Introduction

Nitinol, a remarkable alloy that combines nickel and titanium, has captured the imagination of scientists and engineers alike. Often referred to as a shape memory alloy, Nitinol exhibits unique properties that allow it to return to its original shape after deformation when exposed to heat. This fascinating material is not just a scientific curiosity; it has practical applications that touch our daily lives in ways we often overlook.

Discovering the Magic of Nitinol

The magic of Nitinol lies in its incredible versatility and transformative capabilities. From medical devices to innovative consumer products, Nitinol memory wire showcases the blend of science and creativity that can lead to groundbreaking advancements. As we delve deeper into its characteristics, you’ll discover how this extraordinary alloy can change shape, adapt, and perform in various environments.

The Science Behind Shape Memory Alloys

At the heart of Nitinol's functionality is its ability as a shape memory alloy, which allows it to undergo significant deformation while retaining its original form upon heating. This phenomenon occurs due to specific changes in the crystal structure of the material when subjected to temperature variations. By understanding Nitinol's chemical composition and how these elements interact, we can appreciate why this alloy is so special.

Applications of Nitinol in Everyday Life

The applications of Nitinol are vast and varied, permeating numerous industries from medicine to fashion technology. For instance, Nitinol staples are revolutionizing surgical procedures by providing superior flexibility and strength compared to traditional materials. Meanwhile, innovative uses like Nitinol fabric are paving new paths in wearable technology, demonstrating how this remarkable alloy continues to inspire ingenuity across different fields.

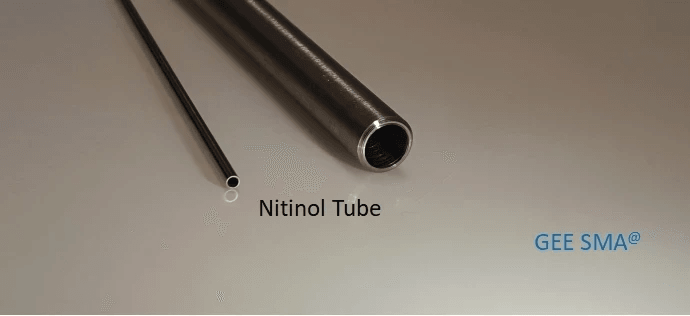

What is Nitinol Memory Wire?

Nitinol memory wire is a fascinating material that combines the unique properties of shape memory alloys with the versatility of wire form. This innovative wire can return to a predetermined shape when heated, making it an essential component in various applications ranging from medical devices to consumer products. Understanding its characteristics and functionality opens doors to endless possibilities.

Definition and Characteristics

Nitinol memory wire is primarily composed of nickel and titanium, forming a distinctive alloy known for its remarkable shape memory effect. When deformed at lower temperatures, this wire can regain its original shape upon heating, showcasing the magic of Nitinol’s chemical composition. Its flexibility and durability make it ideal for applications where traditional materials might fail under stress or strain.

How It Works: The Shape Memory Effect

The shape memory effect in Nitinol memory wire occurs due to a phase transformation within the alloy's crystal structure. When cooled below a certain temperature, the wire adopts a martensitic phase, allowing it to be easily deformed; however, once heated above its transformation temperature, it reverts to its original austenitic phase, restoring its initial shape. This fascinating process not only highlights the unique properties of Nitinol but also demonstrates why it's increasingly sought after in various industries.

Common Uses for Nitinol Memory Wire

Nitinol memory wire finds extensive use in diverse fields due to its exceptional properties. In medicine, it's commonly used for stents and guidewires because it can navigate complex anatomical structures while returning to its intended form once deployed. Beyond healthcare, this versatile wire is also utilized in robotics and actuators where precise movements are crucial—illustrating just how indispensable Nitinol has become across multiple sectors.

The Composition of Nitinol Chemical Composition

Nitinol, a fascinating shape memory alloy, is primarily composed of nickel and titanium. This unique combination gives it remarkable properties that distinguish it from other metals. Understanding the nitinol chemical composition is crucial for appreciating its diverse applications, from nitinol memory wire to nitinol fabric.

Key Elements in Nitinol

The two primary elements in nitinol are nickel and titanium, typically found in a ratio of approximately 50% nickel to 50% titanium by atomic percentage. This precise balance is what enables the material's shape memory effect, allowing it to return to a predetermined shape when heated above a certain temperature. The presence of these key elements also contributes to the alloy's corrosion resistance and biocompatibility, making it ideal for applications such as nitinol staples and nitinol mesh in medical devices.

