Introduction

Nitinol, a remarkable alloy composed primarily of nickel and titanium, has revolutionized various industries with its unique properties. This innovative material is best known for its ability to return to a predetermined shape when heated, making it an essential component in numerous applications, from medical devices to robotics. Understanding Nitinol and its applications provides insight into why this extraordinary material is gaining traction in both commercial and scientific fields.

Understanding Nitinol and Its Applications

Nitinol memory wire is a prime example of how advanced materials can transform our approach to engineering challenges. Its ability to undergo significant deformation while retaining the capacity to revert to its original shape opens up new possibilities for design and functionality. From stents that expand within arteries to actuators in robotic systems, the applications of Nitinol are as diverse as they are impactful.

The Marvels of Shape Memory Alloys

Shape memory alloys (SMAs) like Nitinol exhibit fascinating properties that set them apart from traditional metals. When subjected to temperature changes, these materials can remember their original shapes, allowing them to perform tasks that would be impossible with standard metal wires. The marvels of shape memory wire extend beyond mere novelty; they present practical solutions across various sectors by enhancing performance and reliability.

Why Nitinol Wire Matters

The significance of Nitinol wire lies not only in its unique properties but also in the potential it holds for future innovations. With applications ranging from medical devices—where super elastic Nitinol wire enhances patient outcomes—to industrial uses where flexibility is key, understanding Nitinol wire properties becomes crucial for engineers and designers alike. As we delve deeper into the world of NiTi wire, we uncover why investing in this technology—and understanding factors like Nitinol wire price—can lead to groundbreaking advancements.

What is Nitinol?

Nitinol, a remarkable alloy of nickel and titanium, stands out in the realm of materials science due to its unique properties and versatility. Often referred to as niti memory wire or Nitinol memory wire, this material exhibits both shape memory and superelastic capabilities, making it invaluable across various applications. Understanding its composition, history, and key properties provides insight into why Nitinol has become a staple in industries ranging from medical devices to robotics.

Composition of Nitinol

Nitinol is primarily composed of nickel (Ni) and titanium (Ti), typically in a ratio that ranges from 50% to 60% nickel by weight. This precise composition is crucial for the alloy's ability to undergo phase transformations that enable its unique shape memory characteristics. The combination of these two metals results in what we call NiTi wire, which can return to a predetermined shape when subjected to specific temperature conditions.

Historical Background of Nitinol

The discovery of Nitinol dates back to the early 1960s at the Naval Ordnance Laboratory in Maryland, where researchers were investigating new alloys for use in various applications. Its name comes from a blend of Nickel and Titanium, along with its place of discovery—Naval Ordnance Laboratory (NOL). Since then, Nitinol has evolved significantly; initially used for military applications, it now finds extensive use in medical devices like stents and guidewires due to its exceptional flexibility and resilience.

Key Properties of Nitinol Wire

One of the standout features of Nitinol wire is its ability to remember shapes—this is what makes it so popular as a shape memory wire. When deformed at lower temperatures, it can return to its original form upon heating above a certain transition temperature; this property is particularly useful in medical devices where precision is essential. Additionally, super elastic Nitinol wire exhibits remarkable flexibility without permanent deformation under stress, making it an ideal choice for dynamic applications requiring durability and reliability while maintaining lightweight characteristics.

How Shape Memory Works

When it comes to shape memory alloys, few materials can compete with the wonders of Nitinol. This unique alloy has the ability to return to a predetermined shape when subjected to specific temperatures, making it a fascinating subject of study and application. Understanding how this process works is key to appreciating the versatility and potential of Nitinol memory wire.

