Introduction

Nitinol linear actuators are revolutionizing the way we think about movement and control in various applications. These remarkable devices leverage the unique properties of Nitinol wire, a shape memory alloy (SMA) that responds to temperature changes with impressive actuation capabilities. By employing Nitinol muscle wire, engineers can create compact, efficient systems that mimic natural motion, making them ideal for everything from robotics to medical devices.

Understanding Nitinol Linear Actuators

At their core, Nitinol linear actuators utilize SMA wire to achieve movement through thermal activation. When heated, the Nitinol wire transforms from a deformed state back to its original shape, generating motion in a linear direction—hence the term linear actuator. This two-way actuation capability allows for precise control over movements, offering advantages over traditional mechanical systems that rely on gears or motors.

The Role of Shape Memory Alloy Wire

The magic of Nitinol lies in its ability to remember its original shape after being deformed. When cooled down, SMA wire can be manipulated into various configurations; however, upon heating, it returns to its predefined form with remarkable force and speed. This unique property not only enhances the functionality of Nitinol linear actuators but also enables them to operate efficiently in confined spaces where conventional actuators may falter.

Applications of Nitinol Muscle Wire

Nitinol muscle wire is finding applications across diverse fields due to its lightweight nature and high strength-to-weight ratio. From aerospace engineering—where reliability is paramount—to innovative prosthetics that adapt seamlessly to user movements, the uses are virtually limitless. As industries increasingly turn toward advanced materials like Nexmetal Nitinol Wire for their projects, we can expect even more groundbreaking applications on the horizon.

What is Nitinol Wire?

Nitinol wire, a remarkable alloy of nickel and titanium, is renowned for its unique properties that make it an essential component in various applications, particularly in the realm of linear actuators. This shape memory alloy (SMA) exhibits the ability to return to a predetermined shape when heated, allowing for innovative designs in engineering and robotics. With its flexibility and strength, Nitinol wire has become synonymous with advancements in actuator technology.

The Science Behind Nitinol

The magic of Nitinol lies in its phase transformation behavior. When cooled below a specific temperature, this SMA wire adopts a martensitic phase that allows it to be easily deformed; however, upon heating above this threshold, it transforms into an austenitic phase, restoring its original shape. This characteristic enables the creation of linear two-way actuator wires that can perform complex movements with precision and efficiency.

Notably, the transformation temperature can be tailored during manufacturing processes, making Nitinol wire adaptable for various applications across different environments. This versatility is crucial for industries ranging from medical devices to aerospace engineering where reliable actuation is paramount. Understanding this fundamental science behind Nitinol helps engineers harness its potential effectively.

Characteristics of Nitinol Linear Actuator

Nitinol linear actuators stand out due to their compact size and lightweight nature while delivering impressive force output relative to their dimensions. These actuators rely on Nitinol muscle wire that contracts when heated and expands upon cooling—an ideal mechanism for creating motion without bulky components or complex mechanical systems. Their simplicity not only reduces the overall weight but also enhances reliability by minimizing moving parts.

Another defining characteristic is their ability to operate silently compared to traditional electric or hydraulic actuators—an appealing feature for applications requiring discretion or low noise levels. Moreover, these SMA wires exhibit excellent fatigue resistance and durability under repeated cycling conditions, ensuring long-term performance even in demanding environments like space missions or robotic surgeries.

Differences Between Nitinol and Other Alloys

When comparing Nitinol wire with conventional alloys used in actuator technologies, several key differences emerge that highlight the advantages of using SMA wire for specific applications. Unlike most metals that rely on direct mechanical movement through gears or motors, Nitinol's unique shape memory property allows it to generate motion through thermal activation alone—eliminating the need for external power sources during certain operations.

Additionally, while many alloys may suffer from wear over time due to friction between moving parts, Nitinol's solid-state actuation minimizes wear-and-tear issues significantly—making it an appealing choice for long-lasting solutions such as Nexmetal Nitinol Wire used in cutting-edge projects today. The combination of high strength-to-weight ratio and adaptability makes it superior over traditional materials like steel or aluminum in scenarios where space constraints are critical.

