Introduction

In the realm of cutting-edge technology, few innovations have captured the imagination quite like Nitinol actuators. These extraordinary devices, powered by Nitinol wire, are revolutionizing various industries with their unique properties and capabilities. The magic of Nitinol Muscle Wire lies not just in its ability to create motion but also in how it transforms conventional mechanisms into responsive and efficient systems.

The Magic of Nitinol Actuators

Nitinol actuators harness the remarkable characteristics of Nitinol wire, a nickel-titanium alloy known for its shape memory and superelasticity. When subjected to heat, this innovative material can return to a predetermined shape, allowing it to perform tasks that traditional materials simply cannot achieve. The enchantment of Nitinol Muscle Wire is evident in applications ranging from robotics to medical devices, where precise movements are essential.

How Nitinol Wire Changes the Game

The introduction of Nitinol wire has fundamentally changed the game in actuator technology. Unlike conventional motors or servos that require complex gearing systems, Nitinol linear actuators offer a simpler yet highly effective solution for generating motion. This efficiency not only simplifies design but also enhances performance across various applications, making it a favorite among engineers and designers alike.

The Importance of Smooth Adjustments

Smooth adjustments are crucial in any mechanism that relies on precision movement, and this is where Nitinol actuator wire truly shines. Its ability to provide gradual and controlled motions allows for seamless transitions between states—whether it's opening a valve or adjusting an orthopedic implant. This level of finesse ensures that devices function optimally while minimizing wear and tear, ultimately leading to longer-lasting solutions.

Understanding Nitinol Linear Actuators

Nitinol linear actuators are a fascinating blend of materials science and engineering that have revolutionized how we think about motion. At the heart of these devices is Nitinol muscle wire, a unique alloy that exhibits shape memory properties, allowing it to return to a predetermined shape when heated. This remarkable ability makes Nitinol wire an ideal candidate for applications requiring precise movement and control.

