Introduction

Nitinol springs are a fascinating innovation that combines the wonders of metallurgy with the principles of physics. These unique components are made from a nickel-titanium alloy, renowned for their ability to return to a predetermined shape when heated. This capability raises questions like What is so special about Nitinol? and highlights its significant potential in various industries.

Understanding Nitinol Springs

At their core, nitinol springs are shape memory alloys that can undergo drastic changes in form and function based on temperature variations. When subjected to heat, these springs can revert to their original shape after being deformed, making them incredibly versatile for applications requiring reliability and precision. However, while they offer impressive advantages, it's essential to consider What are the problems with Nitinol? as we explore their practical uses.

Key Advantages of Nitinol Technology

The benefits of nitinol technology extend beyond just its shape memory properties; it also boasts excellent corrosion resistance and biocompatibility, making it ideal for medical devices. Furthermore, nitinol springs can perform under extreme conditions without losing functionality—qualities that make them attractive for aerospace and automotive applications alike. Yet, despite these advantages, one might wonder: Why aren't nitinol engines used? The answer lies in cost and processing challenges that still need addressing.

Real-World Applications of Nitinol

From medical devices like stents and guidewires to innovative automotive suspension systems, the real-world applications of nitinol are vast and varied. In aerospace engineering, nitinol springs have proven invaluable for missions such as Chang’e-5 and Tianwen due to their resilience in extreme environments. Additionally, researchers continue to explore whether Can Nitinol be magnetized? which could open up even more exciting possibilities for future technologies.

Nitinol Springs in Medical Devices

Nitinol springs have revolutionized the medical device industry with their unique properties, particularly biocompatibility and shape memory capabilities. These characteristics make them ideal for various applications, from stents to orthopedic tools, allowing for advanced treatments that were previously unimaginable. As we dive deeper into the world of nitinol springs, it becomes clear why they are a game-changer in healthcare.

Biocompatibility and Safety

One of the most compelling reasons for using nitinol springs in medical devices is their exceptional biocompatibility. This means that when introduced into the human body, nitinol does not provoke an adverse immune response, making it a safe choice for implants and other medical applications. However, what is so special about Nitinol? Its ability to adapt to body temperature allows these springs to perform optimally without causing irritation or complications.

Despite these advantages, some concerns still linger regarding the long-term safety of nitinol-based devices. What are the problems with Nitinol? Issues such as corrosion resistance and potential nickel allergies must be addressed through rigorous testing and innovation. Ensuring patient safety remains paramount as researchers continue to explore solutions that enhance the reliability of nitinol springs in medical settings.

Applications in Stents and Guidewires

Nitinol springs play a pivotal role in modern stent technology by providing flexibility and strength where it's needed most. These stents can expand upon reaching body temperature, allowing them to fit snugly within blood vessels while maintaining blood flow effectively—an innovation that has saved countless lives. The use of nitinol guidewires further enhances this technology by enabling precise navigation through complex vascular structures.

The question often arises: Why aren't nitinol engines used? While they have excellent properties for specific applications like stents, their use as engines is limited due to challenges related to heat management and energy output efficiency. Nevertheless, when it comes to medical devices like stents and guidewires, nitinol's unique characteristics shine brightly.

Revolutionizing Orthopedic Tools

In orthopedics, nitinol springs are changing the landscape by offering innovative solutions for bone fixation devices and surgical instruments. The shape memory effect allows these tools to provide dynamic support while adapting seamlessly during surgical procedures—making surgeries less invasive and recovery times shorter. As we explore what is so special about Nitinol in this context, its ability to return to a predetermined shape after deformation stands out as a major advantage.

However, there are still challenges facing the widespread adoption of nitinol in orthopedic applications; specifically regarding costs and processing techniques—what are the problems with Nitinol? Manufacturers must navigate these hurdles while ensuring quality control remains intact throughout production processes. As research continues into enhancing both performance and affordability of nitinol tools, we can expect even more groundbreaking advancements in orthopedic care.

Nitinol Springs in Automotive Engineering

Nitinol springs are making waves in the automotive industry, offering innovative solutions that enhance performance and durability. The unique properties of this shape memory alloy allow it to adapt under varying conditions, making it a game-changer for vehicle components. As manufacturers seek ways to improve efficiency and reduce weight, nitinol springs are emerging as a compelling alternative.

Enhancing Performance and Durability

What is so special about Nitinol? Primarily, its ability to return to a predetermined shape when heated makes it an excellent choice for applications requiring resilience and adaptability. This characteristic not only enhances the performance of automotive components but also increases their durability by minimizing wear and tear over time. Additionally, nitinol springs can absorb shocks effectively, which contributes to a smoother ride while extending the lifespan of various parts.