How Nitinol Linear Actuators Work

Nitinol linear actuators are fascinating devices that leverage the unique properties of shape memory alloys (SMAs) to create motion. This section delves into the intricate mechanisms behind these remarkable devices, illustrating how they operate and why they are increasingly favored in various applications. By understanding how Nitinol wire functions, we can appreciate its role in modern engineering and innovation.

Mechanism of Shape Memory Alloys

At the heart of every Nitinol linear actuator is the remarkable mechanism of shape memory alloys. When subjected to heat, SMA wire, such as Nexmetal Nitinol Wire, undergoes a phase transformation that allows it to return to a predefined shape, effectively creating movement. This transformation is reversible; when cooled, the wire can revert to its original form, making it an ideal candidate for applications requiring precise actuation.

The ability of Nitinol wire to remember its shape means that it can be used in various configurations and designs without losing functionality. As heat is applied or removed from the SMA wire, it expands or contracts accordingly, enabling controlled actuation in both directions—hence its classification as a linear two-way actuator wire. This dual-action capability sets Nitinol apart from other materials and opens up a world of possibilities for innovative design solutions.

Two-Way Actuation Explained

Two-way actuation is one of the standout features of Nitinol muscle wire technology. In essence, this means that a single piece of SMA wire can perform work in both extension and contraction modes based on temperature changes. By applying heat through electrical current or external sources, engineers can control when and how much movement occurs—making it an incredibly versatile tool for various applications.

For instance, when current flows through the Nitinol linear actuator, it heats up and contracts; once it's allowed to cool down or if current stops flowing, it returns to its original length. This back-and-forth motion enables complex movements within robotic systems or medical devices where precision is paramount. The efficiency gained from using this type of actuator not only improves performance but also reduces energy consumption compared to traditional actuators.

Benefits of Using SMA Wire

SMA wires like Nexmetal Nitinol Wire offer numerous benefits that make them an attractive choice for engineers and designers alike. First off, their compact size allows for integration into tight spaces where conventional actuators might struggle—think tiny robots or miniature medical devices! Moreover, their lightweight nature contributes significantly to overall system efficiency without compromising strength.

Another compelling advantage lies in their durability; Nitinol muscle wires exhibit excellent fatigue resistance over time compared with other materials used for linear two-way actuators. This longevity translates into lower maintenance costs and increased reliability across diverse applications—from aerospace technologies to consumer electronics. With these benefits combined with their unique actuation capabilities, it's no wonder why SMA wires continue gaining traction across multiple industries.

Innovations in Nitinol Technology

The field of Nitinol technology is rapidly evolving, with new innovations making waves across various industries. Central to these advancements is the use of Nitinol linear actuators, which leverage the unique properties of shape memory alloys (SMA) to deliver impressive performance. As we explore the contributions from companies like GEE SMA and recent advancements in actuator design, it becomes clear that Nitinol wire is at the forefront of modern engineering solutions.

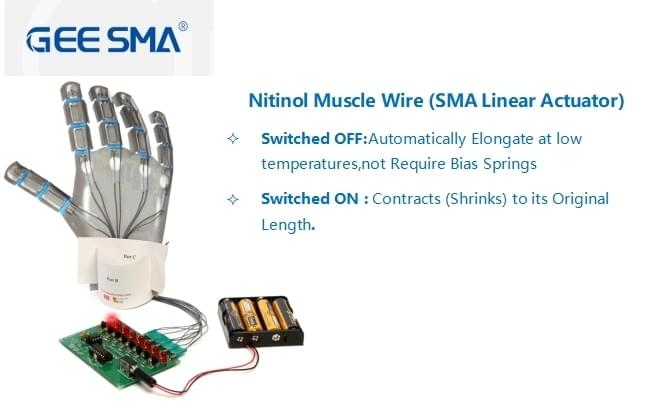

GEE SMA's Contributions to Nitinol

GEE SMA has been a trailblazer in advancing Nitinol technology, focusing on enhancing the performance and applications of SMA wire. They have pioneered techniques that improve the efficiency and reliability of linear two-way actuator wires, ensuring they can withstand demanding environments while maintaining their shape memory properties. Their commitment to innovation has led to significant breakthroughs in Nitinol muscle wire applications, setting new standards for quality and durability.

Moreover, GEE SMA has invested heavily in research and development, enabling them to create specialized Nexmetal Nitinol Wire formulations that cater to specific industry needs. By fine-tuning the alloy compositions and processing methods, they have optimized the characteristics of their wires for better actuation performance. This dedication not only enhances product offerings but also contributes significantly to expanding market opportunities for Nitinol linear actuators.

