Introduction

In the realm of modern engineering, Nitinol wire motors stand out as a revolutionary development in the field of micro-actuators. These unique devices leverage the remarkable properties of Nitinol, a nickel-titanium alloy known for its shape memory effect and superelasticity. As industries increasingly seek efficient and compact solutions, understanding how Nitinol wire motors operate and their vast applications becomes essential.

Understanding Nitinol Wire Motors

Nitinol wire motors are ingeniously designed to convert thermal energy into mechanical motion, making them ideal for various applications where space is at a premium. The ability of Nitinol memory wire to return to a predetermined shape when heated allows these motors to perform intricate tasks with precision and reliability. Their unique characteristics not only enhance efficiency but also reduce the overall size and weight compared to traditional actuators.

Applications of Micro-Actuators

Micro-actuators, including those powered by Nitinol wire motors, find use in diverse fields such as robotics, aerospace, and medical devices. In robotics, they enable delicate movements that mimic human dexterity, while in aerospace applications, their lightweight nature contributes significantly to fuel efficiency. The medical industry benefits from these tiny powerhouses through minimally invasive surgical tools that require precise actuation without bulky mechanisms.

The Future of Smart Materials

The future is bright for smart materials like Nitinol as innovations continue to emerge in material science and engineering design. With increasing demands for energy-efficient solutions across industries, the potential for enhanced Nitinol engine efficiency is paving the way for new technologies that harness its unique properties effectively. As we look ahead, investing in Nitinol technology will likely yield groundbreaking advancements that redefine how we approach automation and control systems.

What is Nitinol Wire?

Nitinol wire, a unique alloy of nickel and titanium, has gained attention for its remarkable properties and applications. This smart material is not only used in medical devices but also plays a crucial role in various engineering fields. With its ability to return to a predetermined shape when heated, Nitinol wire motors are revolutionizing the world of micro-actuators.

Composition and Properties

Nitinol is primarily composed of nickel and titanium, typically in a 50-50 ratio by atomic percentage. This specific combination gives Nitinol its distinctive properties, including excellent corrosion resistance and high elasticity. The unique phase transformation between austenite and martensite allows Nitinol wire motors to exhibit impressive deformation capabilities, making them ideal for applications requiring flexibility and strength.

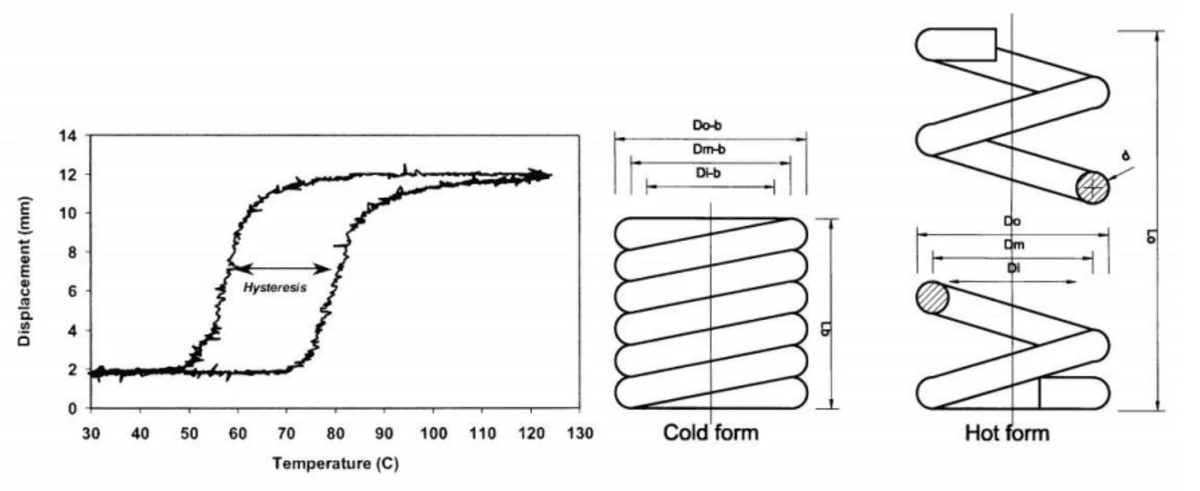

Shape Memory Effect Explained

The shape memory effect is the star feature of Nitinol wire that sets it apart from conventional materials. When deformed at lower temperatures (martensite phase), it can return to its original shape upon heating (austenite phase). This mechanism not only underpins the functionality of Nitinol wire motors but also enhances their efficiency; as they can convert thermal energy into mechanical motion with minimal energy loss—ideal for applications where Nitinol energy efficiency is paramount.

