Introduction

In the realm of innovative technologies, nitinol heat engines stand out as a marvel of engineering and material science. These unique engines leverage the remarkable properties of nitinol—an alloy of nickel and titanium—to convert thermal energy into mechanical work with impressive efficiency. But what is a nitinol engine, and how does it capture the imagination of scientists and engineers alike?

The Marvel of Nitinol Heat Engines

Nitinol heat engines are not just a curiosity; they represent a significant leap forward in how we harness energy. With their ability to undergo dramatic shape changes in response to temperature fluctuations, these engines provide an elegant solution to energy conversion challenges. However, many wonder: why aren't nitinol engines used more widely despite their potential?

Exploring the Space Connection

The connection between nitinol technology and space exploration is particularly fascinating. Space missions have begun to incorporate nitinol due to its lightweight nature and resilience under extreme conditions, but what is so special about nitinol that makes it ideal for such applications? As we delve deeper into this relationship, it becomes clear that the future of nitinol technology holds exciting possibilities for advancing our capabilities in space.

The Future of Nitinol Technology

Looking ahead, the future of nitinol technology appears bright, with ongoing research promising new applications across various fields—including aerospace engineering. Yet questions linger about why is nitinol so expensive compared to traditional materials? By overcoming cost barriers and enhancing manufacturing processes, we could unlock a world where nitinol engines play a pivotal role in our quest for exploration beyond Earth.

What is a Nitinol Engine?

Nitinol engines are a fascinating innovation that harnesses the unique properties of Nitinol, an alloy made primarily of nickel and titanium. This remarkable material exhibits both shape memory and superelasticity, making it ideal for applications where traditional engines may struggle. But what exactly is a nitinol engine? Let's dive deeper into its defining features and mechanisms.

Defining Nitinol and Its Properties

Nitinol stands out due to its distinctive characteristics: the shape memory effect and superelasticity. When subjected to specific temperatures, Nitinol can return to its original shape after being deformed, which is what makes it so special in engineering applications. Additionally, this alloy maintains excellent durability even in extreme conditions, making it an attractive option for aerospace technologies.

What is so special about nitinol? Its ability to undergo phase transformations allows it to efficiently convert thermal energy into mechanical work—a key principle behind nitinol heat engines. This unique property enables these engines to operate effectively in environments that would challenge conventional materials, particularly in space exploration.

Mechanism of Nitinol Heat Engines

The mechanism of nitinol heat engines relies on the transformation between different phases of the alloy based on temperature changes. When heated above a certain threshold, nitinol contracts and generates force; when cooled, it expands back to its original configuration. This cyclical process allows for continuous energy conversion, making nitinol heat engines both efficient and innovative.

In essence, these engines act like a thermodynamic cycle where thermal energy input results in mechanical output—ideal for powering spacecraft or other high-tech applications where lightweight yet powerful solutions are essential. The adaptability of nitinol means that engineers can design systems tailored specifically for their operational needs while benefiting from the inherent advantages of this remarkable material.

Applications in Aerospace Engineering

Nitinol heat engines have found their niche within aerospace engineering due to their lightweight nature and efficiency under extreme conditions. They are being explored as potential power sources for satellites or probes sent into distant realms of our solar system—where traditional fuel sources might falter or be impractical.

Moreover, with ongoing research into how these innovative systems could replace conventional propulsion methods, many are asking: Why aren't nitinol engines used more widely? The answer lies not just in technological readiness but also in cost factors associated with manufacturing these specialized components—an important consideration given that some wonder why is nitinol so expensive?

As we continue exploring the potential applications of nitinol technology within aerospace engineering and beyond, it's clear that this alloy holds immense promise for future advancements in space exploration.

