Introduction

In the realm of modern engineering, shape memory alloys (SMAs) have emerged as fascinating materials that can change their shape in response to temperature variations. These unique properties make them ideal candidates for a variety of applications, particularly in the development of miniature actuators. Understanding what a shape memory alloy actuator is and how it works opens up a world of innovation across numerous industries.

Understanding Shape Memory Alloys

So, what is a shape memory alloy? At its core, an SMA is a metal that can 'remember' its original form after being deformed when exposed to certain temperatures. This remarkable ability arises from specific phase transformations within the material's structure, enabling it to return to its pre-deformed shape when heated. This property not only defines SMAs but also paves the way for their application in various fields such as robotics and aerospace.

The Magic of Miniature Actuation

The magic truly lies in miniature actuation, which refers to the use of small-scale devices that can perform significant movements or functions with precision and efficiency. Shape memory alloy actuators are at the forefront of this technology, providing lightweight yet powerful solutions for complex tasks. Their compact size and reliability make them perfect for applications where space is limited but performance cannot be compromised.

The Role of GEE SMA in Innovation

GEE SMA has positioned itself as a leader in harnessing the capabilities of SMAs for groundbreaking innovations in actuator technology. By focusing on developing advanced shape memory alloy actuators, GEE SMA has contributed significantly to various sectors including aerospace and medical devices. As we explore further into where SMAs are used and delve into what are shape memory polymer-based actuators, it's clear that GEE SMA's impact will continue shaping the future landscape of engineering advancements.

What is a Shape Memory Alloy?

Shape Memory Alloys (SMAs) are fascinating materials that possess the unique ability to return to a predetermined shape when subjected to specific temperature changes. This remarkable property makes them ideal for a variety of applications, particularly in the realm of actuators. But what exactly is a shape memory alloy actuator? Let’s dive deeper into the definition, properties, and types of these innovative materials.

Definition and Properties

A shape memory alloy is a metal that can undergo significant deformation at one temperature but returns to its original, pre-deformed shape when heated above a certain threshold. This transformation occurs due to changes in the crystal structure of the material, specifically between two phases: martensite and austenite. The ability of SMAs to remember their original form allows them to be used effectively in various applications, such as robotics and aerospace technologies.

The key properties that define SMAs include their high energy density, lightweight nature, and excellent fatigue resistance. These characteristics make them not only efficient but also reliable for long-term use in devices requiring repeated motion or actuation. When we ask ourselves, Where are SMAs used? it becomes clear that their versatility spans across multiple industries.

How Shape Memory Works

Understanding how shape memory works involves delving into the phase transformation process within these alloys. When an SMA is deformed at lower temperatures (in its martensitic state), it retains this new shape until it is heated above its transformation temperature. Upon heating, the material transitions back into its original configuration (austenitic state), creating motion or actuation—hence why we refer to them as shape memory alloy actuators.

This transition not only provides mechanical movement but also offers precision control over position and force output in various applications. The efficiency of this process allows engineers and designers to create compact systems with minimal power requirements while maximizing performance—an essential factor for modern technology innovations.

Types of Shape Memory Alloys

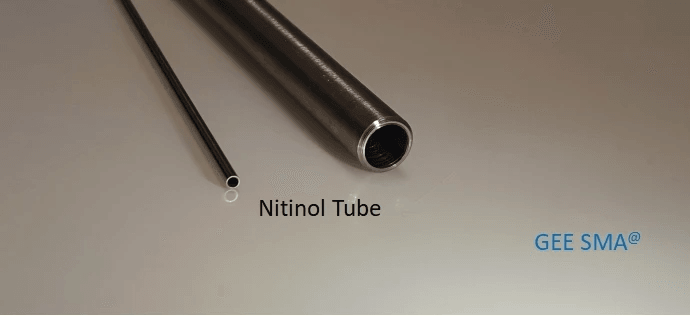

There are several types of shape memory alloys commonly used today, with Nickel-Titanium (NiTi) being one of the most widely recognized due to its excellent properties and adaptability. Other notable alloys include Copper-Aluminum-Nickel (Cu-Al-Ni) and Copper-Zinc-Aluminum (Cu-Zn-Al), each offering unique benefits depending on their specific composition and intended application.