The Science Behind Shape Memory Alloys

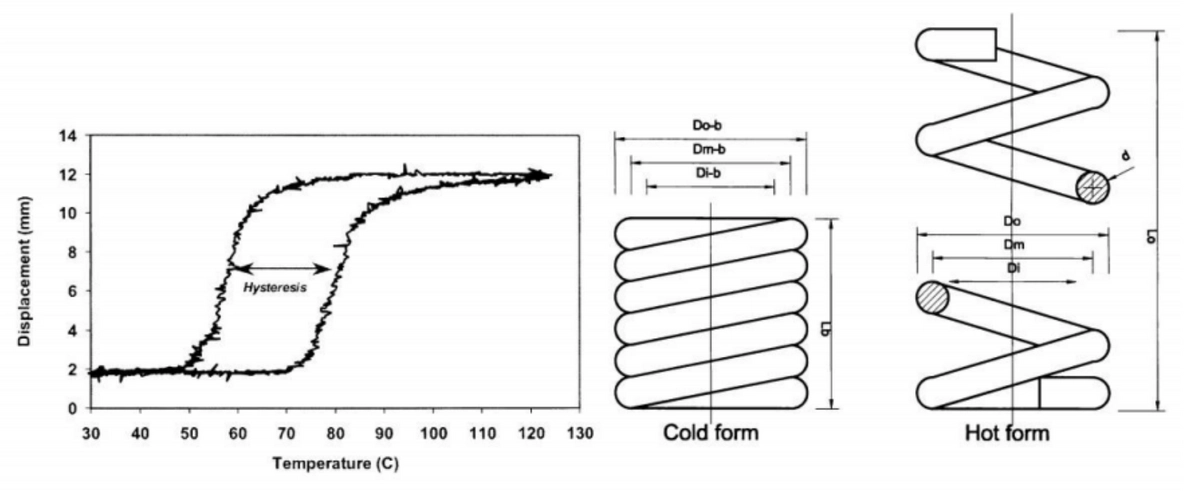

At its core, the science behind shape memory alloys (SMAs) like Nitinol hinges on their unique atomic structure and behavior under varying temperatures. When heated above a certain temperature, known as the transformation temperature, Nitinol undergoes a phase change that allows it to revert to its original form—this is what we call shape memory. Conversely, when cooled below this temperature, the material can be deformed into another shape; upon reheating, it will spring back to its designated form, showcasing remarkable elasticity and resilience.

The Nitinol wire properties that contribute to this phenomenon include its ability to exhibit both martensitic (low-temperature) and austenitic (high-temperature) phases. This dual-phase nature gives Nitinol its super elastic capabilities as well; in fact, super elastic Nitinol wire can stretch significantly without permanent deformation due to its unique crystalline structure. Thus, whether it's being used in medical devices or robotics, understanding these scientific principles is essential for harnessing the magic of NiTi wire.

Nitinol's Unique Phase Transition

One of the most captivating aspects of Nitinol is its phase transition between martensite and austenite forms. In simple terms, martensite is stable at lower temperatures and allows for easy deformation while maintaining strength; when heated beyond the transformation point, it shifts into an austenitic state where it regains its original configuration with impressive force. This transition isn't just an amusing party trick—it's what makes niti memory wire such an essential component in various industries.

The precise control over these phase changes enables engineers and designers to tailor applications based on desired performance characteristics. For instance, by adjusting alloy compositions or heat treatments during production processes like those offered by GEE SMA, manufacturers can customize properties such as recovery stress or transformation temperatures in their Nitinol products. As a result of these innovations in NiTi wire technology, we see expanded applications across fields ranging from aerospace engineering to minimally invasive surgery.

Applications of Nitinol Memory Wire

Nitinol memory wire has found an impressive array of applications due largely to its extraordinary properties stemming from shape memory effects and super elasticity. In medicine specifically, it's utilized in stents that expand upon reaching body temperature or guidewires that navigate through complex vascular pathways effortlessly—both demonstrating how critical this technology is for patient outcomes. Additionally, industries like robotics are leveraging niti memory wire for actuators that mimic muscle movements with unparalleled precision.

Moreover, as researchers continue exploring new avenues for utilizing this innovative material—such as self-healing structures or adaptive building designs—the potential applications seem limitless! The ongoing advancements promise not only improvements in existing technologies but also entirely new inventions that could redefine our interaction with machines and materials alike. With so much on the horizon for NiTi wire applications across diverse sectors—from automotive safety features to consumer electronics—the future looks bright indeed!

