Introduction

In a world where innovation drives progress, Shape Memory Alloys (SMAs) have emerged as a fascinating solution to complex engineering challenges. These unique materials possess the remarkable ability to return to a predetermined shape when subjected to specific stimuli, such as heat. As industries seek more efficient and versatile solutions, the rise of SMA actuators has become a game-changer, paving the way for smarter technologies.

Understanding Shape Memory Alloys

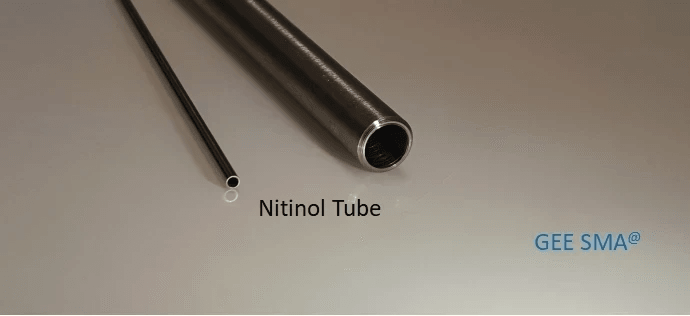

Shape Memory Alloys are metallic materials that can remember their original shape after being deformed. This property is due to the unique crystalline structure of these alloys, which allows them to undergo phase transformations in response to temperature changes. Among various SMAs, Nitinol stands out for its exceptional performance and reliability, making it a popular choice in numerous applications.

The Rise of SMA Actuators

The advent of SMA actuators has revolutionized how we approach automation and control systems across different sectors. Unlike traditional methods such as piezoelectric actuators that rely on electric fields for movement, SMA actuators harness thermal energy to induce motion. This innovative working principle not only simplifies design but also enhances efficiency in applications ranging from robotics to aerospace technology.

How SMAs Transform Industries

The transformative impact of SMAs extends beyond mere functionality; they are reshaping entire industries with their versatility and adaptability. From medical devices that leverage Nitinol actuator technology for minimally invasive procedures to aerospace innovations that demand lightweight yet robust components, the potential applications are vast and varied. As we delve deeper into this topic, it becomes clear that SMA actuator applications will continue to expand as technology evolves.

What is an SMA Actuator?

SMA actuators are fascinating devices that leverage the unique properties of shape memory alloys (SMAs) to convert thermal energy into mechanical work. These materials, particularly Nitinol, exhibit the ability to return to a predetermined shape when heated above a certain temperature. The SMA actuator working principle is based on this remarkable characteristic, allowing for precise movements and applications across various industries.

Defining SMA and Its Properties

Shape Memory Alloys are metallic materials that can remember their original shapes after being deformed. The most commonly used SMA in actuators is Nitinol, an alloy of nickel and titanium, which showcases exceptional elasticity and strength. Key properties of SMAs include their ability to undergo phase transformations at specific temperatures, enabling them to transition between different structural forms while delivering reliable performance in applications ranging from medical devices to aerospace technologies.

Comparing SMA Actuator to Piezoelectric Actuators

While both SMA actuators and piezoelectric actuators serve similar purposes in converting energy into motion, they operate on entirely different principles. Piezoelectric actuators utilize electric fields to induce mechanical deformation in certain materials, providing rapid response times but limited displacement ranges. In contrast, SMA actuators offer greater displacement capabilities and can exert substantial forces; however, their response times are slower due to the thermal activation process inherent in the memory metal actuator technology.

Advantages of Using Nitinol Actuators

Nitinol actuators come with a plethora of advantages that make them increasingly popular in various applications. One significant benefit is their compact size coupled with high force output—ideal for space-constrained environments like medical implants or robotic systems. Additionally, Nitinol's biocompatibility makes it an excellent choice for medical devices, while its durability ensures longevity even under challenging conditions; these factors contribute significantly to the growing interest in shape memory alloy actuator applications across multiple sectors.

SMA Actuator Working Principle

Understanding the working principle of an SMA actuator is essential to appreciate its unique capabilities. At the heart of this technology lies the fascinating phenomenon known as the shape memory effect, which allows these devices to return to a predetermined shape when subjected to specific conditions. This section will delve into the science behind this effect, how temperature influences behavior, and how memory metals change shape, showcasing why SMA actuators are becoming increasingly popular in various applications.

