Introduction

In the ever-evolving landscape of technology, the emergence of shape memory actuators (SMAs) has heralded a new era of innovation. These remarkable devices, capable of transforming their shape in response to temperature changes, are revolutionizing various industries by providing solutions that were once thought impossible. With the ability to harness the unique properties of materials like Nitinol, SMA actuators are not just a scientific curiosity; they are at the forefront of practical applications that enhance functionality and efficiency.

The Revolutionary Concept of Shape Memory Actuators

At the heart of shape memory actuators lies an extraordinary phenomenon known as the shape memory effect (SME). This effect allows certain materials to remember their original form after being deformed, enabling them to return to that shape when exposed to specific thermal conditions. The revolutionary concept behind SMA actuators is their ability to convert thermal energy into mechanical work, making them indispensable in applications ranging from robotics to aerospace engineering.

Applications Driving Innovation in Smart Materials

The versatility of SMA actuators has spurred a wave of innovation across multiple sectors. In aerospace, for instance, these smart materials are being employed in systems that require precise movements and adjustments under varying environmental conditions. Similarly, in robotics and medical devices, SMA actuators are enhancing performance and reliability by providing lightweight yet powerful actuation solutions that traditional mechanisms simply cannot match.

Unlocking the Potential of Nitinol Alloys

Among the various materials utilized for SMAs, Nitinol stands out due to its unique properties—specifically its superelasticity and shape memory capabilities. This nickel-titanium alloy not only exhibits remarkable strength but also retains its functionality even after numerous cycles of deformation and recovery. By unlocking the potential of Nitinol alloys within SMA actuator technology, researchers and engineers are paving the way for advanced applications that promise to reshape our understanding and use of smart materials.

Understanding Shape Memory Alloys

Shape memory alloys (SMAs) are fascinating materials that can remember their original shape and return to it after being deformed. This remarkable ability is due to a unique phase transformation that occurs within the alloy when subjected to specific thermal conditions. The science behind SMAs opens up a world of possibilities, especially in the development of SMA actuators, which leverage this effect for various applications.

The Science Behind Shape Memory Effect

At the heart of the shape memory effect lies a transformation between two distinct crystalline structures: martensite and austenite. When an SMA actuator is cooled below its transformation temperature, it adopts the martensitic phase, which allows for deformation under stress. Upon heating above this temperature, the material transitions back to its original austenitic form, effectively remembering its initial shape and generating movement in SMA actuators.

This phase change is not just about returning to form; it also enables SMAs to exert significant forces while maintaining compactness—an essential feature for many applications. For instance, in robotics or aerospace engineering, where space is at a premium, using an SMA actuator can lead to innovative designs that maximize efficiency without sacrificing functionality. Thus, understanding this scientific foundation is crucial for harnessing the full potential of SMA technology.

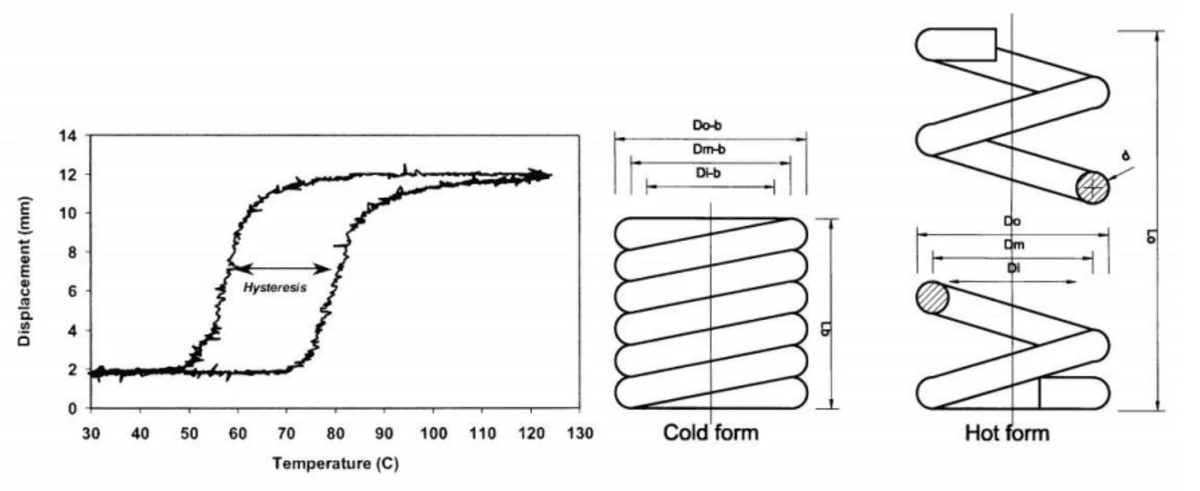

How SMA Actuators Respond to Temperature

Temperature plays a pivotal role in how SMA actuators function and respond to external stimuli. As these materials undergo their phase transformations at specific temperatures—known as transition temperatures—they can be precisely controlled through thermal input. By simply applying heat or allowing them to cool down, engineers can activate or deactivate an SMA actuator with remarkable accuracy.