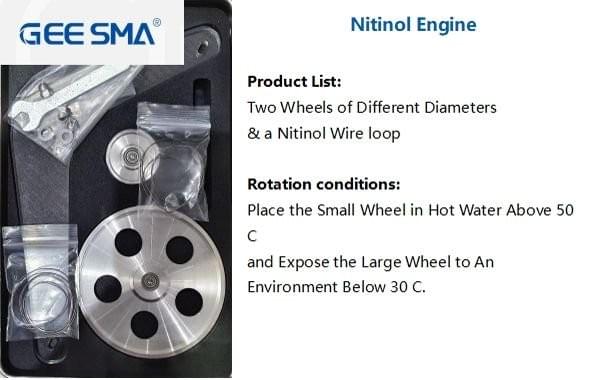

The Role of GEE SMA in Space Missions

Nitinol heat engines have made significant waves in the realm of space exploration, particularly through their application in missions like Chang’e-5 and Chang’e-6. These missions have showcased the unique properties of nitinol, making it a crucial component for various mechanisms involved in space operations. Understanding how these nitinol engines function can help highlight their potential and address questions such as What is a nitinol engine? and Why aren't nitinol engines used more widely?

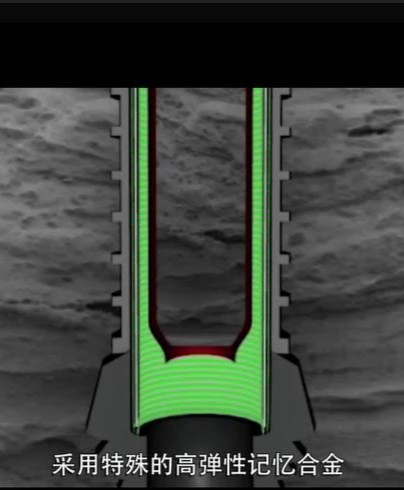

Nitinol in Chang’e-5 and Chang’e-6

In the ambitious Chang’e-5 and Chang’e-6 lunar missions, nitinol played a pivotal role in enhancing the efficiency of deployment mechanisms. The shape memory effect of nitinol allows components to return to predefined shapes when heated, which is particularly useful for deploying solar panels or scientific instruments once a spacecraft has landed on the lunar surface. This innovative use of nitinol engines not only improves reliability but also reduces weight, a critical factor for any space mission.

Moreover, these missions demonstrated how using Nitinol heat engines can lead to more compact designs without sacrificing functionality. Engineers were able to leverage the unique thermal properties of nitinol to create systems that operate effectively even under extreme temperature fluctuations found on the Moon. As we delve deeper into space exploration, understanding What is so special about nitinol? becomes increasingly important as we consider its potential applications.

Contributions to the Tianwen Missions

The Tianwen missions have further underscored the importance of Nitinol heat engines in modern space exploration efforts. By integrating nitinol technology into various aspects of mission design, engineers have been able to enhance performance while maintaining cost-effectiveness—a crucial aspect when considering Why is nitinol so expensive? The use of Nitinol allows for lighter structures that can withstand harsh environments without compromising on durability.

Additionally, these missions illustrate how advancements in Nitinol technology are paving new paths for future explorations beyond our Moon. With its remarkable ability to remember shapes and withstand extreme conditions, it's no wonder that researchers are increasingly asking Why aren't nitinol engines used more widely? The answers often point back to manufacturing challenges and costs associated with producing high-quality nitinol components.

Advancements in Deployment Mechanisms

Advancements in deployment mechanisms utilizing Nitinol heat engines are setting new standards for efficiency and reliability in aerospace engineering. These innovations allow spacecraft systems to deploy with precision after landing or during operation—think solar arrays unfurling effortlessly or antennas extending flawlessly at just the right moment! Such capabilities not only enhance mission success rates but also offer exciting possibilities for future technologies.

As we continue exploring what makes Nitinol so special—its shape memory effect, thermal efficiency, and durability—we find ourselves at an intersection where engineering meets imagination. This marriage of creativity and practicality could very well redefine how we approach future space missions while addressing questions like What is a nitinol engine? with renewed enthusiasm and clarity. It’s clear that as advancements unfold within this field, both engineers and scientists will benefit from diving deeper into this fascinating material.

Why Aren't Nitinol Engines Used More Widely?

Despite the remarkable potential of Nitinol heat engines, their adoption remains limited in various industries. The question arises: why aren't nitinol engines used more widely? The answer lies in several intertwined factors, including manufacturing challenges, cost considerations, and competition with traditional engine technologies.

Challenges in Manufacturing

Manufacturing nitinol components for heat engines is no walk in the park. The process requires precise control of temperature and alloy composition to achieve the desired shape memory effect, which is what makes a nitinol engine so special. Additionally, scaling up production while maintaining quality poses significant hurdles that manufacturers must overcome to make nitinol heat engines a viable option on a larger scale.