The Science Behind Shape Memory Effect

The shape memory effect is a remarkable property exhibited by certain alloys, particularly Nitinol, which is a nickel-titanium alloy. When deformed at lower temperatures, these materials can remember their original shapes and return to them upon heating. This ability makes SMA actuators incredibly efficient for applications requiring precise movements and reactions—something that traditional piezoelectric actuators might struggle with under similar circumstances.

The science behind this effect involves phase transformations within the alloy's crystalline structure. As temperature changes, Nitinol transitions between two distinct phases: martensite (the low-temperature phase) and austenite (the high-temperature phase). This transformation enables the SMA actuator to exert force and create motion in response to thermal stimuli—an elegant solution that showcases both simplicity and sophistication in engineering design.

Temperature-Dependent Behavior

Temperature plays a critical role in determining how an SMA actuator behaves under different conditions. When heated above its transformation temperature, the material shifts from its deformed martensitic state back into its original austenitic form, resulting in significant changes in shape and volume. Conversely, cooling down causes it to revert back into its martensitic form where it can be easily deformed again.

This temperature-dependent behavior sets SMA actuators apart from other technologies such as piezoelectric actuators that rely on electrical stimulation for movement. While piezoelectric devices can provide rapid responses through electric fields, they often lack the substantial force output that SMAs can deliver when transitioning between phases. The ability of Nitinol actuators to harness thermal energy for movement opens up exciting avenues for innovation across industries seeking reliable actuation solutions.

How Memory Metals Change Shape

Memory metals like Nitinol are engineered with specific properties that allow them to change shape dramatically when subjected to heat or cold—a defining characteristic of memory metal actuators. Upon reaching their transformation temperature during heating or cooling cycles, these alloys undergo significant structural rearrangement at the atomic level, translating into macroscopic movement observable in real-world applications.

In practical terms, an SMA actuator can contract or expand significantly based on thermal input; this characteristic is utilized extensively across various sectors including aerospace innovations and medical devices using Nitinol technology. The versatility offered by these shape-changing materials enables engineers and designers to craft solutions tailored precisely for their operational needs—whether it's deploying satellite components or activating stents within human arteries.

In summary, understanding how SMAs work not only highlights their innovative mechanics but also emphasizes their potential across diverse applications—from robotics automation advances to cutting-edge aerospace technologies—solidifying their status as pivotal players in modern engineering landscapes.

Applications of Shape Memory Alloy Actuators

Shape Memory Alloy (SMA) actuators are making waves across various industries, thanks to their unique properties and versatility. From aerospace to medical devices, the applications of these remarkable memory metal actuators are transforming how we approach engineering challenges. Let's dive into some exciting sectors where SMA actuator technology is leading the charge.

Aerospace Innovations with SMA

In the aerospace industry, SMA actuators are revolutionizing design and functionality. These lightweight yet robust components can respond to temperature changes, allowing for innovative solutions such as deployable wing structures or adaptive control surfaces that enhance aircraft performance. The SMA actuator working principle enables these systems to operate efficiently in extreme environments, ensuring reliability during critical missions.

Moreover, the use of Nitinol actuators in aerospace applications facilitates significant weight reduction compared to traditional mechanisms. This weight efficiency translates into fuel savings and improved payload capacities for aircraft and spacecraft alike. As engineers continue to explore the potential of shape memory alloy actuator applications, we can expect even more groundbreaking advancements in aviation technology.

Medical Devices Using Nitinol Technology

The medical field is another area where Nitinol technology shines brightly through its incorporation of SMA actuators. These memory metal actuators are commonly found in stents, guidewires, and other minimally invasive devices due to their ability to return to a predetermined shape upon heating. This property allows for flexible designs that can navigate complex anatomical pathways while providing effective treatment options.

In addition to flexibility, SMA actuators offer biocompatibility—a crucial factor for any medical device component that interacts with human tissue. Their unique characteristics enable them to expand or contract at body temperature, making them ideal candidates for dynamic applications like self-expanding stents that adapt seamlessly within blood vessels. As research progresses, we can anticipate further innovations in medical devices driven by shape memory alloy actuator applications.

