Introduction

In the quest for sustainable energy solutions, Nitinol emerges as a promising contender, showcasing its potential to revolutionize the way we harness and utilize energy. This remarkable material, known for its unique properties and applications, presents an exciting opportunity for innovations in green technology. With advancements in Nitinol engine efficiency and applications like the Nitinol wire motor, the future of energy generation looks bright.

The Promise of Nitinol as Green Energy

Nitinol's ability to convert thermal energy into mechanical work positions it as a game-changer in renewable energy applications. By utilizing Nitinol generators and heat engines, we can tap into previously underutilized sources of energy while minimizing environmental impact. The promise lies not just in efficiency but also in sustainability—making it a material that aligns perfectly with our green aspirations.

What Makes Nitinol Unique?

What sets Nitinol apart from traditional materials is its extraordinary shape memory effect and superelastic properties, which contribute to its versatility in various applications. The unique behavior of Nitinol wire resistance allows it to perform efficiently across a wide range of temperatures, making it ideal for use in dynamic environments such as engines and motors. Moreover, when used as Nitinol Memory Wire, it can return to a predetermined shape after deformation, enhancing its functionality even further.

Exploring GEE SMA's Innovations

GEE SMA has been at the forefront of integrating Nitinol technology into practical applications that push the boundaries of what is possible with traditional materials. Their innovative approaches have led to significant improvements in the design and performance of devices like the Nitinol heat engine and wire motor systems. As we delve deeper into their contributions, it's clear that GEE SMA is not just innovating; they are paving the way for a sustainable future powered by advanced materials like Nitinol.

Understanding Nitinol and Its Applications

Nitinol, a unique alloy of nickel and titanium, has transformed the landscape of engineering with its remarkable properties. From its ability to return to a predetermined shape to its impressive strength-to-weight ratio, Nitinol is rapidly becoming the backbone of innovative applications in energy generation. In this section, we will delve into the science behind the Nitinol wire motor, explore real-world uses of Nitinol engine efficiency, and examine how this extraordinary material plays a crucial role in energy generation.

The Science Behind Nitinol Wire Motor

At the heart of the Nitinol wire motor lies a fascinating phenomenon known as shape memory effect (SME). When heated above a certain temperature, Nitinol wire can revert to its original shape after being deformed—a property that enhances its functionality in motors. This means that when used in a Nitinol wire motor, it can convert thermal energy into mechanical work efficiently, making it an excellent candidate for various applications.

The mechanics of these motors rely heavily on understanding Nitinol wire resistance; as electricity flows through the wire, it heats up and activates the shape memory effect. This interaction between heat and movement allows for precise control over mechanical outputs without complex systems or heavy components. As engineers continue to refine these designs based on principles outlined in resources like the Nitinol engine Wikipedia, we are likely to see even more innovative uses emerge.

Real-World Uses of Nitinol Engine Efficiency

Nitinol engine efficiency is already making waves across multiple industries due to its lightweight nature and high performance under stress. For instance, automotive manufacturers are exploring ways to integrate Nitinol components into their vehicles for improved fuel efficiency—think lighter engines that don’t compromise power! Similarly, aerospace applications benefit from reduced weight without sacrificing durability thanks to this remarkable alloy.

In medical technology, devices utilizing Nitinol Memory Wire have revolutionized minimally invasive procedures by providing flexible yet strong tools that adapt seamlessly within human anatomy. These practical applications demonstrate how harnessing Nitinol's unique properties can lead not only to enhanced performance but also significant cost savings over time by reducing material usage and increasing longevity. The trend toward incorporating such efficient materials signals a broader shift toward sustainability across sectors.

The Role of Nitinol in Energy Generation

The role of Nitinol in energy generation cannot be overstated; it opens new avenues for harnessing renewable resources effectively. One promising application is in solar thermal systems where heat from sunlight can be converted into mechanical energy using specialized designs based on Nitinol heat engines. By employing these systems at scale, we could significantly enhance overall energy output while minimizing environmental impact.

Moreover, research continues into integrating these technologies with existing infrastructures—imagine retrofitting current power plants with advanced generators powered by adaptable materials like those found in modern-day Nitinol generators! Such innovations not only promise greater efficiency but also align perfectly with global goals for cleaner energy production methods moving forward. As we explore further advancements within this field fueled by ongoing research and development efforts surrounding materials like NiTi alloys (nickel-titanium), it's evident that their potential remains largely untapped.