The intricate nature of fabricating nitinol parts means that specialized equipment and skilled labor are necessary. This complexity can lead to longer lead times and increased chances of defects during production runs. Consequently, these challenges deter many companies from investing heavily in the development of nitinol engines despite their apparent advantages.

Cost Factors of Nitinol Constructs

When it comes to why is nitinol so expensive, the answer isn't just about raw materials; it's about the entire lifecycle of production. Nitinol's unique properties demand high-quality nickel and titanium alloys that are not only costly but also subject to market fluctuations. Coupled with complex manufacturing processes, these factors contribute significantly to making nitinol constructs pricier than their traditional counterparts.

Furthermore, research and development costs add another layer to the expense equation. Companies venturing into creating new applications for Nitinol heat engines often find themselves facing hefty R&D bills before they can even think about bringing a product to market. As a result, many businesses hesitate to adopt this technology when cheaper alternatives exist.

Comparison with Traditional Engine Technologies

In comparing nitinol engines with traditional engine technologies like internal combustion or electric motors, it's clear that each has its own strengths and weaknesses. While a nitinol engine offers unique benefits such as lightweight design and efficiency at extreme temperatures, traditional technologies have established infrastructures and proven reliability on which industries depend heavily. This established dominance makes it challenging for new entrants like Nitinol heat engines to gain traction.

Moreover, conventional engine technologies benefit from economies of scale; they are mass-produced at lower costs due to decades of optimization and refinement processes. In contrast, since what is a nitinol engine? remains somewhat niche at present, manufacturers struggle with volume production that could drive down prices significantly over time. Until these hurdles are addressed—whether through innovation or strategic partnerships—nitinol engines may continue lagging behind more conventional options.

The Special Properties of Nitinol

Nitinol, an alloy of nickel and titanium, boasts some remarkable properties that set it apart from traditional materials used in engine technology. Understanding what is so special about nitinol helps us appreciate its potential in various applications, particularly in the field of Nitinol heat engines. This section will delve into the unique characteristics of nitinol that make it a candidate for future innovations.

Shape Memory Effect Explained

One of the most fascinating features of nitinol is its shape memory effect, which allows it to return to a predetermined shape when heated above a certain temperature. This property means that what is a nitinol engine can harness this effect to convert thermal energy into mechanical work efficiently. Imagine a tiny engine component that can change shape and perform tasks without complex moving parts—this is precisely why researchers are excited about integrating nitinol into modern engineering solutions.

The implications for aerospace applications are profound; engines could become lighter and more efficient while also reducing the number of mechanical components needed. However, one might wonder: why aren't nitinol engines used more widely? The answer lies not just in their unique properties but also in the challenges surrounding their production and integration.

Thermal Properties and Efficiency

When discussing thermal properties, it's essential to highlight how nitinol operates at varying temperatures while maintaining high efficiency levels. Nitinol heat engines can effectively convert heat energy from various sources into usable mechanical energy, making them appealing for applications requiring reliable performance under extreme conditions. Their ability to operate effectively across a range of temperatures makes them particularly suited for space missions where environmental factors fluctuate dramatically.

Moreover, the efficiency with which these engines can operate often surpasses traditional materials due to their unique thermal expansion characteristics. In short, if you’re asking yourself why is nitinol so expensive?, part of the answer lies in its exceptional thermal capabilities that lead to superior performance compared to conventional engine technologies.

Durability in Harsh Conditions

Durability is another standout feature of nitinol that cannot be overlooked—especially when considering its application in environments like outer space or extreme industrial settings. Nitinol’s resistance to corrosion and fatigue means it can withstand harsh conditions without losing functionality or structural integrity over time. This resilience positions what is a nitinol engine as an ideal candidate for long-term missions where reliability is paramount.

The ability to endure severe temperature fluctuations and exposure to harsh chemicals makes Nitinol heat engines increasingly attractive for space exploration missions like Chang’e-5 or Tianwen-1, where equipment must perform flawlessly under duress. So while there may be questions about why aren’t nitinol engines used more frequently? The answer often boils down to cost considerations rather than capability—after all, durability comes at a price!

