Introduction

In the realm of modern engineering, the SMA actuator stands out as a remarkable innovation that utilizes shape memory alloys to convert thermal energy into mechanical motion. This unique actuator leverages the fascinating properties of materials that can remember their original shape after being deformed. By harnessing this phenomenon, SMA actuators provide a compact and efficient means of actuation across various applications.

What is the SMA Actuator

An SMA actuator is a device that employs shape memory alloys to produce motion in response to changes in temperature. These alloys, often in the form of wires or springs, undergo phase transformations that allow them to return to their pre-defined shapes when heated. The simplicity and effectiveness of the SMA actuator working principle make it an attractive choice for engineers seeking reliable actuation solutions.

Importance of SMA Actuators

The importance of SMA actuators cannot be overstated; they offer lightweight and compact designs that are essential for applications where space and weight are critical factors. Their energy efficiency allows for precise control while consuming minimal power, making them ideal for battery-operated devices and systems requiring low energy consumption. Furthermore, their versatility enables integration into various sectors, from robotics to medical devices, showcasing their broad utility.

Overview of GEE SMA

GEE SMA has emerged as a leader among SMA actuator manufacturers, recognized for its commitment to quality and innovation in shape memory alloy technology. With a focus on advancing design capabilities and enhancing performance metrics, GEE SMA continues to push the boundaries of what is possible with shape memory alloy wire actuators. Their products not only meet industry standards but also set new benchmarks for reliability and efficiency in actuator applications.

Understanding the SMA Actuator

Shape Memory Alloy (SMA) actuators are fascinating devices that utilize unique materials capable of remembering their original shapes after deformation. These actuators are composed primarily of shape memory alloys, which undergo a phase transformation in response to temperature changes, allowing them to expand or contract significantly. This remarkable property makes SMA actuators ideal for various applications, from robotics to medical devices.

Definition and Components

An SMA actuator is a device that converts thermal energy into mechanical motion through the properties of shape memory alloys. The primary components include the shape memory alloy wire actuator, a heat source for activation, and often a structure to amplify the movement generated by the alloy’s transformation. When heated above a certain temperature—known as the transition temperature—the SMA wire contracts, producing linear or rotational movement depending on its design.

SMA Actuator Working Principle

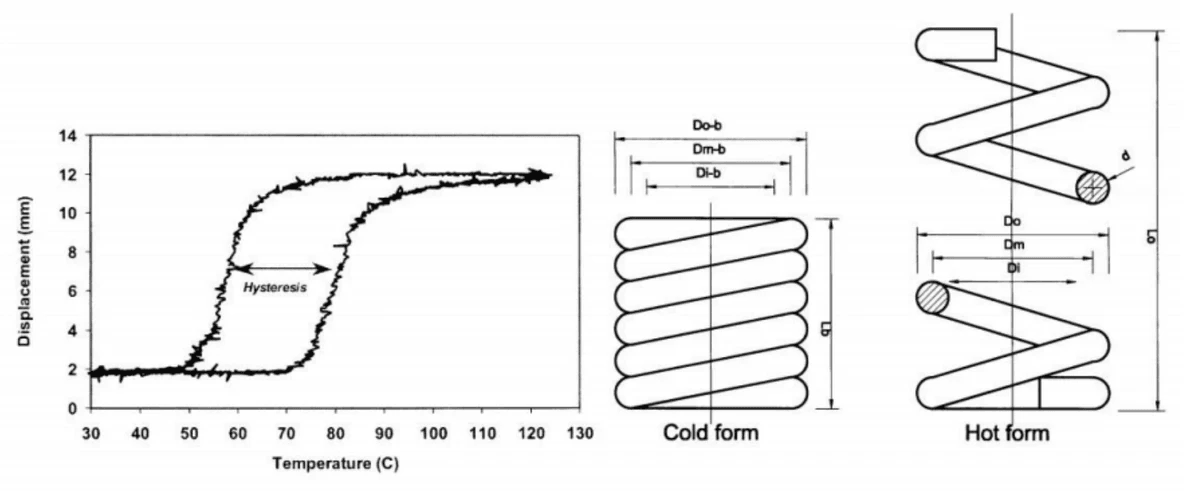

The working principle of an SMA actuator hinges on its ability to undergo reversible phase changes between two distinct forms: martensite and austenite. In its martensitic state at lower temperatures, the material is pliable and can be deformed easily; however, when heated to its austenitic state, it returns to its pre-set shape with significant force. This unique behavior is what allows manufacturers to design compact and efficient systems that can perform precise movements while consuming minimal energy.

