Introduction

In the world of advanced materials, shape memory actuators stand out for their unique ability to respond to changes in temperature and mechanical stress. These remarkable devices utilize shape memory alloys (SMAs), which can return to a predefined shape when heated after being deformed. Understanding the intricacies of these actuators is essential, as they are revolutionizing various industries with their innovative applications.

What are Shape Memory Actuators?

Shape memory actuators are devices that leverage the properties of shape memory alloys to create motion and force in response to thermal stimuli. When an SMA is heated above a certain temperature, it undergoes a phase transformation that allows it to revert back to its original configuration, making it an ideal choice for applications requiring precise movement. These actuators are increasingly popular among shape memory actuators manufacturers due to their efficiency and versatility.

The Science Behind Shape Memory Alloys

The science behind shape memory alloys is rooted in their unique crystalline structure, which allows them to remember their original shapes. When subjected to stress or deformation at lower temperatures, these materials can be reshaped; however, upon heating, they regain their initial form through a process known as martensitic transformation. This fascinating phenomenon not only underpins the functionality of shape memory actuators but also opens up new avenues for innovation across various sectors.

Applications in Various Industries

Shape memory alloys have found applications in diverse fields ranging from robotics and aerospace to construction and medical devices. In robotics, for instance, shape memory alloy wire actuators enable lightweight yet powerful movements that enhance performance without adding bulk. Similarly, in construction, the integration of shape memory alloys offers innovative solutions such as self-healing structures and enhanced earthquake resistance capabilities—demonstrating the vast potential of these materials across industries.

Understanding Shape Memory Actuators

Shape memory actuators are fascinating devices that utilize the unique properties of shape memory alloys (SMAs) to produce motion in response to changes in temperature. These materials can remember their original shape and return to it when heated, making them incredibly useful in various applications. By harnessing this remarkable behavior, manufacturers have developed innovative solutions across multiple industries.

Definition and Mechanism

At their core, shape memory actuators operate based on the principles of thermodynamics and material science. When a shape memory alloy is deformed at a lower temperature, it retains that new shape until it is heated above a specific transformation temperature. Upon heating, the material undergoes a phase change that allows it to revert to its pre-deformed configuration, providing mechanical movement or actuation.

This mechanism is not just about returning to a previous form; it's also about precision and reliability. Shape memory actuators can be engineered for specific applications by adjusting their alloy composition and processing methods. The result is an actuator that can perform tasks ranging from simple movements in robotics to complex functions in construction.

Types of Shape Memory Alloys

There are several types of shape memory alloys used in actuators, with two of the most common being Nickel-Titanium (NiTi) and Copper-Aluminum-Nickel (Cu-Al-Ni). NiTi alloys are renowned for their excellent biocompatibility and high fatigue resistance, making them popular choices for medical devices as well as robotics. On the other hand, Cu-Al-Ni alloys tend to be more cost-effective and exhibit higher transformation temperatures, which can be advantageous in certain industrial applications.

Each type comes with its own set of characteristics that make it suitable for different tasks within the realm of shape memory actuators. For instance, NiTi's unique properties allow for miniaturization without sacrificing performance—a key factor in modern robotic designs. Meanwhile, Cu-Al-Ni may find its niche more often within construction applications where larger structures require significant force output.

Key Properties and Characteristics

The effectiveness of shape memory actuators lies in several key properties intrinsic to shape memory alloys. One such property is superelasticity; when subjected to stress at certain temperatures, these materials can undergo large strains while still returning to their original configuration once the load is removed—an essential feature for dynamic applications like robotics or even adaptive building materials.

Another crucial characteristic is thermal stability; effective shape memory actuators must maintain reliable performance over varying temperatures without degrading over time or losing functionality. This stability ensures longevity in demanding environments such as those found within construction or aerospace industries where safety cannot be compromised.

In summary, understanding these properties helps both engineers and manufacturers optimize design choices when creating advanced systems using shape memory alloys—ultimately leading us toward smarter solutions across diverse fields including construction innovations through smart materials integration.

Shape Memory Alloy Wire Actuators

Shape memory alloy wire actuators are fascinating devices that leverage the unique properties of shape memory alloys to create movement and force. These actuators consist of wires made from materials that can remember their original shape, allowing them to return to it when heated or subjected to specific conditions. This remarkable behavior makes them invaluable in various applications, particularly in robotics, where precision and responsiveness are crucial.