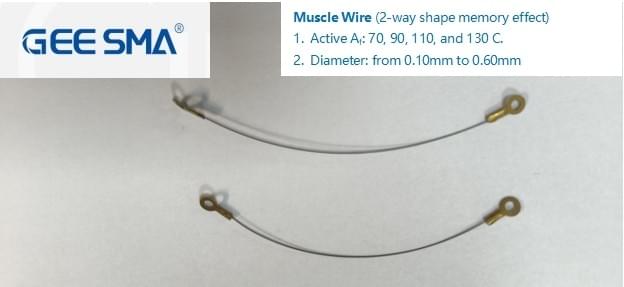

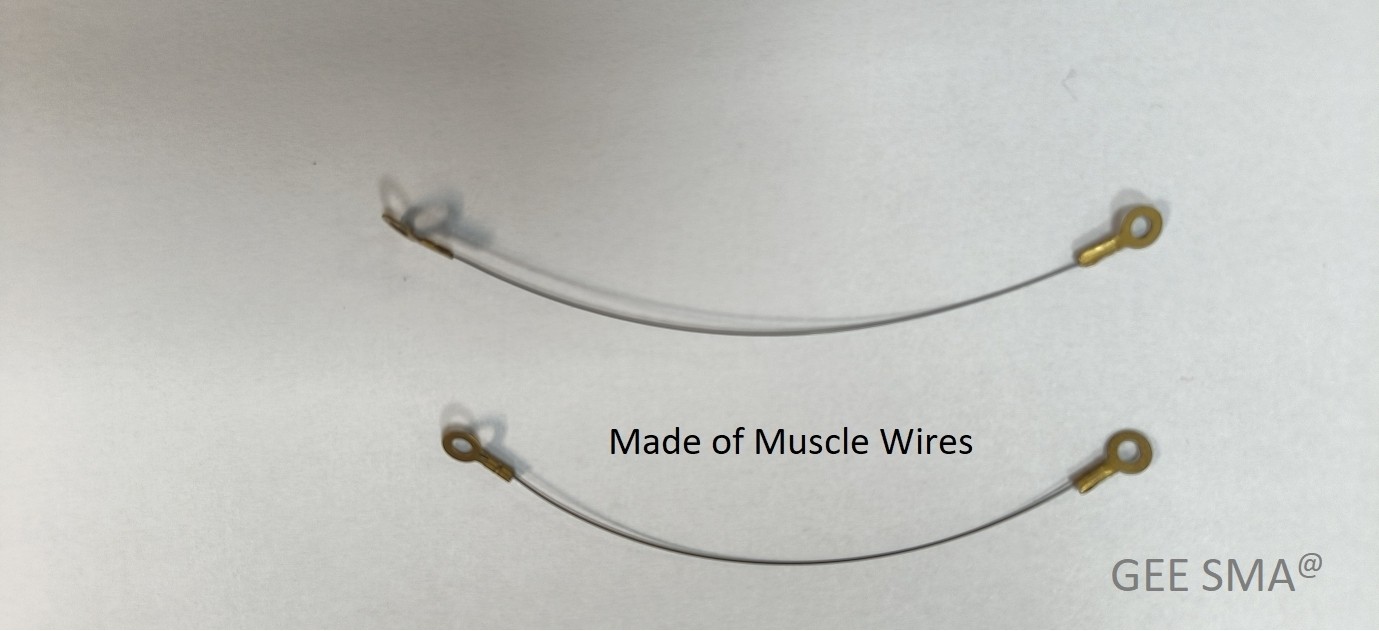

What is Nitinol Muscle Wire

Nitinol muscle wire is a specific type of Nitinol actuator wire known for its exceptional flexibility and strength. Composed primarily of nickel and titanium, this wire can undergo significant deformation while retaining its ability to return to its original form upon activation. Its lightweight nature combined with high tensile strength makes it a popular choice in various applications, from robotics to medical devices.

The versatility of Nitinol muscle wire stems from its unique phase transformation properties, which allow it to operate efficiently under varying conditions. When heated, the wire contracts dramatically; when cooled, it relaxes back into its original state. This dynamic behavior enables designers to create intricate mechanisms that can perform complex tasks with minimal energy consumption.

The Science Behind Nitinol Memory Wire

The science behind Nitinol memory wire lies in its crystalline structure, which changes between two phases: martensite and austenite. In the martensitic phase, the material is softer and more malleable, allowing it to be easily deformed into different shapes. Upon heating above a certain temperature threshold, the memory wire transitions into the stronger austenitic phase, regaining its pre-set shape—hence the term memory.

This transition not only provides mechanical advantages but also allows for highly efficient energy use in systems employing Nitinol linear actuators. The ability of Nitinol memory wire to remember shapes means that it can be used in applications where traditional actuators would require more complex mechanisms or additional components. This simplicity translates into lighter designs and reduced costs for engineers looking to innovate.

How Nitinol Wire Creates Motion

Nitinol wire creates motion through thermal activation; when electrical current passes through the wire or when it's subjected to heat, it contracts rapidly due to its transformation from martensite to austenite. This contraction generates force that can be harnessed for various mechanical movements—think of it as an invisible hand pulling or pushing components together! The beauty of this system lies in how quickly and efficiently these movements occur compared to conventional motors.

Moreover, once cooled down or disconnected from power sources, the Nitinol actuator returns smoothly back into its relaxed state without any need for complex control systems typically associated with electric motors. This characteristic is particularly advantageous in applications where energy efficiency is paramount or where space constraints limit design options—such as inside tiny robotic limbs or delicate medical instruments.

With each cycle of heating and cooling, designers can leverage the capabilities of both Nitinol muscle wires and memory wires effectively across diverse fields—from innovative robotics solutions all the way through advanced automotive systems seeking lightweight alternatives without sacrificing performance.

Applications of Nitinol Actuators

Nitinol actuators are making waves across various industries, showcasing their versatility and innovative potential. From robotics to medical devices and automotive advancements, the applications of Nitinol technology are vast and impactful. As we delve into these areas, it becomes clear that nitinol wire is not just a novelty; it’s a transformative force in engineering.

Innovating Robotics with Nitinol Technology

In the realm of robotics, nitinol actuator wire is revolutionizing how machines interact with their environment. The unique properties of Nitinol Muscle Wire allow for lightweight, flexible designs that can mimic biological movements, enhancing robot agility and efficiency. This adaptability means robots can perform tasks more effectively in varied settings, from manufacturing floors to delicate surgical environments.

Moreover, the use of Nitinol memory wire in robotics introduces an element of responsiveness that traditional materials simply can't match. These actuators can return to their original shape after deformation, enabling robots to execute complex motions with precision and reliability. As robotic applications continue to expand—from drones to humanoid robots—the integration of nitinol linear actuators will undoubtedly play a pivotal role in shaping the future.

Medical Devices and Nitinol Solutions

The medical field has also embraced the advantages offered by nitinol solutions, particularly in devices requiring precise movement or actuation. With its biocompatibility and ability to operate under extreme conditions, Nitinol Muscle Wire is ideal for applications like stents or surgical instruments that need reliable performance inside the human body. The flexibility and strength provided by nitinol wire make these devices less invasive while improving patient outcomes.

Additionally, innovations such as self-expanding stents leverage the unique properties of nitinol memory wire to ensure optimal placement within arteries without requiring complex mechanical systems. This not only simplifies procedures but also reduces recovery times for patients—an essential factor in modern healthcare practices. As research continues into new uses for nitinol linear actuators in medical technology, we can expect even more groundbreaking advancements on the horizon.

