Introduction

In the realm of modern engineering and technology, shape memory actuators stand out as a fascinating innovation that captures the imagination. These remarkable devices, made from shape memory alloys (SMAs), possess the unique ability to return to a predetermined shape when exposed to specific stimuli, such as temperature changes. This magical transformation opens up a world of possibilities for various industries, making shape memory actuator applications increasingly vital in our everyday lives.

Exploring the Magic of Shape Memory Actuators

The allure of shape memory actuators lies in their extraordinary functionality and versatility. By harnessing the properties of shape memory materials, these actuators can perform complex movements with minimal energy input. Imagine medical devices that adapt seamlessly to body contours or robotic systems that mimic natural motion—this is just a glimpse into what SMAs can achieve.

Unveiling the Science Behind Shape Memory Alloys

At the heart of every shape memory actuator is a fascinating science rooted in material properties and phase transformations. Shape memory alloys are metallic compounds that exhibit two distinct phases: a high-temperature phase where they maintain one form and a low-temperature phase where they can be deformed easily. This unique behavior is what allows SMA actuator working principles to create motion through thermal activation, revealing an intricate dance between physics and engineering.

Practical Applications of Shape Memory Technology

The practical applications of shape memory alloy products extend far beyond mere novelty; they have become essential tools in various fields including medicine, robotics, and aerospace engineering. In medical settings, SMAs enable minimally invasive surgical tools that adapt to patient anatomy while reducing trauma during procedures. Meanwhile, in robotics and automation, these actuators facilitate precision movements that enhance efficiency and functionality across numerous tasks—proving that the future truly belongs to those who embrace this innovative technology.

Understanding Shape Memory Alloys

Shape Memory Alloys (SMAs) are fascinating materials that can remember their original shape and return to it when subjected to specific conditions, typically temperature changes. These unique properties make them invaluable in various applications, particularly in the realm of shape memory actuator technology. By harnessing the capabilities of these materials, engineers and scientists can create innovative solutions across multiple industries.

Definition and Characteristics of SMA

At its core, a Shape Memory Alloy is a metallic material that exhibits two distinct phases: a high-temperature phase where the material is more disordered and a low-temperature phase where it becomes more ordered. The most commonly used SMAs include nickel-titanium (Nitinol), which is renowned for its remarkable flexibility and strength. One defining characteristic of SMAs is their ability to undergo significant deformation while still returning to their pre-deformed shape when heated—this is the crux of how Shape memory actuator technology operates.

The Science Behind Shape Memory Materials

The science behind shape memory materials hinges on the unique atomic structure that allows for phase transformations triggered by temperature changes. When an SMA is deformed at lower temperatures, it enters a martensitic phase; upon heating, it transforms back to its original austenitic phase, resulting in recovery of its initial shape. This transformation process underlies the SMA actuator working principle, enabling precise movements and functions in various applications—from medical devices to robotics.

Key Advantages of Using SMAs

One significant advantage of using Shape Memory Alloys lies in their ability to generate large amounts of force from relatively small actuators—making them ideal for compact designs where space is at a premium. Additionally, SMAs are lightweight yet strong, providing efficiency without adding unnecessary bulk—a crucial factor in aerospace innovations with shape memory products. Moreover, their responsiveness to temperature changes allows for seamless integration into systems requiring automatic adjustments based on environmental conditions or operational needs.

How Shape Memory Actuators Work

Shape memory actuators are fascinating devices that leverage the unique properties of shape memory alloys (SMAs) to perform mechanical work in response to environmental stimuli, primarily temperature changes. Understanding the SMA actuator working principle is essential to appreciate their innovative applications across various fields. By harnessing the unique behavior of shape memory materials, these actuators can transform energy into motion with remarkable efficiency.

