Introduction

In the realm of innovative engineering, nitinol linear actuators stand out as a remarkable fusion of advanced materials and cutting-edge technology. These actuators leverage the unique properties of nitinol wire, a type of shape memory alloy (SMA), to create motion that is both precise and efficient. As industries increasingly seek solutions that are adaptable and reliable, understanding the fundamentals of nitinol linear actuators becomes essential for harnessing their full potential.

Understanding Nitinol Linear Actuators

Nitinol linear actuators operate on the extraordinary principle of shape memory, allowing them to return to a predetermined shape when heated. This property is primarily derived from nitinol wire, which can undergo significant deformation and still revert to its original form under specific thermal conditions. Unlike traditional linear actuators with motors that rely on complex mechanical systems, nitinol-based solutions offer simplicity in design while delivering powerful performance.

The Importance of Shape Memory Alloys

Shape memory alloys like nitinol are revolutionizing how we think about actuation technology. Their ability to change shape in response to temperature changes not only enhances functionality but also improves energy efficiency compared to conventional systems. The integration of SMA technology into actuator products results in lighter, more compact devices capable of operating in demanding environments without compromising reliability or performance.

Overview of Nitinol Applications

The applications for nitinol are vast and varied, ranging from medical devices such as stents and surgical tools to robotics and aerospace components. In each case, the unique properties of nitinol wire enable innovative solutions that push the boundaries of what's possible in design and functionality. As industries continue to explore these capabilities, the role of nitinol linear actuators will undoubtedly expand across numerous sectors.

Nitinol Wire: The Heart of Actuation

Properties of Nitinol Wire

Nitinol wire boasts a fascinating combination of elasticity and shape memory capabilities, making it perfect for various applications. This shape wire can return to its predetermined form after being deformed, thanks to its unique phase transformation properties. Additionally, nitinol wire is lightweight yet strong, which allows for compact designs in linear actuators with motor mechanisms that require minimal space without sacrificing performance.

Another crucial property of nitinol wire is its biocompatibility, making it suitable for medical applications where safety and reliability are paramount. The ability of nitinol to operate effectively across a wide temperature range further enhances its versatility in different environments. Overall, these properties make nitinol wire an ideal choice for engineers looking to innovate with SMA linear actuators.

How Nitinol Wire Drives Functionality

The functionality of a nitinol linear actuator hinges on how well the nitinol wire can convert thermal energy into mechanical motion. When heated above a certain temperature threshold, the wire contracts and exerts force in a controlled manner—this is what drives actuation in devices ranging from robotic arms to precision tools. In contrast to traditional systems that rely on bulky motors and gears, the streamlined design offered by a nitinol spring actuator contributes significantly to efficiency and responsiveness.

Moreover, the simplicity of using heat as an activation method allows for more compact designs compared to conventional actuators that require complex electrical systems or hydraulic components. This not only reduces weight but also enhances energy efficiency—a critical factor in modern automation systems where power consumption needs careful management. Thus, by harnessing the unique properties of nitinol wire, manufacturers can create highly functional devices with reduced footprint and increased reliability.

Applications in Automation

Nitinol's unique characteristics open up exciting avenues for automation across various industries—from robotics and aerospace engineering to consumer electronics and medical devices. For instance, in robotics, actuators powered by nitinol wires enable smooth movements that mimic natural muscle contractions while maintaining lightweight profiles essential for agile operation. Furthermore, these SMA linear actuators shine in environments where traditional systems might struggle due to space constraints or weight limits.

In addition to robotics, automation within medical devices has seen significant advancements through the use of nitinol spring actuators—think minimally invasive surgical tools that require precise movements without large mechanical setups taking up valuable space inside operating rooms. The potential applications are vast; from automotive systems needing reliable actuation solutions under extreme conditions to smart home technologies benefitting from their compact nature—nitinol wires are paving new paths forward.

Unique Features of Nitinol Shape Setting

Nitinol shape setting is a fascinating aspect of how this remarkable material functions, particularly in the context of nitinol linear actuators. This process allows nitinol wire to be programmed into specific shapes that it can revert to when heated, making it an essential component in various actuator products. The unique properties of nitinol shape setting provide engineers with unparalleled design flexibility and innovative solutions across multiple industries.

