Introduction

In the realm of advanced materials, few can rival the remarkable properties of Nitinol. This unique alloy, composed primarily of nickel and titanium, exhibits extraordinary characteristics such as shape memory and superelasticity, making it a game-changer in various applications. Understanding these properties is crucial for harnessing the full potential of Nitinol, particularly in the development of innovative technologies like nitinol linear actuators.

Understanding Nitinol's Unique Properties

Nitinol’s ability to return to a predetermined shape when heated sets it apart from traditional materials. This shape memory effect allows for the creation of compact and efficient devices, such as linear actuators that can perform complex tasks with minimal energy input. Additionally, its superelasticity means that nitinol wire can undergo significant deformation without permanent change, further enhancing its utility in dynamic applications.

The Importance of Dimensional Accuracy

In manufacturing nitinol components, dimensional accuracy is paramount to ensure optimal performance and reliability. Linear actuators depend on precise measurements to function correctly; any deviation can lead to inefficiencies or even failure in critical systems. Achieving high dimensional accuracy not only improves actuator performance but also enhances safety in applications ranging from robotics to medical devices.

Applications of Nitinol in Modern Technology

The versatility of Nitinol has led to its incorporation into a myriad of modern technologies, particularly through the use of nitinol linear actuators. These actuators find their place in diverse fields such as robotics and aerospace, where they facilitate movement with unparalleled precision and responsiveness. Furthermore, medical applications leveraging nitinol shape memory have revolutionized minimally invasive procedures by allowing for devices that adapt seamlessly within the human body.

Nitinol Manufacturing Techniques

Nitinol, a remarkable alloy of nickel and titanium, boasts unique properties that make it a favorite in various high-tech applications. The manufacturing techniques employed to create nitinol components are crucial for ensuring the performance and reliability of devices like nitinol linear actuators. This section delves into the various production methods, including sintering and forging processes, as well as precision machining to achieve dimensional accuracy.

Overview of Production Methods

The production of nitinol involves several methods that cater to its complex properties and desired applications. Traditional techniques such as melting and casting are often used, but more advanced approaches like powder metallurgy have gained popularity due to their ability to create intricate shapes with minimal waste. These production methods lay the groundwork for creating components that can be utilized in devices like a linear actuator with motor or even in medical devices utilizing nitinol shape memory.

To ensure the quality and functionality of these elements, manufacturers must adhere to stringent protocols throughout the production process. By employing state-of-the-art technology, they can produce high-quality nitinol wire that meets specific requirements for strength, flexibility, and thermal responsiveness. This attention to detail is essential when developing products like heating actuators or actuator controllers.

Sintering and Forging Processes

Sintering is one of the most widely used processes in creating nitinol components due to its efficiency in producing dense materials from powdered metals. During this process, fine particles are compacted under high pressure and then heated just below their melting point—allowing them to fuse together without fully liquefying. This method is particularly advantageous when crafting parts for nitinol linear actuators because it retains dimensional integrity while enhancing mechanical properties.

Forging is another key technique used in manufacturing nitinol products; it involves shaping metal through compressive forces at elevated temperatures. This method not only improves material strength but also aligns grain structures for better performance under stress—ideal for applications where durability is paramount, such as in an example of an actuator found in robotics or aerospace technologies. Both sintering and forging contribute significantly to optimizing the characteristics required for effective heating actuators.

Precision Machining for Dimensional Accuracy

Achieving dimensional accuracy is critical when producing components intended for precise movements, such as those found in a linear actuator with motor systems. Precision machining techniques allow manufacturers to carve out intricate designs from solid blocks of material or refine sintered parts into exact specifications needed for optimal operation within devices like nitinol shape memory systems. Advanced CNC (Computer Numerical Control) technology plays a vital role here by enabling automated machining processes that can achieve tolerances within microns.

Moreover, precision machining ensures that every piece fits seamlessly into larger assemblies—crucial when integrating actuator controllers that require exact dimensions for proper functioning. The meticulous nature of these processes helps avoid discrepancies which could lead to malfunction or inefficiencies within applications relying on nitinol wire's unique abilities. Ultimately, investing time and resources into precision machining not only enhances product quality but also supports continuous improvement initiatives across manufacturing operations.

