Introduction

In the realm of modern engineering, SMA actuators have emerged as a fascinating solution for a variety of applications. These devices leverage the unique properties of shape memory alloys (SMAs) to create movement and force in response to temperature changes. Understanding how these materials function is essential, especially when considering their reliability and performance across different industries.

Understanding the Basics of SMA Actuators

SMA actuators operate on the principle that certain alloys can remember their original shape when subjected to specific thermal conditions. When heated, a shape memory alloy wire actuator can return to its predetermined configuration, enabling precise motion control. This transformation is not just a party trick; it allows SMA actuators to outperform traditional actuation methods in many scenarios.

The Significance of Shape Memory Alloys

Shape memory alloys are significant because they offer unique advantages over conventional materials, particularly in terms of weight and energy efficiency. Their ability to undergo substantial deformation while still returning to their original shape makes them ideal for applications ranging from robotics to aerospace engineering. As industries increasingly seek lightweight solutions without sacrificing performance, the role of SMAs becomes even more critical.

What Makes an SMA Actuator Reliable

Reliability in an SMA actuator hinges on several factors, including material quality and manufacturing precision from reputable SMA actuator manufacturers. High-quality shape memory alloys ensure consistent performance under varying conditions, which is vital for applications that demand high levels of accuracy and endurance. Additionally, understanding how these actuators compare with alternatives like piezoelectric actuators can help engineers make informed decisions about which technology best meets their needs.

Core Functionality of SMA Actuators

To truly appreciate the capabilities of SMA actuators, one must first understand the underlying principles that govern their operation. Shape memory alloys (SMAs) are unique materials that can remember a specific shape and return to it when heated above a certain temperature. This remarkable property is what makes the SMA actuator an attractive choice for various applications, especially where precision and reliability are paramount.

How Shape Memory Alloy Works

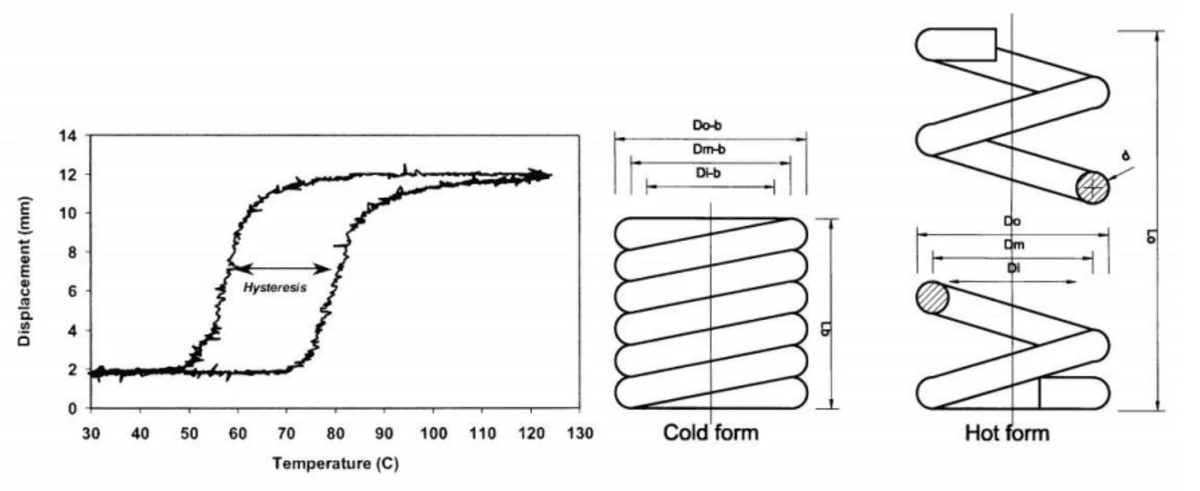

At the heart of every shape memory alloy is a fascinating phase transformation process. When an SMA actuator is in its low-temperature state, it can be easily deformed; however, once heated to its transition temperature, it undergoes a structural change that allows it to return to its pre-defined shape. This transformation generates significant force and movement, making shape memory alloy wire actuators an excellent option for tasks requiring controlled motion or actuation.

The efficiency of this process hinges on the quality of the material used and the expertise of SMA actuator manufacturers. High-quality SMAs ensure optimal performance by providing consistent actuation responses and longevity under repeated cycling conditions. As such, understanding how these materials work is essential for anyone looking to leverage shape memory alloy applications in their designs.