Advancements in Nitinol Linear Actuator Design

Recent advancements in the design of Nitinol linear actuators are revolutionizing how these devices are integrated into various systems. Engineers are now able to create more compact and efficient actuator designs that utilize less space while delivering higher output forces through innovative configurations using SMA wire. These improvements make it possible for manufacturers to embed linear two-way actuator wires into smaller devices without sacrificing performance or reliability.

Additionally, advancements such as enhanced thermal management systems allow for quicker response times during actuation cycles by optimizing heat distribution within the system. This means that engineers can expect faster activation times from their Nitinol muscle wire applications while maintaining energy efficiency throughout operation cycles. The continuous refinement of designs not only improves functionality but also opens doors for new applications across industries ranging from robotics to aerospace.

Real-World Applications in Space Missions

The unique properties of Nitinol wire make it an ideal candidate for various real-world applications, particularly within space missions where reliability is paramount. NASA and other space agencies have begun incorporating linear two-way actuator wires made from high-performance SMA wire into satellite mechanisms and robotic systems due to their lightweight nature and superior strength-to-weight ratios. These innovations ensure that critical components can operate effectively even under extreme conditions encountered beyond our atmosphere.

Moreover, projects like deploying solar panels or adjusting antennas on satellites often rely on precise movements facilitated by advanced Nitinol linear actuators designed by companies such as GEE SMA. The ability of these actuators to return smoothly back to their original shape after deformation plays a crucial role in ensuring mission success without mechanical failure over time or exposure to harsh environments. As we continue exploring space further than ever before, embracing technologies like Nexmetal Nitinol Wire will undoubtedly be integral for future advancements.

Selecting the Right Nitinol Linear Actuator

When it comes to selecting the right Nitinol linear actuator for your project, several key factors come into play. Understanding the specific requirements of your application is crucial, as different projects may demand varying levels of force, speed, and actuation range. Additionally, the choice between different types of SMA wire can significantly impact performance and efficiency.

Key Factors to Consider

First and foremost, consider the actuation force required for your application. The strength of Nitinol wire varies based on its diameter and heat treatment, so selecting an appropriate gauge is essential for achieving optimal performance in a linear two-way actuator wire setup. Next, evaluate the temperature range in which your actuator will operate; Nitinol exhibits unique shape memory properties that are highly sensitive to temperature changes.

Another critical factor is the response time of the Nitinol linear actuator. Depending on your project's demands, you may need an actuator that can quickly respond to thermal stimuli or one that operates more gradually for precision tasks. Lastly, ensure compatibility with other components in your system; using Nexmetal Nitinol Wire can help streamline integration due to its high-quality standards and consistent performance.

Comparison with Other Actuator Technologies

When comparing Nitinol linear actuators with other actuator technologies like electric motors or pneumatic systems, several distinctions become apparent. Traditional electric motors often require bulky components and complex control systems which may not be suitable for compact applications where space is at a premium—something that a slim Nitinol muscle wire excels at providing. Furthermore, pneumatic systems tend to be less efficient due to air compression losses; in contrast, SMA wire offers a more direct conversion of thermal energy into mechanical movement.

Moreover, while many conventional actuators rely on external power sources or complex mechanics for operation, a linear two-way actuator wire made from Nitinol boasts simplicity by requiring only heat to function effectively—making it an ideal choice for portable or battery-operated devices. This simplicity not only reduces potential points of failure but also enhances reliability over time compared to more intricate systems.

Choosing Nexmetal Nitinol Wire for Your Projects

Selecting Nexmetal Nitinol Wire ensures you’re working with top-tier material known for its durability and superior performance characteristics in various applications. This SMA wire is engineered specifically for consistency in actuation properties while maintaining excellent fatigue resistance—a vital aspect when deploying a linear two-way actuator wire under repeated stress conditions. Additionally, Nexmetal’s commitment to quality means you can trust their products will meet rigorous engineering standards.

When incorporating Nexmetal's offerings into your projects involving Nitinol muscle wire technology, consider how their innovative designs align with emerging trends in automation and robotics—fields where efficient actuation solutions are paramount. By choosing high-quality materials like Nexmetal's Nitinol wire, you're not just investing in an actuator; you're ensuring long-term success through reliable performance tailored precisely to meet your project's unique challenges.