The Role of Super Elasticity

Super elastic Nitinol wire is a fascinating material that exhibits remarkable properties, making it a game-changer in various fields. Unlike traditional metals, super elastic Nitinol wire can undergo significant deformation and return to its original shape upon unloading, thanks to its unique phase transformation characteristics. This ability not only enhances performance but also opens doors for innovative applications in both medical and industrial settings.

What is Super Elastic Nitinol Wire?

Super elastic Nitinol wire is a specialized form of Nitinol that showcases extraordinary flexibility and resilience under stress. When subjected to strain, this NiTi wire can stretch considerably without permanent deformation, returning to its predetermined shape once the stress is removed. The secret behind this behavior lies in the material's unique composition and phase transitions between martensite and austenite forms—key features that define its exceptional Nitinol wire properties.

Benefits in Medical Devices

The benefits of super elastic Nitinol wire are particularly pronounced in the medical field, where precision and reliability are paramount. Devices such as stents and guidewires utilize Nitinol memory wire due to its ability to navigate complex anatomies while maintaining structural integrity. Moreover, the biocompatibility of super elastic NiTi wire ensures minimal adverse reactions within the human body, making it an ideal choice for long-term medical implants.

Industrial Applications of Super Elasticity

Beyond medicine, super elastic Nitinol wire finds numerous applications across various industries due to its remarkable versatility. In robotics and aerospace engineering, this Shape Memory Wire can be used for actuators that require lightweight yet strong materials capable of enduring extreme conditions without losing functionality. Additionally, industries focused on safety equipment benefit from the high fatigue resistance offered by super elastic NiTi wire, ensuring durability even under repetitive stress scenarios.

Choosing the Right Nitinol Wire Price

When it comes to selecting the right Nitinol wire for your projects, understanding the pricing landscape is crucial. The price of Nitinol wire can vary significantly based on a multitude of factors, influencing your budget and project feasibility. From specific applications to wire properties and supplier reputation, several elements contribute to determining the final cost of this remarkable material.

Factors Influencing Nitinol Wire Price

Several factors affect the price of Nitinol wire, including composition, diameter, and specific treatment processes used during manufacturing. For instance, Super elastic Nitinol wire often demands a premium due to its enhanced performance characteristics compared to standard options. Additionally, market demand and supply chain dynamics can lead to fluctuations in prices; therefore, staying informed about current trends is essential when considering NiTi wire for your projects.

Another key aspect influencing Nitinol memory wire pricing is the quantity being purchased. Bulk orders typically come at a lower per-unit price compared to smaller quantities; thus, planning ahead can yield significant savings. Furthermore, specialized applications may require unique formulations or treatments that could increase costs but ultimately provide better performance in demanding environments.

Lastly, supplier reputation plays a vital role in determining price points for Nitinol wires. Established manufacturers with proven track records may charge more due to their reliability and quality assurance processes; however, this often translates into superior product consistency and customer support—an investment worth considering for critical applications.

Comparing Nitinol Wire Options

When comparing different options for Shape Memory Wire or Nitinol memory wire, it's essential to evaluate not only the cost but also performance characteristics such as elasticity and shape recovery capabilities. Different suppliers may offer various grades of NiTi wire with distinct properties tailored for specific applications—ranging from medical devices to robotics—so it’s wise to assess these attributes alongside pricing structures.

Moreover, examining customer reviews and case studies can provide valuable insights into how well certain types of Super elastic Nitinol wire perform in real-world scenarios. This feedback helps gauge whether a higher-priced option truly delivers superior results or if more affordable alternatives meet your project requirements adequately. Remember that sometimes investing slightly more upfront can save you from costly failures later on.

Lastly, consider the long-term implications when choosing between different types of Nitinol wires; while initial costs are important, durability and longevity should also factor into your decision-making process. Selecting high-quality materials might mean paying more initially but could lead to reduced maintenance costs over time—a win-win situation!