Key Advantages of Nitinol

Nitinol offers several advantages that make it appealing for various applications, particularly in the realm of micro-actuators like the Nitinol wire motor. Its lightweight nature contributes to overall system efficiency while maintaining high strength-to-weight ratios essential for performance-sensitive environments like aerospace or robotics. Additionally, the durability and fatigue resistance of Nitinol ensure long-term reliability, making it an attractive option for those considering purchasing a Nitinol wire motor for sale.

How Nitinol Wire Motors Work

Nitinol wire motors leverage the unique properties of Nitinol, a nickel-titanium alloy, to create motion through thermal activation. When heated, the Nitinol wire undergoes a phase transformation that allows it to return to a predetermined shape, resulting in movement. This ingenious mechanism is at the heart of many micro-actuators and sets Nitinol wire motors apart from traditional actuators.

Mechanism Behind Motion

The motion in a Nitinol wire motor is driven by the shape memory effect inherent in Nitinol Memory Wire. When the wire is heated above its transformation temperature, it contracts and pulls on a connected mechanism, creating motion. Conversely, when cooled down, it relaxes back to its original shape, allowing for efficient energy use and minimizing wear over time—ideal for applications demanding longevity and reliability.

This remarkable mechanism not only enhances efficiency but also contributes significantly to the overall performance of devices using these motors. With Nitinol engine efficiency often surpassing that of conventional systems, these motors are becoming increasingly popular across various industries. As more engineers discover the advantages of this technology, demand for Nitinol wire motors continues to rise.

Bidirectional Drive Functionality

One standout feature of Nitinol wire motors is their bidirectional drive functionality, which allows them to perform complex tasks with ease. By manipulating temperature changes strategically—heating one segment while cooling another—these motors can achieve movement in both directions without requiring additional components or mechanisms. This capability simplifies designs while enhancing flexibility in applications ranging from robotics to aerospace.

The ability to control direction with precision means that engineers can create more sophisticated systems without adding unnecessary complexity or size constraints. For example, a single Nitinol wire motor can replace multiple traditional actuators in certain designs—reducing weight and improving overall system efficiency. As such innovations become commonplace, expect to see even broader adoption of this technology across various sectors.

Control Systems for Precision

To harness the full potential of Nitinol wire motors effectively, advanced control systems are essential for achieving precision in operation. These systems utilize sensors and feedback loops that monitor temperature changes and adjust power input accordingly—ensuring optimal performance at all times. By integrating smart controls with these innovative motors, users can achieve intricate movements with unparalleled accuracy.

Moreover, as developers continue refining control algorithms tailored for Nitinol energy applications, we can anticipate even greater advancements in micro-actuator technology overall. The combination of precise control with reliable actuation makes these systems ideal candidates for applications requiring fine-tuned movements or delicate handling tasks like surgical instruments or robotic grippers. As interest grows around this field of technology—and as prices stabilize—the future looks bright for anyone seeking a reliable Nitinol wire motor for sale.

GEE SMA: A Leader in Nitinol Technology

When it comes to Nitinol wire motors, GEE SMA stands at the forefront of innovation and excellence. This company has made significant strides in the production and application of Nitinol, establishing itself as a trusted name in the industry. With a focus on quality and performance, GEE SMA is paving the way for advancements in smart materials.

Innovations in Nitinol Wire Production

GEE SMA has revolutionized Nitinol wire production through cutting-edge techniques that enhance both quality and affordability. Their proprietary methods ensure consistent performance and reliability, making their Nitinol wire motors among the best available on the market. By optimizing production processes, GEE SMA can offer competitive pricing for their Nitinol wire motors without compromising on efficiency or durability.

In addition to improving manufacturing techniques, GEE SMA invests heavily in research to unlock new properties of Nitinol energy. This commitment allows them to develop advanced Nitinol memory wire solutions that cater to diverse applications across various industries. As a result, customers can expect not only high-quality products but also innovative solutions tailored to their specific needs.