Future Trends in Nitinol Applications

The future of Nitinol applications looks promising, with a surge in demand for SMA wire and its unique properties. As industries continue to explore innovative solutions, the versatility of Nitinol linear actuators is becoming increasingly apparent. From robotics to aerospace, the potential applications of Nitinol muscle wire are expanding rapidly.

The Growing Demand for SMA Wire

The demand for SMA wire is on the rise as more industries recognize its exceptional capabilities. This linear two-way actuator wire offers unparalleled performance in various applications due to its ability to change shape and exert force upon heating. As technology advances, engineers are increasingly seeking out Nitinol wire for projects that require compact, efficient actuation solutions.

Moreover, the versatility of SMA wire makes it an attractive option across different sectors including medical devices, automotive engineering, and consumer electronics. With companies like Nexmetal leading the charge in providing high-quality Nitinol products, it's no wonder that manufacturers are turning to this innovative material to meet their actuator needs. The growing demand for Nitinol linear actuators signifies a shift toward smarter and more efficient technologies.

Emerging Markets for Nitinol Wire

Emerging markets present exciting opportunities for the expansion of Nitinol wire applications. Countries investing heavily in technology and innovation are beginning to adopt SMA wire solutions across various industries. From robotics manufacturing in Asia to aerospace developments in North America, the potential uses of Nitinol muscle wire are being explored globally.

In particular, sectors such as healthcare are seeing significant growth; surgical tools utilizing Nitinol's unique properties can enhance precision and reduce recovery times for patients. Additionally, renewable energy technologies are also starting to incorporate linear two-way actuator wires into their designs—think smart solar panels that adjust their angle automatically! This trend indicates a bright future ahead as more markets embrace the advantages offered by these advanced materials.

Sustainability and Nitinol in Modern Engineering

Sustainability is becoming a key consideration in modern engineering practices, and Nitinol plays a vital role here too! The use of SMA wire can lead to energy-efficient designs that minimize waste while maximizing performance—a win-win situation! With increasing emphasis on eco-friendly materials and processes, incorporating Nexmetal Nitinol Wire into engineering projects aligns perfectly with sustainability goals.

Furthermore, because shape memory alloys can operate without external power sources under certain conditions, they contribute significantly towards reducing overall energy consumption during operation. This efficiency not only benefits manufacturers but also appeals greatly to environmentally conscious consumers looking for sustainable alternatives. As we move forward into an era where sustainability takes precedence over all else, expect innovations involving Nitinol muscle wire to become even more prominent!

Conclusion

Nitinol linear actuators have emerged as a game-changing technology, utilizing the unique properties of Nitinol wire to provide efficient and reliable actuation. These innovative devices leverage the shape memory effect and superelasticity of SMA wire, making them ideal for various applications across industries. As we summarize their significance, it’s clear that Nitinol muscle wire is not just a trend but a pivotal component in advancing actuator technology.

Recap of Nitinol Linear Actuators

Nitinol linear actuators are distinguished by their ability to convert thermal energy into mechanical motion through the manipulation of Nitinol wire. This remarkable feature allows for two-way actuation, enabling precise control in applications ranging from robotics to aerospace engineering. The versatility and efficiency of SMA wire make it an essential choice for designers seeking reliable solutions in modern engineering challenges.

The Impact of GEE SMA in the Industry

GEE SMA has made significant contributions to the development and enhancement of Nitinol linear actuators, pushing boundaries in actuator design and functionality. Their commitment to innovation has resulted in improved performance characteristics for Nitinol wire, setting new industry standards. By focusing on advancements that cater to real-world demands, GEE SMA strengthens its position as a leader in the field of shape memory alloys.

Embracing the Future with Nitinol Technologies

The future is bright for Nitinol technologies as demand continues to grow across various sectors, including medical devices and robotics. With emerging markets recognizing the benefits of SMA wire, particularly Nexmetal Nitinol Wire, there’s an exciting horizon ahead filled with potential applications that prioritize sustainability and efficiency. Embracing these advancements will not only enhance existing technologies but also pave the way for innovative solutions that harness the full power of linear two-way actuator wires.