Introduction

Nitinol devices have revolutionized various industries with their unique properties and versatile applications. As a remarkable alloy of nickel and titanium, nitinol is not just a scientific curiosity; it’s a game changer in fields ranging from medicine to aerospace. Understanding what a nitinol device is, how it works, and its broad spectrum of uses can illuminate why this material has garnered so much attention.

Understanding Nitinol Devices

What is a nitinol device? At its core, a nitinol device is crafted from shape memory alloys that exhibit extraordinary behaviors under different temperatures. These devices leverage the unique characteristics of nitinol to perform functions that traditional materials simply cannot match, making them invaluable in modern technology.

The Science Behind Nitinol

The science behind nitinol lies in its distinctive properties, particularly the shape memory effect and superelasticity. When heated above a certain temperature, nitinol can return to its original shape after being deformed—a feature that makes it ideal for a variety of applications. This remarkable ability allows engineers and designers to create innovative solutions that adapt dynamically to their environments.

Exploring Nitinol Applications

Exploring what nitinol is mainly used for reveals an impressive range of applications across multiple sectors. From medical devices like stents and guidewires to industrial fasteners and aerospace components, the versatility of nitinol devices knows no bounds. As we delve deeper into specific uses, we will uncover how these remarkable materials are shaping the future across diverse industries.

What is a Nitinol Device?

Nitinol devices are fascinating innovations that leverage the unique properties of a specific alloy made of nickel and titanium. These devices have gained significant attention in various fields, particularly in medicine, due to their remarkable characteristics. But what exactly is a nitinol device? Let’s dive deeper into the world of nitinol alloys and their astounding capabilities.

Overview of Nitinol Alloys

Nitinol, an acronym for Nickel Titanium Naval Ordnance Laboratory, is an alloy renowned for its exceptional flexibility and resilience. Composed primarily of nickel and titanium, this alloy can undergo dramatic changes in shape when subjected to different temperatures or stress conditions. This versatility makes nitinol devices an essential component across multiple industries, from medical applications to aerospace innovations.

The composition of nitinol can vary slightly depending on the desired properties; typically, it contains approximately 55% nickel and 45% titanium. This precise balance allows for the unique qualities that define nitinol devices—namely their ability to return to a pre-defined shape after deformation. Understanding these alloys is crucial when exploring what nitinol is mainly used for.

Unique Properties of Nitinol

One of the most compelling features of nitinol devices is their unique combination of superelasticity and shape memory effect. Superelasticity allows these devices to endure significant deformation while still returning to their original form once the stress is removed. This property makes them ideal for applications requiring both strength and flexibility.

Additionally, nitinol exhibits high corrosion resistance, making it suitable for long-term use in challenging environments like the human body or extreme industrial settings. The ability to withstand harsh conditions without degrading enhances its appeal as a material choice in various applications—from stents in cardiology to fasteners in manufacturing processes.

Shape Memory Effect in Nitinol

The shape memory effect (SME) refers to the ability of certain materials—like those found in nitinol devices—to remember a predetermined shape when exposed to specific temperatures. When heated above a certain threshold known as the transformation temperature, these materials revert back to their original configuration after being deformed at lower temperatures.

This remarkable phenomenon enables innovative designs in medical devices where precision and reliability are paramount—think about how stents expand within arteries or how guidewires navigate through complex pathways during surgical procedures. The implications of SME extend beyond healthcare; they also find uses in robotics and aerospace technology where dynamic movement is essential.

In summary, understanding what constitutes a nitinol device involves appreciating its alloy composition, unique properties such as superelasticity and corrosion resistance, along with its extraordinary shape memory effect—all factors that contribute significantly to its varied applications across industries.

What is Nitinol Mainly Used For?

Nitinol, a unique alloy of nickel and titanium, has carved out a significant niche across various industries due to its remarkable properties. From medical applications to industrial uses and even aerospace innovations, the versatility of nitinol devices is truly impressive. This section delves into what nitinol is mainly used for, highlighting its impact in diverse fields.

Medical Applications of Nitinol

Nitinol devices have revolutionized the medical field with their exceptional biocompatibility and shape memory effect. One of the most prominent uses is in the creation of nitinol stents, which are vital for keeping arteries open after procedures like angioplasty. Additionally, nitinol guidewires are essential tools in various medical procedures, allowing for precise navigation through complex anatomy.