However, it's essential to acknowledge some challenges associated with nitinol technology. What are the problems with Nitinol? The material can be sensitive to temperature fluctuations and may require precise engineering to function optimally in different environments. Despite these hurdles, the advantages of using nitinol springs far outweigh the drawbacks when properly implemented.

Applications in Active Suspension Systems

One of the most exciting applications of nitinol springs lies in active suspension systems that adjust dynamically based on road conditions. By integrating these smart materials into suspension design, vehicles can achieve enhanced handling and improved ride quality. This innovation not only provides drivers with a more comfortable experience but also optimizes vehicle stability during sharp turns or sudden stops.

Moreover, incorporating nitinol into these systems allows for significant weight reductions compared to traditional metal springs without sacrificing strength or reliability. As automotive engineers explore new possibilities for smart vehicle components, they increasingly turn towards what is so special about Nitinol—its ability to revolutionize how cars interact with their environment while maintaining performance standards.

The Future of Smart Vehicle Components

Looking ahead, we can expect an exciting future where nitinol plays a pivotal role in developing smart vehicle components that respond intuitively to driver needs and road conditions alike. Can Nitinol be magnetized? While not typically known for magnetic properties like other materials, ongoing research into its potential magnetic capabilities could open up new avenues for innovative applications in automotive engineering.

As manufacturers continue exploring why aren't Nitinol engines used more widely despite their benefits? It's primarily due to production costs and processing challenges that still need addressing before widespread adoption becomes feasible. Nevertheless, as technologies advance and costs decrease over time, we may soon see nitinol spring technology becoming standard across various automotive sectors.

The Role of Nitinol in Aerospace

Nitinol springs are rapidly becoming a game-changer in the aerospace industry, thanks to their unique properties and versatility. These shape memory alloys have found their way into various applications, particularly in space missions where reliability and performance are paramount. With their ability to return to a predetermined shape when heated, nitinol springs offer innovative solutions for complex aerospace challenges.

Nitinol Springs in Space Missions

In the realm of space exploration, every component must withstand extreme conditions while maintaining functionality. Nitinol springs excel in this environment due to their resilience against temperature fluctuations and mechanical stress. What is so special about nitinol? Its unique ability to adapt under varying thermal conditions makes it ideal for applications such as deployable structures and actuators that require precise movement without the risk of failure.

Moreover, the lightweight nature of nitinol springs contributes significantly to reducing the overall mass of spacecraft, which is crucial for fuel efficiency during launches. As engineers strive for more efficient designs, integrating nitinol technology can lead to breakthroughs that enhance mission success rates. With ongoing research into its properties, we may soon see even broader applications of nitinol springs in future space missions.

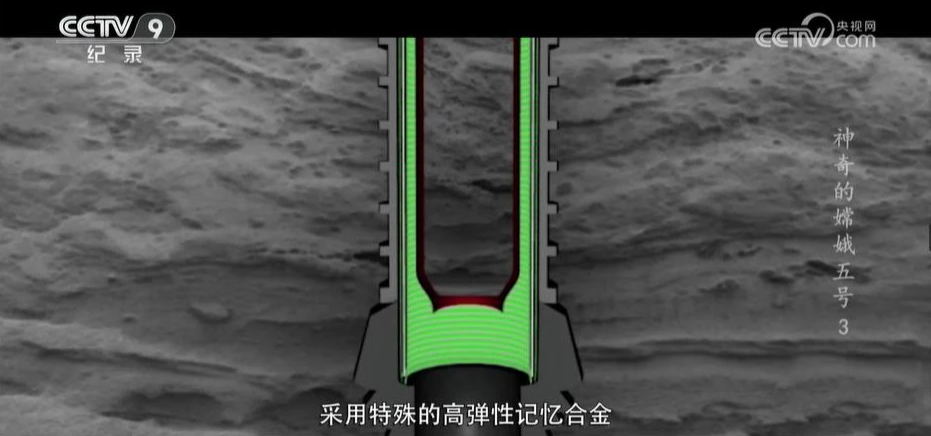

Case Study: Chang’e-5 and Tianwen Missions

The Chang’e-5 lunar mission and Tianwen Mars mission serve as prime examples of how nitinol technology is making an impact on space exploration. In both missions, specialized components made from nitinol were utilized to ensure optimal performance under harsh conditions encountered during launch and operation phases. For instance, these missions employed nitinol springs in mechanisms designed for sample collection and deployment systems.

These real-world applications highlight not only the effectiveness but also the reliability of using nitinol springs in critical aerospace functions. However, one might wonder: why aren't nitinol engines used? While there are promising developments in using this material for propulsion systems, challenges related to costs and processing still need addressing before widespread adoption can occur.