Automotive Advancements Using Nitinol Actuators

In automotive engineering, nitinol actuator wire is paving the way for smarter vehicles that prioritize efficiency and performance. The lightweight nature of Nitinol Muscle Wire allows manufacturers to reduce overall vehicle weight while maintaining structural integrity—an essential aspect when striving for fuel efficiency and reduced emissions. This makes it an attractive option for both electric vehicles (EVs) and traditional combustion engines looking to enhance performance without sacrificing safety.

Furthermore, applications such as active suspension systems have benefited from incorporating nitinol wire technology; these systems adapt dynamically based on driving conditions or driver preferences using linear actuators made from this remarkable material. By providing real-time adjustments that improve ride comfort and handling stability, automakers are able to offer consumers a superior driving experience unlike any other on the market today. The future looks bright as more automotive innovations harness the power of nitinol solutions.

GEE SMA: A Leader in Nitinol Solutions

In the realm of Nitinol technology, GEE SMA stands out as a pioneering force. With a profound understanding of Nitinol actuator wire and its applications, the company has carved a niche for itself in various industries. Their innovative approach to utilizing Nitinol Muscle Wire has led to significant advancements that are transforming how we think about motion and control.

Overview of GEE SMA's Expertise

GEE SMA specializes in the development and application of Nitinol wire, focusing on its unique properties that allow for incredible flexibility and responsiveness. The team's expertise spans across various domains, including robotics, medical devices, and aerospace engineering, where they leverage the capabilities of Nitinol linear actuators to create groundbreaking solutions. By harnessing the power of Nitinol memory wire, GEE SMA is not just keeping pace with technological advancements; they are leading the charge.

Contributions to Space Missions

When it comes to space exploration, every component must perform flawlessly under extreme conditions—and this is where GEE SMA excels with their Nitinol actuator wire solutions. The company's contributions have been instrumental in developing mechanisms that operate efficiently in microgravity environments, ensuring reliability where it matters most. From deployable structures to precision control systems, their use of Nitinol Muscle Wire has enhanced mission capabilities beyond what was previously thought possible.

Customizing Nitinol Functional Materials

One of GEE SMA’s standout features is their ability to customize Nitinol functional materials tailored specifically to client needs. Whether it's adjusting the thermal properties or fine-tuning the mechanical performance of their Nitinol linear actuators, they provide bespoke solutions that meet diverse requirements across industries. This level of customization ensures that clients receive not just products but comprehensive solutions powered by advanced science—making them true innovators in the field.

The Advantages of Nitinol Linear Actuators

Nitinol linear actuators have carved a niche for themselves in various industries, thanks to their unique properties and capabilities. The versatility of Nitinol actuator wire allows for innovative designs that were previously unimaginable with traditional materials. From robotics to medical devices, the advantages offered by Nitinol Muscle Wire are reshaping how we approach mechanical movement.

Benefits of Nitinol Muscle Wire

One of the standout benefits of Nitinol Muscle Wire is its ability to remember shapes through thermal activation, a phenomenon known as the shape memory effect. When heated, this remarkable Nitinol wire can return to a predetermined shape, allowing for smooth and efficient motion without complex mechanisms. This capability not only simplifies design but also enhances reliability in applications where precise movement is crucial.

Moreover, the lightweight nature of Nitinol linear actuators makes them ideal for applications where weight reduction is essential—think aerospace or portable medical devices. The combination of strength and lightness found in Nitinol Muscle Wire translates into better performance without compromising structural integrity. Additionally, its resistance to corrosion ensures longevity and durability across various environments, making it a dependable choice for engineers.

Nitinol memory wire also provides excellent energy efficiency compared to conventional actuators. Its ability to convert thermal energy into mechanical work means that less power is required to achieve desired movements, which can be particularly beneficial in battery-operated devices. Consequently, this efficiency not only reduces operational costs but also extends the lifespan of products utilizing these advanced materials.

Efficiency and Reliability in Mechanisms

Nitinol actuators are redefining what we understand about efficiency and reliability in mechanical systems. These unique components, crafted from Nitinol wire, offer exceptional performance that can adapt to various environmental conditions. Whether in robotics, medical devices, or automotive applications, the versatility of Nitinol Muscle Wire proves invaluable.

Superior Performance in Diverse Environments

One of the standout features of Nitinol linear actuators is their ability to perform reliably across a wide range of temperatures and conditions. Unlike traditional materials that may falter under extreme stress, Nitinol wire maintains its integrity and functionality even when faced with harsh environments. This resilience is largely due to the inherent properties of Nitinol memory wire, which allows it to return to its original shape after deformation.

In practical terms, this means that devices utilizing Nitinol Muscle Wire can operate efficiently without frequent maintenance or replacement. For instance, in robotics applications where precision movement is crucial, the consistent performance of a Nitinol actuator wire ensures that tasks are completed smoothly and effectively. Additionally, the lightweight nature of these wires contributes to overall energy savings—an essential factor for industries striving for sustainability.