The Mechanics of Nitinol Heat Engines

Nitinol heat engines represent a fascinating intersection of material science and energy generation. By harnessing the unique properties of Nitinol, these engines convert thermal energy into mechanical work with remarkable efficiency. Understanding how Nitinol generators function is key to appreciating their potential in revolutionizing energy systems.

How Nitinol Generators Work

Nitinol generators operate on the principle of shape memory alloy (SMA) technology, which allows the material to return to a predefined shape when heated. When a temperature change occurs, the Nitinol wire motor expands or contracts, generating mechanical motion that can be harnessed for power generation. This transformation is not only efficient but also provides an innovative solution for converting waste heat into usable energy.

The efficiency of the Nitinol engine lies in its ability to utilize phase changes within the material effectively. As temperatures fluctuate, the unique properties of Nitinol wire resistance play a crucial role in optimizing performance and ensuring that maximum energy is extracted from heat sources. This level of efficiency positions Nitinol generators as viable alternatives to traditional heat engines, paving the way for greener technologies.

Comparing Nitinol Heat Engine Technology

When comparing Nitinol heat engine technology with conventional systems, several advantages become evident. Traditional engines often rely on complex mechanisms and heavy materials that can limit efficiency and increase wear over time. In contrast, Nitinol's lightweight structure and durability minimize maintenance needs while maximizing output.

Moreover, innovations in Nitinol memory wire have led to significant improvements in engine responsiveness and adaptability across various applications. The ability of these engines to operate effectively under varying thermal conditions makes them suitable for diverse environments—from industrial settings to remote locations where traditional power sources may be impractical. As we explore these comparisons further, it becomes clear that embracing Nitinol technology could lead us toward more sustainable energy solutions.

The Future of Energy with Nitinol

The future landscape of energy generation is poised for transformation with the integration of Nitinol technology into mainstream applications. As research continues and more data emerges from practical implementations—such as those highlighted on platforms like Nitinol engine Wikipedia—the possibilities expand beyond current limitations. With increasing emphasis on renewable resources and sustainability, harnessing the capabilities of Nitinol will likely become a cornerstone in developing advanced energy solutions.

In addition to its applications in power generation, advancements in understanding how to optimize both Nitinol wire motor performance and overall engine efficiency will drive innovation forward. The ongoing exploration into new alloys and configurations promises even greater efficiencies than we currently observe today—opening doors for more compact designs that deliver higher outputs without compromising reliability or durability inherent in existing materials like steel or aluminum.

As we stand at this exciting juncture where technology meets sustainability through materials like Nitinol, it’s clear: our approach toward energy production must evolve if we hope to meet future demands responsibly.

Advantages of Nitinol Over Traditional Materials

Nitinol, an alloy of nickel and titanium, is making waves in various industries due to its unique properties that set it apart from traditional materials. One of the most significant advantages is its remarkable wire resistance, which enhances the performance of devices like the Nitinol wire motor. This means that applications utilizing Nitinol can operate more efficiently, leading to improved Nitinol engine efficiency and overall energy savings.

Nitinol Wire Resistance Explained

The resistance of Nitinol wire is a game-changer in the realm of energy applications. Unlike conventional metals, which often experience significant energy loss due to heat generation during operation, Nitinol's unique properties allow it to maintain lower resistance levels. This characteristic not only boosts the performance of systems like the Nitinol generator but also contributes to higher efficiency rates in various applications, including those involving Nitinol heat engines.

Benefits of Nitinol Memory Wire

Another standout feature is the remarkable capabilities of Nitinol memory wire. This innovative material can return to a predetermined shape when heated, making it ideal for applications where movement or actuation is required without external power sources. The adaptability offered by this memory effect enhances designs in numerous fields—from robotics to medical devices—allowing for greater creativity and functionality compared to traditional materials.

The Durability Factor in Nitinol Applications

Durability is where Nitinol truly shines against its competitors. Its ability to withstand extreme temperatures and mechanical stress without losing functionality makes it perfect for long-term use in demanding environments such as aerospace or automotive sectors. When considering devices like the Nitinol engine or other high-performance applications, this durability translates into lower maintenance costs and longer lifespans—an undeniable perk that positions it as a superior alternative.