Benefits for Extreme Environment Applications

Nitinol’s exceptional properties shine brightly when it comes to extreme environments like those found in outer space or high-altitude flights. The alloy's inherent resistance to fatigue ensures longevity even under rigorous operational stresses that traditional materials might not withstand effectively. This durability translates into lower maintenance costs and increased safety—two essential factors when designing systems that operate far from human intervention.

Additionally, understanding what are the problems with nitinol helps engineers innovate further; issues like high production costs can be mitigated through advancements in manufacturing techniques or economies of scale as demand increases over time. Furthermore, research into whether can nitinol be magnetized opens up new avenues for enhancing its functionality beyond current capabilities—potentially enabling magnetic actuation systems that could revolutionize how we approach aerospace engineering challenges.

As we continue exploring these remarkable properties of nitinol springs within aerospace contexts, it's clear that they hold significant promise for future innovations that could redefine our approach to space exploration.

What is so special about Nitinol?

Nitinol, a unique alloy of nickel and titanium, stands out in the realm of materials science due to its remarkable properties. It is classified as a shape memory alloy (SMA), which means it can return to a predetermined shape when heated above a certain temperature. This exceptional characteristic makes nitinol springs an attractive choice for various applications, from medical devices to automotive engineering.

Unique Properties of Shape Memory Alloys

One of the most fascinating aspects of nitinol springs is their ability to remember their original shape after deformation. When subjected to stress at lower temperatures, these alloys can be bent or twisted without permanent damage; once heated, they revert back to their original form. This property not only enhances the performance of nitinol springs but also opens the door for innovative designs that were previously thought impossible.

In addition to their shape memory capability, nitinol exhibits superelasticity—allowing it to undergo significant deformation without permanent change at specific temperatures. This dual functionality presents exciting opportunities in engineering and medical fields alike. However, while exploring what is so special about Nitinol?, we must also consider its challenges and limitations.

Thermoelastic Behavior Explained

The thermoelastic behavior of nitinol springs is another key feature that sets them apart from traditional materials. When heated above a critical temperature (the transformation temperature), nitinol undergoes a phase change that allows it to exert force as it returns to its memorized shape. This unique response enables applications where precise movement and control are essential—such as in stents or guidewires used in minimally invasive surgeries.

Moreover, this thermoelastic behavior contributes significantly to energy efficiency in systems utilizing nitinol springs. The ability for these materials to perform mechanical work without needing external power sources makes them ideal candidates for various innovations across multiple industries. However, questions remain: What are the problems with Nitinol? Understanding these issues helps clarify both its potential and limitations.

Comparisons with Traditional Materials

When comparing nitinol springs with traditional materials like steel or aluminum, several distinct advantages emerge that highlight why researchers are excited about this alloy's future potential. For instance, while steel may be strong and durable, it lacks the unique properties associated with shape memory alloys such as Nitinol; thus making them less versatile in dynamic environments where adaptability matters most.

Additionally, traditional materials often require complex mechanisms for actuation or control; however, due largely to their inherent properties—Nitinol can achieve similar results more simply and efficiently through thermal activation alone! Despite these benefits though, one must ask: Why aren't Nitinol engines used? The answer lies partly within cost considerations but also involves ongoing research into optimizing performance further still.

Challenges and Limitations of Nitinol

While Nitinol springs have gained a reputation for their unique properties, they are not without challenges. The complexities associated with Nitinol can sometimes overshadow its remarkable capabilities. Understanding these challenges is essential for anyone considering the use of Nitinol in various applications.

What are the problems with Nitinol?

One of the main issues with Nitinol springs is their temperature sensitivity, which can lead to unpredictable behavior if not properly calibrated. This characteristic raises questions about reliability in critical applications, especially where precise performance is crucial. Additionally, the fatigue life of Nitinol can be a concern; repeated cycling may lead to degradation over time, prompting engineers to ask, What are the problems with Nitinol? when evaluating its long-term viability.

Costs and Processing Challenges

The production costs associated with Nitinol springs can be significantly higher than traditional materials due to complex manufacturing processes and raw material sourcing. This price tag often leads companies to hesitate when incorporating it into their designs, raising the question: Why aren't Nitinol engines used? Furthermore, processing challenges such as maintaining specific temperature ranges during fabrication can complicate production runs and lead to inconsistencies in quality.

Addressing the Myths Surrounding Nitinol

Despite its impressive properties, there are many misconceptions about what Nitinol can and cannot do. For instance, some people wonder if Can Nitinol be magnetized? The answer is nuanced; while it has magnetic properties under certain conditions, it's not inherently magnetic like other metals. By addressing these myths and providing clear information about what makes this material special—alongside its limitations—manufacturers can make more informed decisions regarding its use in innovative designs.

