Introduction

In the ever-evolving landscape of automation and technology, linear actuators have emerged as unsung heroes, seamlessly translating rotational motion into linear movement. Their versatility spans various industries, from robotics to aerospace, making them indispensable tools in modern engineering. Whether you're looking to buy a linear actuator for a specific application or simply exploring options, understanding the different types available can significantly enhance your decision-making process.

Explore the Versatility of Linear Actuators

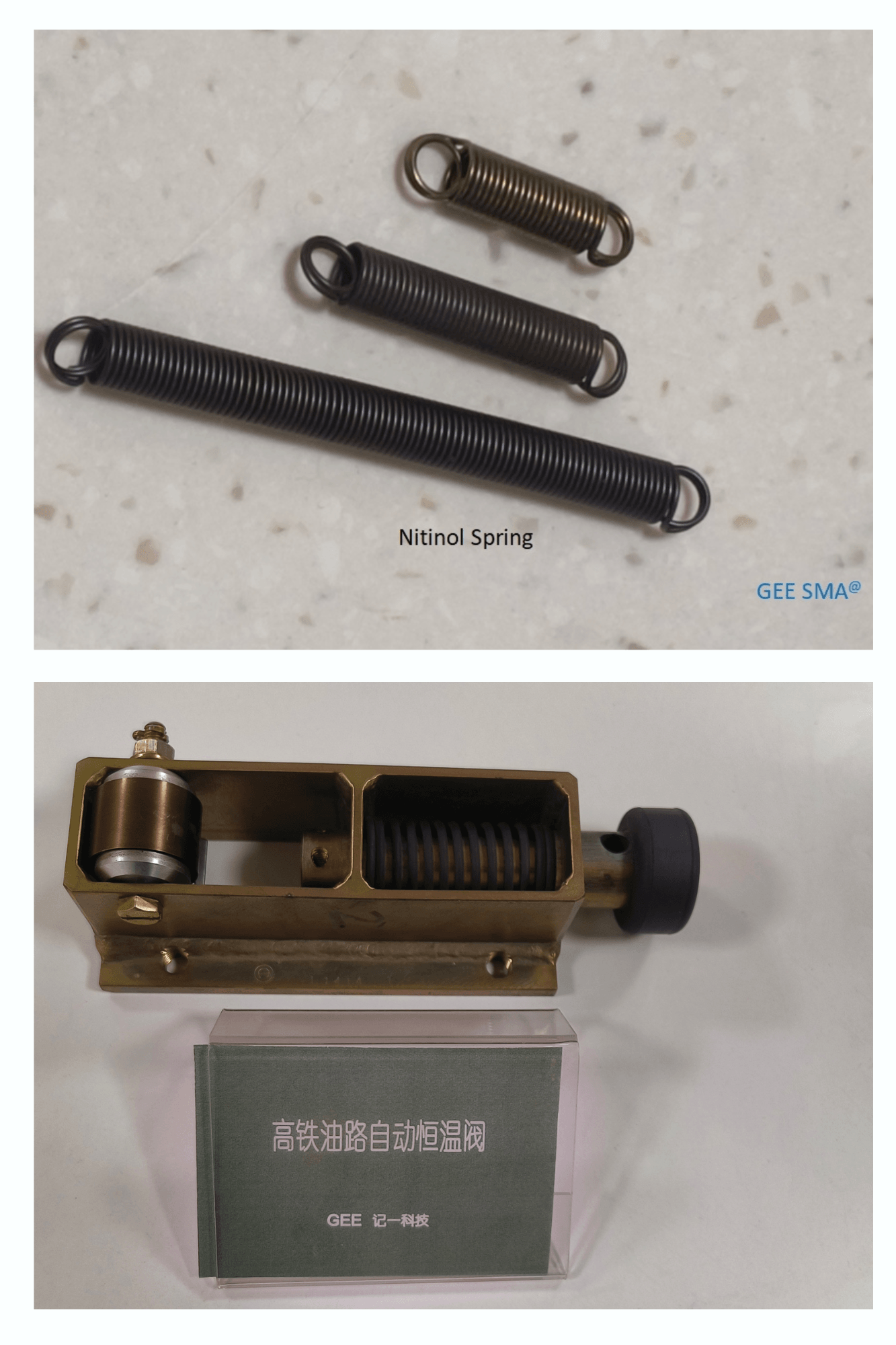

Linear actuators come in various forms and sizes, each designed to meet unique operational demands. They are employed in everything from adjusting solar panels to controlling medical devices, showcasing their widespread applicability and adaptability. With advancements in technology, particularly with the advent of shape memory alloy actuators like SMA actuators and nitinol actuators, the possibilities for innovation have expanded dramatically.