SMA Actuator Diagram

To truly grasp how an SMA actuator functions, visual aids like diagrams can be incredibly helpful. An effective diagram typically illustrates the key components—such as the shape memory alloy wire actuator itself—alongside annotations explaining each part's role in the overall mechanism. By integrating these elements visually, one can better understand how various forces interact within an SMA actuator system during operation.

Key Benefits of SMA Actuators

Shape Memory Alloy (SMA) actuators are transforming various industries with their unique properties and capabilities. Understanding the key benefits of these devices is essential for grasping their impact on technology and applications. This section highlights the lightweight and compact design, energy efficiency, and versatility that make SMA actuators a popular choice among manufacturers.

Lightweight and Compact Design

One of the standout features of SMA actuators is their lightweight and compact design, which sets them apart from traditional actuators. The use of shape memory alloys allows for a significant reduction in weight without sacrificing performance, making them ideal for applications where space is at a premium. This lightweight nature not only enhances portability but also contributes to overall system efficiency, especially in fields like robotics and aerospace.

The compact size of SMA actuators means they can be integrated into smaller devices without compromising functionality. For instance, when looking at an SMA actuator diagram, you’ll notice how these components can fit seamlessly into intricate systems that require precision movement in limited spaces. As more manufacturers recognize the advantages of this design, we can expect to see an increase in innovative applications utilizing SMA technology.

Energy Efficiency and Control

Energy efficiency is another critical advantage offered by SMA actuators. Unlike conventional motors that may draw excessive power during operation, shape memory alloy wire actuators consume energy only when transitioning between states—essentially using power on demand. This feature not only reduces energy costs but also extends the operational lifespan of devices employing these actuators.

Moreover, the control mechanisms associated with SMA actuators allow for precise movement and positioning based on temperature changes or electrical signals. The simplicity of the SMA actuator working principle ensures that users can easily manage performance without complex control systems or heavy-duty electronics involved. As industries increasingly seek sustainable solutions, the energy-efficient nature of these devices positions them as a frontrunner in actuator technology.

Versatility in Applications

The versatility of shape memory alloy actuator applications cannot be overstated; they are found across diverse sectors from robotics to medical devices to aerospace innovations like those from GEE SMA. Their ability to adapt to various environments makes them suitable for tasks ranging from delicate surgical procedures to robust robotic movements in factories or space exploration missions.

Moreover, because different configurations exist—such as linear or rotary motion—manufacturers have flexibility when designing products that incorporate SMA technology tailored to specific needs or challenges faced within their industry sectors. The ongoing development within this field promises even broader applications as more companies explore what shape memory alloys can achieve beyond current limitations.

Shape Memory Alloy Actuator Applications

Shape Memory Alloy (SMA) actuators are revolutionizing various industries with their unique properties and capabilities. From robotics to healthcare and aerospace, the versatility of SMA actuators is undeniable. Understanding the applications of these ingenious devices can illuminate their significance in modern technology.

Robotics and Automation

In the realm of robotics and automation, SMA actuators are becoming indispensable due to their lightweight and compact design. The SMA actuator working principle allows for precise movements, enabling robotic systems to perform intricate tasks with ease. Whether it's in robotic arms or autonomous vehicles, the shape memory alloy wire actuator provides a level of control that traditional motors struggle to match.

Moreover, the ability of SMA actuators to return to a predetermined shape when heated makes them ideal for applications requiring repeatability and reliability. This ensures that robots can operate efficiently in dynamic environments without compromising performance. As manufacturers continue to innovate, we can expect even more sophisticated uses for SMA actuators in robotics.

