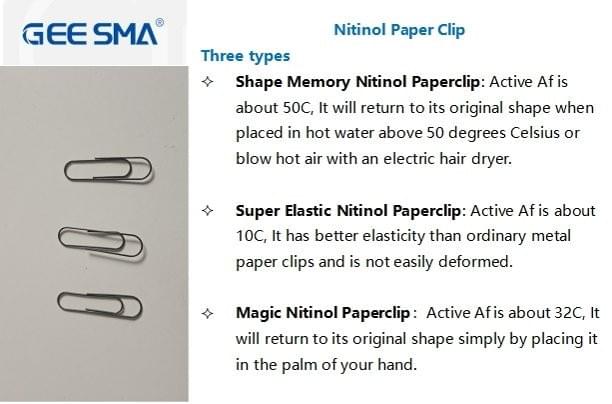

Introduction

In the world of office supplies, few items are as ubiquitous and unassuming as the paper clip. Yet, beneath its simple exterior lies a fascinating material that is revolutionizing how we think about these everyday tools: nitinol. This unique alloy not only offers remarkable properties but also enhances the versatility and functionality of paper clips in ways we never imagined.

Discover the Unique Material of Nitinol

Nitinol, a nickel-titanium alloy, is renowned for its shape memory and superelastic properties. But what are paper clips made of? Traditionally, they have been crafted from steel or plastic, but nitinol paperclips introduce an innovative twist with their ability to return to a predetermined shape when heated. This characteristic makes them not just functional but also a conversation starter in any workspace.

The Versatility of Nitinol Paperclips

Imagine a paper clip that can withstand bending and twisting without losing its grip on your documents—this is where nitinol paperclips shine. Their flexibility allows for creative applications beyond merely holding papers together; they can be used in crafting or even as stylish accessories! With their unique attributes, nitinol paperclips redefine what it means to be versatile in the realm of stationery.

Why Nitinol is a Game Changer

The introduction of nitinol into the world of office supplies marks a significant shift from traditional materials. Not only do these innovative clips offer enhanced durability and resilience compared to typical options, but they also embody cutting-edge technology that captures our imagination. Embracing nitinol means embracing innovation—transforming mundane tasks into extraordinary experiences with every use.

What are Paper Clips Made Of?

When you think about what paper clips are made of, the first materials that come to mind are usually metal or plastic. Traditional paper clips are predominantly crafted from steel, which provides a good balance of strength and flexibility. However, these conventional materials may not always meet the demands of modern-day users looking for durability and innovation.

Exploring Traditional Materials

Traditional paper clips have been primarily made from galvanized steel wire due to its resilience against bending and breaking. These metal clips can hold together multiple sheets of paper without losing their shape, making them reliable for everyday use. On the other hand, plastic paper clips offer a colorful alternative but often lack the structural integrity required for heavier stacks of documents.

While traditional materials like steel and plastic serve their purpose well, they come with inherent limitations—rusting over time or breaking under pressure can be frustrating experiences for users. This is where innovative materials like nitinol start to shine in the world of stationery supplies. The search for better alternatives has led us to explore new frontiers in what paper clips are made of.

Introduction to Nitinol

Enter nitinol—a remarkable alloy composed primarily of nickel and titanium that exhibits unique properties such as shape memory and superelasticity. Unlike conventional materials, nitinol can return to its original shape after being deformed when exposed to specific temperatures. This revolutionary characteristic makes nitinol paperclips not only functional but also fascinating pieces of engineering.

Nitinol's introduction into everyday items like paperclips is a game-changer that challenges our understanding of what these simple tools can do. Imagine a nitinol paperclip that bends but never breaks or loses its grip—sounds too good to be true? Well, it's not; it's simply the magic of this innovative material at work!

Benefits of Nitinol in Paperclips

So why should we care about nitinol when it comes to what paper clips are made of? First off, nitinol offers unparalleled durability compared to traditional metal or plastic options; it won't rust or corrode easily and maintains its strength over time. Additionally, because it can withstand significant deformation without permanent damage, a nitinol paperclip will keep your papers securely fastened even under stress.

Another benefit lies in its flexibility; unlike standard steel clips that may snap if bent too far, nitinol's superelastic properties allow it to bend back into shape effortlessly after use. This means less frustration when dealing with misaligned documents! Furthermore, using nitinol in manufacturing means embracing more sustainable practices since this alloy is recyclable.

