Introduction

In the ever-evolving landscape of robotics, one material stands out for its unique properties and transformative potential: shape memory alloys. These remarkable materials can return to a predetermined shape when subjected to specific stimuli, making them ideal for various applications in robotic systems. Among these alloys, Nitinol has emerged as a game changer due to its exceptional performance characteristics and versatility.

Understanding Shape Memory Alloys

Shape memory alloys (SMAs) are metallic materials that have the extraordinary ability to remember their original shapes after deformation. When heated or cooled beyond certain temperature thresholds, SMAs like Nitinol revert to their pre-set forms, enabling innovative designs in actuators and other mechanical components. This property is not just fascinating; it opens up new avenues for creating compact and efficient devices that can adapt dynamically to changing conditions.

The Role of Actuators in Robotics

Actuators serve as the muscles of robotic systems, converting energy into motion and enabling machines to perform tasks ranging from simple movements to complex operations. The efficiency and effectiveness of an actuator significantly influence a robot's overall performance, making the choice of materials critical. In this context, shape memory alloy actuators offer unique advantages that traditional actuator technologies often struggle to match.

Why Nitinol is a Game Changer

Nitinol actuators are particularly noteworthy for their lightweight design and high energy efficiency compared to conventional options. Their ability to operate effectively in harsh environments further enhances their appeal in various industries, from aerospace innovations to medical robotics. As we delve deeper into the science behind these memory metal actuators, it becomes clear why they are poised to redefine what's possible in robotic applications.

What is a Shape Memory Alloy Actuator

Shape memory alloy actuators, particularly Nitinol actuators, represent a fascinating intersection of materials science and engineering innovation. These unique devices leverage the remarkable properties of shape memory alloys (SMAs) to produce motion in response to temperature changes. By understanding how these memory metal actuators work, we can appreciate their potential applications in various robotic systems.

The Science Behind Nitinol

Nitinol, an alloy of nickel and titanium, exhibits two distinct phases: austenite and martensite. When cooled below a specific temperature, Nitinol transforms into the more malleable martensitic phase, allowing it to be deformed easily. Upon heating above this critical temperature, the alloy reverts to its original shape in the austenitic phase, demonstrating its shape memory effect—a fundamental principle that underpins the functionality of shape memory alloy actuators.

The magic doesn't stop there; Nitinol also possesses superelasticity at certain temperatures, allowing it to undergo significant deformation while returning to its original form upon removal of stress. This dual capability makes Nitinol an ideal candidate for applications where both flexibility and strength are essential. In essence, the science behind Nitinol is not just about changing shapes; it's about creating dynamic movements that can revolutionize how we design robotic systems.

How Memory Metal Actuators Work

Memory metal actuators operate by harnessing the unique thermal properties of shape memory alloys like Nitinol. When a current passes through the actuator or when it is exposed to heat, it triggers a phase transformation from martensite to austenite—this transition generates movement or force that can be precisely controlled. The ability to convert thermal energy into mechanical work allows these actuators to perform tasks ranging from simple bending motions to complex manipulations.

One of the standout features of these Nitinol actuators is their compact size; they can generate substantial force without requiring bulky components or complex mechanisms typically found in traditional actuators. This lightweight design not only enhances efficiency but also opens up new avenues for integration into various robotic systems where space and weight constraints are critical considerations. Ultimately, understanding how these memory metal actuators work provides insight into their transformative potential across numerous fields.

Applications in Robotic Systems

The versatility of shape memory alloy actuators has led them to find applications across diverse robotic systems—from medical devices that assist with delicate surgical procedures to soft robotics that require gentle handling capabilities. In medical robotics, Nitinol's biocompatibility makes it an excellent choice for minimally invasive tools that need precise movements without damaging surrounding tissues. Additionally, its ability to operate effectively in challenging environments positions it as a key player in industrial automation.

In soft robotics specifically, these innovative devices enable robots that mimic biological organisms by providing flexible movement patterns akin to muscle contractions—something traditional rigid mechanisms struggle with achieving effectively. Furthermore, as industries continue exploring automation solutions for manufacturing processes or even advanced aerospace technologies like morphing wings on aircrafts using GEE SMA concepts—Nitinol's role as a game-changing actuator cannot be overstated.

Key Advantages of Shape Memory Alloy Actuators

Shape memory alloy actuators, particularly Nitinol actuators, are making waves in various industries due to their unique properties and performance characteristics. These memory metal actuators offer a blend of lightweight design, energy efficiency, and durability that traditional actuators struggle to match. Let’s dive deeper into these key advantages that set Nitinol apart from the competition.

Lightweight and Compact Design

One of the standout features of shape memory alloy actuators is their lightweight and compact design. Unlike conventional actuators that can be bulky and heavy, Nitinol actuators are made from a specialized alloy that allows them to perform effectively without adding unnecessary weight. This compactness not only makes them ideal for applications where space is at a premium but also aids in enhancing the overall efficiency of robotic systems.

The reduced weight of memory metal actuators translates directly into improved mobility for robotic devices, allowing for more agile movements without compromising on power or control. As robots become increasingly integrated into everyday life—from manufacturing lines to surgical suites—the need for lightweight components becomes critical. Thus, the use of shape memory alloy actuators paves the way for innovative designs that can tackle complex tasks while remaining nimble.