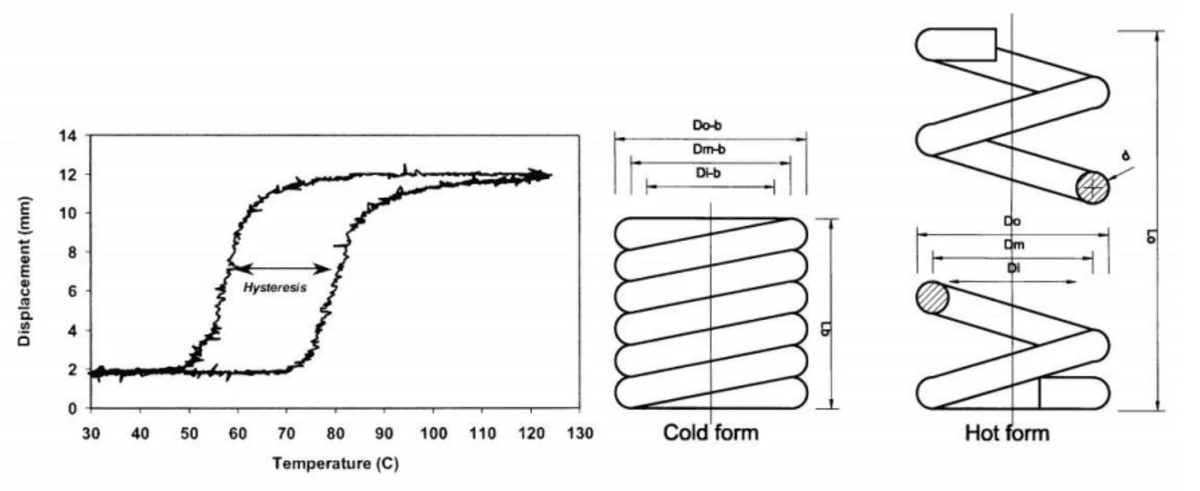

Understanding Nitinol Shape Setting

At its core, nitinol shape setting involves heating the wire to a temperature that allows it to remember a predetermined shape. When cooled, the wire can be deformed into another configuration; however, when heat is applied again, it will revert to its original form, effectively driving the mechanism in a linear actuator with motor applications. This transformative ability is what makes nitinol wire so valuable in creating efficient and compact sma linear actuators.

The science behind nitinol shape setting hinges on the phase transformation between its martensite and austenite states. In simpler terms, this means that by altering temperatures, we can control how the material behaves—allowing for precise movements and actuation without requiring complex mechanical systems. This capability not only enhances functionality but also simplifies designs while reducing overall weight.

Benefits for Design Flexibility

One of the standout advantages of incorporating nitinol shape setting into actuator products is design flexibility. Engineers can create custom shapes tailored specifically for their application needs without worrying about traditional constraints associated with standard motors or other actuation methods. This adaptability opens up new possibilities for innovation in product development that were previously unattainable.

Moreover, because nitinol spring actuators utilize this unique property effectively, they can fit into tight spaces where conventional actuators might struggle due to their size or complexity. The lightweight nature of these materials contributes further to their appeal—designers are no longer limited by bulky components or heavy weights that could hinder performance or efficiency. In essence, this flexibility translates into more creative solutions across various sectors including robotics and medical devices.

Real-World Examples of Usage

Real-world applications of nitinol shape setting showcase its versatility and effectiveness in diverse fields—from aerospace engineering to medical technology. For instance, in robotic systems where precision movement is critical, nitinol linear actuators enable rapid response times while maintaining compactness—a perfect combination for advanced robotics designed for delicate tasks such as surgery or assembly work.

In addition to robotics, you’ll find these innovative materials making waves in consumer electronics as well; think about adjustable eyeglass frames that automatically conform to your face's contours using a simple heat source! Such clever applications highlight just how far we've come thanks to advancements like those offered by sma linear actuators powered by nimble nitinol wires—making everyday items smarter and more user-friendly.

Ultimately, whether it's enhancing mobility aids or revolutionizing industrial automation processes through nimble actuation systems based on smart materials like Nitinol—these real-world examples demonstrate just how pivotal this technology has become across various industries today!

Comparison with Traditional Linear Actuators

When comparing nitinol linear actuators to traditional linear actuators, the differences become strikingly clear. Nitinol wire offers unique properties that set it apart from standard motors, primarily due to its ability to change shape in response to temperature changes. This shape memory effect allows for a more compact design, enabling the creation of smaller and lighter actuator products without sacrificing performance.

Advantages Over Standard Motors

One of the most significant advantages of nitinol linear actuators over standard motors is their simplicity and elegance in design. Unlike a linear actuator with motor systems that require complex gearing and additional components, nitinol actuators operate using just a single piece of nitinol wire. This reduction in mechanical complexity not only lowers manufacturing costs but also enhances reliability by minimizing potential points of failure.