Applications in Aerospace and Robotics

The versatility of Nitinol wire motors makes them ideal for various applications, particularly in aerospace and robotics sectors where precision is paramount. In aerospace engineering, these motors are employed for actuators that control flaps or landing gear systems due to their lightweight nature and exceptional strength-to-weight ratio. Similarly, robotics engineers utilize Nitinol technology for creating compact actuators that deliver high torque with minimal energy consumption.

Moreover, as industries continue to push boundaries towards automation and smart technologies, GEE SMA's contributions are invaluable. The adaptability of their products means they can be integrated into cutting-edge robotic systems or aircraft designs seamlessly—ensuring optimal performance wherever they're deployed. As demand grows for efficient micro-actuators like those made from Nitinol memory wire, GEE SMA remains committed to leading this technological charge.

Commitment to Quality and Efficiency

Quality assurance is at the heart of GEE SMA's operations; they adhere strictly to international standards while continuously improving their processes. Each batch of Nitinol wire motor produced undergoes rigorous testing before reaching customers' hands—ensuring maximum reliability during operation. This dedication not only enhances customer satisfaction but also solidifies GEE SMA's reputation as a leader in the field.

Efficiency is another cornerstone of their philosophy; by focusing on enhancing Nitinol engine efficiency through innovative designs and materials science breakthroughs, they help clients achieve better overall performance from their devices. With an eye toward sustainability too—GEE SMA prioritizes eco-friendly practices within its production facilities while delivering superior products at competitive prices—their commitment reflects positively across all aspects of business operations.

In summary, choosing a reliable supplier like GEE SMA means investing in high-quality solutions backed by extensive expertise within the realm of smart materials such as those found within advanced nitinol technology frameworks!

Nitinol Engine Efficiency and Performance

When it comes to evaluating the efficiency and performance of Nitinol wire motors, comparisons with traditional actuators reveal some fascinating insights. Traditional actuators, often reliant on electric or pneumatic systems, can be bulky and energy-intensive. In contrast, Nitinol engines leverage the unique properties of shape memory alloys to provide high torque in a compact form factor, making them ideal for applications where space is at a premium.

Comparison with Traditional Actuators

Nitinol wire motors stand out against traditional actuators due to their remarkable energy efficiency and lightweight design. While many conventional systems require significant power input to generate motion, Nitinol engines utilize thermal activation that allows them to operate effectively with minimal energy consumption. This not only reduces operational costs but also enhances overall performance metrics when compared side-by-side with traditional options.

Moreover, the responsiveness of Nitinol wire motors is noteworthy; they can transition between shapes almost instantaneously compared to the slower actuation times typical in hydraulic or pneumatic systems. This rapid response time makes them particularly suitable for applications needing quick adjustments or precise control. Consequently, industries ranging from robotics to aerospace are increasingly incorporating Nitinol technology into their designs.

Factors Influencing Efficiency

Several factors influence the efficiency of a Nitinol engine, including temperature control, material composition, and design intricacies. The ability of these motors to convert thermal energy into mechanical work hinges significantly on maintaining optimal operating temperatures; deviations can lead to reduced performance levels or even failure in achieving desired movements. Additionally, advancements in Nitinol Memory Wire production have allowed for enhanced material properties that further improve efficiency.

The design of the motor itself plays a pivotal role as well; engineers must consider factors such as coil geometry and actuator size when developing Nitinol wire motors for specific applications. These considerations ensure that each motor operates at its peak potential while minimizing wasted energy through heat loss or mechanical inefficiencies. As manufacturers continue refining these aspects, we can expect even greater strides in overall engine efficiency.

Real-World Performance Metrics

Real-world performance metrics showcase the impressive capabilities of Nitinol wire motors across various applications. For instance, tests have demonstrated that these engines can achieve up to 90% efficiency under optimal conditions—far exceeding many traditional actuator systems which often struggle below 70%. Such high levels of efficiency translate directly into reduced operational costs and improved sustainability profiles for industries adopting this innovative technology.