The Role of Nitinol Linear Actuators

Nitinol linear actuators are revolutionizing the way we think about motion and control in various applications. These innovative devices leverage the unique properties of nitinol wire, a shape memory alloy, to create precise movements with minimal energy consumption. By utilizing the inherent characteristics of nitinol, engineers can design linear actuators that respond dynamically to changes in temperature, making them ideal for a range of uses.

How Nitinol Wire is Utilized

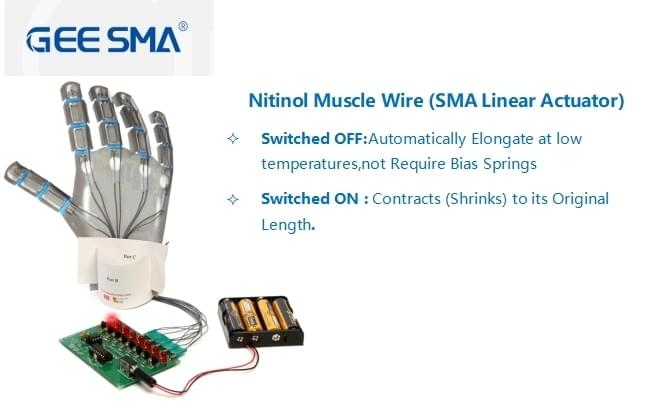

Nitinol wire serves as the backbone of nitinol linear actuators, enabling them to convert thermal energy into mechanical movement. When heated above a certain temperature threshold, nitinol wire undergoes a phase transformation that allows it to contract or expand dramatically. This property is harnessed in actuator designs where controlled heating can trigger specific movements—perfect for applications requiring precision and reliability.

In practical terms, the integration of nitinol wire into actuator systems means that these devices can achieve remarkable dimensional accuracy while remaining lightweight and compact. This makes them suitable for environments where space is at a premium or where traditional actuation methods would be cumbersome or inefficient. The versatility of nitinol wire opens doors to creative solutions across industries such as robotics, medical devices, and aerospace.

Functionality of Linear Actuator with Motor

A linear actuator with motor enhances the capabilities of traditional actuator systems by providing additional control over movement dynamics. In conjunction with nitinol wire, motors can regulate heating and cooling cycles more effectively, allowing for smoother operation and greater responsiveness. This synergy between the motor and nitinol linear actuator results in improved performance metrics such as speed, precision, and reliability.

The functionality extends beyond simple actuation; it involves complex interactions between various components managed by an actuator controller that fine-tunes operations based on real-time feedback. For example, when used in robotic applications or automated systems, this combination allows for intricate maneuvers that would otherwise be difficult to achieve with standard actuators alone. As technology continues to evolve, we can expect even more sophisticated integrations that push the boundaries of what’s possible.

Benefits of Heating Actuators in Applications

Heating actuators offer several compelling advantages over conventional alternatives due to their ability to deliver precise motion control through thermal management. One significant benefit is energy efficiency; by only activating when needed via targeted heating methods, these systems minimize power consumption while maximizing output effectiveness—a win-win scenario! Moreover, because they require fewer moving parts than traditional actuators driven by motors alone, maintenance becomes less frequent and easier.

Additionally, the rapid response time associated with heating actuators makes them particularly valuable in time-sensitive applications like medical devices where quick adjustments are crucial for patient safety and efficacy—think about surgical instruments that must adapt instantly during procedures! Furthermore, their compact nature allows designers more freedom when creating systems without compromising functionality or performance standards.

In summary, nitinol linear actuators exemplify how innovative materials like nitinol wire can transform motion control across various sectors through enhanced functionality provided by integrated motor systems and efficient heating mechanisms.

Actuator Controllers and Their Significance

Actuator controllers play a pivotal role in the functionality and efficiency of nitinol linear actuators. These controllers are responsible for managing the operation of the linear actuator with motor, ensuring precise movements and accurate responses to commands. As nitinol wire expands and contracts with temperature changes, effective actuator control becomes essential for harnessing the unique properties of nitinol shape memory.