SMA Actuator Working Principle Explained

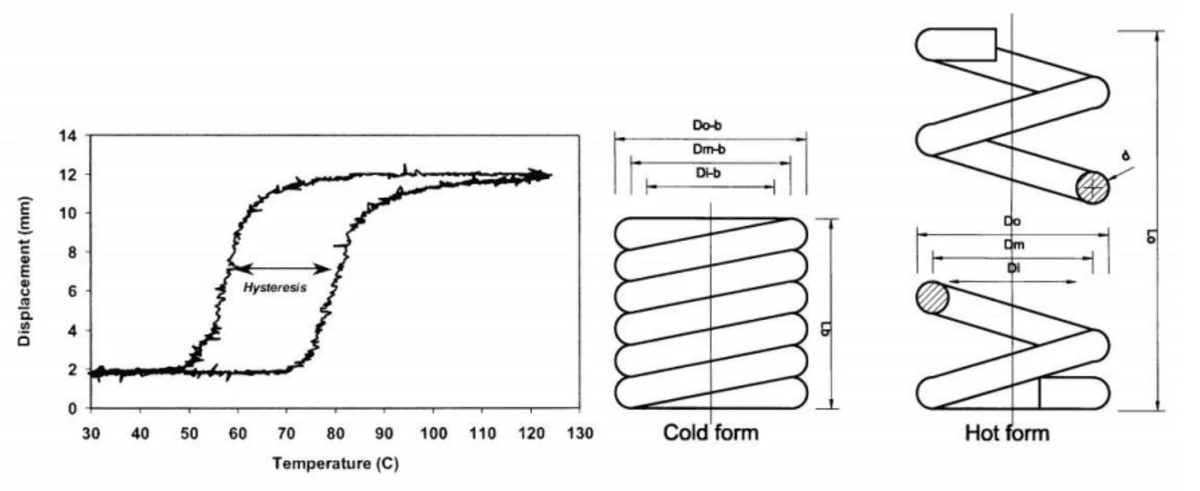

At the heart of every shape memory actuator lies the remarkable ability of shape memory alloys to remember their original shapes. When an SMA is deformed at a lower temperature and subsequently heated above a specific transition temperature, it returns to its pre-deformed shape, thereby generating motion. This transformation is due to a phase change in the material's crystalline structure, which allows for significant mechanical movement without requiring complex machinery.

The simplicity of the SMA actuator working principle makes it an attractive choice for various applications, from medical devices to robotics. As these materials undergo phase transitions—specifically from martensite to austenite—they exhibit impressive force generation capabilities. This inherent efficiency and reliability make shape memory alloy products particularly appealing for industries seeking innovative solutions.

Activation Mechanisms of SMAs

Activation mechanisms play a crucial role in how shape memory actuators function effectively in real-world applications. The most common activation method involves heating the SMA through electrical resistance or external heat sources, which triggers its transformation from a low-energy state (martensite) back to its high-energy state (austenite). Additionally, some SMAs can be activated using other stimuli such as magnetic fields or even stress-induced transformations, further broadening their usability.

This versatility allows shape memory alloy actuator applications to span multiple sectors including aerospace and biomedical engineering—where precise control over movement is paramount. For instance, in minimally invasive surgical tools, SMAs can be activated remotely with heat or electricity, allowing for delicate maneuvers inside the human body without large incisions. Such innovations underscore how understanding activation mechanisms enhances our ability to deploy these materials effectively.

Response to Temperature Changes

One of the most intriguing features of shape memory actuators is their response to temperature changes—a characteristic that sets them apart from traditional actuation methods. When exposed to heat beyond their transition threshold, SMAs undergo rapid structural transformations that lead directly to physical movement; this response can be finely tuned based on material composition and processing techniques.

Conversely, when cooled below this threshold, they revert back into their deformed state until reactivated again by heat—a cycle that can repeat many times with minimal degradation over time. This reliable response makes shape memory materials invaluable in environments where precise thermal control is possible and desirable; think robotic grippers that adapt seamlessly based on ambient conditions or aerospace components adjusting dynamically during flight operations.

Real-World Applications of SMAs

Shape memory alloys (SMAs) are not just a fascinating scientific curiosity; they have real-world applications that are transforming various industries. From medicine to robotics and aerospace, the versatility of shape memory materials is making waves. Let's dive into some of the most innovative uses of shape memory actuators.