In practical terms, users have reported significant improvements in device responsiveness and reliability when switching from conventional actuators to Nitinol alternatives—especially notable in robotics where precision is paramount. Furthermore, as more companies begin offering competitive pricing on Nitinol wire motors for sale, adoption rates are likely to surge as organizations recognize both immediate benefits and long-term value propositions associated with investing in this cutting-edge technology.

Nitinol Wire Motor Pricing

When it comes to Nitinol wire motors, pricing can vary significantly based on several factors. The cost of these innovative devices is influenced by their design complexity, the quality of materials used, and the specific applications they are intended for. Additionally, market demand and technological advancements play a crucial role in determining the Nitinol wire motor price.

Factors Influencing Price

Several key factors come into play when assessing the price of a Nitinol wire motor. First, the manufacturing process and the purity of the Nitinol alloy directly affect production costs; higher purity typically results in better performance but also increases expenses. Second, customization options—such as size and specific functionalities—can lead to variations in pricing; specialized designs often command higher prices due to their tailored nature.

Another significant factor is scalability; manufacturers producing larger quantities may offer lower prices due to economies of scale. Furthermore, advancements in technology can lead to more efficient production methods that reduce costs over time, potentially lowering future Nitinol wire motor prices. Lastly, competition within the market can also impact pricing strategies as companies strive to offer competitive rates while maintaining quality.

Where to Find Nitinol Motors for Sale

Finding a reliable source for purchasing a Nitinol wire motor is essential for anyone interested in harnessing this cutting-edge technology. Numerous online retailers specialize in smart materials and micro-actuators; websites like Amazon or specialized industrial suppliers often have listings for various models available for sale. Additionally, manufacturers' websites frequently provide direct purchasing options or links to authorized distributors who can assist with inquiries about specific products.

For those looking for bulk purchases or custom solutions, reaching out directly to manufacturers like GEE SMA could yield favorable results; they often cater to both individual and commercial needs with tailored offerings. Trade shows and industry conferences also present excellent opportunities to explore different Nitinol motors firsthand while connecting with suppliers ready to discuss pricing options and features.

The Value Proposition of Nitinol

Investing in a Nitinol wire motor offers substantial value beyond just its initial price tag; these devices stand out due to their unique properties such as shape memory effect and energy efficiency. The ability of Nitinol memory wire to return to its original shape after deformation means fewer mechanical components are needed—resulting in lighter systems that consume less energy overall compared to traditional actuators. This not only enhances performance but also contributes positively towards sustainability goals by reducing energy consumption over time.

Moreover, given their versatility across various applications—from robotics and aerospace engineering to medical devices—the long-term benefits often outweigh initial costs when considering performance gains and maintenance savings associated with using a high-efficiency Nitinol engine. As technology continues evolving, investing now could mean reaping rewards later as these smart materials become increasingly integral across industries.

Conclusion

In summary, Nitinol wire motors are revolutionizing the world of micro-actuators with their unique properties and versatility. These innovative devices leverage the remarkable shape memory effect of Nitinol, allowing them to perform complex motions with precision and efficiency. As industries continue to seek advanced solutions for automation and control, the demand for Nitinol wire motors is only expected to grow.

The Versatility of Nitinol Wire Motors

Nitinol wire motors are incredibly versatile, making them suitable for a wide range of applications across various sectors. From medical devices that require precise movements to aerospace technologies demanding lightweight yet powerful actuators, the adaptability of Nitinol is unmatched. Furthermore, with advancements in Nitinol Memory Wire technology, engineers can design systems that respond dynamically to changing conditions, enhancing overall performance.

Future Trends in Micro-Actuators

The future of micro-actuators looks promising as we see emerging trends focused on miniaturization and enhanced energy efficiency. Innovations in materials science will likely lead to even more efficient versions of the Nitinol wire motor, pushing boundaries in robotics and automation. Additionally, as industries increasingly prioritize sustainability and energy conservation, the role of Nitinol energy solutions will become paramount.

Why Invest in Nitinol Technology

Investing in Nitinol technology is not just a forward-thinking move; it’s a strategic choice for businesses looking to enhance their product offerings. With competitive pricing on options like the Nitinol wire motor available for sale today, companies can access cutting-edge technology without breaking the bank—especially when considering long-term savings from improved efficiency and reduced maintenance costs associated with traditional actuators. Ultimately, embracing this innovative material could be key to staying ahead in today's fast-paced technological landscape.