Applications in Robotics and Aerospace

SMA actuators have carved out a niche in both robotics and aerospace due to their lightweight nature and compact design. In robotics, these actuators enable smooth movements in robotic arms or grippers by translating thermal energy into mechanical work with impressive precision. This capability allows engineers to create robots that can perform delicate tasks previously thought impossible without bulky motors.

In aerospace applications, where weight savings are critical, SMAs offer solutions that traditional actuators cannot match. For instance, they can be utilized in deployable structures such as antennas or wings that require reliable actuation mechanisms while minimizing overall mass. The versatility of shape memory alloy applications continues to expand as more industries recognize their potential.

Comparing SMA Actuators to Piezoelectric Actuators

When comparing SMA actuators with piezoelectric actuators, several factors come into play that may influence your choice based on specific needs. While piezoelectric actuators provide rapid response times and high precision at small scales, they often require complex control systems and power supplies that may not be feasible for all applications. On the other hand, SMA actuators excel in simplicity; they operate effectively with just thermal input without needing intricate electronics.

Moreover, durability is another aspect where SMAs shine brightly compared to their piezoelectric counterparts; they typically exhibit greater resilience under cyclic loading conditions due to their inherent material properties. However, it's essential to note that piezoelectric actuators might outperform SMAs regarding speed—ideal for applications demanding quick adjustments or movements like vibration control systems or high-frequency devices. Ultimately, selecting between these two technologies depends on weighing your project's specific requirements against each actuator's strengths.

Material Quality and Composition

When it comes to SMA actuators, the quality of the materials used is paramount. High-quality shape memory alloys not only ensure optimal performance but also enhance the reliability and longevity of these devices. In a world where precision matters, investing in superior materials can mean the difference between a successful application and a costly failure.

Importance of High-Quality Shape Memory Alloys

High-quality shape memory alloys are essential for achieving consistent actuation performance in SMA actuators. The unique properties of these alloys, such as their ability to return to a predefined shape upon heating, depend significantly on their composition and processing methods. Poorly made SMA actuators can lead to unexpected failures, making it crucial for manufacturers to prioritize material integrity in their designs.

Moreover, the mechanical properties of high-quality shape memory alloys directly influence actuation speed and force output. This is especially important when comparing SMA actuators with piezoelectric actuators, which have different operational characteristics. Therefore, selecting an actuator built from premium materials can enhance overall system efficiency across various applications.

GEE SMA and Nitinol Innovations

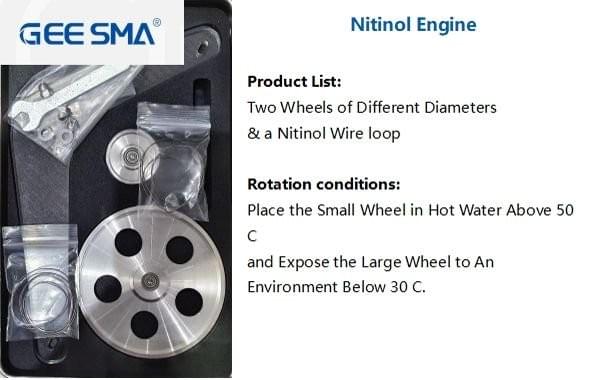

GEE SMA has been at the forefront of innovations in shape memory alloy technology, particularly with its advancements in nitinol—a nickel-titanium alloy known for its remarkable shape memory effects. By refining production techniques and enhancing material properties, GEE SMA has developed high-performance SMA actuators that are increasingly reliable for demanding applications like robotics and aerospace systems. These innovations make GEE one of the leading players among SMA actuator manufacturers.

Nitinol’s versatility allows it to be tailored for specific applications while maintaining exceptional fatigue resistance and corrosion resistance. As industries continue to explore new frontiers for shape memory alloy applications—from medical devices to automotive components—the role of companies like GEE becomes even more critical in providing robust solutions that can withstand rigorous conditions over time.

Evaluating SMA Actuator Manufacturers

When considering an investment in an SMA actuator, evaluating manufacturers is just as crucial as assessing material quality. Customers should look for manufacturers who demonstrate a commitment to using high-grade shape memory alloys along with rigorous testing protocols that ensure product reliability over time. Additionally, transparency regarding manufacturing processes can offer insights into whether a company prioritizes quality control or simply aims for cost-cutting measures.

It's also beneficial to examine customer reviews and case studies related to specific manufacturers' products; real-world experiences often reveal much about performance metrics such as temperature response or actuation speed compared with competitors—especially when juxtaposed against piezoelectric actuator options available on the market today. Ultimately, choosing reputable SMA actuator manufacturers will ensure you get not only superior products but also peace of mind knowing they stand behind their innovation.