Robotics and Automation Advances

Robotics and automation are rapidly evolving fields where SMA actuators play a pivotal role in enhancing performance and functionality. These smart devices harness the power of shape memory alloys to create movements that mimic biological systems—think soft robotics inspired by nature's most agile creatures! The adaptability offered by Nitinol actuators allows robots to perform delicate tasks previously deemed impossible with conventional methods.

Additionally, when comparing SMA actuators with piezoelectric actuators, it becomes evident that SMAs provide greater actuation force over larger displacements while maintaining low power consumption levels—a game-changer for battery-operated robots! As industries increasingly adopt automation technologies, the demand for efficient motion control will undoubtedly drive further exploration into shape memory alloy actuator applications across various robotic platforms.

The Role of GEE SMA in the SMA Industry

In the rapidly evolving landscape of Shape Memory Alloys (SMAs), GEE SMA has carved a niche for itself as a leader in innovation and quality. With a steadfast commitment to excellence, GEE SMA is dedicated to enhancing the performance and reliability of Nitinol actuators across various applications. This commitment not only boosts confidence among industry stakeholders but also positions GEE SMA as a trusted partner in developing advanced SMA actuator technologies.

GEE SMA’s Commitment to Quality

Quality is the cornerstone of GEE SMA’s operations, ensuring that every Nitinol actuator meets rigorous standards before it reaches the market. The company employs state-of-the-art manufacturing processes and stringent quality control measures, which are crucial for applications where reliability is paramount, such as in aerospace and medical devices. By prioritizing quality at every stage—from material selection to final testing—GEE SMA reinforces its reputation for producing top-tier shape memory alloy actuator applications.

Moreover, this commitment extends beyond mere compliance; it fuels continuous improvement initiatives aimed at refining the performance characteristics of their memory metal actuators. For instance, ongoing research into optimizing the thermal properties of SMAs ensures that their actuators respond accurately under varying conditions. As a result, customers can trust that they are investing in cutting-edge technology designed to last.

Nitinol Components in Space Missions

The application of Nitinol components in space missions underscores the versatility and resilience of shape memory alloy actuators. GEE SMA supplies high-performance Nitinol actuators for various space exploration projects, where their unique properties play a critical role in mission success. For instance, these memory metal actuators can withstand extreme temperatures and harsh environments while maintaining precise functionality—qualities essential for equipment used beyond Earth’s atmosphere.

The ability of SMAs to revert to predetermined shapes when heated makes them ideal for deployable structures like antennas or solar panels on spacecraft. These components can be compactly stowed during launch and then expanded once deployed in space, showcasing an innovative use case for Nitinol technology that enhances operational efficiency. In this context, GEE SMA's contributions not only facilitate groundbreaking advancements but also highlight their pivotal role within the broader aerospace sector.

Collaboration with Chang’e and Tianwen Projects

GEE SMA's collaboration with significant space missions like China’s Chang’e lunar program and Tianwen Mars exploration underscores its prominence within the industry. By providing specialized Nitinol components tailored for these ambitious projects, GEE SMA demonstrates how shape memory alloy actuator applications can impact global exploration efforts positively. Such partnerships enable engineers to leverage advanced materials that enhance mission capabilities while ensuring durability against extraterrestrial conditions.

Moreover, these collaborations foster an environment ripe for innovation by pushing boundaries on what can be achieved with SMAs in challenging environments like those found on other planets or moons. As teams work together on groundbreaking technologies incorporating Nitinol actuators into their designs, they set new benchmarks for future explorations—paving the way for subsequent generations of aerospace innovations fueled by shape memory alloys' unique advantages.

Future Trends in SMA Actuator Technology

As we look toward the horizon of SMA actuator technology, it's clear that innovation is not just a buzzword—it's a driving force. Emerging research is paving the way for enhanced performance and expanded applications of SMA actuators, particularly Nitinol actuators, which are renowned for their unique properties. With scientists and engineers diving deep into the mechanics of shape memory alloys, we can expect breakthroughs that will redefine how these memory metal actuators are utilized across various industries.