This thermal responsiveness means that SMAs can be utilized in environments where traditional motors may struggle due to size constraints or power limitations. Imagine an aerospace application where weight savings are critical; using an SMA actuator allows for lighter systems without compromising performance capabilities. Furthermore, this temperature-driven actuation opens doors for smart materials in adaptive systems that respond dynamically based on environmental changes.

Common Materials Used in SMA Actuators

While there are many alloys available on the market today, nickel-titanium (Nitinol) stands out as one of the most popular choices for SMA actuators due to its exceptional properties and versatility. Nitinol’s unique combination of shape memory effect and superelasticity makes it ideal for various applications ranging from medical devices like stents to advanced robotics solutions requiring precise movements.

Other common materials include copper-aluminum-nickel and iron-based alloys; however, they often lack some of Nitinol's superior qualities such as corrosion resistance and fatigue durability. Each material has its advantages depending on specific use cases; thus understanding these options allows engineers and designers to select the best fit for their needs when developing innovative solutions with SMA actuators. Ultimately, choosing the right material ensures optimal performance across diverse industries utilizing smart materials technology.

The Role of Nitinol in SMA Technology

Nitinol, a remarkable alloy of nickel and titanium, plays a pivotal role in the development of shape memory actuators (SMA actuators). Its unique properties make it an ideal candidate for applications that require precise control and adaptability. Understanding these properties is essential for harnessing the full potential of SMA technology.

Unique Properties of Nitinol Alloys

Nitinol exhibits two fascinating phenomena: the shape memory effect and superelasticity. The shape memory effect allows Nitinol to return to a predetermined shape when heated above a certain temperature, making it invaluable in SMA actuators that need to perform specific functions on demand. Meanwhile, its superelasticity enables the material to undergo significant deformation without permanent change, providing an extra layer of versatility in various applications.

These properties arise from the unique crystalline structure of Nitinol, which can switch between different phases based on temperature changes. This phase transformation is what makes Nitinol so special; it can be programmed to remember shapes while being capable of absorbing large amounts of energy during operation. As a result, SMA actuators utilizing Nitinol alloys are not only efficient but also reliable under varying conditions.

Advantages of Nitinol in Actuation Systems

The advantages offered by Nitinol make it a standout choice for actuation systems across multiple industries. First and foremost, its lightweight nature ensures that devices using SMA actuators remain portable and easy to integrate into existing systems without adding unnecessary bulk or weight. This characteristic is particularly beneficial in aerospace applications where every gram counts.

Additionally, Nitinol's resistance to corrosion enhances its longevity and reliability over time—a crucial factor when considering maintenance costs and system downtime. In medical devices where sterility is paramount, this property ensures that SMA actuators can function effectively without succumbing to wear or degradation from environmental factors. Furthermore, the ability to operate silently adds another layer of appeal for applications ranging from robotics to delicate surgical instruments.

GEE SMA’s Contribution to Nitinol Production

GEE SMA has emerged as a key player in advancing the production capabilities of Nitinol alloys for use in SMA actuators. Their innovative manufacturing processes ensure high-quality materials with consistent performance characteristics essential for demanding applications like aerospace and healthcare technologies. By investing heavily in research and development, GEE SMA continues to push boundaries—creating new forms and compositions that enhance the capabilities of shape memory actuators.

Moreover, GEE SMA's commitment to sustainability means they are exploring eco-friendly methods for producing these vital materials without compromising quality or performance standards. This forward-thinking approach positions them as leaders not just within their industry but also as responsible stewards of technology's future impact on society at large. As demand grows for smarter materials capable of revolutionizing various sectors, GEE SMA stands ready with cutting-edge solutions rooted firmly in their expertise with Nitinol.

Applications in Aerospace and Robotics

Shape memory actuators (SMAs) are revolutionizing the aerospace and robotics sectors, offering innovative solutions to complex engineering challenges. Their ability to change shape in response to temperature variations makes them ideal for applications where space and weight are critical factors. From spacecraft deployment systems to advanced robotic limbs, SMA technology is paving the way for smarter, more efficient designs.

