Introduction

In the ever-evolving landscape of engineering, the nitinol actuator revolution stands out as a game changer. This innovative technology harnesses the unique properties of nitinol—a nickel-titanium alloy—to create actuator mechanisms that are not only efficient but also remarkably versatile. As engineers seek to optimize performance and reduce costs, the appeal of low cost linear actuators becomes increasingly evident.

Discover the Nitinol Actuator Revolution

The nitinol actuator has emerged as a revolutionary force in modern engineering, captivating professionals across various industries. With its ability to change shape in response to temperature variations, this remarkable material introduces new possibilities for actuator mechanisms that were previously unimaginable. Whether it's a nitinol spring actuator or a linear actuator use in complex machinery, the adaptability of nitinol opens doors to innovative designs.

Unleashing Actuator Mechanisms in Engineering

Actuator mechanisms play a crucial role in transforming energy into motion, and nitinol actuators are at the forefront of this transformation. By integrating a linear actuator inside devices and systems, engineers can achieve unparalleled precision and control while minimizing space requirements. The compact nature of these actuators allows for seamless integration into applications where traditional solutions may fall short.

Why Engineers Choose Nitinol Actuators

Engineers are increasingly leaning towards nitinol actuators due to their distinct advantages over conventional options. The combination of low maintenance requirements and resilience under extreme conditions makes these actuators an attractive choice for demanding applications. Furthermore, with reduced operational costs associated with low cost linear actuators, it's no wonder that more projects are embracing the application of linear actuators powered by this cutting-edge technology.

Unique Properties of Nitinol Actuators

Nitinol actuators have carved a niche for themselves in the actuator mechanism landscape, thanks to their unique properties that set them apart from traditional options. Their ability to harness thermal energy for movement not only enhances efficiency but also opens doors to innovative applications across various industries. In this section, we will explore the thermally activated movement of nitinol actuators, delve into the fascinating shape memory effect, and highlight the advantages they offer over conventional actuators.

Thermally Activated Movement

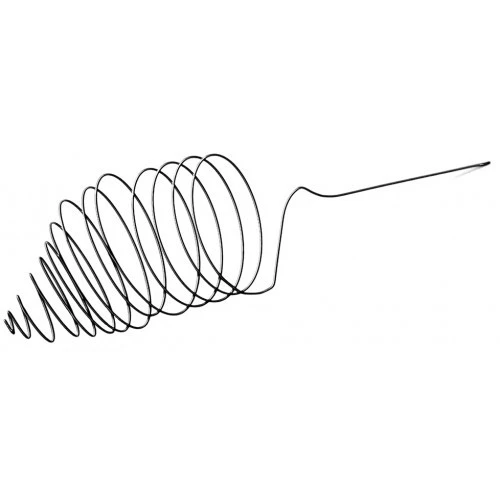

The magic of a nitinol actuator lies in its thermally activated movement, which allows it to change shape and exert force in response to temperature variations. When heated above a certain transition temperature, a nitinol spring actuator can transform from a deformed state back into its original shape, generating motion that can be harnessed for various applications. This feature makes linear actuator use particularly appealing in environments where precise control and responsiveness are essential.

By utilizing thermal energy as the driving force behind movement, nitinol actuators eliminate the need for complex mechanical systems found in traditional actuators. This simplicity not only reduces potential points of failure but also streamlines design processes — making it easier for engineers to integrate these devices into their projects. The result is an effective low cost linear actuator that delivers reliable performance while minimizing maintenance concerns.

Shape Memory Effect Explained

At the heart of every nitinol actuator is the remarkable shape memory effect (SME), which allows these devices to remember their original form even after being deformed under stress or heat. This phenomenon occurs due to specific crystalline structures within nitinol that enable it to revert back when subjected to temperature changes. Understanding this effect is crucial for engineers who wish to exploit its potential in applications ranging from medical devices to robotics.

When designing a linear actuator inside any system, engineers can leverage SME by programming specific temperature thresholds that trigger desired movements or actions at predetermined times or conditions. This level of control makes nitinol actuators an attractive choice for applications requiring precision and reliability without bulky mechanisms or intricate controls typically found in conventional solutions. Thus, embracing this technology means reaping benefits from both innovation and efficiency.