Nitinol in Space Exploration

Nitinol is not just a fascinating material for Earth-bound applications; its unique properties make it an invaluable asset in space exploration. The ability of Nitinol to undergo significant shape changes under varying temperatures allows for innovative designs in spacecraft systems, enhancing both efficiency and reliability. As we delve into the Chang’e missions, we’ll uncover how Nitinol plays a pivotal role in pushing the boundaries of space technology.

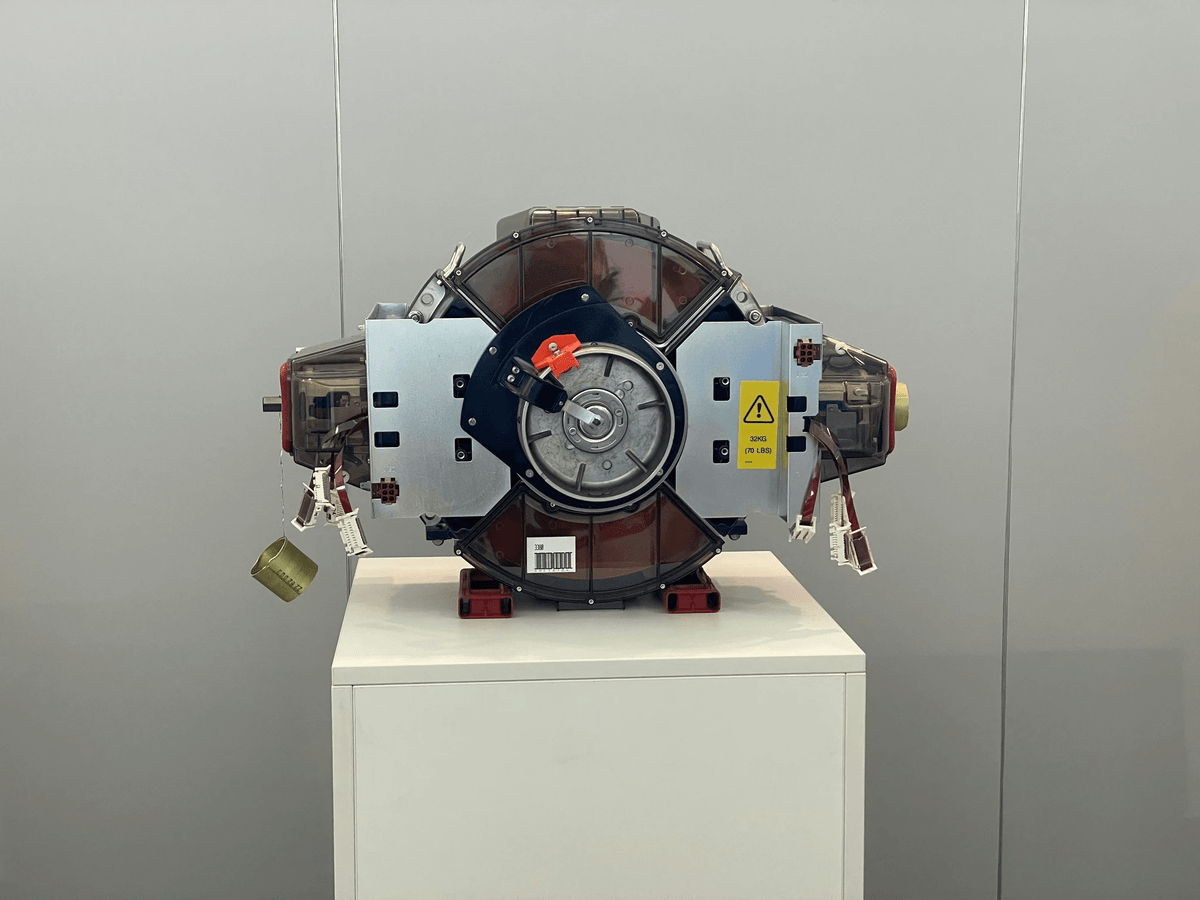

Applications in Chang’e Missions

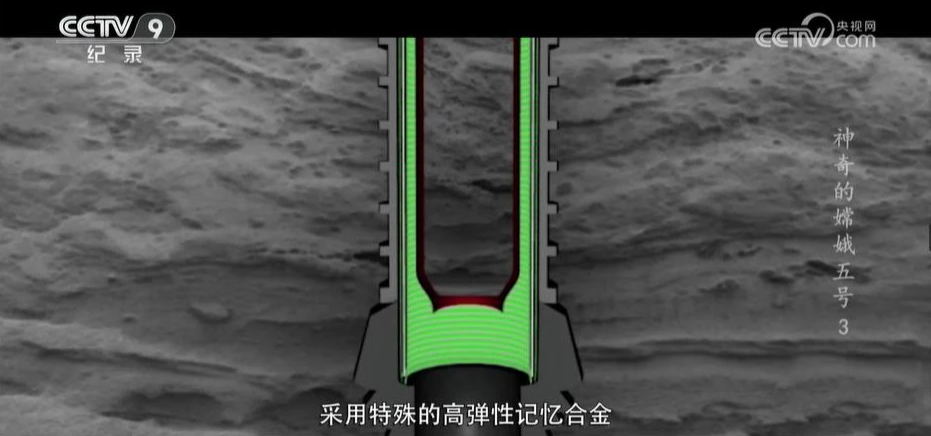

During the Chang’e missions, which aim to explore the Moon and beyond, Nitinol has been employed in various capacities to improve mission success rates. The flexibility and strength of Nitinol wire motors allow for compact yet powerful mechanisms that can operate effectively despite the harsh lunar conditions. Additionally, these motors contribute significantly to Nitinol engine efficiency by providing reliable actuation systems that can withstand extreme temperature fluctuations without compromising performance.

Moreover, the use of Nitinol generators within these missions enables efficient energy conversion from thermal sources available on celestial bodies. This innovation not only enhances power supply but also minimizes weight—crucial for space travel where every gram counts. By integrating these advanced materials into their designs, engineers ensure that missions like Chang’e are equipped with cutting-edge technology capable of enduring long-duration operations.

Ensuring Reliability in Extreme Conditions

One of the most critical challenges faced during space exploration is ensuring that equipment operates reliably under extreme conditions. Here, Nitinol shines due to its remarkable properties such as shape memory and superelasticity, which allow it to adapt seamlessly to temperature changes without losing functionality. In applications like Nitinol heat engines used on spacecraft, this adaptability translates into consistent energy output even when subjected to fluctuating thermal environments.