Why Choose Shape Memory Alloy Actuators

When considering which type of actuator best suits your needs, shape memory alloy (SMA) actuators stand out for their unique properties and benefits. These innovative devices utilize materials that remember their original shape and can return to it when heated or cooled, offering remarkable efficiency and precision. By opting for a shape memory alloy linear actuator, users gain not only reliability but also a compact solution ideal for constrained spaces.

Understanding Nitinol Actuator Benefits

Nitinol actuators are a specific type of SMA actuator that leverage nickel-titanium alloys to deliver exceptional performance characteristics. These nitinol actuators exhibit high strength-to-weight ratios while being lightweight and corrosion-resistant—perfect for demanding environments like aerospace or underwater applications. As you consider your options to buy a linear actuator, recognizing the advantages of nitinol technology will help you make an informed choice that aligns with both performance expectations and application requirements.

What is a Linear Actuator?

When you think of motion control in machinery and devices, the linear actuator often takes center stage. These nifty devices convert rotational motion into linear motion, providing precise movement for various applications. Whether you're looking to buy a linear actuator for robotics or automation, understanding their functionality is key to making an informed decision.

Definition and Functionality

A linear actuator is essentially a mechanical device that creates motion in a straight line, as opposed to the circular motion of traditional motors. They can be powered by various sources such as electric motors, hydraulic systems, or even shape memory alloys (SMAs). The beauty of SMA actuators lies in their ability to change shape with temperature fluctuations—making them unique among other types like nitinol actuators.

Common Applications Across Industries

Linear actuators are ubiquitous across many industries due to their versatility and efficiency. From automotive manufacturing where they assist in assembly lines to medical devices that require precise movements, these actuators play an essential role. Furthermore, you’ll find shape memory alloy linear actuators being used in aerospace applications where weight and space are critical factors.

How Linear Actuators Improve Efficiency

The integration of linear actuators into systems can significantly boost efficiency by automating processes that would otherwise require manual labor or complex mechanisms. For instance, using an SMA linear actuator can streamline operations while reducing energy consumption due to their compact design and lightweight materials like nitinol. By choosing the right actuator when you decide to buy a linear actuator, you not only enhance performance but also contribute to overall productivity gains.

Types of Linear Actuators

From traditional electric and hydraulic models to the innovative shape memory alloy actuators, there’s a plethora of options available for various applications. Understanding the different types can help you make an informed decision when you decide to buy a linear actuator that best suits your needs.

Overview of Common Models

Linear actuators come in several common models, each designed for specific tasks and environments. Electric linear actuators are popular for their precision and ease of control, while pneumatic and hydraulic actuators excel in heavy-duty applications requiring significant force. Among these options, shape memory alloy (SMA) linear actuators, particularly nitinol actuators, stand out due to their unique ability to change shape with temperature variations, making them ideal for compact spaces where traditional models might falter.

Advantages of SMA Linear Actuators

SMA linear actuators offer a range of advantages that set them apart from conventional options. Their lightweight design allows for easy integration into various systems without adding unnecessary bulk or weight—perfect for aerospace or robotics applications. Additionally, their energy efficiency is remarkable; they only consume power during activation, which can lead to significant savings over time compared to continuously powered traditional actuators.

Comparing Nitinol and Traditional Actuators

When comparing nitinol actuation technology with traditional actuator systems, the differences become quite clear. Nitinol actuators respond quickly to temperature changes, providing rapid actuation without the need for bulky motors or complex gear systems found in standard electric models. Furthermore, while traditional options often require extensive maintenance due to mechanical wear and tear, shape memory alloy linear actuators boast durability and longevity—making them a wise investment when you choose to buy a linear actuator.