Advantages Over Traditional Actuators

Nitinol actuators offer several advantages over traditional actuator mechanisms that make them highly desirable across diverse fields of application. First and foremost is their compact design; unlike many conventional alternatives that require extensive space for operation and installation, a linear actuator based on nitinol can fit seamlessly into tight spaces without sacrificing performance or functionality. This space-saving quality proves invaluable when considering modern engineering demands where efficiency is key.

Additionally, nitinol spring actuators boast impressive durability compared with standard options; they can withstand extreme conditions such as high temperatures or corrosive environments without compromising integrity or performance longevity—making them perfect candidates for challenging industrial settings as well as delicate medical devices alike! Coupled with lower operational costs associated with reduced maintenance requirements due to fewer moving parts; it's clear why many engineers are opting for this innovative solution over outdated technologies.

Durability and Longevity

When it comes to actuator mechanisms, durability and longevity are paramount, especially in demanding environments. Nitinol actuators shine in this department, boasting impressive resilience that allows them to thrive under extreme conditions. With their ability to withstand temperature fluctuations, corrosion, and fatigue, nitinol actuator technology proves itself as a reliable choice for engineers seeking long-lasting solutions.

Resilience in Extreme Conditions

Nitinol actuators are engineered to perform admirably even when faced with extreme temperatures and harsh environments. Their unique shape memory effect allows them to return to their original form after deformation, making them ideal for applications where traditional materials might fail. Whether it's the heat of a medical device or the cold of an aerospace application, a nitinol spring actuator stands strong against the elements.

Low Maintenance Requirements

One of the standout features of nitinol actuators is their low maintenance requirements compared to other actuator options. The inherent properties of nitinol minimize wear and tear over time, meaning engineers can spend less time on upkeep and more on innovation. This characteristic not only enhances operational efficiency but also reduces downtime—an invaluable trait for any linear actuator use.

Comparison with Other Actuator Options

When comparing nitinol actuators with conventional alternatives like electric or pneumatic systems, it’s clear why many engineers opt for this low cost linear actuator solution. Traditional actuators often require regular maintenance and can be susceptible to environmental factors that compromise performance over time. In contrast, the robustness of a linear actuator made from nitinol ensures that it remains functional longer without frequent repairs or replacements—truly a win-win scenario for engineering projects.

Compact Design and Space Efficiency

In the world of engineering, space is often at a premium. This is where the nitinol actuator shines, offering a compact design that outperforms conventional solutions in various applications. With its unique properties and efficient actuator mechanisms, the nitinol spring actuator provides engineers with an opportunity to optimize designs without sacrificing performance.