Reliability is further enhanced through the low resistance characteristics of Nitinol wire resistance compared to traditional materials; this means less energy loss during operation and greater overall system efficiency. Moreover, components made from Nitinol Memory Wire can return to their original shape after deformation, making them ideal for mechanisms requiring repeated motion cycles over extended periods—essential for long-term space missions where maintenance opportunities are limited.

The Impact of GEE SMA’s Innovations

The innovations brought forward by GEE SMA have transformed how we utilize materials like Nitinol in aerospace applications significantly. Through advancements in manufacturing processes and design optimization, they have unlocked new potential for implementing Nitinol engine technology across various platforms—from satellites to landers exploring distant moons or planets. Their focus on improving Nitinol engine efficiency has led to more sustainable solutions that align with modern demands for eco-friendly technologies even beyond our atmosphere.

Furthermore, GEE SMA’s contributions extend into developing specialized components such as advanced actuators powered by Nitinol wire motors that enhance maneuverability while minimizing mass—a crucial factor when designing spacecraft meant for deep-space exploration or landing on other celestial bodies like Mars or asteroids. As we look ahead at future explorations fueled by these innovations, it becomes clear that GEE SMA is paving the way toward a new era where sustainable practices meet cutting-edge technology.

The Road Ahead: Nitinol in Sustainable Energy

As the world increasingly shifts towards renewable energy solutions, Nitinol stands out as a promising candidate for enhancing efficiency and sustainability. With its unique properties, such as shape memory and superelasticity, Nitinol can significantly improve the performance of various energy systems. From Nitinol wire motors to heat engines, this innovative material has the potential to revolutionize how we harness and utilize energy.