Moreover, nitinol's inherent properties allow for smoother operation and less noise compared to traditional motors. The seamless motion provided by the shape wire reduces vibrations and results in quieter actuation, making it ideal for applications where sound is a concern. These advantages make nitinol spring actuators particularly appealing for industries such as robotics and medical devices.

Energy Efficiency of Nitinol Actuators

Energy efficiency is another area where nitinol linear actuators shine brightly when compared to their conventional counterparts. Traditional linear actuators often consume significant power during operation due to friction and heat generation within their mechanical systems. In contrast, SMA (shape memory alloy) linear actuators utilize thermal energy more effectively by converting heat directly into motion through the unique properties of nitinol wire.

This efficient use of energy not only extends battery life in portable applications but also reduces overall operational costs in industrial settings. As industries strive for greener solutions, the energy-efficient nature of nitinol actuators positions them as an attractive alternative for sustainable engineering practices. With growing concerns about energy consumption, choosing a nitinol actuator can lead to both environmental benefits and cost savings.

Innovative Applications

The innovative applications of nitinol linear actuators are expanding rapidly across various fields thanks to their unique capabilities. From aerospace engineering—where lightweight materials are crucial—to medical devices requiring precise movements without bulky components, the versatility offered by these SMA devices is remarkable. For example, a nitinol spring actuator can be employed in minimally invasive surgical tools that need rapid yet controlled movement without compromising patient safety.

Additionally, industries such as automotive are beginning to explore how these advanced materials can enhance performance while reducing weight—a critical factor for fuel efficiency and emissions reduction goals. The ability to integrate nitinol shape setting into designs opens up new possibilities that were previously unattainable with traditional actuation methods, paving the way for groundbreaking innovations across multiple sectors.

Nitinol Spring Actuator Benefits

Nitinol spring actuators are revolutionizing the actuation landscape by seamlessly combining the unique properties of shape memory alloys with traditional spring mechanics. This fusion allows for a compact design that can deliver significant force and motion while maintaining energy efficiency. By leveraging nitinol wire's ability to return to its pre-set shape upon heating, these actuators offer a new realm of possibilities for various applications.

Combining Spring Action and Shape Memory

The integration of spring action with shape memory capabilities in nitinol spring actuators creates a dynamic solution for linear movement. When heated, nitinol wire contracts, producing motion akin to that of a conventional linear actuator with motor but without the bulkiness or complexity. This synergy not only simplifies designs but also enhances reliability, making it an attractive option for engineers looking to optimize their actuator products.

Furthermore, the unique property of nitinol shape setting allows these actuators to be tailored for specific tasks, providing designers with unprecedented flexibility in their projects. The ability to customize the shape wire means that each actuator can be fine-tuned for particular applications, ensuring maximum efficiency and performance. As industries continue to explore innovative solutions, nitinol spring actuators stand out as a versatile option that meets diverse operational needs.

Ideal Use Cases for Nitinol Spring Actuators

Nitinol spring actuators are particularly well-suited for applications where space is limited and precision is paramount. In robotics, they can facilitate smooth movements in compact designs without compromising on strength or speed—ideal for robotic arms or grippers needing swift actuation without large motors taking up valuable real estate. Similarly, in medical devices such as minimally invasive surgical tools, these actuators provide reliable performance while being lightweight and easy to integrate.

Another compelling use case lies within aerospace engineering; here, nitinol linear actuators contribute significantly by reducing weight while enhancing functionality in critical systems like landing gear mechanisms or deployable structures. Their ability to operate effectively under varying temperature conditions makes them ideal candidates for environments where traditional motors might falter due to size or energy constraints. As industries evolve towards more efficient solutions, the demand for innovative actuator products like nitinol spring actuators will only grow.

Performance in Harsh Environments

One of the standout benefits of using nitinol spring actuators is their superior performance in harsh environments compared to conventional options like standard motors. Nitinol wire exhibits remarkable resilience against extreme temperatures and corrosive atmospheres—attributes crucial in sectors such as marine engineering and oil exploration where equipment often faces severe conditions. This durability ensures that devices equipped with these SMA linear actuators maintain functionality when it matters most.

Moreover, because they require minimal maintenance due to their simple design devoid of gears or complex electronics found in traditional systems, users can expect longevity from their nitinol-based solutions even under challenging circumstances. This reliability translates into reduced downtime and lower operational costs over time—a win-win scenario across various industries looking at cost-effective yet high-performance actuator products. With all these advantages combined into one sleek package, it's clear why engineers are increasingly turning towards nitinol spring actuators as their go-to choice.