How They Work

The magic behind shape memory alloy wire actuators lies in the phase transformation of the material they are made from, typically nickel-titanium (NiTi) alloys. When these wires are heated above a certain temperature, they transition from a martensitic state (deformed) to an austenitic state (original shape), generating significant force as they contract. This contraction can be harnessed to perform mechanical work, making shape memory alloy wire actuators ideal for applications where compactness and efficiency are paramount.

To control their operation, these actuators can be integrated with electronic systems that manage temperature changes through resistance heating or other methods. For instance, when a current passes through the wire actuator, it heats up rapidly and triggers the phase change necessary for movement. This ability to operate on demand makes them highly versatile components in modern robotics and automation systems.

Advantages of Wire Actuators

One of the standout advantages of shape memory alloy wire actuators is their lightweight nature compared to traditional motors or hydraulic systems. This weight-saving feature is crucial for applications like drones or robotic limbs where every gram counts toward overall efficiency and performance. Additionally, these actuators have no moving parts other than the wire itself, leading to reduced wear over time and increased reliability.

Another compelling benefit is their simplicity in design; fewer components mean easier integration into existing systems and lower manufacturing costs for companies involved with shape memory actuators manufacturers. Furthermore, their ability to function without complex control mechanisms allows for more straightforward designs while still achieving impressive results in terms of motion control and actuation speed.

Lastly, shape memory alloy wire actuators can operate effectively in extreme environments where traditional motors might fail due to temperature fluctuations or exposure to harsh conditions. Their resilience makes them suitable for various industrial applications beyond robotics—think medical devices or aerospace technology—where reliability is non-negotiable.

Common Uses in Robotics

In the realm of robotics, shape memory alloy wire actuators have carved out a niche thanks to their unique capabilities and advantages over conventional actuation methods. One prominent application is within soft robotics; these flexible robots utilize SMA wires for movement mimicking natural organisms' motions—think tentacles or grippers that adapt dynamically based on environmental feedback.

Moreover, robotic prosthetics increasingly integrate shape memory alloys due to their lightweight properties combined with strong actuation capabilities which enhance user mobility without adding unnecessary bulkiness. The adaptability offered by these materials allows designers at shape memory actuators manufacturers to create more functional devices tailored specifically for individual needs.

Finally, SMA wire actuators play a role in robotic exoskeletons designed for rehabilitation purposes; they provide smooth movements while being responsive enough not only during use but also during transitions between states such as standing up or sitting down again! As research continues into optimizing these materials further through innovative engineering approaches like hybrid integrations with traditional motors—the potential uses seem limitless!

Shape Memory Alloys in Construction

The integration of shape memory alloys in construction is revolutionizing how we approach building design and structural integrity. These materials, known for their unique ability to return to a predetermined shape when subjected to specific temperatures, offer innovative solutions that enhance both functionality and safety. With the growing demand for more resilient and adaptable structures, shape memory actuators are becoming indispensable tools for modern engineering.

Innovative Building Solutions

Shape memory alloys are paving the way for innovative building solutions that were previously unimaginable. By incorporating shape memory actuators into architectural designs, engineers can create structures that respond dynamically to environmental changes, such as temperature fluctuations or mechanical stress. This adaptability not only improves the longevity of buildings but also enhances energy efficiency by allowing structures to adjust their form according to external conditions.

Furthermore, these materials enable the development of self-healing mechanisms within construction elements, which can significantly reduce maintenance costs and prolong service life. For example, a shape memory alloy wire actuator embedded in concrete can automatically repair cracks when activated by heat, ensuring structural integrity over time. This ingenuity exemplifies how shape memory alloys in construction are transforming traditional methods into smarter and more sustainable practices.

Structural Health Monitoring Applications

In an age where safety is paramount, the role of shape memory actuators in structural health monitoring cannot be overstated. These advanced materials allow for real-time assessments of a building's condition by providing vital data on stress levels and potential failures before they escalate into serious issues. The integration of sensors with shape memory alloy technology enables continuous monitoring, offering peace of mind to engineers and occupants alike.