How Composition Affects Performance

The performance characteristics of nitinol are heavily influenced by its chemical composition. Variations in the nickel-to-titanium ratio can lead to different transformation temperatures and mechanical properties, which are critical for specific uses like nitinol wire or nitinol memory wire applications. For instance, altering this ratio can enhance flexibility or strength based on the intended application—whether it's creating robust surgical tools or developing innovative wearable technology using nitinol fabric.

Advantages of Nitinol Over Other Alloys

Nitinol stands out among other alloys due to its unique combination of properties derived from its chemical composition. Unlike traditional metals that may bend or break under stress, nitinol exhibits exceptional elasticity and can return to its original shape after deformation—an attribute that is especially valuable in medical devices such as stents made from nitinol staples. Additionally, its biocompatibility allows for extended use within the human body without adverse reactions, making it a preferred choice over many other alloys used today.

Nitinol Wire vs. Nitinol Mesh

When it comes to Nitinol, a fascinating shape memory alloy, understanding the differences between Nitinol wire and Nitinol mesh is crucial for selecting the right material for your project. While both forms share the same remarkable properties of shape memory and superelasticity, their structures lend themselves to distinct applications. In this section, we’ll delve into how these two variants differ in terms of structure and function, particularly highlighting their unique roles in various fields.

Differences in Structure and Function

Nitinol wire is typically a solid strand that exhibits impressive flexibility and resilience, making it ideal for applications requiring bending or shaping without permanent deformation. On the other hand, Nitinol mesh consists of interwoven strands that create a porous structure, allowing for different mechanical properties such as increased surface area and reduced weight. This structural distinction means that while Nitinol wire excels in applications like orthodontics or robotics, where precision bending is essential, Nitinol mesh shines in scenarios requiring fluid movement or tissue integration.

The functionality of each also diverges significantly; Nitinol wire can return to its original shape after being deformed when heated above its transformation temperature—this is known as the shape memory effect. Conversely, the mesh structure allows for better integration with biological tissues due to its larger surface area and ability to accommodate bodily fluids or cells without obstruction. Thus, understanding these differences helps innovators choose whether they need the robust adaptability of Nitinol wire or the integrative benefits offered by Nitinol mesh.

Applications of Nitinol Mesh in Medicine

Nitinol mesh has carved out an impressive niche within medical applications due to its unique properties that facilitate healing and recovery processes. One prominent use is in stents; these tiny devices are placed within blood vessels to keep them open after blockages are cleared. The flexibility of Nitinol mesh allows it to conform seamlessly to varying vessel shapes while providing necessary support—a game changer compared to traditional rigid materials.

Another application lies in surgical implants where biocompatibility is paramount; thanks to its chemical composition that mimics natural tissue characteristics, patients experience fewer complications post-surgery with devices made from this alloy. Furthermore, researchers are exploring innovative uses such as drug delivery systems where the porous nature of Nitinol mesh could allow for controlled release mechanisms tailored specifically for patient needs—an exciting frontier indeed!

Why Choose Nitinol Mesh for Your Projects

Choosing between materials can be daunting but opting for Nitinol mesh offers several advantages that make it an attractive option across various projects—especially those involving medical devices or advanced engineering solutions like robotics. Its lightweight yet durable construction provides excellent strength-to-weight ratios while ensuring compatibility with biological systems—a must-have feature when designing implants or prosthetics.

Additionally, thanks to its unique shape memory capabilities combined with elasticity, projects utilizing this material can achieve remarkable performance under stress without compromising integrity over time—ideal for demanding environments! Lastly, if you’re on the hunt for innovative materials like nitinol staples or nitinol fabric but find yourself drawn toward something versatile yet specialized like nitinol mesh? Look no further; it's undeniably worth considering!

Nitinol Staples and Their Benefits

Nitinol staples are revolutionizing various industries with their unique properties derived from the fascinating world of shape memory alloys. These innovative fasteners, made primarily from Nitinol, offer a blend of strength and flexibility that traditional staples simply cannot match. From construction to medical applications, the versatility of Nitinol staples is reshaping how we think about fastening materials.

Industrial Applications of Nitinol Staples

In the industrial sector, Nitinol staples are making waves due to their remarkable resilience and adaptability. They can withstand extreme temperatures and stress without losing their shape or integrity, making them ideal for demanding environments like aerospace and automotive manufacturing. Additionally, the lightweight nature of Nitinol wire allows for easier handling and installation compared to heavier metal alternatives.