GEE SMA: Leading the Nitinol Revolution

When it comes to pioneering advancements in nitinol technology, GEE SMA stands at the forefront of innovation. With a robust portfolio focused on nitinol linear actuators and shape memory alloys (SMAs), their expertise is unparalleled. This company has effectively transformed how industries utilize nitinol wire, making them a key player in the actuator products market.

Overview of GEE SMA's Expertise

GEE SMA specializes in developing cutting-edge nitinol linear actuators that leverage the unique properties of shape memory alloys. Their team comprises engineers and researchers dedicated to pushing the boundaries of what can be achieved with nitinol wire and its applications. By focusing on design flexibility and performance, GEE SMA has established itself as a trusted name for those seeking reliable actuator solutions.

The company's deep understanding of nitinol shape setting allows them to create customized solutions tailored to specific needs across various sectors. Whether it's for medical devices or aerospace applications, their expertise ensures that each linear actuator with motor is optimized for efficiency and reliability. With years of experience under their belt, GEE SMA continues to lead the charge in the development of innovative nitinol spring actuators that meet stringent industry standards.

Contributions to Space Missions

GEE SMA's contributions extend beyond terrestrial applications; they have played a critical role in several space missions where precision and reliability are paramount. The use of nitinol linear actuators in spacecraft systems has enabled more efficient operations during missions, showcasing the versatility of these advanced materials. Their ability to withstand extreme conditions makes them ideal for use in space environments where traditional components may fail.

One notable application involved using nitinol wire for deployable structures on satellites, demonstrating how effective these actuators can be in challenging scenarios. The innovative designs provided by GEE SMA have not only enhanced mission success rates but also reduced overall weight—an essential factor when it comes to space travel. As they continue collaborating with aerospace agencies, their advancements pave the way for future exploration endeavors.

Custom Solutions for Diverse Industries

GEE SMA understands that no two industries are alike; hence their approach includes offering custom solutions tailored specifically to diverse needs across various sectors. From automotive systems requiring precise actuation mechanisms to robotics demanding lightweight yet powerful components, their range of products showcases versatility at its best with both standard and specialized options available. The integration of nitinol spring actuators into these systems provides an added layer of functionality not typically found with conventional motors.

Their commitment doesn't stop at just providing products; they also offer support throughout the design process ensuring clients maximize performance from every linear actuator with motor they implement into their projects. With an eye towards innovation, GEE SMA is continually exploring new applications where nitinol shape setting can enhance operational capabilities while maintaining energy efficiency—a top priority across all industries today.

In conclusion, whether it’s through enabling groundbreaking space technologies or crafting custom solutions for everyday challenges, GEE SMA exemplifies leadership within the nitinol revolution by harnessing the incredible potential offered by SMAs like no other company can.

Conclusion

In summary, nitinol linear actuators represent a revolutionary leap in actuation technology, harnessing the unique properties of nitinol wire and shape memory alloys. These actuators offer remarkable advantages over traditional linear actuators with motors, including energy efficiency and design flexibility through innovative nitinol shape setting techniques. As industries continue to explore the potential of these SMA linear actuators, the applications are as diverse as they are fascinating.

Key Takeaways on Nitinol Linear Actuators

Nitinol linear actuators stand out due to their ability to convert thermal energy into mechanical motion, thanks to the inherent properties of nitinol wire. The versatility offered by nitinol shape setting allows for customized designs that can adapt to various applications, from robotics to medical devices. Ultimately, these actuators not only enhance performance but also open doors for innovative solutions that were previously unimaginable.

Future Prospects for Actuator Products

Looking ahead, the future of actuator products powered by nitinol is bright and full of promise. Advancements in materials science will likely lead to even more efficient and responsive nitinol spring actuators capable of operating in extreme conditions. As research continues and industries adopt this technology, we can anticipate a surge in novel applications that capitalize on the unique benefits offered by SMA linear actuators.

Why Choose Nitinol for Your Next Project

Choosing a nitinol linear actuator for your next project means embracing cutting-edge technology that offers unmatched performance and reliability. The combination of lightweight design and powerful actuation makes it an ideal choice for various fields such as aerospace, robotics, and automation systems. By opting for nitinol wire-based solutions like the nitinol spring actuator, you position your project at the forefront of innovation while ensuring efficiency and adaptability.