In conclusion, as we explore what modern innovations bring us in terms of stationery supplies like the humble cpaper clip, it's clear that nitinol stands out as an exceptional choice worth considering for those who seek reliability combined with ingenuity.

The Science Behind Nitinol

Nitinol, a remarkable alloy of nickel and titanium, is at the forefront of innovative materials science. This section will delve into the fascinating properties of shape memory alloys, particularly how they function under varying temperatures and their practical applications in everyday items like nitinol paperclips. Understanding these concepts not only highlights what paper clips are made of but also showcases why nitinol paperclips are a game changer.

Shape Memory Alloys Explained

Shape memory alloys (SMAs) are materials that can return to a predefined shape when heated past a certain temperature. Nitinol is one such SMA that possesses this unique ability, which makes it incredibly versatile in various applications, including the production of nitinol paperclips. Unlike traditional metal paper clips made from steel or plastic, nitinol paperclips can bend and twist yet return to their original form when exposed to heat—truly a mind-bending feature!

How Nitinol Reacts to Temperature

The magic of nitinol lies in its response to temperature changes, which is fundamental to its functionality as an innovative material for making paper clips. When cooled below its transformation temperature, the nitinol paperclip takes on a temporary shape; however, once heated above this threshold—often simply by holding it—this clever alloy reverts back to its original design. This unique thermal reaction not only makes nitinol an exciting choice for crafting durable and flexible cpaper clips but also opens doors to numerous applications across various industries.

Practical Applications of Nitinol

Nitinol's remarkable properties extend far beyond just being used in quirky office supplies like nitinol paperclips; they have significant implications in fields ranging from medicine to robotics. In medical devices, for example, nitinol’s ability to revert shapes is utilized in stents and guidewires that adapt within the human body with precision and safety. As we explore what are paper clips made of today—including cutting-edge options like those crafted from this extraordinary alloy—it becomes clear that the future holds endless possibilities for incorporating smart materials into our daily lives.

Nitinol Paperclips: An Innovation

In the realm of office supplies, nitinol paperclips are turning heads and reshaping how we think about what paper clips are made of. Unlike traditional metal clips that can bend and break, nitinol paperclips boast a remarkable resilience due to their unique material properties. This innovation is not just a trend; it’s a revolution in the way we interact with everyday items.

Advantages Over Traditional Paperclips

When comparing nitinol paperclips to their traditional counterparts, the advantages become glaringly obvious. First off, these nifty clips don’t just hold papers together; they do so with a flair for durability that most regular paper clips can only dream of achieving. Additionally, nitinol’s shape memory feature means that even after being stretched or deformed, these paperclips return to their original shape—no more awkwardly bent clips cluttering your desk!

Moreover, the lightweight nature of nitinol means that despite its strength and flexibility, you won’t feel weighed down by your office supplies. In essence, if you’ve ever wondered what are paper clips made of that could withstand the test of time and use, look no further than nitinol. With such advantages in play, it’s clear why these innovative clips are making waves among stationery enthusiasts.

Durability and Flexibility of Nitinol Paperclips

One standout feature of nitinol paperclips is their exceptional durability combined with incredible flexibility—a dynamic duo seldom found in traditional materials used for standard clips. While typical metal or plastic options might snap under pressure or lose their grip over time, nitinol maintains its structural integrity through repeated use without losing its effectiveness as a reliable cpaper clip alternative.

This unique combination ensures that your papers stay secure without any risk of tearing or damaging them during removal—an essential quality for anyone who values both organization and care in handling documents. Thanks to this remarkable material science behind nitinol paperclips, users can experience peace of mind knowing they’re using products designed for longevity and performance.

Creative Uses for Nitinol Paperclips

The versatility inherent in nitinol opens up an entire world of creative uses beyond simply holding sheets together! For instance, artists have begun using these innovative clips as tools for creating dynamic sculptures due to their ability to hold shapes while maintaining flexibility—turning an ordinary office supply into an extraordinary medium for expression!

Moreover, educators have discovered that they make excellent teaching aids; students can easily manipulate them into various forms while learning about physics concepts like elasticity and tension—an engaging way to bring lessons alive! So next time you find yourself surrounded by mundane stationery options when pondering what are paper clips made of worth exploring further—consider the endless possibilities offered by nimble nitinol.