Shape Memory Actuators in Space Missions

In the realm of space exploration, SMA actuators have emerged as game-changers due to their lightweight nature and reliability under extreme conditions. These actuators can be used in various spacecraft components, such as deployable structures like solar panels and antennas that need precise movement without the excess weight of traditional motors. Their ability to perform with high precision while consuming minimal power makes them invaluable for long-duration missions where every ounce counts.

Case Study: Chang’e-5 and Chang’e-6 Missions

The Chang’e-5 and Chang’e-6 missions exemplify the successful integration of SMA technology into aerospace applications. These lunar missions utilized shape memory actuators for critical operations such as sample collection and deployment mechanisms on the moon's surface. The use of SMAs allowed for reliable functioning at varying temperatures, ensuring that these ambitious missions could achieve their objectives efficiently.

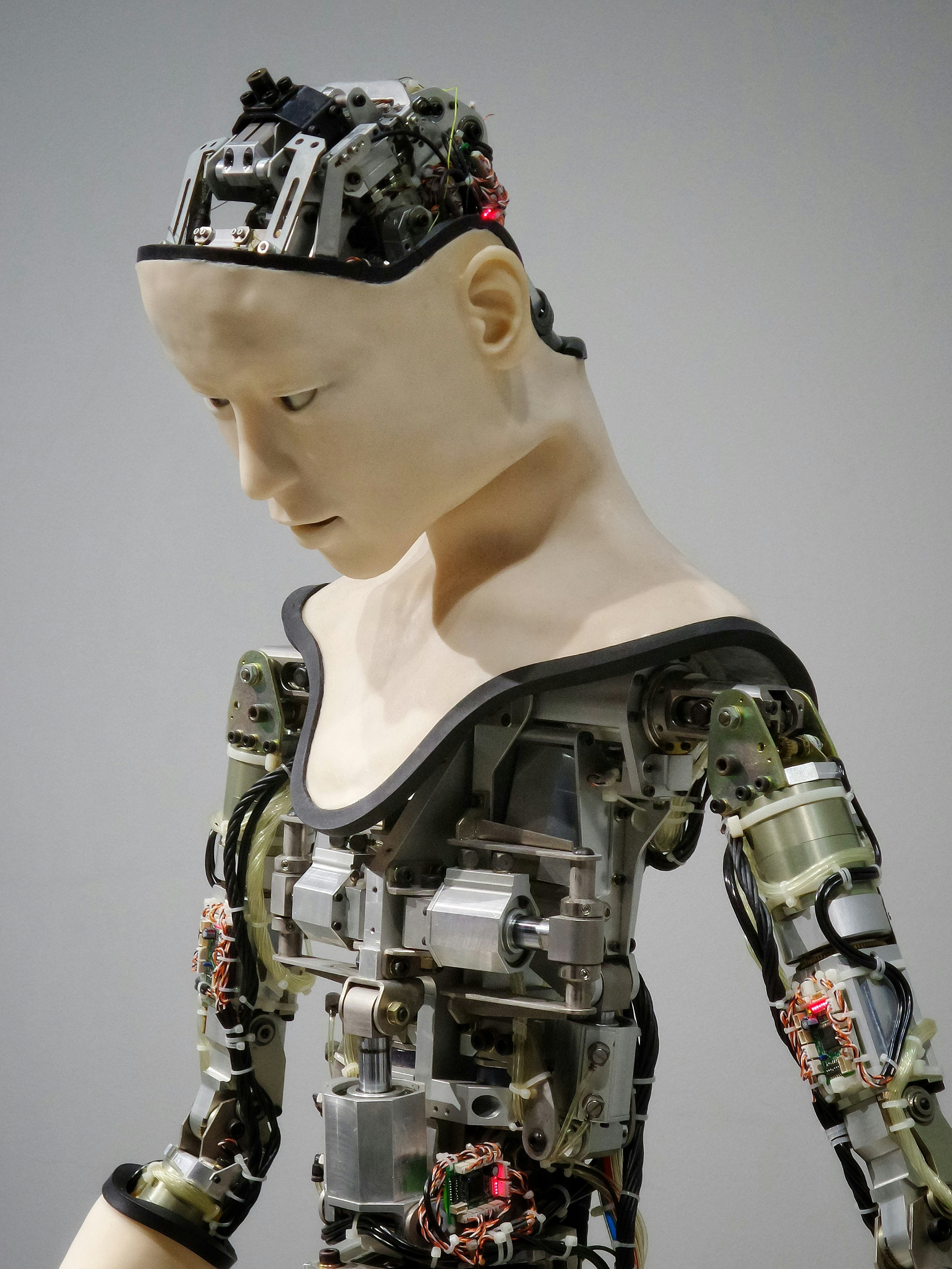

Robotics Innovations Utilizing SMA Technology

Robotics is another field benefiting immensely from SMA actuators, which provide unique advantages over conventional actuation methods. By mimicking natural muscle movements through temperature-induced shape changes, SMA-based robots can achieve remarkable flexibility and dexterity. This innovation opens doors for more adaptive robotic systems that can perform delicate tasks in environments ranging from manufacturing floors to surgical rooms.