Shape Memory Alloy Actuator Applications in Medicine

In the medical field, shape memory alloy actuator applications are nothing short of revolutionary. One prominent example is in stents, where SMAs can expand and contract at body temperature, providing optimal support for blood vessels while minimizing invasiveness. Additionally, SMA-based surgical tools can adapt their shapes during procedures, enhancing precision and reducing recovery times for patients.

Beyond stents, shape memory materials are also used in orthopedic implants that respond to body heat to achieve desired configurations. This adaptability allows for tailored treatments that conform to individual patient needs over time. As research continues, the potential for SMAs in drug delivery systems and minimally invasive surgeries looks promising.

Utilizing SMAs in Robotics and Automation

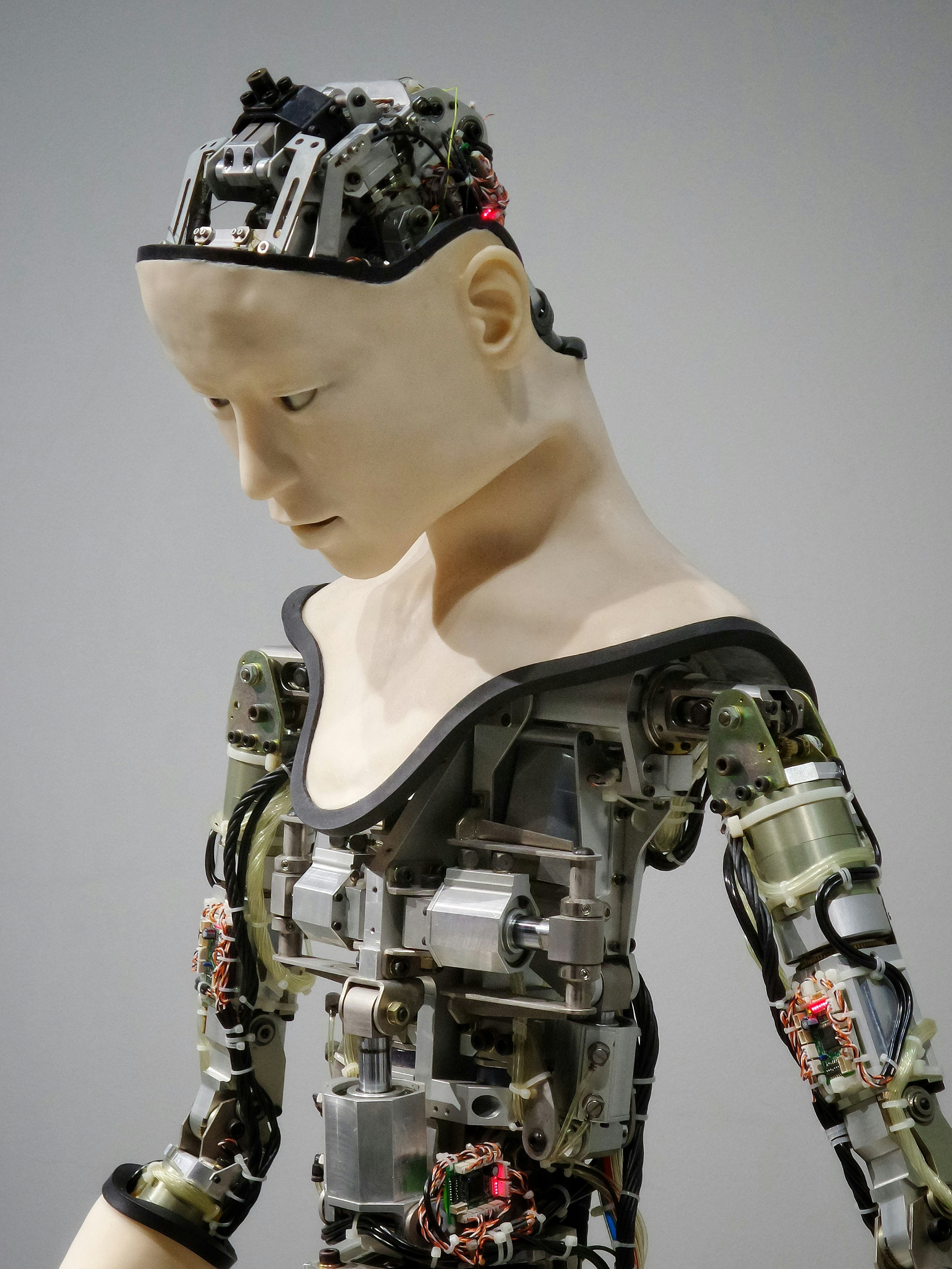

Robotics is another field where utilizing SMAs has sparked innovation and creativity. The unique properties of shape memory materials allow robots to perform complex tasks with remarkable efficiency and flexibility. For instance, SMA actuators can be employed in robotic grippers that change shape based on object size or weight—think about a robot hand that can grasp both delicate flowers and heavy tools with ease!

Moreover, SMA actuator working principles enable soft robotics to mimic natural movements found in animals or humans. This capability enhances their ability to navigate unpredictable environments while maintaining safety around humans—perfect for collaborative robots (cobots). As automation continues to evolve, the integration of SMAs will likely lead to even more sophisticated robotic systems.

Aerospace Innovations with Shape Memory Products

Aerospace innovations featuring shape memory products illustrate yet another exciting frontier for these remarkable materials. In this high-stakes industry, reliability and performance are paramount; hence the use of SMAs has gained traction due to their lightweight yet robust characteristics. For example, SMA actuators can be employed in deployable structures such as antennas or solar panels on spacecraft—these components can change shapes seamlessly during flight based on temperature variations.

Additionally, researchers are exploring how shape memory alloy products might enhance aircraft design by allowing wings or control surfaces to morph dynamically during flight conditions for improved aerodynamics. This adaptability could lead not only to fuel savings but also enhanced safety features by optimizing performance under varying circumstances. With ongoing advancements in material science and engineering techniques involving SMAs, we may soon witness a new era of aerospace technology driven by these extraordinary materials.