Each type has distinct characteristics affecting factors like transformation temperatures, mechanical strength, and response time—making it crucial for designers to choose the right SMA based on their project's needs. As we explore further questions like “What are shape memory polymer-based actuators?” it's important to recognize how different materials can complement or enhance traditional metal SMAs in actuator technology.

What is a Shape Memory Alloy Actuator?

When we talk about cutting-edge technology, the shape memory alloy actuator often steals the spotlight. This fascinating device utilizes the unique properties of shape memory alloys (SMAs) to create motion and force in response to temperature changes. By understanding how these actuators work, we can appreciate their role in various applications across multiple industries.

Mechanism of Action

At its core, a shape memory alloy actuator operates on a remarkable principle: it can remember its original shape and return to it when heated above a certain temperature. This transformation occurs due to a phase change in the material, where the SMA shifts from a low-temperature phase (martensite) to a high-temperature phase (austenite). As this happens, the actuator generates movement—whether it's contracting or expanding—making it an invaluable tool for precise control in various mechanisms.

The beauty of this mechanism lies in its simplicity and efficiency. When cooled down, the actuator returns to its original form, ready for another cycle of action. This cyclical behavior not only enhances performance but also reduces energy consumption compared to traditional actuators that rely on constant power input.

Advantages Over Traditional Actuators

Shape memory alloy actuators come with several advantages that set them apart from conventional options like electric motors or pneumatic systems. First and foremost, they are compact and lightweight, making them ideal for applications where space is at a premium—think aerospace or intricate medical devices. Additionally, their ability to generate significant force relative to their size means designers can achieve more with less material.

Another key benefit is their silent operation; unlike many traditional actuators that produce noise during movement, SMAs operate quietly, which is essential in environments such as hospitals or residential areas. Moreover, they require minimal maintenance since there are fewer moving parts involved compared to mechanical systems that wear out over time.

Applications in Modern Technology

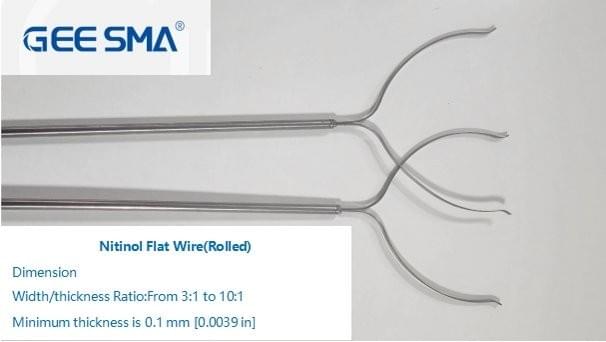

So where are SMAs used? The versatility of shape memory alloy actuators allows them to find homes in an array of modern technologies—from aerospace engineering innovations like morphing wings that adapt during flight to robotic grippers capable of delicate tasks without damaging fragile objects. In medicine, these actuators play critical roles in minimally invasive surgical tools and stents that expand within blood vessels.

Furthermore, automotive industries leverage shape memory alloys for smart seat adjustments and adaptive components that enhance passenger comfort and safety features. With ongoing research into what are shape memory polymer-based actuators as well as advancements in metal SMAs, we can expect even more innovative applications emerging across various sectors.

Where are SMAs Used?

Shape Memory Alloys (SMAs) have carved out a niche in various industries due to their unique properties and capabilities. From aerospace to medical devices, the versatility of these materials is nothing short of remarkable. Let’s dive into some key sectors where SMAs are making waves and transforming traditional practices.

Aerospace Applications

In the aerospace industry, shape memory alloy actuators are revolutionizing flight technology. These actuators can change shape in response to temperature variations, allowing for more efficient control surfaces on aircraft wings and stabilizers. By utilizing SMAs, engineers can create lighter and more compact systems that enhance performance while reducing fuel consumption.

Moreover, the reliability of shape memory alloys in extreme conditions makes them ideal for space missions. They can withstand harsh environments while providing precise actuation when needed most. As a result, aerospace companies are increasingly asking the question: what is a shape memory alloy actuator? The answer lies in their ability to perform under pressure—literally!

Medical Devices and Robotics

SMAs enable minimally invasive surgical tools that adapt to the body's internal environment, offering precision without extensive damage to surrounding tissues. This capability raises the bar for patient care and recovery times.