Key Considerations When You Buy Linear Actuator

When you decide to buy a linear actuator, several key factors come into play that can significantly affect your choice. Understanding these considerations will ensure that you select the right actuator for your specific needs, whether you are looking for a shape memory alloy actuator or a more traditional option. Let's dive into the essential aspects that will guide your purchasing decision.

Load Capacity and Speed Requirements

One of the first things to evaluate when you buy a linear actuator is its load capacity and speed requirements. Different applications demand varying levels of force and speed; for instance, an SMA linear actuator might be perfect for delicate tasks but may not handle heavy loads as efficiently as others. Assessing these requirements upfront ensures that the shape memory alloy linear actuator you choose can perform optimally without compromising safety or efficiency.

Moreover, it's crucial to consider how quickly the actuator needs to respond under load conditions. If you're working on projects where timing is critical, like in robotics or automation systems, selecting a nitinol actuator with appropriate speed specifications becomes vital. Remember, balancing load capacity with speed is essential to achieving maximum performance from your chosen SMA actuator.

Environmental Factors and Material Choices

Environmental factors play a significant role in determining which type of linear actuator best suits your application. Whether you're buying an SMA actuator for outdoor use or in harsh industrial environments, understanding how different materials react to temperature changes, moisture levels, and exposure to chemicals is crucial. Shape memory alloy actuators are often favored for their resilience in extreme conditions due to their unique properties.

For instance, if your application involves high humidity or corrosive substances, opting for a nitinol actuator made from specialized materials can enhance durability and longevity. Additionally, consider whether the operating temperatures align with the specifications of your chosen shape memory alloy linear actuator; this will help avoid performance issues down the line. Ultimately, making informed material choices based on environmental factors can save time and costs associated with replacements or repairs.

Cost vs. Performance Analysis

When weighing options before you buy a linear actuator, conducting a cost vs. performance analysis is essential to ensure you're getting value for money without sacrificing quality or functionality. Although SMA actuators may come with higher upfront costs compared to traditional models due to their advanced technology and unique properties—like those found in shape memory alloys—they often provide long-term savings through improved efficiency and reduced maintenance needs.

It's important not just to focus on initial purchase prices but also consider lifetime costs associated with energy consumption and potential downtimes caused by equipment failure in less reliable actuators. Additionally, evaluating warranties and customer support options offered by manufacturers can provide insight into overall value when investing in nitinol actuators or other types of linear motion solutions.

In summary, being mindful of load capacity and speed requirements alongside environmental factors will help narrow down your options effectively when deciding which SMA linear actuator suits your project best while keeping an eye on cost versus performance benefits ensures you'll make an informed investment decision.

GEE SMA: The Leader in Nitinol Technology

Their offerings are designed to meet diverse needs across various industries, showcasing the versatility and efficiency that SMA linear actuators can provide. If you're looking to buy a linear actuator that combines reliability with advanced technology, GEE SMA is your go-to source.

Overview of GEE SMA’s Offerings

GEE SMA specializes in an impressive lineup of nitinol actuators that cater to both commercial and specialized applications. Their shape memory alloy linear actuator products are engineered for precision and performance, making them ideal for everything from robotics to aerospace. With a commitment to quality and innovation, GEE SMA ensures that each sma actuator they produce meets the highest standards in the industry.

How GEE SMA Powers Space Missions

One of the most exciting applications of GEE SMA's nitinol technology is its use in space missions. The unique properties of shape memory alloys allow these actuators to function effectively in extreme environments where traditional components might fail. By harnessing the capabilities of sma linear actuators, engineers can develop systems that are not only lightweight but also incredibly reliable under the harsh conditions of outer space.

Custom Solutions for Unique Applications

GEE SMA takes pride in offering custom solutions tailored specifically for unique applications across various sectors. Whether you need a specialized shape memory alloy actuator designed for medical devices or a robust solution for industrial automation, their team works closely with clients to create effective designs that meet exact specifications. This emphasis on customization ensures that when you buy a linear actuator from GEE SMA, you're getting something truly suited to your needs.

Best Practices for Implementing Linear Actuators

These guidelines cover everything from installation to maintenance and troubleshooting, enabling you to get the most out of your shape memory alloy linear actuator. Whether you're looking to buy a linear actuator for a specific application or simply want to enhance your existing setup, these tips will help you along the way.