GEE SMA: A Leader in Shape Memory Technology

In the realm of shape memory technology, GEE SMA stands out as a pioneer, particularly known for its innovative use of Nitinol alloys. These unique materials exhibit remarkable properties that allow them to return to a predefined shape when subjected to specific temperature changes. By harnessing the potential of these shape memory materials, GEE SMA has carved out a significant niche in various high-tech industries.

Overview of GEE SMA’s Nitinol Alloys

GEE SMA specializes in advanced Nitinol alloys that are essential for developing cutting-edge shape memory actuators. These alloys are composed primarily of nickel and titanium, which provide exceptional mechanical properties and biocompatibility, making them ideal for a variety of applications. The unique characteristics of Nitinol enable it to undergo phase transformations, allowing it to serve effectively in diverse environments and applications.

The versatility of GEE SMA's Nitinol alloys is evident in their ability to be customized for specific requirements across industries. From medical devices requiring precise actuation to aerospace components facing extreme conditions, these shape memory alloy products deliver reliability and efficiency. As demand grows for innovative solutions that leverage the SMA actuator working principle, GEE SMA continues to lead the charge with its high-quality offerings.

Applications in Chang’e-5 and Chang’e-6 Missions

GEE SMA's contributions were prominently showcased during China's Chang’e-5 and Chang’e-6 lunar missions, where their shape memory alloy actuator applications played a crucial role. In these missions, SMAs were utilized for mechanisms that required precise movement and reliable performance under harsh extraterrestrial conditions. The ability of these actuators to respond dynamically ensured successful deployment and collection operations on the lunar surface.

The integration of shape memory materials into spacecraft design enhances not only functionality but also safety during critical mission phases. For instance, actuators powered by Nitinol can operate efficiently at varying temperatures encountered during space travel without compromising performance integrity. This reliability is vital when exploring uncharted territories like the Moon, where every component must perform flawlessly under challenging conditions.