In robotics, what are shape memory polymer-based actuators? While metal SMAs dominate many applications, polymers offer flexibility and lightweight characteristics that suit various robotic functions perfectly. From soft robots mimicking biological movements to precise surgical robots using SMA technology for delicate tasks, these innovations showcase how far we've come in merging medicine with cutting-edge engineering.

Automotive Industry Innovations

The automotive industry has also embraced shape memory alloys with open arms—especially when it comes to safety features and comfort enhancements. Shape memory alloy actuators play a crucial role in seat adjustments or adaptive mirrors that respond automatically based on driver preferences or environmental conditions. This innovation not only elevates user experience but also contributes significantly to vehicle safety.

Furthermore, manufacturers are exploring how what is a shape memory alloy actuator can improve energy efficiency by reducing weight without compromising functionality or durability in vehicles. With ongoing advancements in SMA technology and applications like self-repairing materials or active suspension systems on the horizon, it's clear that automotive innovations will continue to drive forward with SMAs at their core.

What are Shape Memory Polymer-Based Actuators?

Shape memory polymer-based actuators (SMPAs) represent a fascinating evolution in the realm of smart materials, especially when compared to traditional metal shape memory alloys (SMAs). These innovative materials exhibit the ability to return to a predetermined shape when exposed to specific stimuli, such as heat or light. Unlike their metal counterparts, SMPAs offer unique advantages that make them increasingly attractive for various applications.

Differences from Metal SMAs

When discussing what is a shape memory alloy actuator, it’s essential to highlight the fundamental differences between metal SMAs and their polymer counterparts. Metal SMAs typically possess higher strength and stiffness but can be limited by weight and thermal conductivity issues. In contrast, shape memory polymer-based actuators are lightweight and can be engineered for flexibility, allowing for more diverse applications where weight savings are critical.

Moreover, while metal SMAs often require high temperatures to activate their shape-memory effect, SMPAs can operate effectively at lower temperatures. This characteristic opens doors for integration into sensitive environments where overheating could cause damage or failure. Additionally, SMPAs can be tailored more easily in terms of processing methods and material properties compared to traditional metallic options.

Benefits of Polymer Actuators

What makes shape memory polymer-based actuators particularly appealing? First off, they boast excellent energy efficiency due to their lower activation energy requirements compared to metal SMAs. This means that they consume less power during operation—a crucial factor in applications like wearable technology or portable devices where battery life is paramount.

Another significant benefit lies in their versatility; SMPAs can be molded into intricate shapes during manufacturing processes like 3D printing or injection molding. This capability allows engineers greater freedom when designing components that need precise movement or actuation without compromising on performance. Furthermore, these polymers often exhibit better resistance to environmental factors such as moisture and chemical exposure than metals.

Real-World Applications in Engineering

The question where are SMAs used? naturally extends into the realm of polymers as well—shape memory polymer-based actuators have found their niche across various industries with remarkable success stories. In robotics, for example, SMPA technology enables soft robotics that mimic biological movements while maintaining lightweight structures essential for agile designs.

In the medical field, these actuators play a pivotal role in developing minimally invasive surgical tools that adapt dynamically within the human body—think of stents that change shape upon reaching body temperature! Moreover, automotive manufacturers have started exploring how SMPA systems can enhance vehicle comfort features such as adjustable seating or active suspension systems by responding automatically to driver preferences.

GEE SMA: Leading the Way

In the world of miniature actuation, GEE SMA stands out as a beacon of innovation. This company has harnessed the unique properties of shape memory alloys to create cutting-edge solutions that push the boundaries of what is possible in various industries. With a focus on performance and reliability, GEE SMA is setting new standards for shape memory alloy actuators.

Overview of GEE SMA’s Innovations

GEE SMA has pioneered a range of advancements in shape memory alloy technology, particularly in actuator design. Their innovative approach combines traditional engineering with modern materials science to create highly efficient and responsive shape memory alloy actuators. By optimizing the properties of these materials, GEE SMA has developed actuators that are not only lightweight but also capable of significant force generation, making them ideal for diverse applications.

The company's commitment to research and development ensures that they stay ahead in the rapidly evolving field of actuator technology. For instance, their work on integrating smart sensors with shape memory alloys allows for real-time feedback and control, enhancing the functionality of their products. This level of innovation positions GEE SMA as a leader in shaping the future landscape of miniature actuation technology.