GEE SMA: Leading Nitinol Production

When it comes to the production of nitinol, GEE SMA stands out as a leader in the industry. With a firm commitment to quality, they ensure that every nitinol paperclip produced meets stringent standards. This dedication not only enhances the performance of their products but also reinforces trust among customers seeking innovative solutions in everyday items like paper clips.

Commitment to Product Quality

GEE SMA prioritizes product quality above all else, understanding that what are paper clips made of directly impacts their utility and longevity. They utilize advanced manufacturing techniques and rigorous testing protocols to guarantee that each nitinol paperclip is crafted to perfection. This unwavering focus on quality means that users can rely on these clips for durability and functionality, making them a preferred choice over traditional materials.

Customization of Nitinol Components

One of the standout features of GEE SMA is their ability to customize nitinol components according to specific needs. Whether it's creating unique shapes or adjusting properties for specialized applications, they offer tailored solutions that cater to various industries beyond just office supplies. This flexibility ensures that their nitinol paperclips can serve diverse purposes while maintaining high performance and reliability.

Nitinol in Space Missions

GEE SMA's innovations extend far beyond the realm of office supplies; their nitinol products have even found applications in space missions! The unique properties of nitinol make it an ideal material for components used in aerospace technology, where reliability and adaptability are crucial. By incorporating nitinol into space exploration tools, GEE SMA showcases how what are paper clips made of can evolve into something extraordinary—truly redefining our understanding of everyday materials.

Future Trends in Paper Clip Materials

As we look to the future of stationery, the evolution of paper clips is set to reflect broader trends in material science and technology. The shift towards smart materials is gaining momentum, with innovative designs promising enhanced functionality and user experience. This transformation not only redefines what are paper clips made of but also opens doors for creative applications that were previously unimaginable.

The Move Towards Smart Materials

Smart materials are taking the stage in various industries, and paper clips are no exception. With advancements in technology, nitinol paperclips could soon feature properties like self-repair or adjustable tension based on environmental conditions. Imagine a nitinol paperclip that can adapt its grip strength depending on the thickness of the papers it holds; this would revolutionize how we think about what are paper clips made of!

Sustainability in Paperclip Production

Sustainability has become a buzzword across all sectors, and paperclip production is no different. Traditional metal sources often come with hefty environmental costs, whereas nitinol offers a more sustainable path due to its recyclability and longevity. By choosing nitinol paperclips over conventional options, consumers contribute to reducing waste while benefiting from a product designed for durability.

Nitinol's Role in the Future

Nitinol's unique properties position it as a frontrunner for future innovations in everyday items like paper clips. As industries increasingly seek versatile materials that combine performance with sustainability, nitinol’s shape memory capabilities will likely be harnessed for even more applications beyond just office supplies. In this evolving landscape, understanding what are paper clips made of will not only enhance our productivity but also align with our growing commitment to eco-friendly practices.

Conclusion

In the world of office supplies, few items have remained as unchanged as the humble paper clip. Yet, with the introduction of nitinol paperclips, we see a refreshing twist on what are paper clips made of. Nitinol's unique properties not only enhance functionality but also redefine user expectations for everyday office tools.

Why Nitinol Stands Out in Paperclips

Nitinol paperclips stand out due to their remarkable flexibility and shape memory capabilities. Unlike traditional metal clips that can bend and break, nitinol paperclips return to their original form after being deformed, showcasing resilience that is hard to match. This innovative material transforms what are paper clips made of into something far more advanced and reliable.

The Future of Paperclip Materials

As we look ahead, the future of paperclip materials seems poised for exciting developments, particularly with smart materials like nitinol leading the charge. With increasing demands for durability and functionality in everyday items, nitinol's unique characteristics will likely inspire new designs and applications beyond mere stationery. What are paper clips made of may soon evolve further as industries embrace sustainability alongside innovation.

Embracing Nitinol for Everyday Use

Embracing nitinol for everyday use means welcoming a new era in office supplies that combines practicality with cutting-edge technology. Imagine a world where your nitinol paperclips not only hold your documents together but also adapt to your needs seamlessly! By integrating these advanced materials into our daily lives, we can elevate our organizational tools from mundane to extraordinary.