Medical Devices and Healthcare

The medical field is witnessing a surge in the application of shape memory alloy actuators, driven by their biocompatibility and precision movement capabilities. From minimally invasive surgical tools to advanced prosthetics, SMA actuators enhance functionality while reducing overall weight—an essential factor in medical device design. The unique characteristics of the shape memory alloy wire actuator allow for devices that adapt seamlessly to patient needs.

Additionally, SMA actuators are employed in drug delivery systems where controlled release mechanisms are vital for treatment efficacy. Their energy efficiency means they can operate longer without frequent battery changes or maintenance, which is crucial in healthcare settings where reliability is paramount. With leading SMA actuator manufacturers focusing on healthcare innovations, we can anticipate even broader applications emerging soon.

Aerospace Innovations with GEE SMA

Aerospace technology continues to benefit significantly from advancements made possible by shape memory alloy actuators like those developed by GEE SMA. The lightweight nature combined with high strength makes these actuators perfect for aircraft components that require precise movement without adding excessive weight—critical for fuel efficiency and performance optimization. The innovative designs derived from the sma actuator diagram facilitate mechanisms such as wing morphing or adaptive control surfaces.

Furthermore, GEE SMA has been at the forefront of integrating smart materials into aerospace engineering solutions that enhance safety features during flight operations. Their ability to function reliably under extreme conditions showcases just how adaptable shape memory alloy technology can be within this demanding industry sector. As aerospace challenges evolve, so too will the role of SMA actuators in pushing boundaries further than ever before.

Leading SMA Actuator Manufacturers

When it comes to the realm of SMA actuators, a few key players stand out in the industry. These manufacturers have honed their craft, developing cutting-edge technologies that push the boundaries of what shape memory alloys can achieve. As we delve into GEE SMA and its competitors, it becomes clear that innovation and quality are paramount in this field.

Insight into GEE SMA

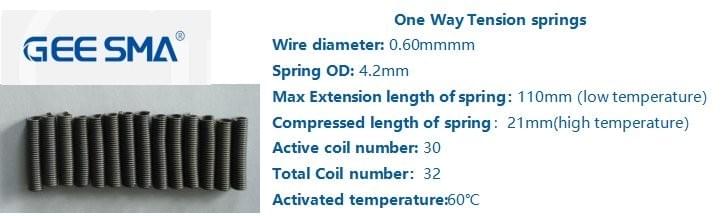

GEE SMA has made a name for itself as a leading manufacturer of shape memory alloy actuators, known for their exceptional performance and reliability. Their products leverage advanced materials and engineering techniques to create efficient SMA actuators that cater to various applications. With a strong focus on research and development, GEE SMA continues to innovate, ensuring that their shape memory alloy wire actuators remain at the forefront of technology.

GEE SMA's commitment to quality is evident in every aspect of their production process. They utilize state-of-the-art technology to produce intricate designs outlined in detailed sma actuator diagrams, which illustrate the sophisticated mechanisms behind their products. This attention to detail not only enhances performance but also guarantees long-lasting durability across diverse applications.

Comparing Market Leaders

In addition to GEE SMA, several other manufacturers have carved out significant niches in the market for sma actuators. Companies like Actuonix Motion Devices and Smart Material Solutions offer competitive alternatives with unique features tailored for specific industries such as robotics or medical devices. By comparing these market leaders, potential buyers can better understand how each brand's approach aligns with their specific needs.

Each manufacturer brings its own interpretation of the sma actuator working principle into play, influencing factors like efficiency and response time. For instance, while some companies focus on miniaturization for compact designs suitable for tight spaces, others prioritize high force output for heavy-duty applications. This diversity allows customers to select from an array of shape memory alloy actuator applications based on their requirements.

Quality and Reliability in Production

Quality assurance is critical when evaluating sma actuator manufacturers since even minor defects can lead to significant operational failures down the line. Leading companies implement rigorous testing protocols throughout the manufacturing process—ensuring each shape memory alloy wire actuator meets stringent standards before reaching consumers’ hands. Such practices foster trust among clients who rely on these components for critical systems across various sectors.

Reliability extends beyond just testing; it encompasses consistent performance over time under varying conditions as well as ease of integration within existing systems. Manufacturers that prioritize these factors not only enhance customer satisfaction but also contribute positively towards advancing overall industry standards for sma actuators globally. As competition heats up among these innovators, we can expect continuous improvements that will benefit users across all application areas.