Types of Actuator Controllers for Nitinol

Various types of actuator controllers are designed specifically for nitinol applications, each catering to different operational needs. Basic on-off controllers provide straightforward functionality, while more advanced proportional-integral-derivative (PID) controllers offer enhanced precision by continuously adjusting based on feedback from the system. Additionally, some systems integrate microcontrollers that allow for programmable control schemes, which can be crucial when deploying an example of an actuator in complex environments.

Innovations in Control Technology

Recent innovations in control technology have significantly advanced how we utilize nitinol linear actuators. Developments such as wireless communication capabilities allow for remote operation and monitoring, enhancing flexibility in applications ranging from robotics to medical devices. Moreover, smart materials integration enables real-time adjustments based on environmental conditions or user inputs, optimizing the performance of heating actuators while maintaining energy efficiency.

Challenges in Controller Integration

Despite advancements, integrating actuator controllers with nitinol systems presents several challenges that engineers must navigate. One primary concern is ensuring compatibility between various components; not all controller types work seamlessly with every linear actuator design or application scenario. Additionally, achieving precise dimensional accuracy during manufacturing is critical since any discrepancies can lead to performance issues or inefficiencies when operating a nitinol linear actuator.

Real-World Examples of Nitinol Actuators

Nitinol actuators have carved a niche for themselves in various domains, showcasing their versatility and unique properties. From robotics to medical applications, the use of nitinol wire in linear actuators has transformed how devices operate. These examples not only highlight the functionality of nitinol but also emphasize the importance of dimensional accuracy in their manufacturing.

Example of an Actuator in Robotics

In the realm of robotics, one standout application is the use of nitinol linear actuators for robotic arms. These actuators leverage the unique properties of nitinol wire to create precise movements, allowing for intricate tasks that require a high degree of accuracy. By integrating a linear actuator with motor technology, robotic systems can achieve smooth and efficient motion control, making them invaluable in industrial automation.

The ability to heat these actuators enhances their performance dramatically; when heated, nitinol wire contracts and expands with remarkable speed and precision. This heating actuator mechanism allows robots to adapt quickly to various tasks, whether it's assembling components or performing delicate surgeries. As a result, they offer a reliable solution for manufacturers seeking efficiency and flexibility in their production lines.

Medical Applications Using Nitinol Shape Memory

Nitinol’s shape memory effect opens up exciting possibilities in medical applications, particularly in minimally invasive surgery tools like stents and guidewires. When deployed within the human body, these devices can change shape according to temperature fluctuations caused by body heat—an incredible feat made possible by nitinol's unique properties. The precision offered by nitinol linear actuators ensures that these instruments can navigate complex anatomical pathways with ease.

Moreover, using actuator controllers allows healthcare professionals to manage these devices effectively during procedures. The combination of nitinol shape memory technology with advanced control systems leads to better patient outcomes through enhanced maneuverability and reduced recovery times. Surgeons now have access to tools that not only perform but also adapt dynamically during operations.

Case Study: Bensun Technology's Contributions

Bensun Technology has made significant strides in advancing nitinol actuator technology through innovative designs and manufacturing processes. Their focus on creating high-quality linear actuators has led them to develop solutions that meet stringent industry standards while ensuring dimensional accuracy throughout production stages. By harnessing the power of nitinol wire combined with cutting-edge heating actuator techniques, Bensun is setting new benchmarks for performance.

One notable project involved collaborating with leading robotics firms to integrate custom-designed nitinol linear actuators into next-generation robotic systems—showcasing how effective actuator controllers can enhance operational efficiency across various industries. Their contributions underscore the importance of continuous improvement techniques within manufacturing processes while pushing forward advancements in both robotics and medical fields alike.

The future looks bright as Bensun Technology continues pioneering innovations that leverage the unique capabilities of nitinol shape memory materials.