Nitinol Springs vs. Conventional Solutions

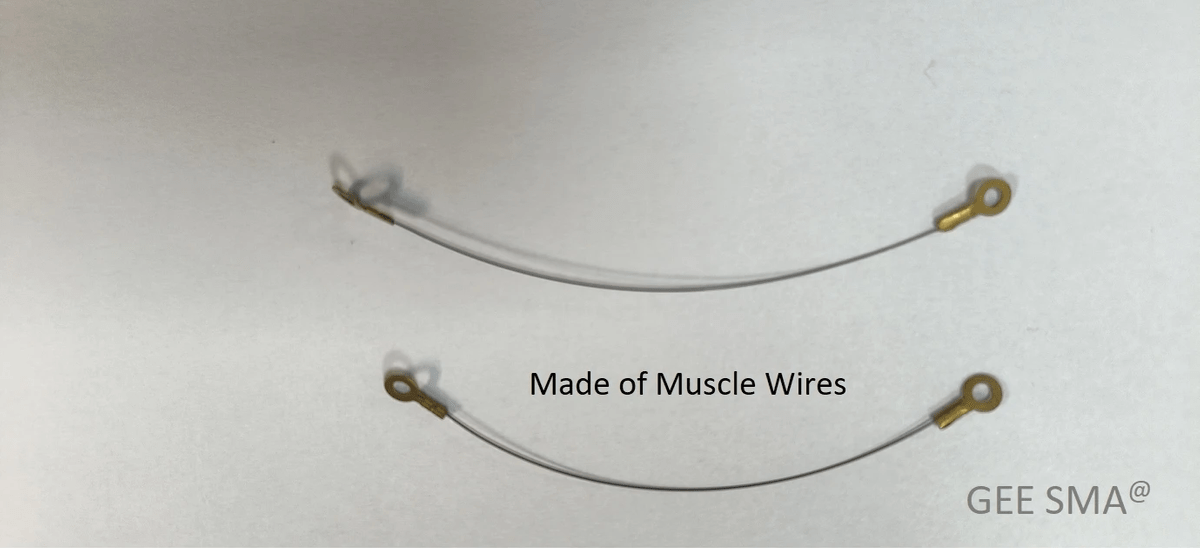

When comparing nitinol springs to traditional actuator options, the advantages become glaringly apparent. Nitinol actuators are not only smaller but also lighter than their conventional counterparts, allowing for innovative designs that were once thought impossible. The shape memory effect inherent in nitinol means these springs can return to their original form after deformation, making them a reliable choice in compact applications where space is limited.

Space-Saving in Engineering Applications

The application of linear actuators has never been more critical than in today’s engineering landscape, especially when it comes to saving space. The low cost linear actuator design allows for integration into tight spots where traditional actuators would struggle or simply fail to fit. By utilizing a linear actuator inside devices like medical equipment or robotics, engineers can maximize functionality while minimizing footprint—an essential balance in modern design.

The Role of Linear Actuator in Design

A linear actuator plays a pivotal role in various engineering applications by providing precise movement and control within confined spaces. With the use of nitinol actuators, designers benefit from enhanced efficiency and reduced size without compromising on power or reliability. This innovative approach not only improves overall design aesthetics but also allows for more creative solutions across multiple industries—making the nitinol spring actuator an indispensable tool for engineers aiming for excellence.

Cost Effectiveness

When it comes to engineering, the bottom line often reigns supreme. Nitinol actuators, particularly low cost linear actuators, are making waves in various industries by offering a unique blend of affordability and performance. By harnessing the remarkable properties of nitinol, engineers can achieve efficient actuator mechanisms that don’t break the bank.

Low Cost Linear Actuator Benefits

One of the standout features of low cost linear actuators is their ability to deliver significant functionality without hefty price tags. Unlike traditional actuator mechanisms that may require extensive maintenance or costly replacements, a nitinol spring actuator operates on simple principles that minimize complexity and expense. This not only streamlines production costs but also enhances accessibility for projects with tighter budgets.

Moreover, the integration of a linear actuator inside various devices means that engineers can optimize designs without worrying about inflated costs. The lightweight nature of nitinol allows for smaller and more efficient designs, which translates into lower shipping and handling expenses as well. In short, when you choose a nitinol actuator, you’re opting for a financially savvy solution that doesn’t compromise on quality or performance.

Reduced Operational Costs

Operational costs can quickly pile up in engineering projects if not managed effectively; however, nitinol actuators shine in this regard too. Thanks to their unique thermal activation capabilities, these actuators consume less energy during operation compared to conventional options—resulting in substantial savings over time. With reduced power requirements for activating a linear actuator, companies can enjoy lower electricity bills while still achieving optimal performance.

Additionally, the durability and longevity of nitinol spring actuators mean fewer replacements and repairs down the line. Engineers can rest easy knowing that their systems will run smoothly with minimal intervention required; this translates directly into reduced operational downtime and associated costs as well. By investing in a nitinol actuator system today, businesses are setting themselves up for ongoing savings tomorrow.

Economic Viability for Engineers

In an ever-competitive marketplace, economic viability is crucial for engineers looking to innovate while staying within budget constraints. The combination of low initial investment with long-term operational efficiency makes nitinol actuators incredibly appealing from an economic standpoint—especially when considering their diverse applications across numerous fields such as robotics or medical devices.

Furthermore, with increasing demand for compact design solutions—where space-saving measures are paramount—the versatile application of linear actuators becomes even more pertinent to modern engineering challenges today. As industries continue embracing new technologies like those offered by GEE SMA’s nitinol products; engineers will find themselves not only meeting project demands but also doing so economically and sustainably over time.