Performance Metrics

When it comes to assessing the performance of SMA actuators, several key metrics come into play. These metrics help determine not only the efficiency of the actuator but also its suitability for various applications. Understanding these metrics is essential for both manufacturers and end-users looking to optimize their designs and implementations.

Key Metrics to Assess SMA Actuators

The primary metrics used to evaluate SMA actuators include actuation force, displacement, response time, and energy efficiency. Actuation force refers to the amount of force generated by the shape memory alloy when it undergoes a phase change, while displacement measures how far the actuator can move in response to that force. Additionally, response time is crucial; a quicker response means better performance in dynamic applications compared to piezoelectric actuators that may lag behind in speed.

Energy efficiency is another critical metric that reflects how much energy is consumed during operation relative to the output achieved. This factor becomes increasingly important as industries strive for sustainable solutions without compromising performance. Manufacturers of SMA actuators must pay close attention to these metrics during production and testing phases to ensure they meet industry standards.

Temperature Response and Actuation Speed

Temperature response plays a vital role in determining how quickly an SMA actuator can react under varying conditions. Shape memory alloys are sensitive to temperature changes; thus, understanding their thermal properties allows engineers to predict their behavior accurately in real-world applications. The actuation speed is influenced not only by temperature but also by the design of the shape memory alloy wire actuator itself—thinner wires generally respond faster than thicker ones.

In high-performance environments like robotics or aerospace, where rapid movements are essential, this characteristic becomes particularly significant. While piezoelectric actuators may offer high precision, they often lack the versatility seen with SMA actuators regarding temperature adaptability and actuation speed under diverse conditions. Therefore, selecting an appropriate SMA actuator involves balancing these attributes based on specific application requirements.

Longevity and Reliability Factors

Longevity and reliability are paramount when considering any actuator technology—especially for applications where failure could have serious consequences. For shape memory alloys, factors such as fatigue resistance and thermal cycling stability directly impact their lifespan and operational reliability over time. Quality control from reputable SMA actuator manufacturers ensures that materials used can withstand repeated use without significant degradation.

Furthermore, environmental conditions such as humidity or corrosive elements can affect longevity; thus understanding these factors helps users make informed decisions about material selection for specific environments or industries like automotive or aerospace sectors where durability is non-negotiable. Innovations from companies like GEE SMA focus on enhancing these qualities through advanced material compositions tailored for extreme conditions while maintaining exceptional performance levels across various shape memory alloy applications.

Design and Integration

The design and integration of SMA actuators into various systems is a crucial aspect of their functionality and effectiveness. As these devices become increasingly prevalent in diverse applications, ensuring they mesh seamlessly with existing technologies is paramount. This section will explore the compatibility challenges, miniaturization trends, and future innovations shaping the landscape of shape memory alloy technology.

Ensuring Compatibility with Existing Systems

When integrating an SMA actuator into an established system, compatibility is key. Many industries are already utilizing piezoelectric actuators, which may require careful consideration when introducing shape memory alloy alternatives. The challenge lies in aligning the operational parameters of an SMA actuator—such as actuation speed and temperature response—with those of existing components to ensure smooth functionality.

Moreover, SMA actuators can often be retrofitted into existing designs without extensive modifications. This flexibility allows for a more straightforward transition for manufacturers looking to enhance their products with advanced materials like shape memory alloys. By collaborating closely with SMA actuator manufacturers, engineers can develop tailored solutions that meet specific operational needs while leveraging the unique benefits offered by shape memory alloys.

Miniaturization and Customization Options

In today's fast-paced technological environment, miniaturization has become a driving force behind the development of SMA actuators. As devices shrink in size while increasing in complexity, manufacturers are challenged to create compact yet powerful shape memory alloy wire actuators that maintain high performance levels. This trend not only enhances portability but also opens new avenues for innovative applications across various sectors.

Customization options further amplify the appeal of SMA actuators, allowing designers to tailor features according to specific requirements such as force output or temperature thresholds. This level of adaptability ensures that users can select or design an SMA actuator that perfectly aligns with their project goals without compromising on quality or efficiency. With advancements in material science and manufacturing techniques from leading SMA actuator manufacturers, bespoke solutions are becoming more accessible than ever.

Future Trends in SMA Actuator Design

Looking ahead, several exciting trends are poised to redefine the design landscape for SMA actuators. One significant development is the incorporation of smart materials that enable enhanced responsiveness and control over actuation processes—bringing together the best qualities found in both shape memory alloys and piezoelectric technologies. Such innovations could lead to more efficient energy usage while improving overall system performance across industries.