Quality Control in Nitinol Manufacturing

In the realm of nitinol manufacturing, maintaining exceptional quality is paramount. The unique properties of nitinol, especially its shape memory and superelasticity, necessitate rigorous quality control measures to ensure that every component meets the required standards for performance and reliability. This section delves into the essential aspects of quality control, focusing on standards, testing methods, and continuous improvement techniques.

Standards and Certifications to Follow

To ensure that nitinol components perform reliably in various applications, manufacturers must adhere to specific standards and certifications. Organizations such as ASTM International provide guidelines for the properties and testing of nitinol materials, ensuring consistency across different batches of nitinol wire. Additionally, ISO certifications play a crucial role in establishing best practices in manufacturing processes for linear actuators, including those utilizing nitinol wire.

These standards not only promote safety but also enhance customer confidence in products like linear actuators with motors that rely on precise dimensional accuracy. Adhering to these established norms helps manufacturers avoid costly recalls or failures while fostering innovation within the industry. Ultimately, compliance with these standards is fundamental for any company looking to lead in the competitive landscape of actuator technology.

Testing Methods for Dimensional Accuracy

Achieving dimensional accuracy is critical when producing nitinol linear actuators since even minor deviations can impact functionality significantly. Various testing methods are employed to assess this accuracy throughout the manufacturing process; techniques such as coordinate measuring machines (CMM) allow for precise measurement of dimensions against specified tolerances. Moreover, non-destructive testing (NDT) methods ensure that internal structures are sound without compromising the integrity of the material.

In addition to traditional measurement techniques, advanced imaging technologies can be used to analyze surface finishes and detect defects at microscopic levels—this is particularly important when dealing with applications requiring high precision like medical devices utilizing nitinol shape memory properties. By implementing robust testing protocols, manufacturers can guarantee that each actuator controller meets stringent requirements before it reaches end-users. This meticulous attention to detail ultimately enhances product reliability and performance across various applications.

Continuous Improvement Techniques

Continuous improvement is a cornerstone principle in any successful manufacturing operation involving nitinol components such as linear actuators. Techniques like Six Sigma or lean manufacturing principles help streamline processes while reducing waste—ensuring that production remains efficient without sacrificing quality or dimensional accuracy. Regular audits and feedback loops are essential; they allow teams to identify areas needing refinement quickly.

Additionally, investing in employee training ensures that all team members understand best practices related to working with nitinol wire and its unique properties—this knowledge translates directly into better quality control across all stages of production from raw material handling through final assembly of heating actuators or actuator controllers. Ultimately, a culture focused on continuous improvement not only enhances product quality but also fosters innovation within organizations striving for excellence in actuator technology.

Conclusion

As we wrap up our exploration of nitinol and its remarkable applications, it’s clear that the future of nitinol linear actuators is bright. With ongoing advancements in material science and engineering, we can expect to see even more innovative uses for nitinol wire across various industries. The integration of these technologies promises to enhance functionality and efficiency, paving the way for smarter actuator controllers that can adapt dynamically to their environments.

Future Trends in Nitinol Actuator Technology

The landscape of nitinol actuator technology is evolving rapidly, with trends indicating a shift towards miniaturization and increased automation. Future designs will likely incorporate advanced sensors and smart materials, allowing the linear actuator with motor to respond intelligently to external stimuli. This evolution not only enhances performance but also opens doors for new applications in robotics, aerospace, and medical devices—where precision is paramount.

Enhancing Dimensional Accuracy in Manufacturing

Dimensional accuracy remains a critical focus in the manufacturing of nitinol components like linear actuators. Techniques such as precision machining are being refined to ensure that every piece meets stringent specifications while maintaining the unique properties of nitinol shape memory alloys. By investing in cutting-edge technology and quality control processes, manufacturers can significantly improve consistency and reliability in their products.

How Bensun Technology Is Leading the Way

Bensun Technology stands at the forefront of innovation within the realm of nitinol linear actuators, consistently pushing boundaries through research and development. Their commitment to enhancing actuator controller systems ensures that each example of an actuator not only meets but exceeds industry standards for performance and durability. By focusing on continuous improvement techniques, Bensun is not just responding to market demands; they're setting new benchmarks for what’s possible with nitinol technology.