials that enhance thermal conductivity and reduce response times while maintaining the unique properties that make SMAs so appealing for linear motion applications. Additionally, integrating smart technologies could allow for real-time monitoring and adjustments based on performance metrics.

There’s also a growing interest in hybrid systems that combine traditional actuators with shape memory alloy technology to leverage the strengths of both approaches. By doing so, industries can achieve faster actuation speeds without sacrificing precision or force output—an exciting prospect for sectors such as aerospace and robotics where every millisecond counts.

How Linear Actuator Manufacturers Are Adapting

In light of these challenges and future prospects, linear actuator manufacturers are adapting by investing heavily in research and development focused on SMA technologies. They are collaborating with universities and research institutions to explore novel SMA compositions that offer improved performance characteristics while reducing production costs. This collaborative approach not only accelerates innovation but also helps bridge the gap between theoretical advancements and practical applications.

Moreover, manufacturers are increasingly prioritizing customization options tailored to specific industry needs—ensuring that their products can meet stringent requirements across various sectors including automotive, medical devices, and aerospace missions. By embracing flexibility in design and production processes, these companies position themselves at the forefront of technological advancement within this niche market.

Conclusion

In the ever-evolving landscape of engineering and technology, shape memory alloys stand out as a transformative force. Their unique properties allow for innovative applications, particularly in linear motion systems where precision is paramount. As we look to the future, the potential for shape memory alloy linear actuators to redefine how we approach various mechanical challenges is immense.

The Future of Shape Memory Alloys

The future of shape memory alloys promises exciting advancements that could revolutionize multiple industries. With ongoing research and development, we can expect enhancements in efficiency and adaptability within linear motor actuators. These innovations will likely lead to even more versatile applications, making shape memory alloy linear actuators a staple in modern engineering.

GEE SMA's Role in Technological Advancement

GEE SMA has positioned itself at the forefront of technological advancement through its pioneering work with nitinol alloys. By focusing on quality and customization, GEE SMA enables industries to harness the full potential of shape memory alloy linear actuators effectively. Their commitment not only enhances performance but also drives innovation across sectors such as aerospace and robotics.

Achieving Precision and Force in Engineering

Achieving both precision and force output with linear actuator manufacturers has never been more feasible thanks to advancements in shape memory alloys. These materials provide an exceptional combination of strength and accuracy that traditional methods struggle to match. As engineers continue to explore new possibilities with shape memory alloy linear actuators, we are sure to witness remarkable breakthroughs that push the boundaries of what is achievable.