The Future of Nitinol Heat Engines in Space

The future of nitinol heat engines is a captivating realm filled with potential and promise. As we push the boundaries of space exploration, these innovative engines could redefine how we approach propulsion systems in extraterrestrial environments. With ongoing research and development, the possibilities for nitinol technology seem endless.

Innovative Research and Development

Innovative research into nitinol engines is currently at the forefront of aerospace engineering, where scientists are continually discovering new applications for this remarkable material. What is a nitinol engine? It’s not just about its shape memory effect; it's about harnessing those properties to create efficient and reliable heat engines that can thrive in extreme conditions. Researchers are experimenting with advanced designs that maximize thermal efficiency while minimizing weight, making these engines ideal candidates for future space missions.

Moreover, recent advancements have focused on integrating nitinol heat engines with renewable energy sources to enhance their sustainability. By combining solar power with nitinol technology, engineers aim to create self-sustaining systems capable of operating indefinitely in deep space. As this innovative research progresses, the question Why aren't nitinol engines used more widely? becomes increasingly relevant—especially when considering their vast potential.

Potential for Mars and Beyond

When we think about the potential for nitinol heat engines on Mars and beyond, it's hard not to get excited about what lies ahead. These engines could revolutionize how we explore other planets by providing efficient propulsion systems that can withstand harsh Martian climates while utilizing local resources for fuel generation. Imagine a scenario where a nitinol engine powers rovers or habitats on Mars—utilizing its unique properties to adapt and respond dynamically to environmental changes.

Furthermore, as humanity sets its sights on destinations like Europa or Titan, the need for robust technologies becomes paramount. Nitinol's exceptional durability makes it an ideal candidate for long-duration missions where traditional materials might fail under extreme conditions. The question What is so special about nitinol? can be answered through its resilience and adaptability—qualities essential for interplanetary exploration.

The Role of Partnerships in Advancements

Partnerships between government agencies, private companies, and academic institutions are crucial in advancing the development of nitinol heat engines. Collaborative efforts leverage diverse expertise to tackle challenges such as manufacturing complexities and cost barriers associated with this technology—after all, Why is nitinol so expensive? remains a pressing concern within the industry. By pooling resources and knowledge across sectors, stakeholders can work towards reducing costs while enhancing performance capabilities.

Additionally, these partnerships foster innovation through shared research initiatives aimed at improving production techniques for nitinol constructs—ultimately making them more accessible for widespread use in aerospace applications. As collaborations grow stronger worldwide, they pave the way toward overcoming obstacles that have historically hindered broader adoption of this promising technology: namely concerns surrounding feasibility and expense related to traditional engine technologies versus newer solutions like those offered by Nitinol Heat Engines.

In conclusion, as we look towards an exciting future filled with opportunities presented by advancements in Nitinol technology—including its application within space exploration—the importance of continued investment into research cannot be overstated!

Conclusion

As we wrap up our exploration of Nitinol heat engines, it’s clear that the innovations driving this technology are nothing short of remarkable. From their unique properties to their potential applications in aerospace, nitinol engines represent a leap forward in engineering capabilities. The ongoing research and development in this field promise to unlock even more advantages, making them a key player in the future of space exploration.

Innovations Driving Nitinol Engine Technology

The world of nitinol engine technology is buzzing with innovation. Researchers are continually discovering new ways to enhance the performance and efficiency of these engines, pushing the boundaries of what we thought was possible. What is so special about nitinol? It's not just its shape memory effect; it's also its ability to operate under extreme conditions that makes it a game-changer for aerospace applications.

Overcoming Cost Barriers in Production

Despite their advantages, many still wonder why aren't nitinol engines used more widely? One significant hurdle is the cost associated with producing nitinol constructs. Why is nitinol so expensive? The manufacturing processes require precision and specialized materials, but as technology evolves and economies of scale come into play, these costs may decrease, paving the way for broader adoption.

A Bright Future for Space Exploration with Nitinol

Looking ahead, the future seems bright for space exploration with nitinol heat engines leading the charge. As partnerships between governmental agencies and private enterprises grow stronger, we can expect accelerated advancements in this field. With innovative solutions on the horizon and an increasing understanding of what a nitinol engine can achieve, we may soon find ourselves venturing further into our solar system than ever before.