Moreover, using shape memory alloys enhances the accuracy of structural evaluations due to their responsive nature; they can indicate changes in a structure's performance immediately upon detection. This proactive approach not only helps prevent catastrophic failures but also facilitates timely maintenance interventions that can save lives and resources. As we continue exploring applications for these remarkable materials, it’s clear that shape memory actuators will play a crucial role in maintaining the safety of our built environment.

Enhancing Earthquake Resistance

One of the most critical applications of shape memory alloys in construction is enhancing earthquake resistance in structures located in seismically active regions. Buildings equipped with shape memory actuators can absorb and dissipate seismic energy more effectively than traditional materials, significantly reducing damage during an earthquake event. The ability of these alloys to revert to their original form after deformation ensures that buildings remain structurally sound even after experiencing intense shaking.

Incorporating shape memory alloy wire actuators into bracing systems or foundations allows engineers to design flexible yet robust frameworks capable of withstanding unpredictable forces from seismic activity. This innovation not only protects lives but also minimizes economic losses associated with earthquake damage—an essential consideration for urban planners worldwide facing increasing natural disaster risks. As research continues into optimizing these materials further, we anticipate even greater advancements in earthquake-resistant technologies driven by the unique properties of shape memory alloys.

Leading Shape Memory Actuators Manufacturers

The market for shape memory actuators has seen significant growth, driven by the increasing demand for innovative solutions across various industries. With numerous manufacturers vying for attention, understanding who stands out can help consumers make informed choices. This section will spotlight GEE SMA and explore other notable names in the industry, while also comparing product quality and innovation.

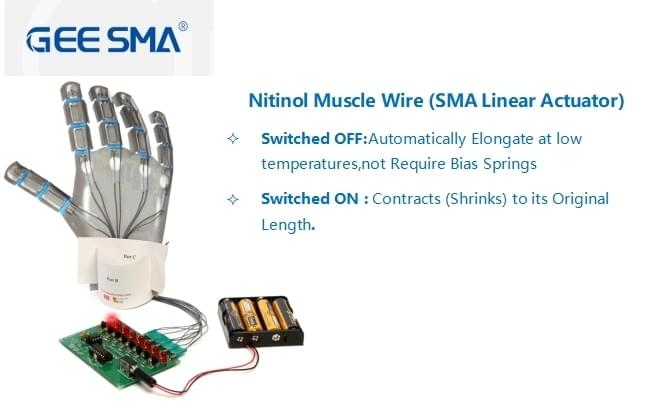

Spotlight on GEE SMA

GEE SMA has carved a niche as a leading manufacturer of shape memory actuators, renowned for its commitment to quality and innovation. Their extensive range of products includes advanced shape memory alloy wire actuators that cater to diverse applications from robotics to aerospace. GEE SMA’s focus on research and development ensures that they remain at the forefront of technology, pushing the boundaries of what shape memory alloys can achieve.

The company’s dedication to customer satisfaction is evident in their tailored solutions designed to meet specific industry needs. By leveraging cutting-edge technology, GEE SMA not only enhances performance but also contributes to the sustainability of projects using shape memory alloys in construction. Their reputation is built on reliability and efficiency, making them a preferred choice among engineers and designers alike.

Moreover, GEE SMA actively participates in industry conferences and collaborations aimed at advancing the field of smart materials. Their efforts in promoting awareness about the benefits of shape memory actuators are commendable, helping potential users understand how these materials can revolutionize their projects. As a pioneer in this sector, GEE SMA continues to set benchmarks for others to follow.

Other Notable Names in the Industry

While GEE SMA shines brightly in the landscape of shape memory actuator manufacturers, several other companies are also making waves with their innovative offerings. Companies like Nitinol Devices & Components specialize in producing high-quality shape memory alloys that are essential for various applications including medical devices and automotive components. These manufacturers have embraced advancements in material science to deliver reliable products that meet stringent industry standards.

Another noteworthy player is Fort Wayne Metals, known for its expertise in manufacturing nitinol wire used extensively in medical applications such as stents and guidewires. Their focus on quality control ensures that their shape memory alloy products maintain exceptional performance under demanding conditions. Additionally, companies like Johnson Matthey are leveraging their extensive experience with precious metals to develop specialized alloys suitable for diverse actuator applications.