Future of Shape Memory Alloy Technology

The future of Shape Memory Alloy (SMA) technology is brimming with potential, particularly in the realm of SMA actuators. As industries seek more efficient and adaptable solutions, the development of SMA actuators continues to evolve. Innovations in materials science and engineering are paving the way for enhanced functionalities and applications that were once thought impossible.

Emerging Trends in Actuator Development

One significant trend in actuator development is the integration of smart technologies into SMA actuators. These advancements enable real-time monitoring and control, making it easier to optimize performance based on specific operational conditions. Furthermore, as sustainability becomes a priority across sectors, manufacturers are focusing on creating eco-friendly SMA actuators that minimize energy consumption while maximizing output efficiency.

Another emerging trend is miniaturization, where SMA actuators are designed to be smaller yet more powerful. This compactness opens up new possibilities for applications in tight spaces, such as inside medical devices or robotic systems. Additionally, researchers are exploring hybrid systems that combine shape memory alloys with other materials to enhance functionality and broaden application scopes.

Innovations in SMA Actuator Designs

Innovative designs are revolutionizing how we understand the SMA actuator working principle. For instance, recent breakthroughs have led to the creation of multi-functional SMA wire actuators that can perform various tasks without needing complex mechanisms or additional components. This versatility not only simplifies design but also reduces overall system costs—an attractive proposition for manufacturers and end-users alike.

Moreover, advancements in 3D printing technology allow for custom-designed SMA actuators tailored to specific applications or constraints. This capability means that engineers can create unique shapes and configurations that traditional manufacturing methods might struggle with—enhancing performance across diverse fields like robotics and aerospace innovations. The flexibility in design paves the way for innovative solutions previously constrained by conventional actuator designs.

The Role of GEE SMA in Advancing Technology

GEE SMA stands at the forefront of these advancements by pushing boundaries within the industry through research and development initiatives focused on cutting-edge technologies related to shape memory alloys. Their commitment to quality ensures that their products meet rigorous standards while embracing new trends like smart integration and miniaturization effectively. As one of the leading sma actuator manufacturers, GEE SMA plays a crucial role in shaping future applications ranging from healthcare devices to advanced robotics.

Additionally, GEE’s focus on collaboration with academic institutions fosters an environment ripe for innovation within shape memory alloy actuator applications—ensuring they remain competitive as technology evolves rapidly around them. By investing heavily into R&D efforts aimed at improving both design efficiency and operational capabilities, GEE is not just keeping pace but actively driving forward advancements within this exciting field of technology.

Conclusion

In wrapping up our exploration of SMA actuators, it’s clear that these innovative devices hold significant potential across various fields. The shape memory alloy actuator, with its unique ability to return to a predetermined shape when heated, showcases remarkable versatility and efficiency. Understanding the SMA actuator working principle not only highlights its importance but also opens doors to numerous applications that can transform industries.

Recap of SMA Actuator Significance

SMA actuators are lightweight, compact devices that offer substantial advantages over traditional actuation methods. Their unique design allows for energy-efficient operation while maintaining high levels of control and precision in movement. As we’ve seen throughout this discussion, the shape memory alloy actuator is not just a novelty; it's an essential component in many cutting-edge technologies today.

The Impact of GEE SMA on Industries

GEE SMA stands out among sma actuator manufacturers, pushing the boundaries of what is possible within this technology realm. By focusing on quality and innovation, GEE SMA has significantly influenced sectors such as robotics and healthcare, enhancing device performance and reliability. The diverse shape memory alloy actuator applications enabled by GEE SMA have led to breakthroughs that improve efficiency and functionality across various industries.

Looking Ahead: The Future of SMA Technology

The future looks bright for shape memory alloy technology as ongoing research continues to unveil new possibilities in actuator designs. Emerging trends indicate a growing interest in integrating smart features into sma actuators, enhancing their adaptability and responsiveness in real-time applications. With leaders like GEE SMA at the forefront, we can expect exciting advancements that will further revolutionize how we think about motion control and automation.