Medical Applications of SMA Actuators

Shape memory actuators (SMAs) are revolutionizing the medical field, providing innovative solutions that enhance patient care and treatment outcomes. These remarkable materials can be programmed to change shape in response to specific stimuli, particularly temperature changes, which is essential for various medical devices. From minimally invasive surgical tools to life-saving implants, SMA actuators are making a significant impact on healthcare technology.

Shape Memory Alloys in Medical Devices

Shape memory alloys (SMAs) have emerged as critical components in many medical devices due to their unique ability to return to a predetermined shape when heated. This property allows for the development of devices that can adapt and respond dynamically within the human body, improving functionality and effectiveness. For instance, SMA actuators are used in catheters and guidewires that can navigate complex anatomical pathways with ease and precision.

The use of SMAs also extends to implantable devices where their ability to compress or expand based on temperature plays a crucial role. In stents, for example, these alloys allow for less invasive procedures by enabling them to be delivered in a compact form and then expanding once they reach the target site. This adaptability not only enhances patient comfort but also reduces recovery time significantly.

Enhancements in Stents and Surgical Tools

The incorporation of SMA actuators into stent design has led to remarkable advancements in vascular treatments. Traditional stents often require larger incisions or more invasive procedures; however, with the use of SMAs, these devices can be deployed through smaller access points while still providing excellent support once implanted. The ability of shape memory alloys to conform precisely to vessel walls ensures optimal blood flow restoration while minimizing tissue damage.

In addition to stents, surgical tools equipped with SMA technology offer surgeons unprecedented control during procedures. Tools like forceps or clamps made from SMAs can change shape or stiffness based on temperature variations controlled by the surgeon's instruments or even body heat itself during surgery. This innovation not only enhances precision but also allows for more delicate manipulations within sensitive areas.

GEE SMA in Healthcare Innovations

GEE SMA is at the forefront of developing cutting-edge applications utilizing shape memory actuator technology within healthcare innovations. By focusing on improving the manufacturing processes and material properties of SMAs, GEE SMA is enhancing device performance across various medical fields—from cardiology to orthopedics. Their commitment ensures that healthcare providers have access to advanced solutions that improve patient outcomes and streamline surgical procedures.

Moreover, GEE SMA's research into new alloy compositions continues to push boundaries within this sector by creating stronger yet lighter materials ideal for long-term implants or dynamic surgical tools. As they collaborate with leading medical institutions and engineers, GEE SMA is paving the way for breakthroughs that could redefine how we approach treatment methodologies using smart materials like SMAs.

With continued investment in R&D focused on integrating SMA actuators into next-generation medical devices, GEE SMA exemplifies how innovation can lead us toward a healthier future filled with smarter solutions tailored specifically for patients' needs.

The Future of Smart Materials

The future of smart materials, particularly in the realm of shape memory actuators (SMAs), is poised for exciting advancements. As industries continue to explore the unique capabilities of these materials, new applications and innovations are emerging that promise to reshape our understanding of technology. With a focus on sustainability and efficiency, SMA technology is set to play an integral role in various sectors.

Upcoming Trends in SMA Technology

One prominent trend in SMA technology is the integration of artificial intelligence (AI) with shape memory actuators. By leveraging AI algorithms, SMA actuators can be programmed to respond more intelligently to environmental changes, improving their efficiency and adaptability. Furthermore, researchers are exploring hybrid systems that combine SMAs with other smart materials for enhanced performance and functionality.

Another trend gaining traction is miniaturization; as devices become smaller and more compact, so too must the components that power them. Shape memory actuators are being designed at micro and nano scales, enabling their use in applications ranging from medical devices to intricate robotic systems. This miniaturization not only increases design flexibility but also opens up new avenues for innovation across multiple industries.

Lastly, sustainability is becoming a crucial consideration in the development of SMA technology. Manufacturers are increasingly focusing on eco-friendly materials and processes while optimizing energy consumption within SMA actuators. This shift toward sustainable practices will not only benefit the environment but also enhance the marketability of products utilizing these advanced technologies.