The adaptability of Nitinol actuators extends beyond just temperature; they also excel in varying humidity levels and corrosive environments. This makes them particularly appealing for use in medical devices exposed to bodily fluids or automotive parts subjected to rain and road salt. With their superior performance characteristics, it’s clear why engineers are increasingly turning to Nitinol Muscle Wire as a go-to solution for reliable mechanisms.

Future Trends in Nitinol Technology

As we look ahead, the future of Nitinol technology is bursting with potential. With innovations in smart technologies and sustainable solutions on the horizon, Nitinol actuator wire is poised to transform industries in ways we can only begin to imagine. The versatility of Nitinol Muscle Wire will continue to expand its applications, making it an exciting area for researchers and engineers alike.

Smart Technologies with Nitinol Wire

The integration of smart technologies into everyday devices is becoming increasingly prevalent, and Nitinol wire plays a crucial role in this trend. Imagine a world where your smartphone case can change shape based on temperature or where wearable health monitors can adjust their fit dynamically—this is the promise of Nitinol Muscle Wire. With its ability to respond to stimuli such as heat or electrical current, Nitinol memory wire offers unprecedented adaptability that could revolutionize personal electronics.

Moreover, the use of Nitinol linear actuators in robotics opens up new avenues for creating intelligent machines that mimic natural movements. These actuators can provide smooth and precise motion control, allowing robots to perform delicate tasks with ease. As we develop smarter technologies that rely on real-time data processing and feedback systems, the role of Nitinol wire will only grow more significant.

Potential Breakthroughs in Engineering

Engineering fields are always on the lookout for materials that provide both efficiency and reliability—and here comes our hero: Nitinol actuator wire! The unique properties of this alloy not only allow for compact designs but also enable engineers to create mechanisms that were previously thought impossible. As research progresses, we may witness breakthroughs that enhance structural integrity while reducing weight across various sectors.

Additionally, innovations involving shape memory effects could lead to self-healing materials or components capable of adapting under stress without permanent deformation. This would be particularly beneficial in aerospace engineering, where every ounce counts and reliability is paramount. The potential applications are vast; from bridges that can adjust their structure during earthquakes to vehicles that optimize aerodynamics based on driving conditions—Nitinol Muscle Wire could be at the heart of it all.

Nitinol Actuators in Sustainable Solutions

Sustainability is no longer just a buzzword; it’s an imperative driving innovation across industries—and guess who’s joining the party? That’s right—Nitinol actuator wire! Its energy-efficient performance means less power consumption while providing impressive actuation capabilities, making it an ideal candidate for green technologies.

In renewable energy systems like solar panels or wind turbines, using Nitinol linear actuators could enhance efficiency by enabling optimal positioning without excessive energy expenditure. Furthermore, these actuators can contribute significantly to smart grids by adjusting loads dynamically based on real-time data analysis—leading us toward a more sustainable future powered by responsive technology.

In conclusion, as we explore these future trends in Nitinol technology—from smart devices to engineering breakthroughs and sustainable solutions—the possibilities seem endless! The continued development and application of materials like Nitinol Muscle Wire will undoubtedly pave the way for innovative advancements across multiple sectors.

Conclusion

Nitinol actuators are revolutionizing various industries by providing innovative solutions that enhance functionality and efficiency. Their unique properties, such as shape memory and superelasticity, make Nitinol muscle wire an ideal choice for applications ranging from robotics to medical devices. As more sectors recognize the advantages of Nitinol wire, we can expect a wave of transformative technologies that leverage these remarkable materials.

Transforming Industries with Nitinol Actuators

The versatility of Nitinol linear actuators is reshaping how industries approach design and engineering challenges. From enabling precise movements in robotics to enhancing the performance of medical instruments, Nitinol actuator wire is at the forefront of innovation. With its ability to respond dynamically to temperature changes, Nitinol muscle wire opens up new possibilities for creating adaptive systems that can improve user experiences across various fields.

The Role of GEE SMA in Innovation

GEE SMA has established itself as a leader in the development and application of Nitinol technology, particularly in creating customized solutions tailored to specific needs. Their expertise in crafting high-quality Nitinol memory wire has made significant contributions to advancements in space missions and other high-stakes environments. By continuously pushing the boundaries of what’s possible with Nitinol actuator wire, GEE SMA is paving the way for future innovations that will further integrate these materials into everyday applications.

Looking Ahead: The Future of Nitinol Technology

The future holds exciting prospects for Nitinol technology as smart systems become increasingly prevalent across industries. Innovations involving Nitinol muscle wire could lead to breakthroughs in fields like sustainable engineering and energy-efficient designs, addressing pressing global challenges. As research continues and new applications emerge, it’s clear that Nitinol linear actuators will play a pivotal role in shaping our technological landscape for years to come.