Versatile Applications

Nitinol actuators have carved a niche for themselves across various industries, showcasing their adaptability and innovative potential. Their unique properties not only enhance existing technologies but also pave the way for groundbreaking advancements. As engineers continue to explore the application of linear actuators in diverse fields, the possibilities seem endless.

Medical Devices Utilizing Nitinol Actuators

In the realm of medical devices, nitinol actuators are nothing short of revolutionary. From stents that expand within arteries to surgical tools that require precise movements, these low cost linear actuators play a crucial role in enhancing patient care and outcomes. The shape memory effect of nitinol springs allows for compact designs that can be easily integrated into devices requiring a linear actuator inside, ensuring functionality without compromising on space.

Moreover, the durability and biocompatibility of nitinol make it an ideal choice for long-term medical applications. Surgeons and engineers alike appreciate how these actuator mechanisms can respond dynamically to temperature changes in the human body, making them invaluable in minimally invasive procedures. As innovation continues to flourish in healthcare technology, it’s clear that nitinol actuators will remain at the forefront.

Robotics and Automation

Engineers are increasingly opting for this innovative technology due to its ability to deliver smooth movements with minimal energy consumption—an essential factor when designing systems that rely on a linear actuator for precise control. The compact nature of nitinol spring actuators allows designers to create smaller robots without sacrificing performance or reliability.

Furthermore, as industries embrace automation trends, integrating low cost linear actuator solutions becomes more feasible than ever before. These actuator mechanisms enable robots to perform complex tasks with ease while maintaining a lightweight structure—perfect for applications ranging from assembly lines to autonomous vehicles. With their responsive nature and adaptability, nitinol actuators are becoming indispensable components in modern robotics.

Innovative Fields Embracing Nitinol Technology

Beyond traditional applications, innovative fields are increasingly harnessing the power of nitinol technology for creative solutions. From aerospace engineering where weight savings are critical to consumer electronics aiming for sleek designs, the use of nitinol actuators is expanding rapidly across sectors seeking efficiency improvements through advanced materials like shape memory alloys (SMAs). The application of linear actuators is now being explored in smart textiles and wearable devices that require movement responsiveness without bulkiness.

Moreover, as sustainability becomes a priority globally, engineers are looking at how these low cost linear actuators can contribute by reducing energy consumption while enhancing performance across various systems. In this context, the durability and longevity offered by nitinol spring actuators ensure they remain functional even under challenging conditions—making them an attractive option for forward-thinking companies eager to innovate responsibly. The future looks bright as more industries adopt this transformative technology.

Conclusion

In the ever-evolving landscape of engineering, embracing nitinol actuators signifies a leap into innovative actuator mechanisms that push boundaries. The unique properties of these devices—such as their thermally activated movement and shape memory effect—offer engineers unparalleled advantages over traditional solutions. As industries increasingly recognize the benefits of nitinol technology, it becomes clear that these actuators are not just a trend but a cornerstone for future developments.

Embracing Nitinol Actuators for Innovation

Nitinol actuators are revolutionizing how we think about actuator mechanisms in various applications, from medical devices to robotics. Their compact design and low cost linear actuator options make them attractive for engineers looking to optimize space without sacrificing performance. By integrating a linear actuator inside their designs, engineers can create more efficient systems that respond dynamically to environmental changes.

The Future of Actuator Mechanisms in Engineering

The future of actuator mechanisms is bright with the integration of nitinol technology, paving the way for advancements previously thought impossible. As we explore new applications of linear actuators across diverse fields, the demand for reliable and durable solutions will only grow stronger. With ongoing research and development, nitinol springs are set to dominate markets by providing innovative solutions that meet both functional and economic needs.

GEE SMA: Leading the Nitinol Charge

At the forefront of this exciting revolution is GEE SMA, a company dedicated to advancing nitinol actuator technology and ensuring its widespread adoption across industries. Their commitment to developing low cost linear actuator options positions them as leaders in promoting efficient engineering solutions worldwide. By harnessing the power of nitinol spring actuators, GEE SMA is not only driving innovation but also shaping the future landscape of engineering.