The benefits don’t stop there; nitinol also plays a crucial role in orthopedic implants due to its strength and flexibility. These medical devices with nitinol not only enhance patient outcomes but also reduce recovery times significantly. As healthcare continues to evolve, the demand for innovative solutions like these will likely grow, solidifying nitinol's place in medicine.

Industrial Uses of Nitinol

Beyond healthcare, what is nitinol mainly used for in industrial sectors? The answer lies in its unique mechanical properties that allow it to be utilized as fasteners and actuators across various applications. For instance, manufacturers leverage nitinol devices for their ability to return to a predetermined shape when exposed to specific temperatures—this makes them ideal for applications requiring reliable movement or fastening.

In addition to fasteners, nitinol's resilience makes it suitable for components that endure extreme conditions or require high precision. Industries ranging from robotics to consumer electronics benefit from this alloy’s reliability and performance under stress. Thus, understanding what are the nitinol related devices helps businesses innovate while ensuring durability and efficiency in their products.

Aerospace Innovations with Nitinol

When it comes to aerospace innovations, what is a nitinol device doing among high-tech materials? The aerospace industry has begun incorporating these alloys into designs where weight reduction and strength are critical factors—think lightweight structures that can withstand harsh environments! Nitinol’s ability to change shape at different temperatures allows engineers to create adaptive components that enhance aircraft performance.

Moreover, using nitinol devices can lead to breakthroughs such as deployable structures or mechanisms that adjust automatically during flight conditions—a feature not easily achievable with traditional materials. As space exploration missions continue pushing boundaries, the adoption of innovative materials like nitinol will be crucial for developing next-generation spacecraft systems. Clearly, when pondering over what is nitinol mainly used for within aerospace applications reveals exciting possibilities ahead!

What Are the Nitinol Related Devices?

When diving into the world of nitinol devices, one can’t help but marvel at their transformative potential across various fields, particularly in medicine and manufacturing. Nitinol, a unique alloy of nickel and titanium, boasts properties that make it incredibly versatile. From stents to guidewires and fasteners, these nitinol-related devices are revolutionizing how we approach challenges in healthcare and industry.

Nitinol Stents in Cardiology

Nitinol stents are a game-changer in cardiology, providing a minimally invasive option for treating blocked arteries. These nitinol devices expand upon deployment to hold open blood vessels, ensuring proper blood flow while being flexible enough to navigate the body's intricate pathways. The biocompatibility of nitinol also reduces the risk of adverse reactions, making these stents an appealing choice for patients.

The unique shape memory effect of nitinol allows these stents to return to their original shape after being compressed during insertion. This means they can be delivered through smaller incisions without compromising their effectiveness once they reach the target area. As a result, doctors can perform procedures with greater precision and patients enjoy faster recovery times.

Moreover, ongoing innovations continue to enhance the design and functionality of nitinol stents. With advancements such as drug-eluting coatings that release medication over time, these devices not only keep arteries open but also help prevent re-blockage. Clearly, when considering what is nitinol mainly used for in cardiology, stents lead the charge as vital tools for saving lives.

Nitinol Guidewires in Medical Procedures

Another remarkable application of nitinol devices is found in guidewires used during various medical procedures. These slender wires serve as navigational tools that assist surgeons in reaching specific areas within the body with precision and ease. The flexibility and strength inherent in nitinol allow these guidewires to bend around curves without breaking or kinking—an essential feature when dealing with complex anatomy.

Nitinol guidewires are particularly advantageous during catheterization procedures where access points may be challenging due to anatomical variations or blockages. Their ability to maintain stiffness while also being pliable ensures that healthcare professionals can maneuver through tight spaces effectively. This capability significantly enhances procedural success rates while minimizing patient discomfort.

In addition to their use in cardiovascular interventions, nitinol guidewires find applications across numerous specialties including gastroenterology and urology—demonstrating just how versatile these devices truly are! As we explore what are the medical devices with nitinol further down this rabbit hole of innovation, it's clear that guidewires play an indispensable role.

Nitinol Fasteners in Manufacturing

Beyond medicine, nitinol's unique properties extend into industrial applications like fasteners—a crucial component across various manufacturing processes. These fasteners leverage the shape memory effect inherent in nitinol materials; they can expand or contract based on temperature changes which allows them to securely hold components together under varying conditions without loosening over time.