Budgeting for Projects with NiTi Wire

Budgeting effectively for projects involving NiTi wire requires careful planning and consideration of all associated costs beyond just purchasing the material itself. It’s important to account for additional expenses such as tooling adjustments or specialized equipment needed when working with shape memory alloys like Super elastic Nitinol wire since they may require different handling techniques compared to traditional materials.

Furthermore, always leave room in your budget for unforeseen expenses that might arise during development phases—especially when experimenting with innovative applications using nitinol memory wire technology where outcomes can be unpredictable! Having contingency funds ensures you’re prepared should any unexpected challenges arise without derailing your entire project timeline.

Finally, take advantage of potential discounts by establishing long-term relationships with suppliers or negotiating bulk purchase agreements whenever feasible; every little bit helps! By strategically managing your finances while taking full advantage of available resources related specifically to nitrile memory wires’ unique properties will set you up for success in whatever venture you embark upon next.

GEE SMA: Leaders in Nitinol Production

When it comes to the world of Nitinol production, GEE SMA stands out as a pioneering force. Their expertise encompasses the intricate processes involved in creating high-quality NiTi wire that meets various industrial and medical needs. With a commitment to innovation, GEE SMA has positioned itself as a leader in the realm of shape memory alloys.

Overview of GEE SMA's Expertise

GEE SMA specializes in developing advanced Nitinol memory wire that showcases exceptional performance and reliability. Their team consists of seasoned professionals with extensive knowledge about Nitinol wire properties, ensuring that every product meets rigorous standards. By focusing on research and development, they continually refine their manufacturing techniques to produce super elastic Nitinol wire tailored for specific applications.

Applications of GEE SMA's Nitinol Alloys

The versatility of GEE SMA’s Nitinol alloys opens doors to numerous applications across various sectors. In the medical field, their niti memory wire is used in stents and guidewires, providing critical support during procedures while maintaining flexibility and strength. Beyond healthcare, industries such as aerospace and robotics benefit from the unique qualities of NiTi wire, utilizing it for components that require reliable shape memory effects.

Innovations in Nitinol Components

Innovation is at the heart of GEE SMA's mission, driving them to explore new frontiers within the realm of shape memory wires. They are constantly experimenting with different alloy compositions to enhance performance characteristics while keeping an eye on affordability—an essential factor when considering Nitinol wire price for large-scale projects. By integrating cutting-edge technology into their production processes, GEE SMA ensures that their products remain at the forefront of advancements in super elastic Nitinol wire applications.

Conclusion

In the ever-evolving landscape of technology, Nitinol stands out as a remarkable material with promising potential. Its unique properties, such as shape memory and super elasticity, make it an invaluable asset across various industries. As we look to the future, Nitinol memory wire is poised to revolutionize applications in medicine, robotics, and beyond.

The Future of Nitinol in Technology

The future of Nitinol in technology is bright and full of possibilities. With ongoing research and development, we can expect to see enhanced versions of Nitinol wire that offer improved functionality and efficiency. Innovations such as advanced NiTi wire formulations could lead to breakthroughs in minimally invasive surgical techniques and smart materials that adapt to user needs.

Advancements in Shape Memory Alloys

Advancements in shape memory alloys are paving the way for new applications that were previously thought impossible. Researchers are exploring ways to optimize the properties of Nitinol memory wire to create even more versatile products. These advancements will not only enhance existing technologies but also inspire entirely new fields where shape memory capabilities can be harnessed creatively.

Why You Should Consider Nitinol Wire

Considering the myriad benefits associated with Nitinol wire makes it an attractive choice for engineers and designers alike. Its exceptional properties—such as super elastic behavior and reliable shape recovery—make it ideal for a range of applications from medical devices to actuators in robotics. When evaluating options like Nitinol wire price versus performance, one quickly realizes that investing in this innovative material pays off through durability and versatility.