Exploring Nitinol's Magnetic Properties

Nitinol, known for its unique properties as a shape memory alloy, also presents intriguing magnetic characteristics that are worth exploring. While it is not inherently magnetic like iron or nickel, researchers have found ways to manipulate its magnetic behavior under certain conditions. This section delves into whether nitinol can be magnetized, its applications in magnetic actuation systems, and the exciting future research directions in this area.

Can Nitinol be magnetized?

The question of Can Nitinol be magnetized? is a fascinating one. Nitinol itself does not exhibit permanent magnetism; however, it can display some weak ferromagnetic properties when subjected to specific treatments or alloying with other elements. This characteristic opens up new avenues for utilizing nitinol springs in various applications where magnetic actuation might enhance performance.

While nitinol springs are primarily recognized for their shape memory and superelasticity, their potential for magnetization adds another layer of versatility. Researchers are keenly investigating how these properties can be optimized to create more efficient systems that leverage both the mechanical and magnetic capabilities of nitinol alloys. As we continue to explore what is so special about nitinol, the interplay between its thermal and magnetic behaviors will undoubtedly lead to innovative solutions across multiple industries.

Applications in Magnetic Actuation Systems

Magnetic actuation systems represent an exciting frontier where nitinol springs could play a pivotal role. The ability to combine the unique properties of nitinol with magnetic fields allows for precise control mechanisms that can enhance functionality in various devices. For instance, in robotics and automation, integrating nitinol springs into actuators could lead to lighter components that respond rapidly to external stimuli without requiring extensive energy input.

Moreover, these applications extend beyond just robotics; think about medical devices where controlled movement is crucial—imagine a stent that not only adapts its shape but also responds dynamically to changes in blood flow through magnetic signals! This potential opens discussions on why aren't nitinol engines used more broadly? The answer often lies in cost and processing challenges associated with developing such advanced technologies.

Future Research Directions

Looking ahead, the future research directions surrounding nitinol's magnetic properties are vast and promising. Scientists are focusing on improving the understanding of how different compositions affect both the mechanical and magnetic behaviors of nitinol springs. By creating tailored alloys or hybrid materials that enhance these attributes simultaneously, we could unlock new applications previously deemed impractical due to limitations inherent in traditional materials.

Additionally, addressing what are the problems with nitinol—such as cost efficiency and manufacturing scalability—will be critical as researchers push towards commercial viability for these advanced systems. Innovations could lead us toward smart materials capable of self-regulation based on environmental changes through integrated magnetic responses—a true game changer across multiple sectors from aerospace to automotive engineering!

Conclusion

In wrapping up our exploration of Nitinol technologies, it’s clear that the future holds exciting possibilities for this remarkable material. With its unique properties, Nitinol springs are poised to revolutionize various industries, from medicine to aerospace. As we continue to innovate and address existing challenges, the full potential of Nitinol will undoubtedly be realized.

The Bright Future of Nitinol Technologies

The future of Nitinol technologies looks promising, especially as research progresses in understanding What is so special about Nitinol? Its shape memory and superelastic properties make it an ideal candidate for applications that require resilience and adaptability. Moreover, advancements in manufacturing techniques may help overcome current limitations and pave the way for broader adoption across different sectors.

Key Takeaways on Nitinol Springs

Nitinol springs stand out due to their unique characteristics that offer solutions where traditional materials may fall short. However, it's essential to consider What are the problems with Nitinol? such as high costs and processing challenges that can hinder widespread use. Despite these hurdles, the versatility of Nitinol springs makes them invaluable in medical devices, automotive engineering, and aerospace applications.

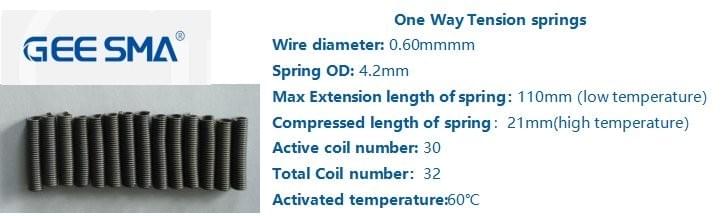

GEE SMA's Contributions to Innovation

GEE SMA has made significant strides in advancing Nitinol technology by focusing on innovative applications while addressing common concerns like Can Nitinol be magnetized? Their commitment to research not only helps tackle existing challenges but also explores new frontiers such as integrating nitinol engines into modern machinery—though one might wonder: Why aren't nitinol engines used? The answer lies in ongoing research and development aimed at maximizing efficiency while minimizing costs.