Impact on Space Missions

One area where GEE SMA's innovations shine brightly is in space missions, where every gram counts and reliability is paramount. Shape memory alloy actuators developed by GEE SMA have been successfully utilized in satellite deployment systems and robotic arms used for extraterrestrial exploration. These actuators provide precise movement and control, essential for tasks ranging from adjusting solar panels to manipulating scientific instruments.

The ability to function effectively under extreme conditions makes these shape memory alloy actuators indispensable for space applications. They can withstand temperature fluctuations and radiation exposure while maintaining performance integrity—qualities that are crucial when operating beyond Earth’s atmosphere. As space exploration continues to expand its horizons, GEE SMA's contributions will play a vital role in ensuring mission success.

Future Prospects in Actuator Technology

Looking ahead, the potential for growth and development within actuator technology is immense, especially with advancements like those from GEE SMA leading the charge. The integration of artificial intelligence with shape memory alloy actuators could pave the way for even smarter systems capable of autonomous decision-making based on real-time data analysis. Such innovations could revolutionize industries ranging from aerospace to medical devices by enhancing efficiency and precision.

Moreover, as we explore alternatives such as shape memory polymer-based actuators alongside metal SMAs, we open up new avenues for lightweight designs that do not compromise strength or durability. The future holds exciting possibilities where hybrid systems combining both types may emerge—offering unparalleled versatility across various sectors including robotics and automotive technologies. With companies like GEE SMA at the forefront, we can expect groundbreaking developments that redefine what's achievable with miniature actuation solutions.

Conclusion

As we wrap up our exploration of shape memory alloys (SMAs) and their fascinating applications, it's clear that the future of miniature actuators is bright and full of potential. The ability to harness the unique properties of SMAs opens doors to innovative solutions across various industries, from aerospace to healthcare. With advancements in technology and materials science, we can expect even more sophisticated applications for shape memory alloy actuators in the years to come.

The Future of Miniature Actuators

The future landscape for miniature actuators is likely to be dominated by developments in shape memory alloy technology. These remarkable materials promise not only enhanced performance but also miniaturization, which is crucial for modern engineering challenges. As we delve deeper into understanding what a shape memory alloy actuator can achieve, we anticipate a surge in creative designs that leverage their unique capabilities.

Imagine robots that can adapt their forms or medical devices that respond dynamically to patient needs—this is just the tip of the iceberg when considering where are SMAs used today and where they could go next. With ongoing research into new types of shape memory alloys and polymers, engineers are poised to create even more versatile systems. The integration of smart technologies with these advanced materials will likely redefine how we think about actuation in everything from consumer electronics to space exploration.

Key Takeaways on SMAs

To recap our journey through the world of SMAs, it’s essential to highlight a few key takeaways about what a shape memory alloy is and its significance in modern technology. First off, these materials possess an incredible ability to return to a predetermined shape when subjected to specific stimuli like heat or stress—making them ideal candidates for actuators that require precise movement or force application. Additionally, understanding what is a shape memory alloy actuator helps us appreciate not just their mechanics but also their myriad applications across different sectors.

Moreover, one cannot overlook how versatile these alloys can be; from aerospace innovations where weight savings are critical to medical devices requiring intricate movements—where are SMAs used? The answer spans many fields! Lastly, with emerging technologies such as shape memory polymer-based actuators gaining traction, it's evident that this area will continue evolving with exciting possibilities ahead.

Importance of GEE SMA in Advancements

When discussing advancements in actuator technology, GEE SMA stands out as a pioneer leading this charge forward with innovative solutions tailored for diverse applications. Their commitment not only drives research into new types of shape memory alloys but also emphasizes real-world usability and efficiency—an essential factor when considering what are shape memory polymer-based actuators versus traditional metal options. By focusing on practical implementations while pushing boundaries within the field, GEE SMA plays a crucial role in shaping future technologies.

In conclusion, as we look towards an era filled with potential breakthroughs driven by miniature actuation systems utilizing SMAs, it’s clear that companies like GEE SMA will be at the forefront—transforming ideas into reality while enhancing functionality across numerous industries. The importance they hold cannot be overstated; they’re paving pathways toward smarter solutions tailored for tomorrow's challenges!