Additionally, advancements in 3D printing technology are paving new paths for creating complex geometries within SMA designs that were previously unattainable through traditional manufacturing methods. These capabilities allow for even greater customization potential while reducing production costs—a win-win for both developers and end-users alike! As we continue embracing these transformative trends, it's clear that the future holds immense promise for shape memory alloy applications across various fields.

Real-World Applications

Shape memory alloy (SMA) actuators are making waves across various industries, showcasing their versatility and reliability. From medical devices to automotive innovations, the applications of SMA technology are expanding rapidly. Let’s dive into how these remarkable materials are reshaping our world.

Shape Memory Alloy Applications in Medicine

In the medical field, shape memory alloys are transforming treatment options and surgical procedures. SMA actuators are utilized in stents, where their ability to expand at body temperature allows for minimally invasive surgeries with enhanced patient outcomes. Additionally, shape memory alloy wire actuators play a crucial role in robotic surgery, providing precise movements that can adapt to complex anatomical structures.

Furthermore, SMA applications extend to orthodontics with self-adjusting braces that align teeth more effectively over time without frequent adjustments. The unique thermal properties of shape memory alloys enable them to respond dynamically within the human body, improving comfort and efficacy in various devices. As SMA actuator manufacturers continue to innovate, we can expect even more groundbreaking advancements in medical technology.

Automobiles and Aerospace Case Studies

The automotive industry is also embracing SMA technology for various components such as adaptive suspensions and active grille shutters that optimize aerodynamics and fuel efficiency. These systems rely on the quick response of shape memory alloy actuators to environmental changes, enhancing vehicle performance while reducing emissions. Moreover, manufacturers are increasingly integrating piezoelectric actuators alongside SMAs for hybrid systems that offer improved control and responsiveness.

In aerospace engineering, SMAs have proven invaluable for applications like morphing wings or deployable structures that adjust during flight for optimal performance. By utilizing shape memory alloy applications in such critical areas, engineers can achieve lightweight solutions without compromising strength or reliability. The collaboration between different actuator technologies continues to pave the way for innovative designs in both automobiles and aerospace sectors.

Innovations from GEE SMA in Space Missions

GEE SMA has been at the forefront of incorporating shape memory alloys into space missions with remarkable success stories under its belt. Their developments include deployable solar panels that utilize SMA actuators for efficient energy collection once spacecraft reach orbit—this is a game-changer given the constraints of space travel where weight savings are paramount! Additionally, GEE's innovations have enabled reliable mechanisms for satellite antennas that require precise positioning during operation.

The adaptability of shape memory alloys allows these components to withstand extreme temperatures and conditions found beyond Earth’s atmosphere while maintaining functionality over extended periods—a critical factor in long-term space missions. As GEE SMA continues its pioneering work with these materials, we can expect future explorations beyond our planet will benefit significantly from their advancements in actuator technology.

Conclusion

In wrapping up our exploration of SMA actuators, it’s clear that these remarkable devices harness the unique properties of shape memory alloys to deliver innovative solutions across various industries. From robotics to aerospace, understanding the nuances of SMA actuator technology is essential for making informed selections. As we look ahead, the interplay between material quality and design will continue to shape the future landscape of actuator technology.

Essential Takeaways for SMA Actuator Selection

When selecting an SMA actuator, it's vital to prioritize high-quality materials and reliable manufacturers. The performance metrics such as actuation speed and longevity should be at the forefront of your decision-making process. Additionally, consider the specific applications—whether you need a shape memory alloy wire actuator for precision tasks or a robust solution for heavy-duty environments.

The Future of Shape Memory Alloy Technology

The future of shape memory alloy technology is bright and brimming with potential innovations that could redefine how we approach engineering challenges. With advancements in material science and manufacturing techniques, we can expect SMA actuators to become even more efficient and versatile in their applications. As industries evolve, integrating these cutting-edge technologies will likely lead to revolutionary breakthroughs that enhance performance across sectors.

The Role of GEE SMA in Advancing Actuator Reliability

GEE SMA stands at the forefront of advancing actuator reliability through its commitment to innovation and quality in shape memory alloys. By focusing on rigorous testing and development processes, GEE SMA ensures their products meet the highest standards demanded by modern applications. Their contributions not only enhance the reliability of SMA actuators but also inspire confidence among manufacturers looking for dependable solutions in a competitive landscape.