Challenges and Solutions in Development

Despite the promising future of shape memory actuators, several challenges remain that need addressing to fully realize their potential. One major hurdle is ensuring consistent performance under varying environmental conditions; fluctuations in temperature or humidity can affect the reliability of SMA actuators significantly. Ongoing research aims to develop more robust SMAs capable of maintaining performance across a broader range of conditions.

Another challenge lies in material fatigue; repeated cycling can lead to degradation over time, impacting actuator lifespan and reliability. To combat this issue, scientists are investigating novel alloy compositions that exhibit improved fatigue resistance without sacrificing functionality or responsiveness. By enhancing durability through innovative material science approaches, manufacturers can ensure longer-lasting shape memory actuators.

Finally, cost remains a critical factor for widespread adoption; while Nitinol offers exceptional properties for SMAs, its production can be expensive compared to traditional materials. To overcome this barrier, companies like GEE SMA are working on refining manufacturing processes and exploring alternative materials that maintain high performance while reducing costs significantly. These efforts will be essential for making SMAs accessible across diverse markets.

The Role of GEE SMA in Future Innovations

GEE SMA stands out as a key player driving forward innovations within the field of shape memory actuators (SMAs). Their commitment to advancing Nitinol production techniques has positioned them at the forefront of this technology's evolution—ensuring high-quality materials are readily available for various applications. Through continuous research and development efforts focused on enhancing actuator performance and reducing costs, GEE SMA plays an integral role in shaping future advancements.

Moreover, GEE SMA's collaboration with industry leaders fosters a dynamic exchange of ideas aimed at overcoming current challenges facing SMAs today—such as material fatigue or inconsistent performance under extreme conditions. By partnering with experts from diverse fields including aerospace engineering and healthcare technologies, they contribute valuable insights towards creating next-generation solutions using shape memory actuators effectively.

In conclusion, GEE SMA’s unwavering dedication ensures they remain pivotal players as we venture into uncharted territory within smart material development—unlocking new possibilities that could revolutionize industries worldwide through innovative applications powered by advanced SMAs.

Conclusion

The world of technology is ever-evolving, and shape memory actuators (SMAs) are at the forefront of this transformation. These remarkable devices are not just a novelty; they are revolutionizing industries by introducing innovative solutions that enhance functionality and efficiency. From aerospace to medical applications, SMA actuators are proving that smart materials can change the way we design and implement systems.

Transforming Industries with SMA Actuators

SMA actuators have become indispensable in various sectors, driving advancements that were once thought impossible. In aerospace, for instance, these actuators enable precise control mechanisms that can withstand extreme conditions while maintaining reliability. Meanwhile, in robotics, SMA technology is paving the way for more adaptive machines capable of performing complex tasks with ease.

The versatility of SMA actuators allows them to be integrated into a wide range of applications—from small-scale devices to large machinery—thereby transforming how industries operate. As companies continue to explore the potential of these smart materials, we can expect even greater innovations on the horizon. The ability to harness the unique properties of shape memory alloys will undoubtedly lead to breakthroughs that redefine industry standards.

The Critical Impact of Nitinol Technology

At the heart of many successful SMA actuator designs lies Nitinol—a unique alloy known for its exceptional properties such as superelasticity and shape memory effect. The critical impact of Nitinol technology cannot be overstated; it serves as a foundation for creating highly efficient and reliable actuation systems across various fields. By leveraging Nitinol's capabilities, engineers can develop solutions that enhance performance while minimizing weight and size.

Moreover, Nitinol’s biocompatibility opens new avenues in medical applications where precision is paramount. This has led to significant improvements in devices like stents and surgical tools that require exact movements within delicate environments. As researchers continue to unlock the potential of Nitinol technology, its influence on future innovations is set to expand even further.

Pioneering a New Era of Smart Materials

The integration of SMA actuators into modern technologies marks the beginning of a new era characterized by intelligent design and functionality. With ongoing research focused on enhancing performance and addressing challenges in development, we are on the brink of discovering even more sophisticated smart materials tailored for specific applications. Companies like GEE SMA are leading this charge by investing in advanced manufacturing processes that push the boundaries of what's possible with shape memory alloys.

As we look ahead, it's clear that SMA actuators will play an essential role in shaping our technological landscape—enabling smarter products that respond dynamically to their environments while offering unparalleled efficiency and adaptability. The future promises exciting developments as industries embrace this innovative approach to material science and engineering.