Nitinol’s Role in Renewable Energy Solutions

Nitinol's application in renewable energy solutions is particularly noteworthy due to its ability to enhance engine efficiency. The integration of Nitinol wire motors into solar and geothermal systems could lead to more efficient energy conversion processes. Furthermore, with advancements like the Nitinol generator, we can expect a boost in performance metrics that traditional materials simply cannot match.

Moreover, Nitinol's unique properties allow it to adapt dynamically to changing temperatures and conditions, making it ideal for environments where conventional materials may falter. This adaptability is crucial for renewable energy applications that often encounter fluctuating operating conditions. By utilizing Nitinol heat engines, we can optimize energy output while minimizing waste—an essential goal in our quest for sustainable solutions.

Challenges Facing Nitinol Adoption

Despite its advantages, several challenges hinder widespread adoption of Nitinol technology in renewable energy sectors. One major hurdle is the high cost of production associated with manufacturing components like Nitinol wire resistance elements or memory wires at scale. These costs can deter companies from investing heavily in this promising material when cheaper alternatives are readily available.

Additionally, there exists a knowledge gap regarding the capabilities and benefits of using materials like Nitinol among industry professionals and decision-makers. Many still rely on traditional methods without fully understanding how innovations such as the Nitinol engine could transform their operations for greater efficiency and sustainability. Bridging this gap through education and outreach will be essential if we want to see broader acceptance of this cutting-edge technology.

Lastly, regulatory hurdles also pose challenges when introducing new technologies into established industries dominated by conventional materials. Navigating these regulations while proving the reliability and efficiency of new systems will be critical for companies looking to incorporate advanced materials like those found in a Nitinol generator or heat engine design.

The Future Landscape of Nitinol Technology

Looking ahead, the future landscape of sustainable energy powered by innovative materials like Nitinol appears bright but requires concerted efforts from multiple stakeholders. As research continues into optimizing designs involving elements such as Nitinol wire motors or enhanced engine efficiency mechanisms, we may witness breakthroughs that further lower costs while increasing reliability across various applications.

The ongoing development of smart technologies that harness data analytics could also play a vital role in maximizing the potential benefits offered by these advanced materials. Imagine an intelligent system capable of adjusting operational parameters based on real-time feedback from a network powered by a combination of traditional resources alongside cutting-edge innovations like those seen with the latest iterations of the Niton generator or heat engines.

In conclusion, while challenges remain on the road ahead for integrating technologies such as those involving memory wires into mainstream practices within renewable sectors; with ongoing innovation combined with strategic collaborations among manufacturers; we can envision an exciting era where sustainable energy becomes more efficient than ever before—thanks largely due to revolutionary advancements brought forth by utilizing remarkable substances like good old-fashioned NiTi alloys!

Conclusion

The exploration of Nitinol has illuminated a path towards a more sustainable energy future, positioning it as a game changer in various applications. Its unique properties, such as shape memory and superelasticity, enable innovative solutions that traditional materials simply cannot match. With the potential to revolutionize energy generation and efficiency, Nitinol stands at the forefront of green technology.

Nitinol: A Game Changer for Energy

Nitinol's exceptional qualities make it a standout player in the realm of energy solutions, particularly through its applications in Nitinol wire motors and heat engines. The remarkable Nitinol engine efficiency allows for enhanced performance while reducing waste and maximizing output. As we harness the power of this unique alloy, its impact on renewable energy systems becomes increasingly evident, promising a cleaner future.

GEE SMA's Pioneering Contribution

GEE SMA has been instrumental in advancing Nitinol technology, pushing boundaries to develop cutting-edge innovations like the Nitinol generator and advanced heat engines. Their commitment to research and development has led to breakthroughs that optimize Nitinol wire resistance and improve overall system reliability. By integrating these advancements into practical applications, GEE SMA is paving the way for widespread adoption of Nitinol solutions across various sectors.

Envisioning a Green Future with Nitinol

Looking ahead, the potential for Nitinol is vast—particularly in sustainable energy initiatives where its properties can be fully utilized for maximum impact. As we confront challenges such as climate change and resource scarcity, embracing technologies like the Nitinol Memory Wire will be crucial for developing efficient systems that support our planet’s health. By envisioning a future where Nitinol plays a central role in energy generation and conservation, we can create an ecosystem that balances human needs with environmental stewardship.