In manufacturing settings where reliability is paramount—think aerospace or automotive industries—nitinol fasteners provide an added layer of security against vibrations or thermal fluctuations that could otherwise compromise structural integrity. Their lightweight nature coupled with high strength makes them ideal candidates for applications where traditional metal fasteners might add unnecessary weight or bulkiness.

As industries continue adapting advanced materials like those found within what are the nitinol related devices category, it’s evident that innovations such as these fasteners will pave new paths toward efficiency and safety standards previously thought unattainable! The future looks bright indeed!

What Are the Medical Devices with Nitinol?

Nitinol devices have revolutionized the medical field, particularly in surgical applications where precision and flexibility are paramount. This unique alloy is not only biocompatible but also exhibits remarkable shape memory properties, making it ideal for various medical devices. From stents to guidewires, nitinol's versatility is making waves in how surgeries are performed today.

Overview of Nitinol in Surgery

When we talk about what a nitinol device is, it's essential to highlight its significance in surgery. Nitinol’s ability to return to a pre-defined shape after deformation allows surgeons to navigate complex anatomical structures with ease. Additionally, the superelasticity of nitinol means that instruments can withstand significant stress without permanent deformation, ensuring reliability during critical procedures.

Nitinol devices are increasingly being utilized in minimally invasive surgeries due to their flexibility and strength. Surgeons are leveraging these properties for tasks such as catheter placements and vascular interventions, improving patient outcomes while reducing recovery times. As we delve deeper into what nitinol is mainly used for, it becomes clear that its role in surgery is both transformative and essential.

Benefits of Nitinol in Orthopedics

Orthopedic applications of nitinol devices showcase some of the most compelling benefits this material offers. The unique properties of nitinol allow for implants that can adapt to the dynamic nature of bone healing; they can expand or contract based on temperature changes within the body. This adaptability not only promotes better integration with surrounding tissues but also enhances overall stability.

Another advantage lies in the lightweight nature of nitinol compared to traditional materials like titanium or stainless steel; this makes it easier for patients post-surgery while maintaining strength and durability. Furthermore, using nitinol reduces complications associated with foreign body reactions due to its biocompatibility—an invaluable trait when considering what are the medical devices with nitinol at play here.

In summary, incorporating nitinol into orthopedic devices has led to fewer revisions and enhanced healing processes for patients undergoing surgeries like joint replacements or fracture repairs. The ongoing research continues to unveil new possibilities for these innovative tools within orthopedic practices.

Use of Nitinol in Vision Correction

Vision correction technologies have also benefited from advancements involving nitinol devices; they offer a blend of precision and comfort that's hard to beat! In procedures such as LASIK or cataract surgery, specialized instruments made from nitinol allow ophthalmologists greater control during delicate operations on the eye's surface or lens structure. The superelasticity feature enables these tools to navigate tight spaces without causing trauma—essential when dealing with such sensitive areas.

Moreover, because many vision correction procedures require implantable lenses or supports that must maintain their shape over time, using a material like nitinol ensures long-lasting results without compromising safety or effectiveness. As we explore what are the medical devices with nitinol further, it's evident that these innovations continue shaping how we approach eye care solutions today.

In conclusion, whether it's through surgical enhancements or orthopedic improvements, the role of nitinol devices cannot be overstated; they represent a leap forward in medical technology across various fields including vision correction!