These manufacturers contribute significantly to expanding the capabilities of shape memory actuators across different sectors by investing heavily in research and development initiatives focused on emerging technologies. As competition intensifies within this space, each company strives not only to enhance product offerings but also improve efficiency through innovative manufacturing processes tailored towards specific market demands.

Comparing Product Quality and Innovation

When evaluating leading shape memory actuator manufacturers like GEE SMA alongside others such as Nitinol Devices & Components or Fort Wayne Metals, several factors come into play regarding product quality and innovation capabilities. One key aspect is material integrity; reputable manufacturers utilize high-grade raw materials ensuring durability while maintaining optimal performance characteristics inherent within shape memory alloys.

Innovation remains paramount; companies invest considerable resources into R&D activities aimed at developing next-generation solutions that push boundaries beyond conventional uses of these smart materials—think new applications within construction or advanced robotics utilizing state-of-the-art wire actuators! Furthermore, customer feedback plays an essential role; top-tier manufacturers actively seek input from clients which informs ongoing improvements enhancing user experience while reinforcing trustworthiness amongst stakeholders involved with these unique technologies.

Ultimately choosing between different suppliers often boils down not just technical specifications but also support services offered post-purchase—ensuring seamless integration into existing systems or providing training where necessary enhances overall satisfaction levels among end-users relying heavily upon effective implementation strategies involving sophisticated yet reliable mechanisms like those found within today's cutting-edge designs featuring advanced shapes made possible through modern advancements surrounding smart materials!

Future Trends in Shape Memory Actuators

The future of shape memory actuators is bright, driven by continuous advancements in materials science and engineering. As industries seek more efficient solutions, the demand for innovative shape memory alloys is expected to surge. With their unique properties, these materials will likely revolutionize various applications across multiple sectors.

Emerging Technologies and Materials

Emerging technologies are paving the way for new types of shape memory actuators that offer enhanced performance and versatility. Researchers are exploring advanced alloys that not only improve the responsiveness of shape memory alloys but also reduce costs associated with production. Additionally, the integration of smart sensors with shape memory alloy wire actuators is set to create more intelligent systems capable of real-time adjustments based on environmental conditions.

Predictions for Market Growth

The market for shape memory actuators is anticipated to experience significant growth over the next decade. Analysts predict a compound annual growth rate (CAGR) that reflects increasing adoption in sectors like robotics, aerospace, and construction—particularly with innovations in shape memory alloys in construction aiding structural resilience. As manufacturers continue to refine their technologies, we can expect a broader range of applications and increased competition among leading shape memory actuators manufacturers.

Potential New Applications

The versatility of shape memory actuators opens doors to numerous potential new applications beyond traditional uses. In healthcare, these actuators could be deployed in minimally invasive surgical tools that adapt dynamically during procedures, enhancing precision and patient outcomes. Furthermore, as urban areas grow denser, integrating shape memory alloys into smart infrastructure could lead to buildings that respond actively to environmental stressors like earthquakes or extreme weather conditions.

Conclusion

In wrapping up our exploration of shape memory actuators, it's clear that these remarkable devices are reshaping the landscape of various industries. Their unique ability to return to a predetermined shape when exposed to specific stimuli has opened doors to innovative applications, particularly in robotics and construction. As we move forward, the impact of shape memory alloys will only grow, making them an essential component in modern engineering solutions.

The Impact of Shape Memory Actuators

The influence of shape memory actuators on technology and industry cannot be overstated. By providing precise movement and adaptability, these actuators enhance the functionality of machines and structures alike, leading to smarter designs and increased efficiency. From robotics that can mimic human motion to buildings that adapt during seismic events, the applications are as diverse as they are transformative.

Advancements in Smart Material Technologies

With advancements in smart material technologies, the potential for shape memory alloys is expanding exponentially. Researchers are continually exploring new compositions and applications for these materials, paving the way for innovations that were once considered science fiction. As we embrace these developments, we can anticipate a future where shape memory actuators play an even more significant role across various sectors.

Why Choose GEE SMA for Your Needs

When it comes to selecting a manufacturer for your shape memory actuator needs, GEE SMA stands out from the competition. Their commitment to quality and innovation ensures that you receive top-notch products tailored to your specific requirements. With a strong reputation in the market and a focus on cutting-edge technology, choosing GEE SMA means investing in reliable solutions backed by expertise in shape memory alloys.