High Energy Efficiency

Energy efficiency is another compelling advantage offered by shape memory alloy actuators like Nitinol. These memory metal actuators operate using phase transformation rather than continuous electrical power, which means they consume significantly less energy during operation compared to traditional motors and servos. This feature not only lowers operational costs but also extends battery life in portable robotic devices.

Moreover, the ability of Nitinol to return to its original shape after deformation allows for efficient energy recovery during actuation cycles. This unique property ensures that less energy is wasted as heat—a common issue with conventional actuator technologies—further solidifying the case for adopting shape memory alloys in robotics. In an era where sustainability matters more than ever, high energy efficiency makes these actuators an attractive choice for eco-conscious developers.

Robust Performance in Harsh Conditions

Shape memory alloy actuators excel in environments where other technologies may falter due to extreme conditions like temperature fluctuations or corrosive atmospheres. The inherent properties of Nitinol allow it to maintain functionality across a wide range of temperatures without losing performance quality—a significant advantage over traditional materials prone to failure under stress or adverse conditions.

Additionally, these memory metal actuators exhibit remarkable resilience against fatigue and wear over time, making them suitable for long-term applications in challenging settings such as aerospace or deep-sea exploration where reliability is paramount. Their robust nature ensures consistent performance even when subjected to harsh mechanical stresses or environmental factors—making them indispensable components in modern robotics.

Real-World Applications of Nitinol Actuators

The versatility of Nitinol actuators, a type of shape memory alloy actuator, is reshaping various industries by providing innovative solutions to complex challenges. From aerospace to medical robotics and manufacturing automation, these memory metal actuators are proving their worth in real-world applications. Let's dive deeper into how Nitinol is making waves across these fields.

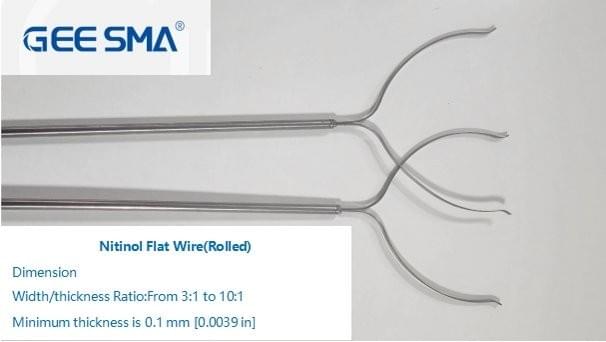

Aerospace Innovations with GEE SMA

In the aerospace sector, GEE SMA (Geometric Engineered Elastic Shape Memory Alloys) is leading the charge in revolutionizing aircraft design and functionality. The lightweight nature of shape memory alloy actuators allows for significant weight savings, which directly translates into improved fuel efficiency and performance. Additionally, the ability of Nitinol actuators to operate under extreme temperatures makes them ideal for applications such as deployable structures and morphing wings.

One standout example includes their use in adaptive wing technology, where the shape memory alloy actuator can adjust wing configurations during flight for optimal aerodynamics. This capability not only enhances maneuverability but also contributes to safer and more efficient flights. As aerospace continues to push boundaries, integrating these memory metal actuators will undoubtedly play a crucial role in future innovations.

Robotics in Medicine

The medical field is another area where Nitinol actuators shine brightly due to their precision and reliability. In minimally invasive surgeries, shape memory alloy actuators are used in devices like stents or guidewires that expand or contract at body temperature, providing doctors with enhanced control during procedures. These memory metal actuators enable surgeons to navigate through complex anatomical structures with ease while minimizing patient trauma.

Furthermore, robotic prosthetics are increasingly incorporating Nitinol technology for improved functionality and responsiveness. The lightweight design of a shape memory alloy actuator allows for more natural movements that closely mimic biological limbs—an essential factor for user comfort and usability. As advancements continue in this sector, we can expect even greater integration of Nitinol-based systems into medical robotics.

Automation in Manufacturing

In manufacturing environments where efficiency is key, shape memory alloy actuators offer transformative solutions that streamline processes while reducing energy consumption. These innovative devices can be employed in automated assembly lines where precise movements are crucial; they provide rapid actuation without the bulkiness associated with traditional pneumatic or hydraulic systems. This compactness not only saves space but also enhances overall system responsiveness.

Moreover, the durability of Nitinol actuators under harsh conditions makes them ideal candidates for industrial applications that require resilience against wear and tear over time. Factories utilizing these memory metal actuators can expect fewer breakdowns and maintenance costs due to their robust performance characteristics—making them a smart investment for long-term operational success. With such advantages on offer, it’s no wonder that companies are increasingly turning towards shape memory alloy technology as they modernize their manufacturing processes.

Challenges and Limitations

While shape memory alloy actuators, particularly Nitinol actuators, offer groundbreaking advantages in robotics, they are not without their challenges. Understanding these limitations is crucial for developers and engineers looking to harness the full potential of memory metal actuators. From temperature sensitivity to cost factors, addressing these issues will ensure that Nitinol can thrive in various applications.