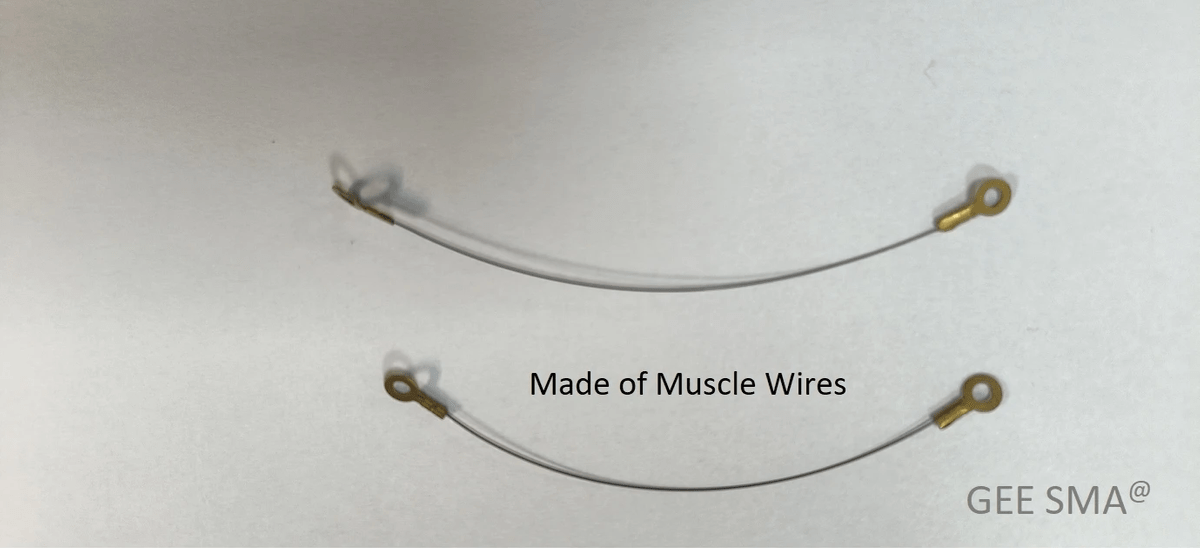

GEE SMA and Nitinol Technology

The realm of Nitinol technology is significantly enhanced by the contributions of GEE SMA, a company at the forefront of innovations in shape memory alloys. Their expertise in Nitinol devices spans multiple industries, making them a pivotal player in harnessing the unique properties of this remarkable alloy. By focusing on advancements in Nitinol applications, GEE SMA not only elevates existing technologies but also paves the way for future breakthroughs.

GEE SMA’s Expertise in Nitinol

GEE SMA has carved out a niche as a leader in the development and application of nitinol devices. Their extensive research and development efforts have led to an impressive portfolio that showcases what is a nitinol device? This includes everything from medical instruments to industrial components, demonstrating their versatility and adaptability across various sectors. With a deep understanding of the material's unique properties, GEE SMA ensures that their products meet rigorous industry standards while pushing the boundaries of innovation.

Innovations in Nitinol Shape Memory Alloys

When it comes to innovations in nitinol shape memory alloys, GEE SMA is setting new benchmarks. They are continually exploring how to enhance the performance characteristics of nitinol devices through advanced manufacturing techniques and novel alloy compositions. These innovations not only improve functionality but also expand what is nitinol mainly used for?, allowing for applications that were previously deemed impossible or impractical.

Nitinol in Space Missions

One fascinating application of nitinol technology can be found in space missions, where its unique properties offer significant advantages. The lightweight yet strong nature of nitinol devices makes them ideal candidates for aerospace engineering challenges, such as deploying satellite components or ensuring structural integrity under extreme conditions. As space exploration continues to evolve, the role of nitinol will likely expand further, showcasing its potential beyond traditional uses—definitely something worth watching!

Conclusion

In summary, nitinol devices represent a fascinating intersection of material science and practical application, paving the way for innovative solutions across various fields. As we look to the future, advancements in nitinol technology promise to enhance its capabilities and broaden its applications even further. Whether in medicine, aerospace, or industrial settings, the potential for nitinol devices is virtually limitless.

The Future of Nitinol Devices

The future of nitinol devices is bright, with ongoing research focused on enhancing their properties and expanding their uses. Innovations such as improved shape memory effects and increased biocompatibility are just a few areas where advancements are being made. As industries continue to explore what is a nitinol device capable of achieving, we can expect to see even more groundbreaking applications emerge.

Nitinol's Impact on Multiple Industries

Nitinol's impact on multiple industries cannot be overstated; it has revolutionized how we approach challenges in medicine, manufacturing, and beyond. In the medical field alone, what is nitinol mainly used for? From stents that save lives to guidewires that facilitate intricate procedures, its versatility is astonishing. Beyond healthcare, industries like aerospace leverage nitinol's unique properties for lightweight components that enhance performance without compromising safety.

Why Nitinol Is a Game Changer

Nitinol is undeniably a game changer due to its unique combination of flexibility and strength along with the remarkable shape memory effect it exhibits. This duality allows what are the nitinol related devices to perform tasks that traditional materials simply cannot match—think self-expanding stents or adaptive fasteners in manufacturing processes. The ability to respond dynamically to environmental changes makes these devices not just useful but essential in pushing technological boundaries forward.