The use of Nitinol mesh in conjunction with these staples further enhances their utility by providing additional structural support where needed. This combination not only improves durability but also reduces the overall weight of assemblies in various applications. As industries increasingly seek efficient solutions, the demand for nitinol for sale continues to grow.

Advantages in Medical Devices

When it comes to medical devices, Nitinol staples shine brightly as a game-changer in surgical procedures. Their unique shape memory effect allows them to return to a predetermined shape when heated, which is particularly useful during surgeries that require precise fastening without damaging surrounding tissues. This characteristic makes them an excellent choice for suturing internal organs or securing implants.

Moreover, the biocompatibility of Nitinol ensures that these staples can be used safely within the human body without adverse reactions—a critical factor when developing medical devices. The reduced risk of infection associated with using nitinol mesh or staples further enhances their appeal in healthcare settings. With these advantages combined, it's clear why many surgeons are opting for nitinol over traditional materials.

Why Nitinol Staples Are a Game Changer

Nitinol staples represent a significant advancement over conventional fastening methods due to their ability to adapt under varying conditions while maintaining strength and reliability. Their innovative design not only streamlines manufacturing processes but also minimizes material waste—an essential consideration in today’s eco-conscious landscape. By integrating nitinol fabric technology into staple designs, manufacturers are finding new ways to push boundaries even further.

The future looks bright as more industries begin exploring the potential applications of these remarkable fasteners beyond current limits—think wearable technology that incorporates both nitinol wire and fabric! As research continues into optimizing nitinol's chemical composition for specific uses, we can expect even greater innovations on the horizon. With an increasing number of suppliers offering nitinol for sale, now is an exciting time to delve into this cutting-edge material.

Exploring Nitinol Fabric

Nitinol fabric is a fascinating innovation that combines the unique properties of shape memory alloys with textile technology. This material not only offers flexibility and durability but also responds to temperature changes, allowing it to return to a predetermined shape. The result is a fabric that can adapt and perform in ways traditional textiles simply cannot.

What Makes Nitinol Fabric Unique

What sets nitinol fabric apart from conventional materials is its incorporation of nitinol's shape memory effect, derived from its chemical composition of nickel and titanium. When subjected to heat or specific environmental conditions, this fabric can morph into different shapes or configurations, providing enhanced functionality. Additionally, the lightweight nature of nitinol wire woven into the fabric adds strength without compromising comfort.

Applications in Wearable Technology

The applications of nitinol fabric in wearable technology are both exciting and diverse. From smart clothing that adjusts to body temperature for optimal comfort to fitness gear that monitors physiological signals, nitinol's capabilities are being explored extensively. Moreover, integrating nitinol staples into these fabrics enhances their durability and performance, making them ideal for active lifestyles.

Future of Nitinol Fabric in Fashion

Looking ahead, the future of nitinol fabric in fashion appears bright and innovative. Designers are beginning to experiment with this remarkable material to create garments that not only look stunning but also offer practical benefits such as self-repairing features or adjustable fits. As more consumers seek functional yet stylish options, the demand for products incorporating nitinol memory wire will likely rise exponentially.

Conclusion

In summary, Nitinol memory wire stands out as a fascinating example of how science can create materials with unique properties that are both functional and innovative. Its ability to return to a predetermined shape when heated, thanks to the shape memory effect, makes it an invaluable resource across various industries. From medical devices to wearable technology, the applications of Nitinol wire are not just impressive; they're revolutionary.

Key Takeaways About Nitinol Memory Wire

Nitinol memory wire is a remarkable shape memory alloy that has captured the attention of engineers and designers alike. Its unique ability to remember shapes allows it to be used in everything from orthodontic devices to robotics, showcasing its versatility and reliability. Understanding its characteristics helps users harness its potential for creative solutions in their projects.

The Versatility of Nitinol Alloys

The versatility of Nitinol alloys extends beyond just memory wire; it encompasses various forms such as Nitinol mesh and staples, each serving distinct purposes in multiple fields. For instance, Nitinol fabric is making waves in wearable technology due to its lightweight and durable properties, while Nitinol staples revolutionize surgical procedures with their biocompatibility and strength. This adaptability makes Nitinol a go-to material for innovators looking for cutting-edge solutions.

Where to Find Nitinol for Sale

For those interested in incorporating these incredible materials into their projects or products, finding reliable sources for purchasing nitinol is essential. Many suppliers offer various forms of nitinol—be it wire, mesh, or fabric—catering to both industrial and personal needs. A simple online search can lead you to reputable vendors where nitinol is readily available for sale at competitive prices.