Emerging Research and Developments

The landscape of SMA actuators is rapidly evolving, with research focusing on optimizing their working principles to achieve higher efficiency and reliability. Studies are exploring novel alloy compositions and processing techniques to enhance the thermal response of Nitinol actuators, making them more adaptable for diverse applications. As researchers uncover new insights into the shape memory effect, we can anticipate smarter designs that leverage these advancements to create more responsive and versatile SMA actuator systems.

The Impact of SMA on Sustainable Solutions

Sustainability is at the forefront of technological development today, and SMA actuators are stepping up to meet this challenge head-on. By utilizing shape memory alloys in energy-efficient applications—such as renewable energy systems or eco-friendly robotics—these memory metal actuators contribute significantly to reducing carbon footprints. As industries increasingly prioritize sustainable solutions, the role of Nitinol actuators will likely expand, offering innovative ways to enhance performance while minimizing environmental impact.

Anticipating Market Growth and Innovations

The future looks bright for the market surrounding SMA actuator technologies as demand continues to soar across various sectors. Analysts predict robust growth driven by advancements in automation, aerospace innovations, and medical device applications—all leveraging the unique benefits offered by Nitinol actuators over traditional piezoelectric actuator options. With an eye toward continuous innovation, companies investing in R&D for shape memory alloy actuator applications will likely lead the charge in creating next-generation technologies that transform industries.

Conclusion

In wrapping up our exploration of Shape Memory Alloys (SMAs) and their transformative impact across various industries, it’s clear that SMA actuators are not just a fleeting trend but a cornerstone of innovation. These remarkable devices harness the unique properties of memory metals to provide solutions that are both efficient and versatile. From aerospace to robotics, the applications of SMA actuators continue to expand, showcasing their potential in enhancing technology and improving lives.

The Versatility of SMA Actuators

SMA actuators stand out due to their ability to convert thermal energy into mechanical movement, making them incredibly versatile for numerous applications. Unlike traditional piezoelectric actuators, which require precise electrical input for movement, SMA actuators respond to temperature changes, allowing for simpler designs and reduced energy consumption. This versatility is particularly beneficial in environments where space is limited or where weight constraints are critical, such as in aerospace innovations.

Moreover, the adaptability of Nitinol actuators allows them to be incorporated into various systems without extensive modifications. Their ability to change shape upon heating or cooling means they can perform tasks ranging from precision actuation in medical devices to robust movements in robotic systems. As industries continue seeking more innovative solutions, the versatility of SMA actuator technology will undoubtedly play a crucial role in shaping future advancements.

Key Takeaways on Nitinol Applications

When considering Nitinol applications, it's essential to recognize its unique characteristics that set it apart from other actuator technologies like piezoelectric systems. The shape memory effect inherent in memory metal actuators enables them to return to a predetermined shape after deformation when exposed to specific temperatures—this quality opens doors for creative engineering solutions across multiple sectors. Additionally, the lightweight nature and corrosion resistance of Nitinol make it an ideal choice for demanding environments such as space missions and medical implants.

Furthermore, Nitinol's biocompatibility positions it as a game-changer in the medical field; from stents that expand within arteries to surgical tools that adapt during procedures—Nitinol is paving the way for safer and more effective healthcare solutions. As we look at these key takeaways on Nitinol applications, it's evident that this material is not just another component but rather an essential player driving innovation forward.

Looking Ahead at Shape Memory Alloys

The future of Shape Memory Alloys seems bright with emerging research promising even greater capabilities for SMA actuators than we see today. Innovations are underway that may enhance their responsiveness and efficiency while also exploring new materials beyond traditional Nitinol compositions—an exciting prospect indeed! As industries increasingly prioritize sustainability and energy efficiency, SMA actuator technology will likely align with these goals by providing eco-friendly alternatives without sacrificing performance.

Market growth predictions indicate an expanding demand for memory metal actuators across various sectors—from automotive safety features utilizing SMAs for active control systems to smart textiles incorporating shape memory properties for adaptive clothing designs. Looking ahead at Shape Memory Alloys reveals a landscape rich with possibilities where creativity meets functionality; indeed, we are only scratching the surface of what SMAs can achieve!