The Role of GEE SMA in Harsh Environments

When it comes to operating in harsh environments—be it outer space or extreme industrial settings—GEE SMA’s shape memory products shine brightly due to their resilience and adaptability. These materials maintain their structural integrity even when exposed to temperature fluctuations or mechanical stressors that would typically challenge conventional materials. As such, they are increasingly being adopted across sectors where durability is paramount.

The superior performance characteristics of shape memory actuators make them ideal candidates for applications ranging from robotics in hostile terrains to medical devices operating within human bodies under varying conditions. By leveraging cutting-edge research and development practices focused on enhancing the capabilities of SMAs, GEE SMA ensures that its products remain at the forefront of technology advancements. In doing so, they not only meet current demands but also pave the way for future innovations within this fascinating field.

Future Trends in Shape Memory Actuator Development

The future of shape memory actuators is poised for exciting innovations that promise to enhance their functionality and broaden their applications. As researchers delve deeper into the properties of shape memory materials, we can expect breakthroughs that will lead to more efficient designs and increased performance capabilities. This evolution will not only refine existing Shape Memory Alloy actuator applications but also pave the way for entirely new uses across various industries.

Innovations on the Horizon for SMAs

Innovations in the field of shape memory alloys are quickly transforming how we perceive actuator technology. One promising area is the development of multi-functional SMAs that can respond to various stimuli beyond temperature, such as magnetic fields or electric currents, thereby expanding their versatility. Additionally, advancements in manufacturing techniques, including 3D printing of shape memory materials, are enabling the creation of complex geometries that were previously unimaginable, enhancing the design possibilities for shape memory actuator applications.

Potential New Markets for Shape Memory Products

The potential new markets for shape memory products are vast and varied, ranging from consumer electronics to automotive industries. For instance, as smart devices become increasingly prevalent, incorporating SMA technology could lead to more responsive and adaptive components in gadgets like smartphones or wearables. Moreover, with a growing emphasis on sustainability and energy efficiency, industries may leverage shape memory actuators in systems designed to optimize energy use or reduce waste — a trend that aligns perfectly with modern environmental goals.

The Role of Research and Development in SMA Technology

Research and development play a critical role in advancing SMA technology by pushing boundaries and exploring new frontiers within this fascinating field. Ongoing studies focus on enhancing material properties such as fatigue resistance and response time while simultaneously reducing costs associated with production — a key factor in making these technologies accessible to broader markets. As R&D continues to innovate within the realm of shape memory materials, we can anticipate a surge in both commercial viability and application diversity for shape memory actuators.

Conclusion

In wrapping up our exploration of shape memory actuators, it's clear that these remarkable devices are reshaping industries across the globe. From medicine to aerospace, the impact of shape memory alloy actuator applications is profound and far-reaching. As we continue to innovate and adapt, the potential for shape memory materials in various sectors seems limitless.

The Impact of Shape Memory Actuators on Industries

Shape memory actuators have revolutionized several industries by offering unique solutions that traditional technologies simply cannot match. In healthcare, for instance, SMA actuator working principles allow for minimally invasive procedures that enhance patient recovery times and reduce surgical risks. Meanwhile, in robotics and automation, these smart materials enable precise movements and adaptability in dynamic environments, showcasing their versatility across applications.

Advancements in Shape Memory Alloy Applications

Recent advancements in shape memory alloy products have opened new doors for innovation and efficiency across multiple fields. Researchers are continually refining SMA technology to enhance performance characteristics such as response time and energy efficiency. These improvements not only bolster existing applications but also pave the way for exciting new uses in emerging technologies like soft robotics or even self-repairing structures.

The Future of Shape Memory Materials in Technology

Looking ahead, the future of shape memory materials is bright with promise and potential breakthroughs on the horizon. As research and development efforts intensify, we can expect to see more sophisticated shape memory actuator designs that cater to increasingly complex needs across industries. With ongoing advancements, it’s likely that we'll witness a surge in novel applications that leverage the unique properties of SMAs—transforming how we interact with technology.