Temperature Sensitivity Issues

One of the primary challenges with shape memory alloy actuators is their temperature sensitivity. Nitinol actuators require precise temperature control to function correctly; even slight variations can lead to performance inconsistencies. This sensitivity can limit their use in environments with fluctuating temperatures or where rapid thermal changes occur, potentially restricting the versatility of memory metal actuators in diverse applications.

Durability Concerns

Durability is another critical concern when it comes to Nitinol actuators. While they are generally robust, repeated cycling between shapes can lead to fatigue over time, which may compromise their effectiveness. Engineers must carefully consider the lifespan of a shape memory alloy actuator when designing systems that rely on consistent performance; otherwise, premature failure could hinder project success.

Cost Factors Compared to Traditional Actuators

Cost remains a significant barrier for widespread adoption of shape memory alloy actuators like Nitinol compared to traditional alternatives. The manufacturing processes involved in creating high-quality memory metal actuators often result in higher expenses per unit than conventional materials. This economic factor can deter industries from fully embracing this innovative technology despite its many advantages, making it essential for researchers and manufacturers to explore cost-effective solutions.

Future Trends in Shape Memory Alloy Technology

The landscape of shape memory alloy technology is rapidly evolving, particularly with Nitinol actuators leading the charge. Innovations in design and functionality are paving the way for these remarkable materials to find even broader applications across various industries. As we look forward, it's clear that the future holds exciting possibilities for memory metal actuators.

Advances in Nitinol Actuator Design

Recent advancements in Nitinol actuator design focus on enhancing performance while minimizing size and weight. Engineers are experimenting with new alloy compositions and manufacturing techniques to create more efficient shape memory alloy actuators that respond faster and operate under a wider range of temperatures. These innovations not only improve the actuator's functionality but also expand its applicability in complex robotic systems, making it a cornerstone of modern automation.

Moreover, researchers are exploring ways to integrate smart materials into Nitinol actuators, enabling them to self-adjust based on environmental conditions or operational demands. This adaptability opens up new realms for robotics where precision and responsiveness are critical, such as surgical robots or drones operating in unpredictable environments. With continued investment in R&D, we can expect breakthroughs that will redefine what is possible with shape memory alloy actuators.

Integration with Smart Robotics

The integration of Nitinol actuators into smart robotics represents a significant leap forward in automation technology. As robots become increasingly sophisticated, incorporating shape memory alloy actuators allows for smoother movements and enhanced dexterity that traditional motors simply cannot match. This capability is vital for applications ranging from delicate surgical procedures to complex assembly lines where precision is paramount.

Furthermore, the synergy between artificial intelligence (AI) and memory metal actuators enables real-time data processing and decision-making within robotic systems. Imagine a robot that can adjust its grip strength based on the object it’s handling—thanks to advanced sensors paired with Nitinol technology! Such innovations promise to revolutionize industries by making robots safer and more efficient while reducing human error.

Sustainability and Environmental Impact

Sustainability is becoming an essential consideration in all technological developments, including those involving shape memory alloy actuators like Nitinol. The lightweight nature of these materials contributes significantly to energy savings across various applications—from aerospace engineering to automotive designs—by reducing fuel consumption during operation. Furthermore, their durability means fewer replacements are needed over time, ultimately leading to less waste.

In addition, ongoing research aims at developing eco-friendly production processes for creating memory metal actuators that minimize environmental impact without compromising performance quality. By focusing on sustainable practices throughout their lifecycle—from production through usage—Nitinol actuators can help pave the way toward greener technologies while maintaining high efficiency standards necessary for modern robotics.

Conclusion

In summary, shape memory alloys represent a remarkable advancement in material science, particularly through the lens of Nitinol actuators. These innovative materials possess the unique ability to return to a predetermined shape when subjected to specific temperatures, making them invaluable in various applications. The potential of memory metal actuators is vast, with ongoing research promising even more exciting developments.

The Promise of Shape Memory Alloys

The promise of shape memory alloy actuators lies in their ability to revolutionize how we approach engineering challenges across multiple industries. With Nitinol's distinct properties, these actuators can be designed for precise movements and functions that traditional materials struggle to achieve. As researchers continue to unlock the secrets behind these remarkable materials, we can anticipate breakthroughs that will push the boundaries of robotics and beyond.

Enhancing Robotics with Nitinol

Nitinol is not just another material; it’s a game changer for robotics that enhances performance and efficiency in ways we are only beginning to explore. By incorporating shape memory alloy actuators into robotic systems, engineers can create lighter and more compact designs without sacrificing power or precision. This transformative capability allows robots to navigate complex environments more effectively while reducing energy consumption—a win-win situation for both developers and users.

GEE SMA's Role in Future Innovations

GEE SMA is at the forefront of integrating shape memory alloy technology into future innovations, driving advancements that could redefine entire industries. Their commitment to developing cutting-edge Nitinol actuators ensures that this technology remains at the cutting edge of robotics and automation solutions. As we look ahead, GEE SMA's contributions will undoubtedly continue shaping how we interact with machines, paving the way for smarter, more efficient robotic systems.