Installation Tips for Optimal Performance

Installing your shape memory alloy actuator correctly is crucial for achieving optimal performance. Start by ensuring that the mounting surfaces are clean and level; this helps prevent misalignment that could lead to premature wear or failure of the SMA actuator. Additionally, pay attention to the wiring and connections—secure them properly to avoid any electrical issues that might arise during operation.

Another important aspect is selecting the right environment for your nitinol actuator; temperature fluctuations can affect its performance due to its unique properties. If you're operating in extreme conditions, consider using protective enclosures or insulation materials designed specifically for SMA linear actuators. Always refer to the manufacturer's guidelines when installing your device; they often contain valuable insights tailored specifically for their products.

Lastly, don't forget about testing after installation! Conduct thorough checks under various load conditions before putting your shape memory alloy linear actuator into full operation. This ensures that everything is functioning as intended and can help identify potential issues early on.

Maintenance Guidelines for Longevity

To ensure a long life for your SMA linear actuator, regular maintenance is key! Start with routine inspections—look out for signs of wear or damage such as frayed wires or rusted components that could compromise functionality over time. Keeping moving parts lubricated will also minimize friction and prolong the lifespan of both traditional and shape memory alloy actuators.

Another tip is to keep an eye on environmental factors that could impact performance; dust accumulation can hinder movement in any actuator system, including nitinol ones. Use compressed air or soft brushes periodically to clean around these devices without causing damage. Remember, prevention is always better than cure!

Finally, document all maintenance activities performed on your shape memory alloy actuator. Keeping track not only helps you stay organized but also provides valuable insights should any issues arise down the line—making it easier when you need to troubleshoot later on.

Troubleshooting Common Issues

Even with proper installation and maintenance practices in place, sometimes things don’t go as planned with your linear actuators—especially if they’re SMA actuators! One common issue users face is erratic movements or failure to respond; this could be due to poor connections or insufficient power supply feeding into your nitinol actuator system. Double-check all electrical connections before delving deeper into potential mechanical problems.

If you notice unusual noises during operation (like grinding sounds), it may indicate misalignment within components—a common culprit behind many operational hiccups with shape memory alloy linear actuators! Adjusting alignment carefully can often resolve these concerns without needing extensive repairs.

Lastly, if you've ensured everything seems fine but still experience issues, consult troubleshooting guides provided by manufacturers like GEE SMA who specialize in Nitinol technology solutions—they often have specific recommendations tailored just for their products! Embracing innovation means knowing when it's time to seek expert advice!

Conclusion

In the ever-evolving landscape of automation, selecting the right linear actuator is crucial for optimizing performance and efficiency. With a variety of options available, understanding your specific needs will help you buy linear actuators that perfectly suit your applications. Whether you’re drawn to traditional models or intrigued by the innovative capabilities of shape memory alloy actuators, there’s a solution waiting for you.

Discover the Best Linear Actuator for You

When it comes to choosing a linear actuator, considering factors like load capacity, speed requirements, and environmental conditions is key. SMA actuators, particularly shape memory alloy linear actuators made from nitinol, offer unique advantages such as compact size and energy efficiency that can elevate your project. By evaluating these criteria thoroughly, you can make an informed decision and ensure that your investment in a linear actuator yields optimal results.

GEE SMA’s Role in the Future of Automation

GEE SMA stands at the forefront of innovation in nitinol technology and is reshaping how industries approach automation with their advanced SMA linear actuators. Their commitment to developing cutting-edge solutions has made them a trusted partner for space missions and other high-demand applications where reliability is paramount. As we move forward into an era defined by technological advancements, GEE SMA's expertise will undoubtedly play a significant role in driving progress across various sectors.

Embrace Innovation with Shape Memory Alloys

The potential of shape memory alloys extends far beyond conventional applications; they represent a leap toward smarter automation solutions. By integrating nitinol actuators into your systems, you're not just keeping pace with industry standards—you're embracing innovation that can transform operations altogether. So when you're ready to buy linear actuators that combine efficiency with groundbreaking technology, consider making the switch to SMA or shape memory alloy options for unparalleled performance.